| Author | Message | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 632 Registered: 04-2019 |

Well I have been told to start a new thread because the other is too long.  433 post | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 635 Registered: 04-2019 |

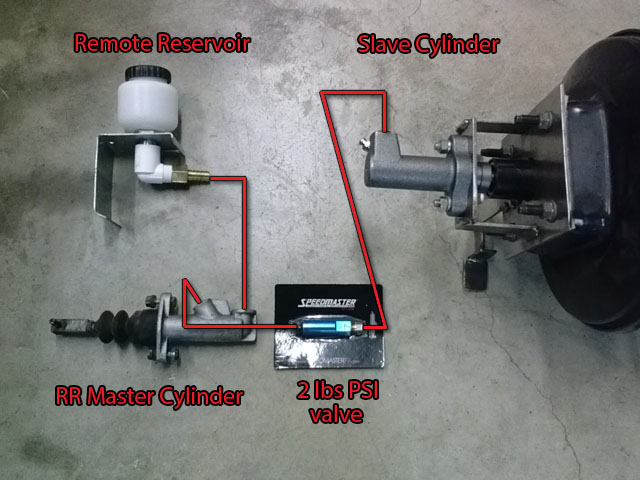

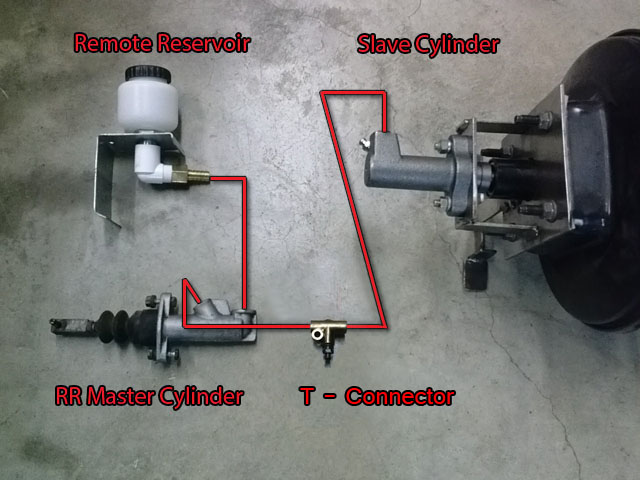

In the previous episode of As The Rolls Turns, with all your help we have gotten to this point, and thanks to everyone for your help! It was Patrick Lockyer's contention that the "2lb psi holding the slave is another IMO no go" In other words the 2 lb psi on the slave cylinder would hold the brakes, not producing the result wanted, which is to only stop backflow. To which I replied: That well may be, I have been told to use one not sure why in this application. Only that if it is under the calipers it will have backflow.  I now believe that Patrick's contention is correct that the 2 lbs psi is not needed because of the gravity fed remote fill reservoir. What do you think? . | ||

David Gore Moderator Username: david_gore Post Number: 3348 Registered: 04-2003 |

Mike, The only problem I can see is the possibility of airlocks in the line from the master cylinder to the PSI valve and the line between the PSI valve and the slave cylinder if the actual pipework configuration side view after installation is as shown. If this is the actual routing, you may have to consider pressurised bleeding after filling the system with brake fluid and thereafter whenever the lines are disconnected and reconnected for servicing purposes. I think you can safely deleted the PSI valve as you have positive pressure in the system from the remote reservoir. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 642 Registered: 04-2019 |

David I get what you are saying. The bleed screw is on the valve above the RR master cylinder not on the master cylinder itself. I'm going to leave it off then see if I need to shorten the spring in the slave cylinder so it does not hold the brakes on under vacuum. Nice thought. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 643 Registered: 04-2019 |

The old girl is airborne, time to start ripping the lines out.  | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 456 Registered: 05-2016 |

I don't think that I would be brave enough to crawl under there unless the blocks were substantially wider and longer, it just takes one other enquiring person to come along and lean on the car and the whole lot could topple. Be safe Mike. | ||

Hubert Kelly Prolific User Username: h_kelly Post Number: 340 Registered: 03-2012 |

Mike I'm with Larry on this, mind yourself. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 646 Registered: 04-2019 |

