| Author | Message | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 507 Registered: 10-2008 |

My 1983 Mulsanne has just developed a very heavy engine knock which can be felt on the carburettors, but seems to defy a stethoscope ! The knock varies in loudness and disappears sometimes. It also seems to disappear when revs rise. Oil pressure and temperature is normal andI have just completed a run of 300 miles without problem save for this knock. It seemed to develop last weekend, but the car has been virtually unused for the last 3 weeks due to weeping radiator and the poor weather. The fan is clear of the housing and nothing is rubbing. Also, I removed each plg lead on A bank without any change in the loudness of the knock. Will do B bank Wednesday. Any suggestions welcome. Mark | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 2024 Registered: 6-2006 |

Hi, does it change if you pump the brakes or depressurise the accumulators? | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 508 Registered: 10-2008 |

Hi Paul,I will try depressurising the accumulators on Weds and report back. Thanks Mark | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 509 Registered: 10-2008 |

Tried depressurising accumulators this morning, no change.Ran the engine for an hour 400 ml of ATF in the engine oil. Knock disappeared after 15mins, but recurred after an hour, but not as loud.If the engine is revved whilst knocking,the engine "note" is also slightly different, not quite as smooth ?I am wondering if a valve may be sticking ? If so has anyone tried running an engine with ATF mixed in the fuel ? All suggestions gratefully received ! Mark | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1808 Registered: 9-2004 |

Mark, if possible, can you carry out a variation with the ignition timing ie retard timing with the engine running [with noise] to see if a change in the sound occurs first. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 2025 Registered: 6-2006 |

Is there oil in the dash pots? Try spraying the fan belts with lubricant. It would be unusual for a valve to stick after a short period. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 510 Registered: 10-2008 |

Paul, I have lubricated belts and checked the dashpots, all ok.I will remove a rocker cover at the weekend, as I think the noise is around o/s/f cylinder. Patrick, will try at weekend. Thanks Mark | ||

richard george yeaman Grand Master Username: richyrich Post Number: 945 Registered: 4-2012 |

Mark I would try more ATF or Diesel in the engine oil, and then take it for a short run. Richard. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1809 Registered: 9-2004 |

Could be a hydraulic tappet, heavy knock though, not so sure! What miles has the engine oil done and what type. | ||

Neville Davies Frequent User Username: nev_davies Post Number: 78 Registered: 9-2006 |

Mark A loud heavy knock is also a symptom of a cracked drive plate or faulty Torque convertor.Not that common but does happen Nev | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 511 Registered: 10-2008 |

Patrick, 95k miles, 15/50 mineral oil ( Fuchs Titan 15/50). Nev, seems difficult to pin point the source of noise. Using a long screwdriver suggests front of engine., but it seems to transmit. Will continue investigating at weekend. Mark | ||

Omar M. Shams Grand Master Username: omar Post Number: 1437 Registered: 4-2009 |

Dear Mark I know exactly what you mean because my 91 Turbo R is the same. I have not driven the car since this happened 3 years ago because I just started to use a different car. However the symptoms sound identical. I have not solved my problem yet but I associate my problem with either a collapsed tappet or a broken push rod for one of the two pumps. The sound will transmit woefully making your stethoscope test non-conclusive. You will hear it everywhere. I have resigned to removing the tappet chest as I feel my problem lies in the V. Thnaks Omar | ||

Vladimir Ivanovich Kirillov Grand Master Username: soviet Post Number: 834 Registered: 2-2013 |

Mark is it right to assume this car always ran appropriate coolant and that it cannot be the case of the liners grabbing the pistons? Also, perhaps you should record the knocking on a device and then using the tachometer calculate backwards to attempt to identify the foul culprit.ie so many beats per minute for crank as opposed to hydraulic tappet. Thinning the oil with ATF appears to be holding up a clue. Does sound like a hydraulic tappet sticking but that's a wild guess. I would try the ATF trick again to rule out coincidence. Most surprised you cannot locate the source with a stethoscope. | ||

Vladimir Ivanovich Kirillov Grand Master Username: soviet Post Number: 835 Registered: 2-2013 |

Omar there is no such word as Thanks. Report to Sir as he is jolly baity and mail your 91 Turbo R to me directly as penalty. | ||

Dick Campbell Experienced User Username: dick_campbell Post Number: 14 Registered: 5-2015 |

