| Author | Message | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 365 Registered: 5-2013 |

Hi Folks, When jacking the bow, I jack each side independently and position the floor jack under the "bumps" of the wishbone suspension element. I consider that this is reasonable, since the weight of the car is on that suspension that I am lifting. When jacking the stern, I've been positioning the jack under the differential, because I was told by a local shop that it was acceptable. I'm beginning to doubt that advice. How do you jack the stern? Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 876 Registered: 5-2012 |

Hi Chris It is ok to jack the stern from under the diff, however make absolutely sure the jack does not foul the rear cross member - it is possible to crack it. I always use a prothane jack pad to cushion the diff. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 366 Registered: 5-2013 |

Hi Geoff, Thanks. I use a six-inch segment of 2x4 as a "cushion" I asked because I see a leak where the drive shaft meets the differential at the flange. I can't say that it is a new leak, but I can say that I've never noticed it before, so it occurred to me that I may have caused it... Well, there's another project to add to the list... Thanks for the help, Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 878 Registered: 5-2012 |

Hi Chris In case it is an old leak, check the oil level in your diff. Geoff | ||

richard george yeaman Grand Master Username: richyrich Post Number: 340 Registered: 4-2012 |

Hi Geoff and Chris SRH 19529 October 1974 Sy1 is sitting jacked under the diff also cushioned by a piece of 4x2 the U K equivalent to Chris 2x4 probably either will do the job and at least one pair of Suitable Axle stands. Richard. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1554 Registered: 6-2009 |

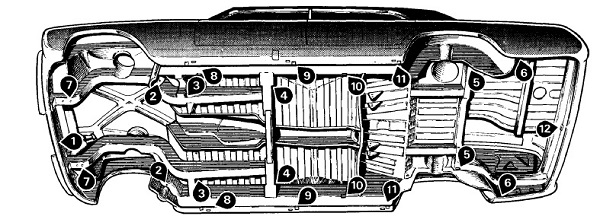

Chris, See Tee-One Topics, Issue 38 for the diagram of jacking points and sill block points for the SY and SZ cars [Jacking Points/Sill Blocks on PDF p. 13 & truss stand p.4]. I have always placed the floor jack head centered under the differential/final drive and use tire tread samples I get from my local tire shop as the cushioning:  I don't ever think I've raised either the front or the rear of the car on a single side. I tend to raise either both front wheels using the point numbered 1 in the diagram where the two large nuts can be seen and used as the target under which the jack with cushion is placed. If you've never checked the oil level in your Detroit/trunnion joints you definitely need to do that, too. It generally slowly drains into the differential over time and a lot of these cars are run for long periods of time with nearly dry trunnion joints because the oil level remains unchecked. Brian | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 332 Registered: 5-2015 |

I jack up the front using the very robust centre wishbone front mounting thingy. The rear I use the diff. My views is that the diff subframe mountings must be strong enough to support the weight of the car if not then the mountings are cracked . Known fault. I use a 8 x 2 soft wood protector between my high lift Badbury TI Jack. I also have a Yankee Jack. Orange with a white handle. 2 tons. Also a folded rubber door mat gives good grip. When I do brakes I get the car up on 4 axle stands. My stands are matched set rated at 2500 kgs each. Also 4 other stands which are all different. Plus scissor jacks hydraulic bottle jacks. 500 kg chain hoist. 2000kg floor crane. The roof of my workshop is safe to 1000kg point loading. Also a pile of 4x4 fence post off cuts. And a 12x12x18 lump of oak. With that lot pulling cars apart is easy and relatively safe. When a floor tolley jack is used the arm goes in an arc. This causes the jack to drag itself towards the car. As the jack gets higher its more pronounced. The danger here is that one end of the car is on stands and the car must not move towards the jack. SO----. Make sure the jack can roll. Oil the jacks wheel bearings. Lay down a 4x4 ft 1/8 hard board sheet so that the jack can freely roll. Then use the hard board for laying on. The supplied RR jack works well and I have had occasion to use it. I got bored while staying in Norfolk so I took the wheels off and checked the brakes out. Put the wheels under the car. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 368 Registered: 5-2013 |