You may remember the movie called "Cast Away" with Tom Hanks as a FedX employee who ended up alone on an island with his handmade volleyball friend, Wilson. Well, I would not even need the volleyball. The only problem with that is the only way anyone would know I died is when people start smelling me. Like a guy in front. The landlord comes time to time to see if I am still alive, I guess I worry him. Long story short there will be no leaning. But thanks. (Now if I had satellite internet and they would deliver online goods by dropping from a plane, I'd be set. Electric solar vehicle, download movies, a fishing pole, I'd be good with that.)  | ||

ross kowalski Grand Master Username: cdfpw Post Number: 1148 Registered: 11-2015 |

Mike, Getting crushed to death is probably slightly better then getting crushed half to death with the other half coming a day or two later. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 651 Registered: 04-2019 |

See this is my master plan to convert you all over to the dark side of working on cars. To do it by any means necessary, including loss of life (your own). Come over to the dark side Luke. Don't underestimate the Force. May the car force be with you.  | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 656 Registered: 04-2019 |

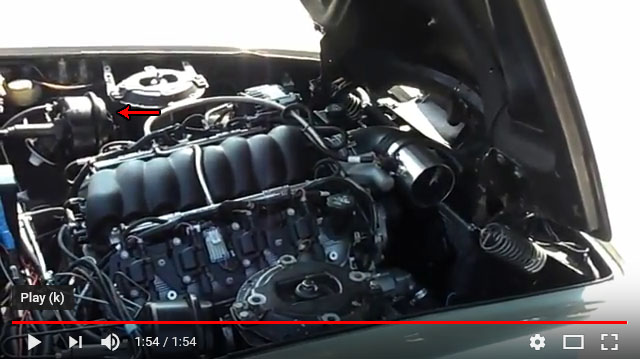

Most of you will probably never have to remove the accumulators + valves (hooked together) but it is a real fun job. Removing the accumulators is not that hard, but then getting them out is another thing. Especially if you have California emission control (CEC). You would have to take off the exhaust. Me I was not going to put back the CEC so I just bent that mysterious pipe I asked about (on the right hand side), out of the way with a big pipe wrench. My car had an accumulator on each side of the engine so on the left hand side you do have to remove part (not all) of the exhaust (a short piece with two donut rings). The accumulators are a lot heavier than I thought, and you would need to discharge the pressure. (Mine had none.)  And this is what you will look like if you lay under the car to get them out.  | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 663 Registered: 04-2019 |

I have two questions (or three) if someone would kindly answer. Is there any reason that I could not use a rubber freeze plug for the hole that will be there after I take out the brake pumps, and do you know the screw size and pitch (to maybe get an oil drain plug)? And does the push rod from the cam to the brake pump just come out? (I pulled on it somewhat and it seemed it won't come out.) Thanks a lot.  | ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 237 Registered: 07-2004 |

Michael, that rubber freeze plug should work just fine. The brake pump threads are 1 1/8"-16. The pushrod will pull right out but there is a cam follower at the bottom that must come out too. If it isn't pulled out with a magnet, the cam will pop out of it's bore and it will exit the window. This is what's bolted to the bottom of the valley cover.   BritishToolWorks.com | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 664 Registered: 04-2019 |

Thanks Kelly, So are you saying that the push rod and the cylinder below it, in the bottom picture, must come out, or the cylinder will fall out into the engine? And use a small magnet (like for small parts) to pull it out? | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2113 Registered: 05-2012 |

Mike Check out this video: https://www.youtube.com/watch?v=-Y_7a4tUh_U It will tell you how to remove the push rod and follower. The relevant part is 5 mins in. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 688 Registered: 04-2019 |

I have most of the original brake plumbing out, (that I could get to). And I needed to climb into the trunk of the car. It went down quite a bit like the shocks were bad. Question: does the height adjusters provide some of the dampening of bounce to the rear end? If so, could I fill up the hydraulic lines with fluid and plug them to provide dampening? | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 458 Registered: 11-2017 |

The shocks control the spring energy of bouncing. The rams in the rear only compensate for loads in the trunk and rear seat. | ||

gordon le feuvre Frequent User Username: triumph Post Number: 305 Registered: 07-2012 |

As Robert says the rams have NO effect on damping the work the springs do, the dampers take care of that. If the tank is only half full and only driver in car if all set up correctly the rams would not have raised at all. if car fully loaded and rams extended to level body once this condition achieved the rams are effectively shut off trapping hydraulic fluid, so is not involved in damping springs. Of course over a period there is some system bleed through solenoid valve, to compensate for fuel tank emptying. Clever or what! | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 344 Registered: 03-2012 |

https://www.rrsilvershadow.com/ETechn/Hydr/Comprams.htm Mike you could always do your own diy height control with the rams, once the seals are in good condition. You could either fill ram with brake fluid and block same or develop a 12 volt system in boot to raise, lower same?. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 690 Registered: 04-2019 |