Hi Mark, Long time no see. I had a horrible noise once...it was a loose water pump pulley. Also on a Shadow a broken rear hydraulic pump push rod. Must get another RR or B....miss this banter. Regards, Dick. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 512 Registered: 10-2008 |

Hi Dick, what have you in your collection that you could swap for another RR or B, would cure the withdrawal symptoms from endless repairs ! Mark | ||

Maxwell Heazlewood Prolific User Username: tasbent Post Number: 158 Registered: 9-2017 |

>>>>.Patrick, 95k miles, 15/50 mineral oil ( Fuchs Titan 15/50). Nev, seems difficult to pin point the source of noise. Using a long screwdriver suggests front of engine., but it seems to transmit. Will continue investigating at weekend.>>>>>> Mark, 15W50 seems an excessively heavy oil for this engine, what sort of mechanical condition is it in? It would exacerbate any noises when cold starting especially in your environment. I would say you have an hydraulic lifter that's not pumping up. Does the rhythm of the knock stay pace with engine revs? Tracking a noise in an alloy engine can be time consuming compared to a cast iron block. | ||

Vladimir Ivanovich Kirillov Grand Master Username: soviet Post Number: 836 Registered: 2-2013 |

Omar I cannot stand the spelling auto correct. As Sir knows I was referring to your typo of thanks in your last post. Now Sir is really jolly baity. | ||

Omar M. Shams Grand Master Username: omar Post Number: 1438 Registered: 4-2009 |

Dear Vlad, That spell check got you in style. I almost always type thnaks instead of Thanks. And that indeed gets Sir to be Jolly Baity...... Now back to our friend Mark's problem. My next step was to remove the two hydraulic pumps to see if the push rods were the problem. If so, put that right. If not then carry on digging until you get to the lifters and then look at those one at a time. Thanks to all and thnaks to Vlad. Omar | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 2028 Registered: 6-2006 |

As Omar suggests plus the hydraulic pump spring. They can snap and move around giving odd noises. . . But usually findable with the dip stick listening method. | ||

David Gore Moderator Username: david_gore Post Number: 2848 Registered: 4-2003 |

Vladimir, Don't blame spell check as your friendly pedantic moderator corrected Omar's typo. I was strongly influenced during my school days to use correct spelling and grammar [remember "spare the rod and spoil the child" when teachers could use corporal punishment on wayward pupils to enforce correct English usage]. Be aware, very aware of my retribution if and when the American spelling practice of using a "z" instead of the grammatically correct "s" rears its ugly head in print. Sir speaks softly but carries a VERY big stick..........  . . P.S. I have seen the Dudley Cook/Dudley Moore video - this does not apply to me whatsoever. | ||

Omar M. Shams Grand Master Username: omar Post Number: 1439 Registered: 4-2009 |

I think it should be obligatory for all people to watch Derek and Clive humour..... I was told that it doesnt suite everyone's taste in humour... how odd. And David - thanks for the corrections - they are most appreciated. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 513 Registered: 10-2008 |

Hi all, the noise was a loose crankshaft pulley ! worrying is how has this worked loose and it appears to have damaged the keyways, as we cannot get the flange off of the crank even though it will rock slightly and move back and forth slightly. .It will retighten, but obviously there is a reason it has come loose. We will decide how to proceed tomorrow depending on the weather. however it is looking like a retighten with 638 locktight. Mark | ||

richard george yeaman Grand Master Username: richyrich Post Number: 946 Registered: 4-2012 |

Hi Mark eventually it would have made an awful mess of your radiator, I hope your repair works out, Richard, | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1810 Registered: 9-2004 |

Mark good you found the noise, a puller will be needed if you decide to remove the flange. The Woodruff key when worn tip and catch up in the key way of the flange. Hopefully the Woodruff key has not worn the crank. | ||

richard george yeaman Grand Master Username: richyrich Post Number: 947 Registered: 4-2012 |

Mark pity you cant remove the driving flange and fit a new oversized key. Richard | ||

Vladimir Ivanovich Kirillov Grand Master Username: soviet Post Number: 838 Registered: 2-2013 |