Hi Brian, That tire tread pad is a really good idea. I even have a segment hanging around. I laid a bunch of pavers and I used it to shield the cement blocks I put in as a perimeter when I hammered on them to adjust their height to uniformity. I think I even know where it is... Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1558 Registered: 6-2009 |

Chris, Do I have any other kind? [Be kind, don't answer.] Brian | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 40 Registered: 3-2016 |

Hi all, The Tee One diagram mentioned above by Brian shows 4 locations where car jacks and sill blocks should be fitted. To locate precisely these points I've used the "drain holes in the sill" mentioned in the article. It looked OK (picture 1).  But with the four wheel lifted off the ground and the car resting solely on the four stands I could hardly open the front-right door ! I then was ready for a disaster. Hopefully when the car was back on her wheels everything went back in order. So my question : on the following picture showing the front-right of the car (A) is what I used and it is an ERROR. Are B or C better locations ? Or any other places (for jack stands) ?  Thanks for your help ! | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2293 Registered: 6-2009 |

JC, I believe going further in on the sill would be better. That being said, I'm not trusting my memory. I have a number of pictures of SRH33576 up on jack stands and have just reinstalled Google Picasa on my computer again so that I can locate them, as I'm not sure where they are. Once I've got some examples I'll post them. I know that I never needed the cut-outs in the sill blocks because the positioning I use does not involve "straddling" the drains. The first set I made had them but none of the subsequent ones have. Brian | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 41 Registered: 3-2016 |

Thank you Brian, "Going further in on the sill" (on B) is what I'm tempted to do, but your pictures - if you can post them - shall help me for sure. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2294 Registered: 6-2009 |

JC,  This is the best I can do quickly. I know I have posted photos to this site, the US RROC forums, and rollsroyceforums.com of SRH33576 both from the side and from the underside when she's been up on jack stands and on the lift. I use the same spot for my sill blocks in either case. From the photo above it looks like I'm a bit forward of where you placed yours. I'll keep looking, but you might want to do site searches on my content as well. Brian | ||

John Beech Grand Master Username: jbeech Post Number: 392 Registered: 10-2016 |

Jean-Christophe, the bottom of my sills look vastly different from yours. Moreover, I see an obvious floor patch, which has not been weld into place but is apparently secured through rivets. I would advise using more substantial boards, perhaps 60cm long to better spread the loads. Also, lift from directly beneath the car at position 'B' instead. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2298 Registered: 6-2009 |

John, That's the rat trap cover, and I can guarantee you there's one on your car, though it may be on the opposite side. It's held on with screws, is aluminum, and is not structural (or at least that's how it is on the two series cars). Also, I agree with you entirely that the 'B' area in the photo is the area of the sill under which I'd be placing the sill block, I would never, ever lift from there if we're talking about using a floor jack. If one is going to lift one side you should place the jack and sill block directly under the center point where the jack that's in your boot/trunk would be inserted in the small door above. Brian | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 42 Registered: 3-2016 |

Thank you John, Brian I'll remove the rat trap cover to see - maybe - more of the structure and I'll follow your advices on spreading the load with a bigger block and also where to place the jack stand. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2303 Registered: 6-2009 |

JC, Although I'd encourage you to take off that cover just for having had the experience of doing so and taking a look at the general state of the rat trap, and particularly whether there's anything other than a collection of dry RR363 on the inside of the cover and perhaps a drop of RR363 hanging from your valves, it's not necessary for getting sill block placement. I'm still looking for those photos of my car up on sill blocks taken from beneath when I was working on the height control valves & having little luck finding them, Brian | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1815 Registered: 6-2006 |

Depending on the job but . .. . Jack it up in the rear under the diff first (The rear valance is very low once the front is up on stands. Make sure that the jack is ONLY on the diff and never on the diff carrier. There are good places on the rear subframe for stands. Where there is a round 'alignment lug' facing downwards. Then jack the front up in the centre bearing pin block. (Two 'eyes' looking at you when you look under the front of the car). Put the stands under the anti-roll bar mounting brackets. I would avoid supporting it on the sils. | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 43 Registered: 3-2016 |

Mates again thank you, The jacking points have always been clear in my mind. I can see clearer now for the stand spots. This picture (location of the body drain holes from the Workshop Manual) may help.  If I got it right, the spots mentioned by Paul are near the spots 7 and 5 and also shown on the pictures below.   |