Thanks all for the info. To run a vacuum hose under and through moving parts and up to the top of the engine was an all day job. I thought it was going to be easy. I needed to put a hole in the trunk (boot) as well.   I think the shocks are bad (as Bette Davis said “Fasten your seatbelts, it's going to be a bumpy night.”) https://www.youtube.com/watch?v=3vEEh0GF_C8 . | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 691 Registered: 04-2019 |

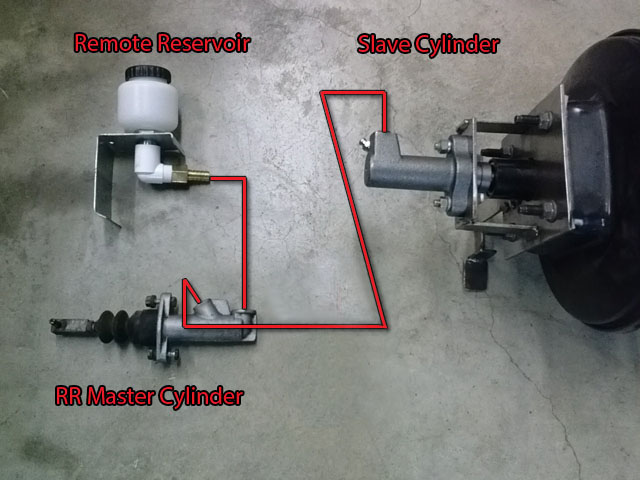

Bubble flare as opposed to double flare for brake lines. All the flares I have made are double flares. It seems they are less likely to leak than the DIN/ISO SAE bubble flare. As one tightens a double it just gets tighter and less likely to leak. It seems with the bubble flare the more you tighten it the more likely it will leak due to deformation. There are lots of videos on how to make a bubble flare with a double flare tool kit. Just turn it over on the flat side. Has anyone tried this? . | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 706 Registered: 04-2019 |

I found out the hard way that on the clutch slave cylinder the line fitting size is different than any brake fitting I have (maybe for a reason of not confusing the two). So I had to go buy one. For the clutch slave cylinder (for Jeeps) which is a Power Torque CS2235 the fitting is a 3/16 X 1/4 Edelmann 121034. (Shown to the right.)  | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 710 Registered: 04-2019 |

Different bubble flares.  | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 460 Registered: 11-2017 |

Just use flareless fittings especially if using a cheap flaring tool. https://www.discounthydraulichose.com/flareless-compression-tub | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 711 Registered: 04-2019 |

So that David does not have to do this: The Top Three Reasons to Avoid Brake Line Compression Fittings Compression fittings can leak at high temperatures Compression fittings do not provide a solid structural connection Compression fittings are against the law in many states http://www.brakeconnect.com/top-3-reasons-not-to-use-brake-line-compression-fittings | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 461 Registered: 11-2017 |

I figured you would go this route...it's cheap and easy and defies common sense. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 712 Registered: 04-2019 |

The surprises never end with this car. It turns out that the RR original master cylinder has two different sizes of fittings for the inlet and outlet. The inlet, shown below, is not only bigger but looks like it uses a double flare, where as all other fitting (it seems) are bubble flares. Also the line size is the same as on the accumulators and pumps. It seems they just made this up as they went along.  | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1163 Registered: 11-2015 |

Mike, Bubble flares work fine, they tighten up when you tighten them and then never leak just like a double flare. Of course both are easier to do in CuNiFer. Flareless hydraulic fittings are fine to use for high pressure hydraulic applications. They are not subject to temperature or structural failure but are illegal in many places because people install them incorrectly to patch a rusty brake line because they are lazy or do it incorrectly and it fails. The alternative is to flare the ends of the pipes and use a flare union. As for the two fittings being different on the RR MC, who knows. The problem is common as was the case on all american cars from 1975 ish to present with regard to SAE and metric fasteners. It's no big deal you just flare up whatever you need, job done. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 723 Registered: 04-2019 |

