| Author | Message | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 14 Registered: 7-2009 |

Hi all, Ive had my car for about a year. See Attached. Fixed a number of things in that time and am generally happy with it. Replaced the Gas springs, accumulators, one rear strut, tyres, brake pads, steering rack and sundry other little gremlins. One of the biggest joys is you fix something and it stays fixed unlike lesser beasts. That and the learning experience. There is one thing that keeps bugging me. At 2500>>2600 rpm the car feels very flat, acellerates beyond this but very flat in comparrison with idle to the 2500. I have progressively gone through a number of the systems. Like a vacuum switch that wasnt, a non return valve that returned, a sticky wastegate control solanoid and an corroded ignition amplifier. All these bits seem to work fine including the electrical signals they get. There must be something that I havnt looked at. Spark, that seems to be fine and advances roughly to what one expects, air well thats plentiful, and now I have fixed all the turbo related bits and the signals works as advertised air shouldnt be an issue, juice well it runs well at everything up to 2500. That 2500/2600 is quite a clean problem point. Fuel being an issue I would envisage the RPM issue would be a bit of pot luck. It is not rough, just flat. Would simply put it aside but one weeked I took it for a drive (couple of months ago) and it opened my eyes to what the car really can do. Something is intermittant, unfortunatly not mittant enough. Any thoughts Thanks Stefan  | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 15 Registered: 7-2009 |

Peoples, Thought I would add a couple of observations. BTW the Car is Bentley Turbo R 89 Chassis number but build is as per pre 89. For those interested the Mog is 1973 Turbo +8. Yes Turbo (factory fitted for Le Mans but never raced as race spec changed), not too many of them, from what I can gather 4. The problem doesnt appear to be throttle position as the throttle position to get to these RPM is quite different for neutral, 1st 2nd 3rd yet the issue is always distinct at 2500>>2600 rpm. Laterally thinking I dont think it would be the air volume sensor that controls the fuel delivery pressure, as the volume of air required again would be quite different from say neutral to 3rd so the metered air cone position would be quite different. If that hold true then the POT that measures this air volume should also follow suit. The timing changes and is very stable through the whole RPM range. Compression is good, cold engine 138psi +/-2psi, imagine that would improve on a warm engine but i dont feel like burning my fingers. In my mind the only consistant thing with these differeing engine loads, is the RPM. This would come from the sensor at the back of the engine. Which is detected by the ignition ECU and distributed to Boost and Fuel ECU. When the car did work as it should it felt like a cushion of power throught the whole rev range. At the moment it feels good to 2500 and then not much. On the flat its happy to keep acellerating but up a significant hill it almost feels like a brick wall. Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 16 Registered: 7-2009 |

Hi, One other thing that might help me and from what I have seen in a couple of other posts is to understand what the turbo boost does to manifold pressure in a known working Bentley setup. I played around with a Twin Turbo Toyota Supra, amazing japanese muscle out of quite a small engine. Anyway, boost means boost. The owner had modified it to pump 25 PSI. More than spec but thats his isssue. My point is the manifold pressure goes to 25PSI, ie about 11PSI above atmosphere. I read that the Bentley is supposed to cut out around 8 PSI. Ie a bit below atmosphere. It makes sense, with no boost the manifold will have an increased vacuum. So anything to get this pressure closer or even above atmosphere is in the right direction. I think I'm right in thinking atmosphere is 14psi roughly. I've measured the APT levels over rev ranges. Engine off but ignition on is 2V roughly. This would be 14psi or one atmosphere. Turn the engine on to idle, APT drops to .7V. To my mind assuming the sensor is reasonably linear this slightly less than half atmosphere, maybe about 5psi. What I have noticed is you increse the RPM, the boost doesnt really increase the pressure, the voltage stays about 0.7V, ie the manifold pressure remains at 5psi. If you didnt have the turbo working I think Im right in saying this pressure (ie voltage) would drop proportionally to the incresing rpm as the engine tries to suck more air in. The turbo working simply feeds more air to maintain this -ve pressure. Quick acelleration changes from idle shows a drop to about 0.2V which quickly reverts to the 0.7V, like wise quickly dropping the RPM shows a peak of about 2V then reverts to the 0.7V. Assume this is about the response time of the bypass valve in the plenum and the response of the wastegate. Problem is I have extrapolated this from observations on my car. Has anyone else done this on a car that works. I think this aspect of my car logically is working but in comparison to the Boost on the Supra the Bentley is not quite boost more maintaining a fixed manifold -ve pressure. Has anyone checked out what their manifold pressure is doing? The other thing that bugs me about the 2500>>2600 issue. The RPM seems to be the only constant at the moment, if the RPM is derived from the sensor at the back of the engine, and the ignition timing is a result of this sensor. If there where a problem with this then surely this would show up as a timing stability issue when using a timing light. Regards Stefan | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 384 Registered: 6-2006 |

Stefan, Boost pressure is ambient air pressure plus the turbo boost pressure. So in effect 0 psi plus the boost. Ambient pressure is variable because of weather conditions, height above sea level etc. Watch a barometer. MAP and MAF sensors work this out. Without a turbo or supercharger there is indeed a -ve manifold pressure but the charger increases the pressure so that the air is forced into the engine. But once again, it's ambient less the pressure drop. For your problem - Check all connections are clean and tight. Similar faults have been found by poor (low voltage) feeds to the ignition packs, engine ECU's etc. which become worse at certain revs. | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 17 Registered: 7-2009 |

Paul, Thanks. Will get myself a pressure gauge and monitor the manifold pressure. Trying to measure the APT is hardly giving me an absolute measure. Boost wise, trying to get my head around it. A normally aspirated car will allways be less than atmosphere at the manifold. For a Turbo car there needs to be a fair volume of air that needs to be moved before it becomes a +ve pressure with repect to atmosphere. Surely this -ve region is still defined as boost. Does the manual mean +ve pressure above atmosphere. Or +ve pressure above the normally aspirated -ve condition. With regards to connections, not sure there is that much left to check. Certainly found a couple of things in the process. If what you say is true about being above atmosphere then maybe my boost is not doing quite what I think. Pressure gauge is the first stop. Cheers Stefan | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1908 Registered: 4-2003 |

Stefan, I suggest that you search for this subject recently presented by Udo Hoffmüller on this Forum. He has a Turbo R with what sounds like the identical issue to yours. You may try sending him a private message.The last time I recall the subject appeared in a thread about headlamp sequence relays. Search for: Bistable relay instead of foot operat His has been a long-standing issue, but he had some leads in the last weeks and may have solved it already. RT. | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1910 Registered: 4-2003 |

Sorry, Search for Udo Hoffmüller or TurboR boost control failure I note that you have been a contributor to these and other threads on the subject. RT. | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 385 Registered: 6-2006 |

Boost wise, trying to get my head around it. A normally aspirated car will allways be less than atmosphere at the manifold. For a Turbo car there needs to be a fair volume of air that needs to be moved before it becomes a +ve pressure with repect to atmosphere. Surely this -ve region is still defined as boost. Does the manual mean +ve pressure above atmosphere. Or +ve pressure above the normally aspirated -ve condition. +ve above ambient pressure. At tickover with the throttle closed the pressure will be most -ve. The longer and smaller the air intake pipes and the air filter are the higher the vacuum will be. That's why nat asp racing cars have short trumpets, and no filters. At wide throttles and lower revs the vacuum is lowest , depending on intake restrictions. As Revs rise, the intake restrictions slow the flow and the vacuum will rise again. (Message edited by paul_yorke on 28 August 2009) | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1914 Registered: 4-2003 |

Paul, It all refers to nominal atmospheric pressure, 1013 Millibars. Under almost all conditions, except when driving hard, the manifold will be under a vacuum, -ve pressure as you name it. The pressure transdcers measure the pressure difference above or below 1013 millibars. Hence, the Turbo cars have a huge advantage at altitudes as the Turbo corrects the pressure to behave as if it were at sea-level. Unusually for a Turbo motor, the compression ratio on these cars is 8:1 as on the naturally-aspirated cousins. Hence there is no need nor possiblity for Turbo boost until you demand more torque than a naturally-aspirated Silver Spirit etc. Thats why many Turbo Rs have an inoperative Turbo system, and the owners dont even know. They just believe that the Turbo R is not a very fast car. Most other Turbo cars have maybe 5:1 compression ratios, and need the turbo boost far more regularly otherwise they are gutless. RHT. | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1915 Registered: 4-2003 |

ps: for Stefan. I suggest that you follow Udos lead. Fit a voltmeter or light bulb to the dump valve connection. You will then quickly see if the dump valve is functioning properly. Udo disconnected his dump valve circuit for a test, and it accelerated like a bat out of hell. You will then know if you have a dump valve control problem, the most common cause of loss of boost. If the dump valve itself is faulty, then it is easily and cheaply rebuilt. The unique dump valve system on these cars is the secret to thir amazing lack of Turbo lag. The turbo keeps spinning with no load until the dump valve redirects the air from recirculating to pressurising. RHT. | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 18 Registered: 7-2009 |