Ekkkk! This is precisely what happens to V12 Jaguars and the solution is to replace the crank, errk and errrk again. Once you have the pulley off you need to inspect the crank meticulously. If the crank is damaged you could try repairing it with mig weld. The problem with that is mig weld are nastily hard and total mongrels to grind back to spec. Put simply even your mother in law will cast pity. Honest car dealers would fix it with Devcon, claim the engine has been reconditioned, change their name to Smith and flee to Cambodia with proceeds of sale. When I rebuild the Camargue's engine the crankshaft bolts will drown in loctite. Errk now a story about my rebuilding a Noyce engine engine in an International Truck. Noyce is not correct spelling but is phonetically correct. The truck was owned by my shrink who correctly assumed that I had had enough of representing Australia's criminally insane. I was sent to his farm where he made me live in his large stone mansion and asked to repair his truck used to cart the worlds best sandstone. Yes, no sooner had I fired the engine up that I observed the crankshaft pulley wobbling like a politican's promise. I turned the engine off. Just then in walks then farm manager who said " you would not bloody believe it but my son rebuilt one of those engines and a minute after he started it the bloody thing threw the crankshaft pulley right through a bloody brand new radiator! I later realised that on that type of engine once the crankshaft pulley is removed you simply cannot put it back on the crank. You have to spend an hour pulling apart all the shims and whatnot, clean them, grease them and you slide the bastard on. Its ugly but true that engine is a Dutch tractor engine and I think the fellow that engineered it was as dumb as five chickens and if he ever ventures into my pub I will beat him to death with a large fish. There is zero room for error when it comes to crankshaft pulleys - on a race track in the 1960's one exploded on a 1964 Holden EH, ripped through the bonnet/hood and removed half the head off a spectator! | ||

Rowland Palmer Experienced User Username: rowland Post Number: 22 Registered: 12-2016 |

If I were you Mark I would pull the pulley off and check the crank for damage. Do not just retighten it as there is a reason it came loose. I brought a puller from the British Tool Co, as well as the castled nut remover. Good Luck | ||

gordon le feuvre Prolific User Username: triumph Post Number: 235 Registered: 7-2012 |

Mark,In '70's we had issues with oil pump skew nut not being tightened correctly on production. What I can't remember is crank pulley boss on crank a parallel fit or taper? Would it affect the crank pulley boss nut tightness if the one behind (oil pump skew gear nut) was not tight enough, is there an inter-dependence? Just another thing to ponder! | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1811 Registered: 9-2004 |

Early 70's cranks parallel, later cranks taper. No interdependence between cam gear, oil pump and the drive flange. Seem to remember issues with a VW that had a taper pulley assembly that had no Woodruff key by design, the drive for OHC camshaft etc was attached so setting the crank timing was critical. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 514 Registered: 10-2008 |

Tightened pulley, and Loctite 638 the pulley nut . Will now use the car and see if the problem re occurs. Also changed a Merc 190E water pump today, outside, in the snow. Mark | ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 196 Registered: 7-2004 |

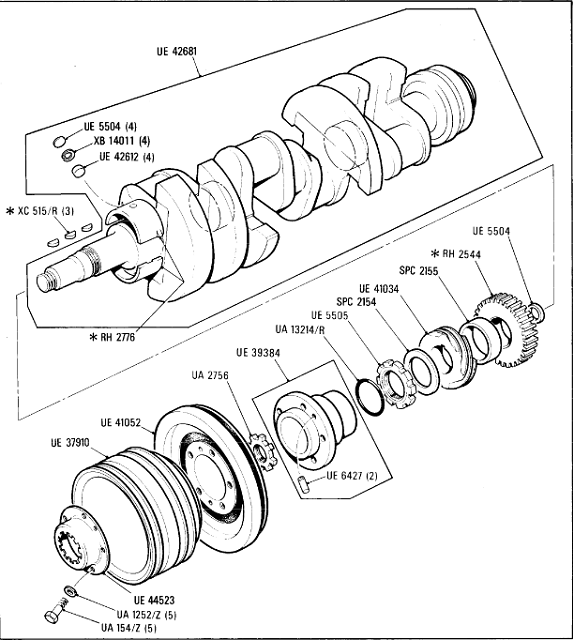

Mark, how did UA2756 come loose? Is UE44523 missing? Its purpose is to keep the slotted nut from coming loose.  http://britishtoolworks.com | ||

Dick Campbell Experienced User Username: dick_campbell Post Number: 15 Registered: 5-2015 |

Hi Mark, Pleased that you have found the problem. Surprising the noise that loose pullies make. I wonder what caused it to come loose though. I am down to the TR3a and just finishing off the Talbot 105. I had disciplined myself not to acquire anything else until the Talbot is on the road...I could write a book and make the film on this project! I might have a flirt with a 'Volkswagon' Continental GT but a DB9 and a 407 Bristol have some appeal as well. Perhaps we should go for another meet up this year and catch up. Regards, Dick. | ||

richard george yeaman Grand Master Username: richyrich Post Number: 948 Registered: 4-2012 |