I had the good fortune that I could not get out the inlet line to the Master cylinder, so I will try to just use that original line and not have to make one (and find a fitting for it). I am really poking along on this brake system because I hate being under the car, having all that crud on me and black stuff sneaking it's way into my eyes. And it is 100 degrees already in my garage everyday now. And Texas is like Siberia the mosquitoes will suck all the blood out of you if you open the doors. I soon will have no choice. 120+ degrees is not fun. | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 347 Registered: 03-2012 |

Swimming goggles I have found invaluable to keep dirt out of eyes (clear set) while carrying out work under the Rolls. | ||

Vladimir Ivanovich Kirillov Prolific User Username: soviet Post Number: 1504 Registered: 02-2013 |

Mike you do realise that Speedo was an Australian brand don't you ? That aside please refrain from defaming Siberian mosquitos. They are bigger than Texas mosquitos and they come for you in packs of billions such that large animals die not from the bites but from suffocation. "I could not get out the inlet line to the master cylinder..." If you post up a pic I will post up certain techniques for its removal that may be of use to you to remove it. Perhaps some Australian Bushman's spray on with DEET at 40 percent may help you or may make you sick. As for the heat wetting your hair and tee shirt and having a normal fan or fans aimed at under the car may make you more comfortable. | ||

Omar M. Shams Prolific User Username: omar Post Number: 1847 Registered: 04-2009 |

Dear Vlad, Your reference to DEET reminded me of a review I once read about a product called VEET. Here it is if you wish to roll around the floor with laughter.......http://rats-funnybone.com/veet-hair-removal-gel-for-men-funniest-review-ever/ | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 727 Registered: 04-2019 |

Omar, That was funny. I think I will stick to the garage door being closed as long as I can take it. I value my strawberry ice cream too much.  Shooting carrots at the miss seems more of a Russian roulette type of game. Maybe blue squids at the mates, see if they will stick. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 728 Registered: 04-2019 |

Vlad, The problem is not the taking of the inlet line out, it was getting it back in. When I took it out a few months back I pushed it up and twisted it out of the way. To get it back in was very hard because it has to be just right or the threads don't match. Remote to RR master cylinder  Lines back in the RR master cylinder. Tee connection for bleeding the MC.  Back brakes connector in place.  Don't forget to read Omar's post above, it's a killer. . | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 743 Registered: 04-2019 |

For my front brakes all I need is a 4 tee connector and a 3 tee connector. I will run 2 lines from the 4 tee to the left front tire, then use one line to another 3 tee connector and 2 lines to the right front tire. And of course 1 line from the master cylinder to the 4 tee connector for fluid to all brakes.  | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 744 Registered: 04-2019 |

Any suggestions of what I can use to fill the hole in the trunk (boot) where the brake lines and vacuum hose go through and will prevent chaffing? | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 348 Registered: 03-2012 |

How about covering brake pipe with a rubber pipe, at the point it enters/exits boot. With the brake pipe well anchored ie a clip, friction should be to a minimum if any at all?. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 748 Registered: 04-2019 |

The problem is the vacuum hose takes up about all the room in the enter/exit hole, and the lines are anchored. I was thinking some kind of spray rubber, maybe for houses or something, or thin electrical plastic cover. Something like that. | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 349 Registered: 03-2012 |

https://www.google.ie/search?client=ms-android-alcatel&espv=1&biw=320&bih=407&tbm=isch&sa=1&q=rubber+pipe+over+copper+brake+pipe&oq=&aqs=#imgrc=GwwFbF_Nk2nTxM%3A How about a rubber pip like same in photo | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 350 Registered: 03-2012 |

Diesel injector return rubber pipe may fit the bill?. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 749 Registered: 04-2019 |

I'm thinking maybe just some black silicone to fill the hole and keep everything together and keep the metal lines from the body trunk (boot) floor metal, simple, easy. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 750 Registered: 04-2019 |

It seems part of the fuel tank is the floor of the boot, is that true? I need to anchor the brake device to the floor, but it looks like I can't. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 754 Registered: 04-2019 |

I am used to American cars when doing a brake system. They all have double flares for the ends, period (all I have worked on). But Rolls Royce likes to be different I guess. They even have two different flares on the same line. So I was not thinking and used a bubble flare (which is the first flare of a double flare) on the nut fittings (seen on right) on one side of the front. They were so hard to put on taking them off is just not something I want to do (not having anything to do with the flare). Has anyone tried to use a bubble flare on a nut fitting, and did it leak (I'm thinking it will).  | ||

Jim Walters Frequent User Username: jim_walters Post Number: 256 Registered: 01-2014 |