Thanks Paul and Richard, Okay happy with that; +ve pressure above atmosphere. Will get a pressure guage, but running on my assumption over the voltages I measure on the APT I dont think the turbo is doing much at all. Electrically I have fixed a couple of issues. Udo and myself have communicated on the forum. My Dump valve solanoid didnt work because the vacuum switch that is supposed to control it was faulty. Bought a new vacuum switch and the dump valve solanoid now operates electrically. Also the dump valve itself clicks now on rapid RPM increse as the manual states. Secondly I had a sticky wastegate solanoid since cleaned. Electrically that now works after a secondary issue was fixed. Secondary issue was power supply brown outs related to ignition amplifier corrosion problem dropping supply to the boost controller. Not quite sure how but once the amplifier was cleaned the problem went away. Anyway the wastegate solanoid now functions. Problem is it appears the boost is still not happening. Either my wastegate is permantly stuck open (seems unlikely given it would be more likely to be stuck shut through non use) or the dump valve is permanenly stuck despite now hearing a sound from it. The other thing I note in the manual is the dump valve itself can act as a relief valve, assume on its own. Maybe this isnt quite happening as it should allowing the dump to open. Have to figure out how to take the Intake elbow off to have a look. Should keep me occupied for the weekend. Cheers Stefan | |||

Dr. Omar M. Shams Experienced User Username: omar Post Number: 39 Registered: 4-2009 |

Stefan, you are not alone on this matter. I am waiting for my 90 Turbo RL to come back from having the steering rack seals replaced before I do my invetsigations on the turbo system. These cars should fly like bullets, but mine (like yours) has a flat spot. I have toyed with the idea of replacing the ambient temperatur guage in the cockpit with a turbo boost guage in order to know what the manifold is seeing under all driving conditions. I may look into this in more detail. | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1916 Registered: 4-2003 |

The beloved steering rack again. See my articles. | |||

Dr. Omar M. Shams Experienced User Username: omar Post Number: 40 Registered: 4-2009 |

Richard, where would I find these articles? I have had steering rack issues with every ShadowII/Wraith/Spirt/ Spur and Turbo RL that I have owned. I always put it down to the extreme heat where we live....... I am intrigued. can you please send a link? Thanks | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1919 Registered: 4-2003 |

Dr As I am in transit to Oz, I can only give you a start on the first article, the main one. Have a look at Tee-One here, and see a so-far success: http://rrtechnical.info/TeeOne/TO52.pdf I have had a new seal type on trial for a year now, a far better one than the original. I shall report the success or not ASAP, but am so far convinced. | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1921 Registered: 4-2003 |

Dr Also, if you look at Praeclarvm and Modern Lady around the time, you will see the whole bit, including the vital part on gapping the PTFEs. Your best rebuilders do not know about this. | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 19 Registered: 7-2009 |

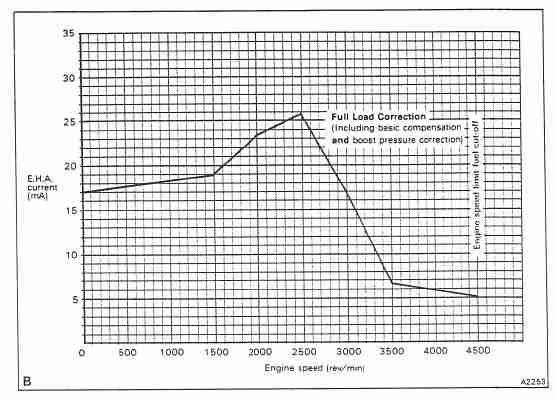

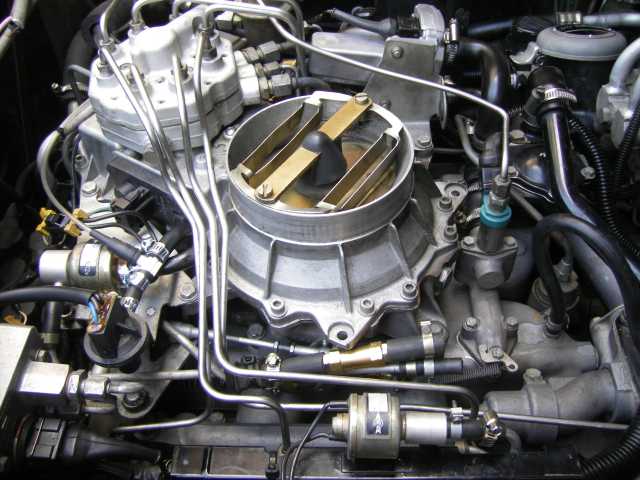

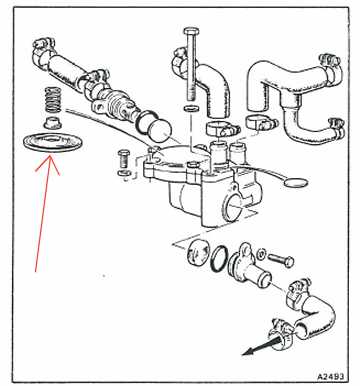

Hi all, Well I got the Cast Elbow off, dump valve all looks fine and operates as advertised. Also tested the wastegate and that operates fine. Tested the fuel pot as well given the elbow was off. The mechancial fuel regulator vane moves freely as well. Physically I have checked each item related to the turbo. I will be testing the system with a pressure gauge in a week or so. Dont get me wrong the turbo is working, but only below the 2500>2600 and just above idle based on the vacuum switch. I have also gone through the process of disabling apsects of assorted parts of the system. None have been conclusive. Given I fixed the couple of parts that where faulty and now I am not getting anywhere looking at these parts the problem has to be elsewhere. Observation, the manual is not totally clear when trying to logically follow things. I made comment on negative pressure to make reference to pressure below atmosphere. Vacuum is not quite the right word even though its widely used in referece to what I called negative pressure. Semantics, but when you try to follow the manual one does get a bit lost. Started drawing up a diagram to make it clearer the interactions of all the parts. When done I will forward it to the forum. Steering rack wise mine started leaking from the left side on hard lock. (Right hand Drive car). Installed the reconditioned rack and functions fine. After pulling the old rack apart my two bobs worth is probably the biggest issue for these racks is the incredible lock on the cars. Combine that lock with verging on tyre scrubbing when at full lock and the forces on the center of the rack forcing the rack to writhe like a smake is proably the biggest killer on the ptfe bushes with the end result being the seals suffering. The only other car in my experince that has a comparable lock is the old VW beetles. Back to the topic at hand. I'm happy all the turbo related bits are functioning. I'm slowly convinced something beyond the turbo is causing an issue. I noticed something in the manual releated to the EHA in relation to the fuel mapping. Fuel mapping to the EHA ramps up to 2500 rpm. Then drops off quite markedly to the 4500rpm cutoff. Are my symptoms coincidence or more than that!!! They make reference to the turbo on the same map. Laterally thinking if this is the possible common thread then maybe the mapping is done under the pretext that at the lower RPM the engine needs slightly more fuel than the mechanical regulator can deal with hence the paralell EHA and when at the higher RPM there is sufficient boost pressure to force the mechanical fuel regulator into becoming the prime source and the EHA can back off with its supply.  It makes logical sense this is the intent of the mapping. If this is the source of the problem than my issue could be insufficanet fuel delivery at the higher volume or possible insufficient fuel delivery by the paralell mechanical regulator. I have a new high pressure fuel pump, and fuel filter. Howeever I havnt looked at the pump or filter in the Tank. Feel like a dog with a bone. But I am determined to solve it. Cheers Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 20 Registered: 7-2009 |

Hi, Just for interestes sake, compression ratio of Toyota Supras are somewhere in the order of 8.8:1 to 9.2:1 depending on the year. Add twin turbos and a bit of money and it beomes little wonder they can get towards 1000hp. Dont know how you control that sort of power in such a small car. Guess thats not the point. Stefan | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1922 Registered: 4-2003 |

Stefan, I am watching this topic very keenly. I do hope that you may write it all up for us: maybe for Tee-One Topics if Bill agrees ?? Semantics: agreed, not a vacuum. But semantics again: there is no such thing as negative pressure either. Itßs all relative huh ? Jokes aside, you are onto a subject seldom understood, one from which we will all presper once you succeed. RHT. | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 21 Registered: 7-2009 |