I like others would be more interested in what caused it to come loose rather than how it was repaired. Richard. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1813 Registered: 9-2004 |

All IMO, with a loose taper flange of this type. The woodruff key is only for location and to hold onto the drive, it is the taper that fixes the flange hub to the shaft under torque of the nut. Once set all should be ok in a perfect world. However over time the different expansion contraction of the crank and flange with variable heat is just the first of the prob. Next is the dynamic run out with the damper also the stress on flange by the pulley caused over time by different belt drive tension and balance. Mark, great job should be Ok with loctite on nut but better with some in the flange taper as well. Roll back the years to cars with axles with half shafts with tapers and keyways. Quite a common failing on some cars was the one piece brake drum to come loose on the taper. IMO, cause drum heat, power torque with side stress, over torquing of nut. The N/S was the common side to let go, most had LH nuts fitted to stop the nut coming completely off. Once the tapers had wear the long term reliability was in doubt. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 515 Registered: 10-2008 |

I have spoken to a specialist this morning, and I understand that it is not uncommon for these pulleys to come loose, particularly on Shadow2 and pre 20000 series SZcars.Also broken crank nose is not rare! Reason is unknown!Perhaps slackening off the belts and checking this should be a service item Mark | ||

Omar M. Shams Grand Master Username: omar Post Number: 1440 Registered: 4-2009 |

Dear Mark, How obvious was the loose pulley? was it a no brainer or did you have to take all the belts off to see it? Thanks Omar | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 516 Registered: 10-2008 |

Omar, other than the noise,I could not see the pulley running out of true.The looseness was only apparent with all of the belts removed. Once the pulley had been removed, the nut appeared to have wound itself off with about 30 thou clearance between the nut and the flange (UE393894) above. I have since spoken to another specialist who has had customers with this problem. Kelly, the wobbling pulley destroys the tangs on UE44523, but how does the nut come loose originally ? I don't think the nut has been removed in the past, but as I have only owned the car for 3 years I do not know, although I have all invoices for the last 21 years. Mark | ||

Omar M. Shams Grand Master Username: omar Post Number: 1441 Registered: 4-2009 |

Dear Mark, Thanks for this. Most fascinating!!! Something does not add up in my head. How did this happen in the first place? the set up is more than belts and braces and the likelihood of the pulley working loose is zilch (in my opinion). And is this a common fault??? first I have heard of it. Next come your amazing detective work. What made you take all the belts off and then check the pulley? i know that this is what i now need to do on my car so thanks for saving me a lot of lost time. I would have focused on the top of the car and you got it first time by looking at the bottom. Well done man!! | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1814 Registered: 9-2004 |

IMO. One cause of the crank nose breakage after say the harmonic damper replacement etc etc is the over torquing of the slotted flange nut. No more than 145 lbf.ft in two stages. Have heard of the use of a air impact wrench being used and no flywheel lock bad news! Many things at play when this has been carried out. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 517 Registered: 10-2008 |

Omar, we took the belts off to try and eliminate possible ancillary noises. Did not occur that the bottom pulley would be loose. We thought it was a waterpump problem initially. Started up without the belts, and oh what a clatter ! Mark | ||

Omar M. Shams Grand Master Username: omar Post Number: 1443 Registered: 4-2009 |

mate - that was such a stroke of good luck. Well done for following that train of thought. It certainly paid off. Thanks for this very interesting thread. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 756 Registered: 4-2015 |

I would submit that the question has not been addressed of how/why the nut 2756 came loose in the first place especially considering that the design is specifically intended for 44523 to prevent that. Also, while it may be true that a wobbling pulley will destroy the tangs of 44523, the pulley cannot wobble without slack in the system and properly installed, the bolts 154/Z firmly connect everything between 44523 and the flange at 39384 which is in turn fastened by the nut 2756 and locked by 44523. Therefore properly assembled, the design prevents any looseness. Given that eventual looseness is frequently the result of improper assembly rather than defective design, I would submit that somewhere along the line things were not put together properly and with that .030 clearance built in. Thus it did not "get loose", it was "assembled loose". Further if there are indeed multiple reports of such looseness and damages, that in itself supports the premise that after market (not factory trained) hands have difficulty properly assembling the components and those "known" problems are not design related, but rather assembly related. . |