It depends entirely on what it attaches to. Match the flare to what it fits onto or into. Double flare to hose end, bubble usually into a caliper or cylinder. It's not Rolls-Royce that determined the type of flare, it was Girling. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

David Gore Moderator Username: david_gore Post Number: 3388 Registered: 04-2003 |

Mike, When I did a complete overhaul of the hydraulic system on 1973 Corniche DRH14434 in the early 1990's, all the original pipe fittings were double flared and as every pipe under the car was heavily corroded, I had to make new bundy steel pipes [at the time, I was not aware of Cunifer 90/10 Copper Nickel alloy much to my later regret - I would not use any other material now for hydraulic system pipes]. https://www.copper.org/applications/automotive/brake-tube/brake.html You mention finding single flared hydraulic pipes and, to the best of my knowledge, this is not consistent with my experience of original RRMC systems and given the condition of your car. I strongly suspect these have been associated with later repairs/maintenance by cut-price mechanics or a DIY owner ignorant of the R-R hydraulic system. Double flares or nothing should be your practice for all hydraulic connections IMHO. . | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 351 Registered: 03-2012 |

Mike its a double flare for the nut to flexible tube at front wheel hub. Use a little WD 40 on the flexi hose bolt end and thread same in and out till it becomes easy to thread.yes they will need to be tightened,best doing this when system is fully operational?. | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 352 Registered: 03-2012 |

Mike the above applies assuming you have a standard rolls flexible pipe on car and not some other form of pipe which indeed may require other flare | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 468 Registered: 11-2017 |

Over tightening will destroy the flair and it will never seal properly. Torque values are one of the most important things to learn when working on any car especially a RR. Torque figures are in Chapter P of TSD4200 FYI All 3/16 Bundy lines with a male end are set at 5-7 lbs and female ends are 8-10lbs Wheel nuts are 45-50 ft lbs. Flares done with cheap tools often result in poor sealing and causing over tightening to making it seal often leading to leakage, deformed flare and in some cases stripped internal threads. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 756 Registered: 04-2019 |

Thus answering my question that it seems bubble flares will leak as opposed to double flares. While giving false and inexperienced information that may have resulted in an accident or death to me or others. No one should trust your specious information. You said: Robert J. Sprauer Posted on Thursday, 11 July, 2019 - 14:02: "Just use flareless fittings especially if using a cheap flaring tool. https://www.discounthydraulichose.com/flareless-compression-tub" When confronted with the fact that flareless fittings are illegal: Mike Thompson Posted on Friday, 12 July, 2019 - 00:20: You covered up your malice attempt with: Robert J. Sprauer Posted on Friday, 12 July, 2019 - 01:25: "I figured you would go this route...it's cheap and easy and defies common sense." No one should trust you. | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 470 Registered: 11-2017 |

Mike Chill out. Compression fitting are used in hydraulic applications. You could use them in return lines that have no pressure. Inexperienced info? Really. Look who is coming here for answers when while trying to do a Rube Goldberg brake job. Quite obvious. and good luck..You could use it | ||

David Gore Moderator Username: david_gore Post Number: 3389 Registered: 04-2003 |

Robert and Mike, Please agree to disagree on this subject and move on, you both have strong opinions and have expressed them accordingly. Time will tell whether one or both of you were correct. In the meantime, we can form our own opinions and take responsibility for our decisions. | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 471 Registered: 11-2017 |

Comment deleted by Moderator as it contained an unacceptable description of another forum member. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 759 Registered: 04-2019 |