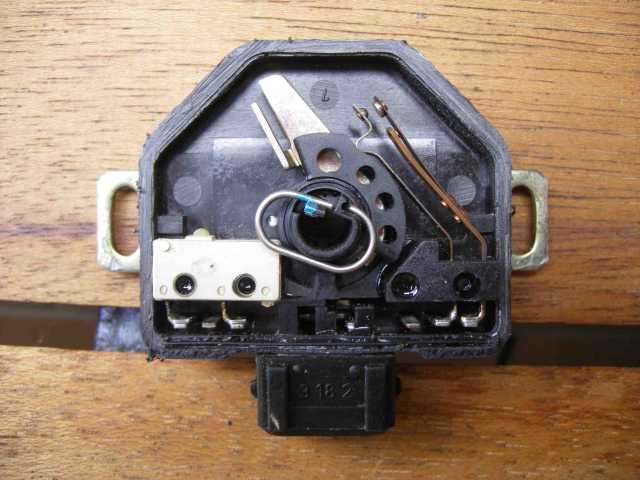

Hi, Been a little busy. Ordered a vacuum/pressure guage but it appears my boost is working from other tests. Still have an issue at 2500rpm... Since found a couple of things that might account. Though I'd share in case. By no means finished but it looks promising. My TPS wont switch to the full load map. Adjustment made no difference, contacts are stuffed. Ive ordered a new one. BTW they are made for SAAB and AUDI as well as Bentley and Rolls Royce. Bosch part number 0280120300. I got quoted $370 for a new one from factory, $49 from EBAY in the states. Anyway this is only a minor inconvience as when I defeat the TPS for full load map my base goes from 5.8ma to 16.5ma to the EHA as indicated in the manual. Thats good. But it doesnt follow the map as indicated earlier in this topic. Just doesnt change beyond that base change. All the sensors appear to function as per the attached pdf. The only ones that I have no idea on is the two extra wires not indicated in the manual. As I have a catylitic converter I assume they have an Oxygen sensor. Most other cars with oxygen sensors that fail put the ECU into a limp mode. If this is the case all I would be running on is the mechanical metering vane for fuel delivery given I see no changes in the EHA current beyong the base. Has anyone had experice with the Oxygen sesnors and the Bentley response to these being dead?

What surprises me is how well the car appears to be working despite. The work on the Turbo had to be done but thats not the full picture. Next stop is to figure out a source for the Oxygen sesnors. Hopefully there will be an aftermarket fit for them as well. Cheers Stefan | |||

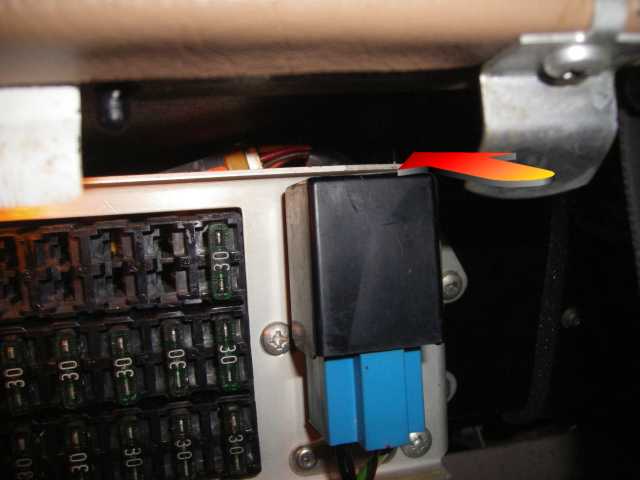

Stefan Morley Experienced User Username: myupctoys Post Number: 22 Registered: 7-2009 |

Hi, Slight correction. Pin 15 to the Fuel ECU is in fact the ground. See attached. Cant account for Pin2 being the same colour, be nice to assume its a ground as well. But I measured 10R there to chassis. Doesnt sound right for a ground. Could still be an Oxygen sensor, or a bad ground..... Why would the manual leave out the ground in the first place. Oh well. Stefan

| |||

Dr. Omar M. Shams Experienced User Username: omar Post Number: 41 Registered: 4-2009 |

Stefan, The TPS is available for $20 from http://www.saabdepot.com/cgi-bin/ppcart/ppcart.pl?cat&usedsaab900parts&Computers/Sensors Thanks or your updates and good luck - we are all watching this thread!!! Omar | |||

Arthur F. Unregistered guest Posted From: 210.50.228.4 |

Forgot, You may need to remove the E.H.A to get access to this screw. (Message approved by admin) | |||

Arthur F. Unregistered guest Posted From: 210.50.228.4 |

The E.H.A should have an adjustment screw to alter its working parameters (fuel enrichment). I saw a Mercedes 300CE with a flat spot issue cured by adjustment of the Electro Hydraulic Actuator. Hope this helps. (Message approved by admin) | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 23 Registered: 7-2009 |

Arthur, Dont think the EHA has any external user adjustment. Think its closed loop from the ECU. If I pulled it off and start changing that then the ECU might start playing up as and when I do get the rest of the parts working. The manual suggests, if I read it right, that once the idle speed is set the rest of the control happens based on the ECU and sensor information as a closed loop response. The issue I seem to have found is the EHA only has a base mixture current applied to it and nothing more. It does change current based on the TPS for the different load maps but follows none of the engine sensor information. Like its open loop. What is surprising is how much power there is despite things not as they should be, or the fact that it even runs at all. The next step is to find out what is causing the open loop response. Hopefully not a dead ECU. Doubt it as there are some things happening. TPS is a side issue at the moment. Good to know there is a cheaper source of TPS. Hopefully someone has experience with a Bentleys response to dead Oxygen sensors. Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 24 Registered: 7-2009 |

Hi, BTW, whilst I dont have the pressure gauge yet, the turbo related issue I started with in this thread is partially solved. The root cause of my issue was the Vacuum switch that controls the dump valve. I replaced it with a new one. The problem remained. Guess what; the new one was wired differently from the origional. This was from the factory at a ridiculous price. Hand made cars and all that. No matter a couple of crimps later and my APT measurements are showing boost. I say partially as I'm back to the point of having the boost controller turning off the wastegate solanoid. Least all the bits work. Something has to be telling the boost controller to open the wategate solanoid or the boost controller is playing up. First things first. Need to have the fuel system running in closed loop. Worry about the wategate later, maybe one will fix the other. Might seem like going around in circles but faults are being found and rectified. Cheers Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 25 Registered: 7-2009 |

Addition, The reason I hope the two are inter-related is the RPM range I loose power is 2500, roughly the RPM the wategate solanoid opens. Thats logical, you loose boost, you loose power. However thinking of it in another way and not totally sure how the three systems communicate their states electrically (Ignition, Boost and Fuel) other than there are some common wires. If the fault is the Fuel ECU (which I now now is not working correctly) tells the boost controller to reduce the manifold pressure to protect the engine. It is plausible, increse boost without increse in the fuel would make the mixture too lean and makes sense the ECU would try and prevent this. If this does hold true, it suggests that the fuel ECU is perfectly aware it is in closed loop mode otherwise it would aberrantly assume all was well and push more fuel in response to the increased air. Find that open part of the loop is key. Be nice if this older system had some form of self diagnostics like the later motronic. Stefan | |||

Arthur F. Unregistered guest Posted From: 210.50.228.4 |

My understanding of the E.H.A function is that it does not alter base idle mixture (that is set elsewhere)but enrichens the mixture based on signals received from the oxygen sensor via the ECU.On a Mercedes the EHA has a tiny adjustment screw which if memory serves me correctly was on the underside requiring the EHA to be removed for adjustment in very small increments. (Message approved by david_gore) | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 399 Registered: 6-2006 |

"Dont think the EHA has any external user adjustment. Think its closed loop from the ECU. If I pulled it off and start changing that then the ECU might start playing up as and when I do get the rest of the parts working. The manual suggests, if I read it right, that once the idle speed is set the rest of the control happens based on the ECU and sensor information as a closed loop response." " that once the idle speed is set " The idle speed and mixture is set - the the EHA makes fine adjustments. Like many things - you are not supposed to touch or adjust them. The EHA mainly does small adjustments, but they can also block slightly putting the whole range out of kilter. I think there is a allen key? adjustment on it, behind a screew on the mounting face. Any adjustment is MINUTE and only recommended if the alternative is to bin it. They do respond well to be cleaned out though. Bad starting. (Running very rich. intermittent rough idling. ) Have you said what happens when running with it disconnected? I'm fairly sure that they don't give any feed back to the ECU. Also make sure you have the correct one for your car. Grey or Black. This can make them feel gutless. Have you measured plunger fuel pressure etc? And see if there's any variation at 2500 RPM (Message edited by paul_yorke on 04 September 2009) | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 33 Registered: 7-2009 |

Hi Paul, Seems I started a paralell thread. Divereted off looking at the pressure regulator and wrote up part number variations I found from bosch that didnt quite make sense. Since cleared up. My car starts easily, hot or cold, idles beautifully and never misses a beat till I get to the 2500rpm. In the other thread I mentioned fuel pressure tests which came up perfectly. The "plunger fuel pressure" you refer to, where is the tap for that on the distributor. If the pressure your referring to is the lower pressure chamber then that was done and came up at 78psi, both at idle and didnt budge at all when taken over 2500 rpm. Same for the primary pressure at 85Psi both right as per manual. I've learnt a lot but seems a bit more learning to be done  Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 34 Registered: 7-2009 |

Paul, Hart to tell due to ageing exactly what colour, it is sort of brown, gery black. But the Bosch part number on the EHA is 2437 020 010. No I havnt tried disconnecting the EHA and running it. Certainly will give it a try. Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 35 Registered: 7-2009 |

Hi, Electrically the only question mark I have come up with is measuring the Engine RPM output from the ignition ECU sourced from the engine position sensor. The Engine position sensor puts out 124 sine pulses and one large one (about twice the amplitude of the rest) presumably indicating TDC. From the Ignition ECU there is a square wave pulse twice per rev. I dont know if this is supposed to happen but it seems to coincided with firing on two of the coils and then a delay for the other two pots. Making 4 sparks per rev. The waveform looks like its intentional. But one pulse from the engine position sensor and two from the Ignition ECU is a quation mark. Probably fine. But could account for Boost controller opening early and stuffing with the fuel ECU. Wont ever know unless someone else uses a CRO triggering off the engine position sensor also looking at the ECU rpm output. Stefan | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 40 Registered: 2-2008 |

Dear Stefan, I did not read the whole thread in full. But it seams that discussing your problem one point is missing: It think, a loss of pour at 2.500 rpm (maybe it is really 2.400 rpm because of a certain incorrectness of the rev counter) means that the engine is knocking or that the boostECU decides that it is knocking altough it is not, and that happens if (even only one) knock sensor data is missing. Did you chek if the knock sensor data arrive correctly at the boostECU? Do the sensors work (test by knocking with a screw driver on the sensor connected to a voltmeter AC)? Did you drive with a voltmeter connected to the APT? You would be able to detect at which pressure exactly the power stops: 2.3 V means ambiant air pressure, every 0,25 V correspond to 100 mbar. The only connection between boostECU and engineECU is by the enginespeed signal (pin25). Every other data supplied to engineECU is meaningless for the boost management. Sorry if I repeated things already discussed, but the thread is already so long that I hoped to bring it back to the central problem. I got the impression that the discussion is already far away from the problem. On the other hand, forget my ideas if you think they are already discussed and out of interest. Regards - Udo (Message edited by udo on 04 September 2009) | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 36 Registered: 7-2009 |

Gday Udo, I agree this thread is getting a bit long. Around the point but still sort of on topic. Small diversion with fuel issues (reason for a new thread) I needed to make sure where addressed but still on the point. Power to the ground the end results is what we are all after. Firstly I totally disconnected the boost ECU. Forced the dump valve in to only boost mode only, the wastegate not to open and took it for a drive. Still a problem. Ignoring the fact that the boost is or isnt doing things disconnected and defeated I still have a problem. Therefore the issue should be coming from another circumstance. Not sure which thread I mentioned it on. But the only question mark electrically I have come up with is the two pulses per rev from the Ignition ECU (derived form the crank position sensor) that gets distributed to the Boost (temporarily disconnectd) and fuel ECU. However this is probaly a valid ECU output but cant be positive. Electrically the question in my mind is what is the common thread causing my issue (possibly yours) where the boost controller was taken out of the equation but was shared between the Fuel and Ignition ECU. The only ones I can land on are the Engine Speed indicator and the TPS. Fuel pressures (primary and lower chamber) checked, at both idle and over 2500 rpm, electrically most things checked, not too many questions left to ask; yet there is still an issue. Tomorrow I am going to take the catalytic convertor off and see what transpires there. Back pressure and all that. Should just be able to see look throught the convertor all being well. If not might take the car for a brief drive with no convertor and see what transpires. That should wake the neighbours. The other thing I will try that Paul suggested is disconnect the EHA and see what happens. Idle is a bit rough without the EHA connected but still idles. I've had too much amber lubrication to take it for a spin tonight. Tomorrow. Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 37 Registered: 7-2009 |

Udo, I'm not sure any of us knows where the symptoms will take us. The more I've pushed the boundaries the less like it seems like one symptom. You get a ford, I've got oil in the water. Well, youll get that occasionally........ Not that sort of symptom  My sense of humour couldnt help it. 4.1 litre Fords and all that. My sense of humour couldnt help it. 4.1 litre Fords and all that. I finally have a boost pressure guage. Will let you know what transpires. Stefan | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 41 Registered: 2-2008 |

Stefan, first of all you must explain for me what you mean with "ignition ECU". From the manual I do not find any ECU like that. My car MCX 35566 (has no dump valve) has no "ignition ECU". The only thing it has is the "engine ECU". I hope this is the same. And if it is the same, then I would say that you are wrong: The only data lead from the engineECU to the boostECU is the enginespeed signal pin 25. The boostECU does not know what the crank position sensor tells the engineECU, there is no way for the boostECU to get this information. And what is the "fuel ECU"? What does this ECU do? Is my car so different? My car has no fuelECU, the fuel pump is simply monitored by the engineECU, i.e. the fuel pumps start for one second after ignition is switched on, then stop. When the engine arrives more then 35 rpm (or a similar value) the pumps start working again. That's it. No fuelECU. Are our car so very different??? If yes, we cannot compare our two cars. Regards - Udo | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 39 Registered: 7-2009 |

Udo, The Fuel and Ignition ECUs I'm referring to are two separate modules mounted just above the acellerator and brake pedals collectively known as KE2-Jetronic. The later Motronic combines these two systems into one unit, not sure where the module is mounted. There are also a couple of extra thing the Motronic does. Has two engine postiion senosrs, also has the O2 sensor just after the warm up catalytic convertor. Fuel pump wise similar end function. My car has the old system. Boost controller the same and most of the physical bits are the same. But the management system is different. Also a lot better desription for the newer one in the manual. The signal I am referring to is the engine position sensor mounted near the bell housing near the distributor. I measure this which goes into the the Ignition ECU, then the Ignition ECU changes this to a signal that pulses twice per engine rev. This signal gets distributed to the Fuel ECU and the Boost ECU. Presumably the motronic does something similar, monitors the engine postion sensor and feeds a modified version of that signal to the boost ECU. Stefan | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1927 Registered: 4-2003 |

The Motronic ECU is located underbonnet, under the plastic cover between the right hand suspension tower and the bulkhead. It was moved there as it is a hotter, colder, damper, drier, wetter and muddier environment, take zour pick, than insider the cabin. | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1928 Registered: 4-2003 |

ps: the KE-3 Motronic has the four segment sensor on the flywheel as its rotational position sender. The KE-2 Jetronic is completely different, and has the multi-toothed sensor with missing tooth as its rotational position sender. | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 43 Registered: 2-2008 |

Sorry, Stefan, I did not realize that your car has the Jetronic, but I was suspecting so because your description did not correspond to what I now from my car. Therefor my confusion. In my car I changed everything from sensors to engineECU which was faulty, but this did not do any effect to the turbo problem. As your system is different I will not meddle any longer - but read what happens. Regards - Udo | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 42 Registered: 7-2009 |

Udo, What country was your car origionally delivered to? BTW whilst the engine managment systems are different the boost controlers should be very similar, at least according to the manual. Stefan | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 44 Registered: 2-2008 |

The car is Monaco/France specification, but the buyer died before he could receive the car, so it was delivered in UK to his family, but LHD. The family did not want to stay with a LHD car in UK, so we were the car offered by Jack Barclay as we had been looking for one - our first TurboR had an accident, it was a total. So we own this car practically since new. Yes, the boostECUs should be the same, as the whole thing is Saab made (my boostECU shows even the Saab parts number). But my workshop manual and parts list starts at 1990, so I cannot verify as far to the parts number if they are really the same for cars before 1990. Regards - Udo (Message edited by udo on 06 September 2009) | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 45 Registered: 2-2008 |