Robert you are giving illegal advice to use compression fittings. Robert J. Sprauer Posted on Thursday, 11 July, 2019 - 14:02: "Just use flareless fittings especially if using a cheap flaring tool. https://www.discounthydraulichose.com/flareless-compression-tub" When confronted with the fact that flareless fittings are illegal: Mike Thompson Posted on Friday, 12 July, 2019 - 00:20: http://www.brakeconnect.com/top-3-reasons-not-to-use-brake-line-compression-fittings You covered up your inappropriate advice with an offensive personal reference: Since deleted by Moderator for non-compliance with Forum standards I am tired of being abused by this member. Constantly deriding me. He can disagree with out the personal attacks. That usually are based on he has more money than me or thinks the right way to do it, which will involve much more money than the car is worth, is the right way. This time he used advice to illegal components. This I feel this warrants: The Owners and Administrators of RR Forums reserve the right to suspend membership to any of the RR Forums at any time without notice. Patrick Lockyer adamantly disagrees with me but has never given a personal comment about my wealth, status or any other personal comment. If Robert J. Sprauer can keep getting away with these violation of the rules, then the rules have no meaning. Moderation intervention and editing has now been applied as a consequence of failure to comply with a specific request for compliance with Forum standards See Internet troll: In Internet slang, a troll is a person who starts quarrels or upsets people on the Internet to distract and sow discord by posting inflammatory and digressive,[1] extraneous, or off-topic messages in an online community (such as a newsgroup, forum, chat room, or blog) with the intent of provoking readers into displaying emotional responses[2] and normalizing tangential discussion,[3] whether for the troll's amusement or a specific gain. https://en.wikipedia.org/wiki/Internet_troll Robert, in my opinion, you are behaving like a Troll. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1174 Registered: 11-2015 |

David, Sage words indeed. Agreeing to disagree is of key importance. My best friend is on the diametric opposite end of the political spectrum. I am demonstrably right when looking at our positions through a historical lens, but I am not going to argue his position away just as he is not going to argue mine away. There's lots of good and varied ideas on this forum which is why I chose this one. To take advantage of it we need to be civil. Posts lacking civility put David in a difficult position as a moderator. Maintaining a civil discourse is our thank you to him. Also, thanks David. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2125 Registered: 05-2012 |

Agreed that we all should refrain from personal abuse. Interesting discussion though. I have done a quick duckduckgo search and the answers as to whether compression fittings are illegal was mixed. We need "document peruser extraordinaire" Brian, to give the definitive answer. A while ago I had to replace a brake line on a Ford Explorer. I found that Autozone do sell brake line compression fittings. I decided against using one however, as I was using cunifer and thought the softer metal would not work well with a compression fitting, so opted to buy a brake flaring tool. It occurs to me that compression fittings may be ok on steel lines but not on the softer cunifer lines. Just a thought. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 762 Registered: 04-2019 |

Moving on, but I love when the Republicans say it is the party of Abraham Lincoln. Republicans at that time was the liberal party, (think freed slaves) so are Republicans trying to say they are Liberals? Don't think so. I believe it was not until Strom Thurmond that the parties switched to their current state. (I think there might have been a few flip flops in between.) A Quote: "Running for President as a Dixiecrat in 1948, Strom Thurmond declared that "all the laws of Washington and all the bayonets of the Army cannot force the Negro into our homes, our schools, our churches and our places of recreation." By 1964, with civil rights marching onward, it was clear that his fellow Democrats disagreed. Thurmond jumped ship, joining the Republican Party that year. The first major Southern pol to cross the aisle during the civil rights era, the South Carolina Senator marked the beginning of the GOP's appeal to white, Southern conservatives, and helped turn a former blue state red." http://content.time.com/time/specials/packages/article/0,28804,1894529_1894528_1894521,00.html Now for the post. Some think that it would have been easier to have just somehow fixed the original brake system. It is probably due to they have never brought a junk car back to the road. A car that was running and driving just a short time ago, for example, is not the same as a pure junk car. Nothing works as brakes, all the interior needs to be replaced etc. I knew that with the brakes if it has no fluid it will need all the parts replaced or rebuilt. In the case of a Rolls Royce, that means thousands of dollars that I don't have for this project. Every line would need to be replaced, not sure that can be done without taking the subframes off. So I chose to go the easiest cheapest way. The drawing I made for this system looks like a stick drawing of a person, as compared to the metro rail of New York City for the original system. Below is a pot I took out and the original uncleaned condition. Think of what is in each part of that system. I tried to use air to shoot them out. the only thing that shot out was a little rusty goo. So I'm absolutely convinced I made the right choice for this junk car and my budget. By the way I have no party, I don't like either one of them.  | ||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 475 Registered: 05-2016 |

Going back to bubble vs double flares the above photo of the pipe (posted 20/7 at 11.56) with a male and female fitting on opposite ends would appear to have a metric thread on the male flare nut but I could be wrong. I think metric flare nuts usually have a nick cut in the flats (as is the case above) to distinguish them from other thread patterns but maybe I'm mistaken. I'm not aware of any metric brake connections on the Silver Shadow except perhaps on some front callipers. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 765 Registered: 04-2019 |