Stefan, just two more questions to understand what you did and what you didn't: 1.) You drove the car while you had "totally disconnected the boost ECU". That means ...? The only point for the boostECU to govern the system is via the boost control solenoid. So you would have had to disconnect the solenoid and the ECU had no more possibility to affect the boost control, instead you put 10 or 12 V to the solenoid. Did you do so? And the dump valve (does not exist on later cars) was forced to stay closed? 2.) You told us the voltage at the APT. But this part of your report sounds strange to me: Engine off , but ignition on gives 2V, but 2V are not 14 psi (965 mbar) but correspond to only 12,2 psi (845 mbar). The correct voltage for ambient pressure is very close to 2,3 V ie 14,5 psi (1000 mbar). Everything else is wrong, I would say. A voltage of 2 V means a very very bad weather at only 12,2 psi (845 mbar). Are you sure the values you told us (more on the top end of the thread) are correct? Your car has only one APT for the engine and for the boostECU. My car has two APT, one for the engineECU and another seperate one for the boostECU. Both of them show the values I mention. I guess you know that you have to calculate P = 40V + 8 resp. V = p/40 -0,2 result in kPa (10 mbar, devide the result by 6.9 and you get psi) resp. Volt. So if you tell me that 2 V at the APT are shown at ambient air pressure - your APT is faulty. Ambient air pressure is about 14 psi under normal conditions, but that is close to 2,3 V! Calculation (the formula given by RR is using kPa): V = 100 kPa/40 -0,2 = 2,3. 100 kPa equals 14,5 psi. And more: As your car has only one APT for both systems (engine and booster), both of the systems are working with wrong data - always given the values you reported are what you have been shown by your voltmeter. And this would explain why you do not get power with or without booster connected or disconnected. Both systems receive the same wrong data. Therefor my question: Are you sure the values you told us are what the voltmeter showed? Best regards so far - Udo (Message edited by udo on 07 September 2009) (Message edited by udo on 07 September 2009) (Message edited by udo on 07 September 2009) | |||

Dr. Omar M. Shams Experienced User Username: omar Post Number: 45 Registered: 4-2009 |

Stefan, Just to add to Udo's previous messages, and to assist with your troubleshooting...... I am not entirely sure if my symptoms are exactly the same as yours. My car has been in the garage for so long that I cannot remember exactly what my symptoms are like. I know that my car is not as powerful as I expected it to be. You, on the other hand, alreday have plenty of power, just not consistent over the whole speed range. I think I have limited or very little boost across the whole speed range. I will focus on the boost issue as soon as I get my car back from that damn steering rack leak issue. I have taken the rack apart 3 times and it still leaks... I am starting to lose it with this rack problem, but that is a separate issue for a different thread. Thanks Omar | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 47 Registered: 2-2008 |

Hello Omar! This is out of the theme of this thread - but did you talk to Richard Treacy as far to your leaking steering rack? I had the same problem, I have the fourth rack installed now, every time sent back to Introcar in London, every time a case of warranty. The reason is/was a wrongly handled seal inside the rack, but the problem should be completely sorted out, as far as I know in assistance of RT - my last rack has now done 40.000 km in the meantime without starting to leak again - okay, who knows how long it will last still!? And your turbo problem? You may have read about my own problem. Without engine speed signal the boost pressure is perfect - but I will have to sort out the problem and am suspecting the knock sensor insulation. I do not like to run the engine without the knocking of the engine monitored as consequence of the blocked engine speed signal. Regards - Udo | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 43 Registered: 7-2009 |

Udo, Answer your comments point wise. #1 I pulled the rubber pipe from the solanoid that goes to the wastegate and blocked it off. Also blocked the outlet of the solanoid to stop air leaking from the turbo. No pressure on the wastegate diaphram means wastegate stays closed (ie no exhaust bypass). Dump valve means I had no vacuum going to the dump valve diaphram meaning boost pressure can only go into the engine(no recirculation). Electrically I pulled the plug on the Boost controller to ensure nothing eletrically was upsetting the fuel and ignition ECU's. So I had permanent boost purley dependant on exhaust gas throughput and still had the flat point above 2500. The other point is by disabling the boost controller means if the boost controller was the root cause of my issue and it was disconnected, changes in what the boost controller had been doing would no longer be causing apparent changes in operation. Yet I still feel the issue. I would imagine the performace would change anyway but the problem point would shift or transition more smoothly. #2 2.182V, I had measured this previosly but didnt focus on it in my writeup as I had moved on from it. I live at about 600m so reading is a bit less than at sea level and its winter here. When I took this reading it was 1007 at sea level, so with 600m the level is probably about right. #3 I have two APT's Both voltages are very close to one another. My car is early 89, I call it 88 to stop confusion because in late 89 the Motronic systems where introduced. Omars comment, I dont know what to expect from a Bentley Turbo R. I love the engineering behind it and the main reason I dipped my toe in. I expect a car to meet its form and function and will ask no more from it. Handling wise, for a big car its incredible. Power wise I notice this issue at 2500rpm. Is it normal or isnt it. Some people say these cars are incredible, yet thats not what I find and presumably quite a number of others. How do you compare apples with apples when you only have one. Separate. I am focussing on the full load map and what that should mean to the Fuel ECU and what that does to the EHA. I have found a circuit and have found one inconsistanciy between the manual and what the circuit is. When I had the connector out for the boost ECU I seem to remember a similar inconstancy between the manual and what I had in my hand. I will also be opening up the boxes to confirm with a CRO electrically all signal are doing something internally. My line of thought is, firstly the EHA current not following the full load map from the fuel ECU. Second line of thought is why does the boost ECU open the wastegate valve (turn power off to the solanoid). Third is other than a couple of peripheral issues nothing core appears to be wrong other than these two differences. Stefan | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 48 Registered: 2-2008 |

Stefan, now I am more or less up to date with your investigations. And my solution was no solution :-( I understand that you really had the boostECU "out of service". And I see that you have 2.182 V at 600 m which is 953 mbar - that's realistic, especially if both of the APTs show the same value. One last question: Your boostECU turns the voltage at the solenoid to 0 V at which rpm? 2000? 2500? Can you exclude that reading of 2500 is 2400 in real because your rev counter is exact enough? I ask because as to the manual loss of boost pressure at 2.400 rpm means failure at a knock sensor, at 2.400 rpm the boost pressure is 200 mbar (basic pressure). My ECU cuts the power of the solenoid off at 2.000 rpm ie 0 mbar, the starting point of boost. Maximum pressure with power off at the solenoid is 200 mbar. Why didn't you run the car with the voltmeter connected to one of the APTs? You would know the pressure at any moment while driving. The fact that the solenoid is closed at close to 2.400 rpm could mean that the engine is knocking or the ECU believes so. Knocking can be caused by a hot running engine, ignition too early, aged lambda sonde ... many reasons. Are you sure, your ignitionECU is always using the correct ignition field (sorry, don't know the correct term)? The wrong ignition field under hard acceleration may cause knocking of the engine - and cutting off the power at the solenoid at basic pressure ie about 2.400 - 2.500 rpm. And also without boost pressure the wrong ignition field should cause loss of power. Do you exclude this possibility? Or is this idea nonsense? I am always fiddling about the number 2.500 - it is so close to the rpm where the solenoid cuts off the pressure in consequence of an inaudibly knocking engine - whatever maybe the reason for the sensors to detect knocking. And at the same time it must explain why you have loss of power at the same rpm without boostECU. The basic pressure of 200 mbar should always be present. Best regards - Udo | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 44 Registered: 7-2009 |

Udo, Did you find any existing holes suitable for wiring stuff into the cabin. Not really happy making the firewall look like swiss cheese. Really I need to run some of the tests whilst driving so we can compare notes. I assume you mean the wastegate solanoid. As close as I can measure changes to zero volts at 2150 rpm. Stefan | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 49 Registered: 2-2008 |

Stefan, change to 0 V at 2150 rpm is rather crazy - I do not know any conrete condition that would change at 2150 rpm, 2000 rpm - yes, 2400 rpm - yes, but 2150?? Very strange indeed. As far to the cables - I fitted two thin black cables in between the gap that is left by the mud guard, it is nearly unvisible. The gap between door an body is wide enough to enter the car. Regards - Udo | |||

Udo Hoffmüller Experienced User Username: udo Post Number: 50 Registered: 2-2008 |

Ups - the pics have not been uploadad. Perhaps now ...   (Message edited by david_gore on 08 September 2009) | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 45 Registered: 7-2009 |

Udo, Thats a nice metallic blue. Will set something up tomorrow. There is a couple of things I want to monitor. I know the RPM is weird. I compared frequeny on a DMM with what my tacho is saying, multiplied by 60 and it seems spot on. Cheers Stefan | |||

Omar M. Shams Experienced User Username: omar Post Number: 46 Registered: 4-2009 |

Udo, many thanks for your steering advice. I am waiting for RT to return from his trip to advise me on the rack issue. Stefan, sounds to me like you are not able to get enough fuel into your engine at 2500 rev/min. You did say something about your low pressure fuel pump. Are you able to monitor fuel pressure whilst driving? I know you have already measured it staionary but did you see what happens under load? if the pump cannot deliver due to wear and tear then you will only get symptoms of reduced performance at peak load. Another issue to consider is the possiblity of your new pump not being a good one!! Not all parts are perfect straight out of the box. I am convinced from what you have said that you do not have an air issue - strictly fuel. Good luck Omar | |||