The piston shown above is from a front caliper. I thought I had finished them all but one was left. They are relatively easy to do even though they are completely stuck. Using a vice grip and a hammer. That is because you can get to them and the front pistons have a lip. Now I am doing the back calipers and they are completely different. You cannot get to the pistons, and they have no lip. I have watched a lot of videos, where they use the car or motorcycle brake system to build up pressure to pop the usually single piston out. That won't work on the back calipers, because they have 4 pistons. The stuck one is the one you want to come out. So one guy used a "C" clamp on the easy to move piston and the stuck one came out. One guy drilled a hole in the end of the piston and used a screw driver to work it back and forth until it came out, but he had no plan to reuse the piston. And one guy put a bolt into the inlet line of the caliper, and used the bleeder screw to pump grease into the caliper. That worked but what a mess, and as the video I think you should watch, he points out grease in a brake system probably is not a good idea. The last video I watched has a cool idea that I think maybe you should see. Take a look: How to Unstick Frozen Brake Caliper Pistons https://www.youtube.com/watch?v=qc4zlGaJgoA Unfortunately I don't have this equipment so one caliper piston, I have yet to figure out how to get out. Oh and bubble flare nuts, it seems all of the nuts have the nick cut into the flats (on mine, remember my SS is a Tweener, not sure that makes any difference, but it sure did on the electrics). Edit: After posting this I found another DIY video I was thinking of using this idea before I seen it actually done. (Copy and paste the link, in edit mode it never works.) Bleed brakes by yourself - DIY Brake Bleeder tool - Brake flush https://www.youtube.com/watch?v=ioHjV4d6BWk Fixed -  | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 773 Registered: 04-2019 |

Thanks David, (?) I have been working on an idea that is similar to the diesel fuel pump in the video above. I have a 50 ton (?) jack that I found along the road. Obviously fell off a work truck, and was in some pieces. I hoped to fix it, but if I can get it apart, I hope to be able to use it like in the video to pump the caliper piston out. That getting it apart bit is not going to be easy as big as it is. I believe the body as well as the top really big nut screw in. Not sure how I will get the body to unscrew. It took wedging the jack in a tree "V" and a pipe wrench to unscrew the big nut. First I tried to put it under my 6000+ LBS Imperial and held it with another jack, but could not get in there with the pipe wrench.  | ||

Jim Walters Frequent User Username: jim_walters Post Number: 259 Registered: 01-2014 |

Just use a grease gun, that's the way every other professional I know does it. It is the safest and best way to remove seized pistons. Steel bar to take the place of the rotor, and short steel blocks strategically placed to isolate the piston you want to force out. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 774 Registered: 04-2019 |

Jim, So what do you do with all the grease now in every cavity in the caliper, and what will that do to the rubber seals ect. if you don't get it all out? | ||

David Gore Moderator Username: david_gore Post Number: 3394 Registered: 04-2003 |

Kerosene [paraffin] does the trick - just immerse the calliper in a bucket after freeing the piston, cover it with kerosene and let soak for a day or two. The grease will dissolve into the kerosene and any internal residues in the housing will soften and can be easily washed out using a trigger pack spray bottle filled with clean kerosene. Wash the calliper with hot water and a good liquid dish detergent to remove the kerosene residues and let dry in the sun. | ||

Jim Walters Frequent User Username: jim_walters Post Number: 260 Registered: 01-2014 |

Obviously one would wash out the caliper in solvent, split the halves, and replace the seals. Surely you are not reusing the seals? SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 775 Registered: 04-2019 |

Thanks David (+ Jim), But that still leaves a two step process that if the jack can be made to work, eliminates the grease and mess, just leaving the diesel/kerosene to clean out with soap and water. (If I can't figure out how to make the jack into a caliper piston pump, still the jack will be all apart and maybe I can fix it, so nothing lost.) Again: How to Unstick Frozen Brake Caliper Pistons https://www.youtube.com/watch?v=qc4zlGaJgoA Edit: Here s the video that inspired me to fix or use my jack. (He found a jack in the trash.) Reparacion de gato hidraulico tipo botella https://www.youtube.com/watch?v=zjwR48xyJ2w  | ||