Udo Hoffmüller Frequent User Username: udo Post Number: 52 Registered: 2-2008 |

Dear Stefan, I did not want to show you the nice blue metallic colour of our car which is called royal blue metallic. What I wanted to show you are the black wires leading from the ATP (outside the pic) to the inner part of the car. Did you detect them? If you did not - well, that's what I wanted to show you, too, they are (nearly) invisible :-) But I have a problem with my english or yours: "I know the RPM is weird. I compared frequeny on a DMM with what my tacho is saying, multiplied by 60 and it seems spot on." What does that mean? Your tacho is telling you the correct rpm or is it telling you simply nonsense? Sorry, but as I never lived where english is been spoken, my knowledge of common speech is very limited. In spanish it would be much better for me :-) Best regards - Udo | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1940 Registered: 4-2003 |

A note: traditionally, electronic tachometers are driven by the ignition coil low tension. That means 4 pulses per revolution for a V8 with a single coil. Generally, manufacturers have stuck to the figures when grafting a conventional electronic tacho to an ECU. That means that at 1,000 RPM (revolutions per minute) on a conventional V8 petrol 4-stroke, the digital multimeter (DMM) will read a frequency of 1000x4/60 Hz = 67 Hz (Hz = Hertz = cycles, or pulses, per second). RHT. | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1942 Registered: 4-2003 |

Maybe we need a new thread for this one. You may read about the rack issue in Praeclarvm issue No. 4-06. August 2006. It is available to members on www.rroc.org.au under Club Magazine Archive. It also features in Modern Lady and elsewhere. These racks are of a very good basic design. However, the final execution leaves a little to be desired, and that is being kind. Unusually careful attention to detail seems to work in the best Royce tradition. Workmanship triumphs over design. You cannot successfully simply bang in a repair kit and hope for the best. With careful attention to the key details I outline, the racks seem much better. Introcar's subcontractor adopted all my recommendations, and has saved a fortune on warranty claims ever since. After a rash of failures with professionally-rebuilt ones on my Turbo R, I did the present one myself. The present rack has not needed a drop of top-up since 2005. The main thing that people do not know is how to gap the main PTFE bushes, but there are several other such essential points to note too. RHT. ps: to calibrate a V8 tacho, best is to use a signal generator. If you have none, simply use a 240VAC to 9VAC power adaptor and a bridge rectifier (4 diodes and no filter capacitor) as a 100Hz source. The bridge produces a 100Hz pulse wave 0V to +12V. You may use an old power adaptor from a mobile phone or whatever provided it is a transformer-type and not a switch-mode type. The small light newer ones are switch mode. Open it, and connect the bridge rectifier directly to the 9VAC output of the transformer. Connect the -ve of the rectifier bridge output to the chassis of the tacho and the +ve to the signal input of the tacho, and set the needle to 1500RPM. (Message edited by Richard Treacy on 08 September 2009) | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1943 Registered: 4-2003 |

You may read and download the rack article on: http://www.rrtechnical.info/rackextract.pdf Best is to subscribe to Praeclarvm of course. That supports the publishing of such articles. RHT. | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 46 Registered: 7-2009 |

Udo, Richard, The tacho derives its signal from one of the coil packs ignition pulse. The Bentley has two coil packs. Each coil pack fires twice per rev. Therefore 1500 rpm will give 1500pulses/60seconds/2coil packs or 12.5hz. My DMM has a resolution of .001hz Udo, yes I did see the wires and will do something similar. With regards to fuel pump, assume your talking the one in the fuel tank. When I replaced the high pressure one I did check that the in tank one worked. Maybe I should have pulled it out. Fuel wise, which my biggest question mark and follows on from your suggestion is the EHA. How do other people interpret the diagram on attached second sheet. The red line is what my car is doing. The chart is from one of the test flowcharts. The motronic has a similar sort of test. I dont see the 16.8ma indicated at the start of this chart change with so much of a flicker until I get to 2500 where it start dropping. This fits with the fuel hypothesis. It is quite capable of going to the 150ma under cranking so its not about the drive output to the actuator. Plus all the senosr can be measured going into the fuel module. Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 47 Registered: 7-2009 |

Sorry meant to attach a the file.

Second sheet, chart on the left. Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 48 Registered: 7-2009 |

Richard, Maybe I'm flawed in my thinking. But RPM is revolutions per minute. Hz is per second so to get them to the same base the rpm needs to be divided by 60. Either that or my guage is way out. Stefan | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1945 Registered: 4-2003 |

OK, as I noted, with a single coil it has 4 pulses per revolution or 67Hz at 1,000RPM. If driven by one of the twin coil low tensions, then there are 2 pulses per revolution, or 33Hz at 1,000RPM. That is of course if the tacho is driven by the ignition. It will be obvious on the test bench. With the 100Hz setup I mentioned, for a 4 cylinder motor or an 8 with twin 4 cylinder distributors like ours, the tacho should read 3,000RPM. Looking at it your way will give the same answer: 1500RPM, two pulses per revolution, 3,000 pulses every minute, 50Hz. 3,000RPM = 6,000 pulses/min, 100Hz | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 49 Registered: 7-2009 |

Richard, I mixed things up. Was measuring the crank sensor and combining that with the 2 coil packs. Sorry. This fault is doing my head in. When I measure the frequecy from one coil pack it all makes sense. 50hz is right for the 1500rpm as I see 20ms between pulses. The tacho is derived from one of the coils. Stefan | |||

Stefan Morley Experienced User Username: myupctoys Post Number: 50 Registered: 7-2009 |

Hi, Went to a car meet tonight. Hotted up japanese stuff. Oportunity to listen. They are all revheads but do get a lot out of their machines. Something one of them said was interesting. Dont trust a Emissions test in a motor registry to give you the full picture, trust it on a dyno. Seems a bit rare but I had a look at my defect paperwork, there is just a box ticked. Not much else. Doesnt pay to ask too many questions if they are ticking boxes. Based on ealier disciussions I think I will take my catalytic converter off tomorrow and see what transpires. Udo my first pressure guage was faulty. Should get new one end of the week so we can compare readings. Stefan | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1951 Registered: 4-2003 |

Stefan, They are surely correct. However, standard-spec fuel-injected motors are not so critical as others. A good mixture on idle certainly does not indicate a good mixture on load in all situations. You may put wildly incorrect SU needles on carburettor cars and tune for a perfect CO output on idle, yet have something really lousy when driving hard. Many Silver Shadows, and especially MkVI and S cars, are so poorly set up that way. With carburettors, the air filter and induction system health is so often very poor, and setting to a good CO reading on idle often corresponds with fouled plugs, burned valves, and rotten behaviour on all but idle. At least with fuel injection, the air's volumetric rate determines the fuel squirted into the system. For example, a clogged or non-standard air filter on an injected motor will not affect the mixture. If the system is set up correctly during manufacture, only the idle mixture need be adjusted during the life of the vehicle unless modified, for example by changing the fuel type and spark timing, the compression ratio or the camshaft profile. By comparison, with carburettors, dirty or non-standard filters can only be corrected on a dyno and with a range of needles to select from to set the thing up on load. That's why I don't give a toss about air filter brands with injection, but do with carburettors. Putting a cheapo or non-standard air filter on a MkVI can only be successful if accompanied by $1,000 of tuning and needle selection on the dynamometer. That’s also the way I had to go with my R-Type when I fitted a high-lift overlap long-duration camshaft and a high-compression cylinder head. With our unmodified injected cars we have it easy. RHT. | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1952 Registered: 4-2003 |

A concrete example of the above. Many people like to fit low-restriction air filters to our cars, especially to English-spec MkVI cars. Watch out. More generally: Low restriction air filters, K&N being classic examples. Carburettor naturally-aspirated cars: a disaster. The motor runs very lean on load and burns up its valves and cracks the plug insulators. Eventually the pistons say goodbye. Dynotuning is required. Injected naturally-aspirated cars. No adverse effects. Increased air rate is rewarded by increased power availability as the injection system matches fuel to air flow. If only the filter type is altered, no Dynotuning should be necessary. This is often referred to as Stage ½ performance tuning. Injected Turbocharged cars: no change as the Turbocharger compensates for everything. No power increase is achieved. Carburettor Turbocharged cars: same as carburetor non-turbos except for the few pressurized-chest carburetor cars like the rare early Bentley Turbos. RHT. | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 51 Registered: 7-2009 |

Richard, Thanks for that, makes a lot of sense. The air fuel mix should always be optimal because the turbocharged/fuel system by it very nature compenstates for changes. Took the converter off, no blocks, looks good. Except the bolts snapped despite onight covered in penetrene. Oh well minor detail nothing an ezy out wont solve. Will wait on my boost/vacuum guage. Cheers Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 52 Registered: 7-2009 |

Udo, Reason I'm adding a boost/vacuum guage is I want to compare the real state of affairs against the measured voltages from the APTs. They should be one and the same but will let you know. When I get the converter back on!!! Car sounds pretty mean without it on, head turner for all the wrong reasons. No didnt take it out, just moved it back into the garage. Stefan | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1953 Registered: 4-2003 |

The question has always been WHY was a boost gauge never fitted in the first place ? Our T-Series doesn't even have that boring and useless temperature gauge, nor a voltmeter or outside ambient temperature gauge, and doesn't need them. The car looks after all that. Surely a Turbo boost gauge on our Turbocharged cars would be interesting at least ? RHT. | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 53 Registered: 7-2009 |

Richard, Maybe mundane things like the engine operation is beneath consideration. But the outside air temperature well that is a lot more important. I found a link that made me feel a little better. Wont put the link in as parties might get upset but search for "troubled bentley" in google. Your troubles will seem irellavant. Stefan | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 401 Registered: 6-2006 |

R-R couldn't cope with the amount of calls they got about gauge readings etc,which were correct – so they thought it easier to drop as many as they could.... When the first turbo Bentleys came out - there were inundated with customers ringing up or calling in because their "TURBO LIGHT" in the middle of the dashboard wasn't coming on! 'There's something wrong with my turbo!' The outside temperature gauge was crucial for health and safety reasons. Because of the automatic air condition, occupants of the car may have got "Thermal Shock" when they alighted from their cars! | |||

Udo Hoffmüller Frequent User Username: udo Post Number: 54 Registered: 2-2008 |

Stefan, I will be in Portugal from this Friday with the Bentley. For the next three weeks my access to the internet will be limited. There are many public WIFI places in Portugal, in parcs or bars, but I will not always have the laptop with me. But even then the voltmeter will be fitted to the APT and/or solenoid, just for fun to see what is going on there. To me happened the same as to you: Suddenly the whole thing works correctly for some time! Also for this reason I am surching for an electrical cause. Regards - Udo | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 57 Registered: 7-2009 |

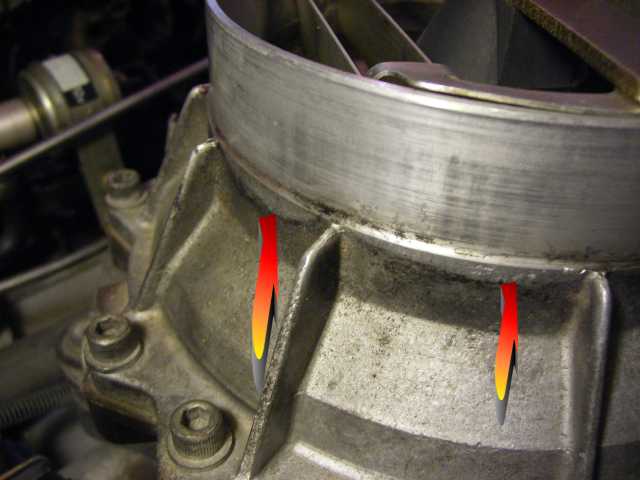

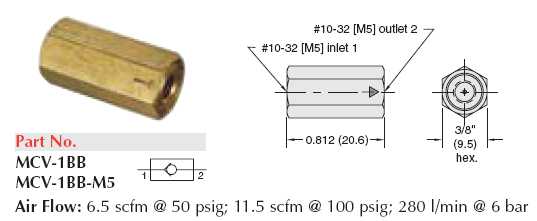

Hi Udo, Enjoy the drive to Portugal. The difference a boost/vacuum guage in the car makes. So much clearer than looking at numbers on a DMM, an old analogue multimeter might have been a bit better. I'm only barely getting 1.5psi boost. The upper value varies a little bit by say +/-.5psi. The APT DMM reading confirms that. What the DMM doesnt show, but the guage does, is when I get to that point, the boost alternatly jumps between say 1.5psi and 0 and that happens about the 2500rpm mark. The jumping seems random. Now I've checked the exhaust system, dump valve both operationally and physically. All the aux bits now work. Only leaves the turbo, wastegate and or the boost controller. The boost controller is definetly getting all the right info and I had that box out and there is nothing physically wrong on the circuits. There is almost no play in the turbine and it spins freely. Not much left other than to look at the wastegate. I checked it as far as the manual suggests in driving pressure down the line and your supposed to hear it click. Which it does. Anyway off with the wastegte to look at that. If it wasnt sealing fully, part of the gasses would bypass the turbine accounting for the low pressure. What is happening to the toggling of the 1.5psi >> 0? Might simply be the wastegate seating and unseating with play and leaking like a sieve. Intermittantly it has worked but incresingly getting to the point I have a normally aspirated car. Will keep you posted. Will take photos if I find anything wrong. BTW fitted my new TPS. Not the easiest job. In case peoples are wondering whats in it here is a pic of the old one dicesected.  The Dump Valve innards  The Air Metering setup, in case people are wondering the brass thing near the wastegate solanoid is my replacement for the platic one way check valve used for the gearbox kickdown. Heat made the plastic one brittle.  Cheers Stefan | |||

Omar M. Shams Experienced User Username: omar Post Number: 48 Registered: 4-2009 |

Great stuff Stefan. Do you have a picture of the manifold pressure guage set up? Thanks Omar | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 59 Registered: 7-2009 |

Hi Omar, Inside the car is very agricultural at the moment. The guage is "Blu Tac"ed to the column shift temporarily. Not really sure where to fit the guage so it looks the part without changing the look of the dash. The engine vacuum tap is taken off the line going to the vacuum switch. You can see the "T" in the photo just to the right of the Dump Valve solanoid. Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 60 Registered: 7-2009 |

Omar, As i said very agricultural. But until I figure that how to do a decent unmolested job this will do.  Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 61 Registered: 7-2009 |

Addition, When cold the guage sits about 16.5inches, after warmed up about 18.5inches. Very Stable. When the Idle speed solanoid cuts in the guage drops (ie air conditioner on) about 1 inch. At 100kms, trailing throttle (no throttle), in second (somewhere around 1500rpm) about 24.5inches. Reading what I can about vacuum guage readings I think the engine is fine. Be interesting to see how this compares with others. BTW the voltage from the boost APT roughly corresponds. Just a lot harder to see a trend on a DMM. Cheers Stefan | |||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1958 Registered: 4-2003 |

Stefan, What's that speedo that you have there ? The puny 220km/h ones were superseded in March 1987 by the 270km/h ones. | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 62 Registered: 7-2009 |

Richard, This car is a strange one. Assorted interior parts have 87 and 88 written on them along with my cars serial number on them, but the chassis number is comes up as an 89. Most of the circuit boards have reference to being made in 88. Also 89 and a vinyl roof!!! Seems a little bit out of vouge. I thought that idea went out in the late 70's. Other slighly out of the ordinary things is square headlights (like a spirit) metalic paint job and picnic tables. Three years to make a car.... No Idea. Maybe the orgional purchaser was a bit slow in his payments. Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 63 Registered: 7-2009 |

Richard, Chassis number SCBZS0TA4JCH22888. I think the J refers to 89!! Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 64 Registered: 7-2009 |

Richard, The other thing (looking at http://rrtechnical.info/ChassisNumbers/sz_vin.pdf) "OT" is defined as a non catalyst pre 88. Yet my car does have a converter. Coupled with "J" for the year 89 and "ZS" Turbo R prior to 89. Got no idea. Stefan | |||

Eugene Oleinik New User Username: eugenerus Post Number: 7 Registered: 8-2009 |

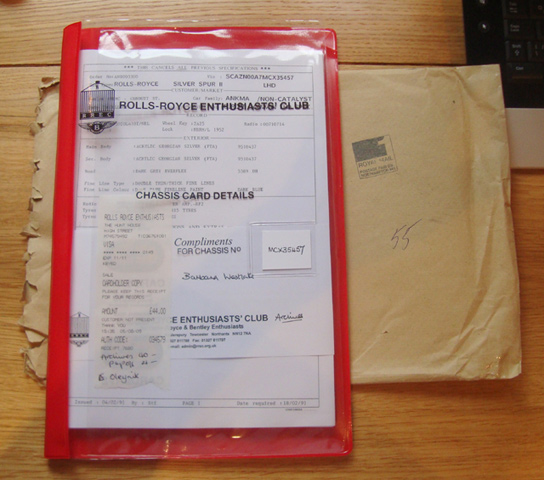

Stefan, Do you have a build history? This will tell you what happened to your car before it was given to the customer. It will most likely even tell you when and how the customer paid. My car was also made over 3 years, initial order placed in 90 and the car dispatched in 93. I found build history most useful and it will tell things like the key numbers, colours, serial numbers of components used, original features and the package, assembly and driving test results, paint job rectifications, first customer name, order changes (e.g. on my particular example the customer changed their mind and asked the factory to fit the flagpole on the opposite side to what was specified) and any invoices and payments. Eugene | |||

James Feller Frequent User Username: james_feller Post Number: 72 Registered: 5-2008 |

Hi Stefan, Just answering your question re 'square headlights like the Spirit' late 88 for 89 model years the Turbo aquired its new front air dam and side and rear skirts. I think 89 was the year Crewe changed all Bentley models from the old rectangular 'Spirit' lights to the paired 7' rounds ones. Yes I would agree with Eugene, see if you can get the orginal build history Stef. My Turbo seemed to have been built with lightening speed compared to my Spirit. The build date is June 89 and its Aussie compliance was Oct 89, so 4 months to ship it to Aus. Where as my Spirit is Built Sept 86 and Aussie complied Aug 87. Big difference!!! I'm not sure why you would have 'many parts form different years' on your car. Richard pointed out something I noticed too, strange your speedo doesn't go to 260? yours being an 88 car Stefan. I have wound my Turbo out to 200 and its sensational, although 260 might be pushing it.....!!! What does its build plate say? If you have the hand books when was it first delievered to the first owner? This should be a good starting point. You can track its delivery history and service history through David Vann in the RROC. Provided of course it was serviced at RR&B as there was a requirement that copies of paperwork and service book vouchers went back to RR&B in UK for Achiving. Its worth it Stefan and its interesting reading. I requested the hisoroty on both my cars and little tit bits like the orginal spec sheets and trim requests to England are eveen included... anyway, all 89 and on Bentleys got the paired headlights. You can get them retrofitted but the jet wash feature will be useless or more so than it already is... Cheers J | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 65 Registered: 7-2009 |

Thanks James and Eugene, Yes I will try and track down build details. The car history is known since 2003 but not much before other than it came from Japan with very low kms. It has been well cared for, state of the oil and engine bay is testament to that but as for RR serviceing, not since 2003. Irritating the book isnt with the car. As for the lights they are a part of the cars history and it would be wrong to play with them. The car intermittantly used to go well. Just the fault is no longer intermittant more permanent. Touch wood I'm getting close to the root cause. Cheers Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 66 Registered: 7-2009 |

James, Eugene, Tried doing a quick search for David Vann with no luck. Assume he is attached to the UK branch. But found no reference to him. Would one have access to this information being a member, seem more pertinant to become a member of a local branch in OZ than UK. Seems to be something on this page http://www.rroc.org/page.asp?SID=1&Page=3 (link "Car Records 1980 to 2002" in left hand column) but password protected. Thanks Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 67 Registered: 7-2009 |

Hi, Reading the manual and looking at the wastegate doesnt seem to be as simple an operation as it states. Might take a bit longer, the drain return from the turbo gets in the way of simply removing the wastegate. Fortunately the nuts are in good condition. Stefan | |||

Eugene Oleinik New User Username: eugenerus Post Number: 8 Registered: 8-2009 |

Stefan, RREC UK holds all build records in their archives so it makes sense to order it directly through them (Barbara Westlake, records archivist). More info can be found here: http://www.rrec.org.uk/History/Construction_and_Test_Records.php Note that this is available to non-members of RREC too.  I note your other thread titled Pressure Regulator - the build history will give an answer to similar questions. | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 405 Registered: 6-2006 |

Stefan - The Japan link may answer a few questions and be worth looking into. Speedo's for Japan were probably the reason for the lower top speed calibration. Also things like over-speed ecu's were fitted. I don't know if there is a list of country specific differences anywhere, but as you look through the parts books, you'll see astrix's on many parts - you then need to look at the additional info box. The build sheets may show up these items as well. | |||

James Feller Frequent User Username: james_feller Post Number: 73 Registered: 5-2008 |

Hi Stef, David Vann, is the achivist for the Aust RR branch I think. I got his details from one of the L&D newsletters some years back. I'll send you his details by private email. Paul has a point, as your car from your accounts looks to be a Japanese spec the complete service history maybe difficult. However the original build sheet should easily be available from the RREC UK as Eugene suggets. Cheers J | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 408 Registered: 6-2006 |

Stefan, not sure if you've read this - or how much is applicable to your vehicle. Might be helpful though?

| |||

Stefan Morley Frequent User Username: myupctoys Post Number: 68 Registered: 7-2009 |

Thanks Eugene, James and Paul Will contact him. Be interesting even if I cant get the full picture. The pdf is similar is many ways. Can see what Udo is on about in relation to some of the tests he has run. From what I can see most of the stuff is functionally similar. Minus fault codes in mine of course, also they make comments about on road, full load tests that the earlier manual doesnt really make clear. The symptoms for the wastegate describe my circumstances pretty closely. Only difference is mine is toggling randomly, could be attributed to a weak spring. Before I pull off wastegate etc etc. The Garrett T04B Turbo chargers are easy to get parts for. The external wastegate is not so easy. From what I can gather the Wastegates on the Bentleys are also made by Garrett, however from two distributors they suggest Garrett no longer make the external wastegates. Offering alternative modified solutions. Has anyone found or had need to find a source of parts for the wastegates? Cheers Stefan | |||

Omar M. Shams Frequent User Username: omar Post Number: 52 Registered: 4-2009 |

Paul, Great article.... I am unable to view the images though. Is it my computer or is there something wrong with the document? Thanks Omar | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 411 Registered: 6-2006 |

Omar, neither. The graphics are via the links to other documents. The post is a PDF I made of teh main article. Have you got a copy of Assist? It's tucked away on there. Cheers, Paul. | |||

Omar M. Shams Frequent User Username: omar Post Number: 53 Registered: 4-2009 |

Thanks for your reply Paul. I am either too old or that PhD was a waste of 4 years of hard work.............. I can't seem to view anything but script on the attachment. I have to say, the stuff that I can read is very good indeed - It is just a shame I can't see the whole document in all its glory. | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 412 Registered: 6-2006 |

Omar. Sorry, I mustn't have explained that properly. The PDF I posted is JUST the script. The original article had the links embedded into it and those links were to the graphics. Do you have a copy of ASSIST 1990 - 2000? Are all your cars pre 1990? Even so, lots of the items are the same or similar. It's a great resource but infuriatingly non-intuitive. Although saying that, it's still much better than many other manufacturers. I stumbled upon the article when looking for something completely different. | |||

Omar M. Shams Frequent User Username: omar Post Number: 54 Registered: 4-2009 |

Paul, I do not have a copy of ASSIST 1990-2000 or for that matter 2009. In fact I don't know what ASSIST is!! My cars are indeed all 1990 and older. I will go on the net to look up this ASSIST thing now........... Many thanks again. Omar | |||

Paul Yorke Grand Master Username: paul_yorke Post Number: 413 Registered: 6-2006 |

IETIS? | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 69 Registered: 7-2009 |

Hi, The pdf gives a lot better indication of how things are intended to function. The things that makes the cars similar is greater than the things that make them different. Specifics certainly change but the background function seems to be very similar. Garrett TO4B Turbos as I said are easy to get parts for. Ordered a rebuild kit just in case I make a mess. You can even get ball bearing retro kits to replace the bushes and 360 degree thrust bushes if one so desires. Apparenlty standard is 270 degrees. The Wastegate is another story. From Garrett they no longer make and support the external wastegates. Also three other of my normal sources have nothing. They might be very reliable and infinitely repairable but this poses a problem. Guess have to take a punt and take it off and see what gives. Touch wood it'll be simple. Stefan | |||

Stefan Morley Frequent User Username: myupctoys Post Number: 70 Registered: 7-2009 |

Omar, I couldnt read the charts either. Its not just you, just so you dont feel bad. I've sent Barbera at RREC.org an email. She is yet to respond but I'm looking forward to anything that turns up. Its quite feasible there is a governing of top speed given the car is japanese, but that doesnt account for my fault. Plus the car used to respond beautifully for my purposes. I spent ten years in another life maintaining helicopters, french, english and american. One thing you get to appreciate is the design methodology in making those aircraft maintainable. Things that are likely to need maintenance have had thought into how that would be carried out. The number of things I've come across with the Bentley, whilst they are beautifully made; the irritating access. Anyone who has tried to replace a steering rack will attest to that. The wastegate is no different. Stupid position for the Turbo return oil drain pipe in relation to the wastegate. Oh well love the beast. Stefan | |||

Eugene Oleinik New User Username: eugenerus Post Number: 9 Registered: 8-2009 |

Omar, Stefan, Assist, also known as TSD6000 is a collection of technical materials for our cars (90 onwards) that contains workshop manuals, parts manuals etc. They come either as a DVD or as a printed material. DVD is much better though (and costs less too). I do not posess a copy of these but have ordered one recently and believe it will be a very good investment. | |||

Omar M. Shams Frequent User Username: omar Post Number: 55 Registered: 4-2009 |