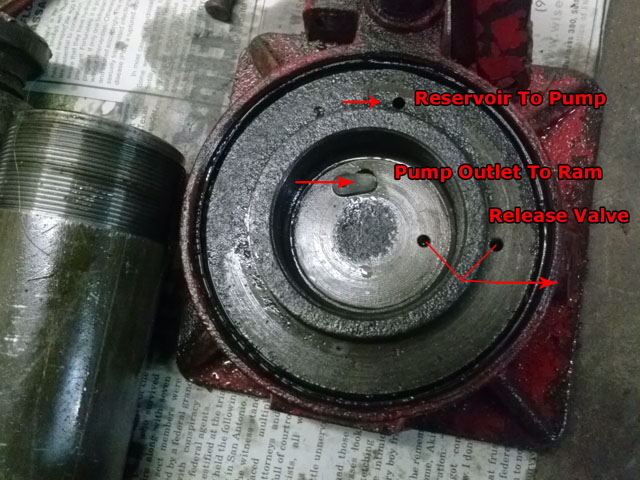

Mike Thompson Frequent User Username: vroomrr Post Number: 777 Registered: 04-2019 |

So, the body of the jack does just come off as in the video above. Mine had a bigger rubber O-ring holding it, so it seemed to be screwed in. Then the pipe that holds the ram (the jack part) screws in and I needed the "V" in the tree again and a pipe wench to unscrew that out. If you have wondered what is in a jack this is it. That little piece of plastic holds up your house or crain.  All I need to do to make a caliper piston pump is to attach a reservoir to the hole to the pump, and a line from the ram hole, that would hook to the caliper.  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2129 Registered: 05-2012 |

I found pipe cleaners very useful in cleaning out the grease, in addition to the solvent of course. Best to split the calipers so the pipe cleaners go all the way through. I was able to blow out all the pistons using a tire air pump, bar one, which required the grease treatment. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 778 Registered: 04-2019 |

Geoff, the tire pump is a good idea. I might try that before changing the jack to the point I cannot be used again. See if I can jigger something to hook it too. Thanks again. | ||

David Gore Moderator Username: david_gore Post Number: 3397 Registered: 04-2003 |

Mike, For safety reasons do not use air or other gas to pressurise the calliper housing as there is too much potential stored energy to send bits and pieces flying when they release. Murphy's Law principles always apply as one or more of the projectiles will inevitably cause unexpected and potentially dangerous injuries/property damage. Using an incompressible liquid/grease is much safer as there is little or no risk of sending projectiles flying with consequent risks to yourself and/or surroundings. . | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 781 Registered: 04-2019 |

David, Too late already tried it, didn't budge it. Too many places for air to come out. Put in one time at the end where the cross over goes into the side the stuck pot is in (back calipers) and nothing happened like it is not hooked to anything (just built pressure). | ||

Jim Walters Frequent User Username: jim_walters Post Number: 261 Registered: 01-2014 |

And using diesel or kerosene can be dangerous too (and messy) if there is any air trapped in the system when you pump the caliper full of fluid. There are good reasons a grease gun and grease are used by professionals to remove seized pistons. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2130 Registered: 05-2012 |

I'd just like to clarify that when I used a tire inflator pump, the type powered from the cigar lighter of the car, it was just to push out the unseized pistons. Low pressure is involved here and I do not believe there would have been a safety issue, particularly as I had a piece of wood in place to prevent the pistons actually dropping out. It occurs to me maybe its possible to remove the brake pads whilst the calipers are still on the car and use the foot brake to push the pistons out against the rotor. The point about using diesel is an interesting one. A trapped pocket of air, enriched with diesel fumes under increasing and great pressure is a recipe for an explosion. That would certainly free a seized piston, although not much fun retrieving it from your face  | ||

David Gore Moderator Username: david_gore Post Number: 3400 Registered: 04-2003 |

Geoff, You need a virtually instantaneous compression ratio of 18:1 to get a diesel engine to generate a large enough temperature rise to get a suitable fuel/air mixture to self-ignite. My diesel needs glow plugs to reliably trigger ignition on cold mornings [i.e. 10deg Celsius or less]. When I last had to replace the glow plugs, I had been resorting to a short spray of ether into the air intake to facilitate starting. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 783 Registered: 04-2019 |

So David I think you are saying that the method shown in this video is safe, unless you for some reason you preheat the caliper to enough temp to cause ignition and a ratio of 18:1 instantaneous, correct? How to Unstick Frozen Brake Caliper Pistons https://www.youtube.com/watch?v=qc4zlGaJgoA Plus you need to block all the holes with bleeder screws or plug screws and put in the 4 pistons with the loose ones secured so only the stuck pistons can come move. | ||

David Gore Moderator Username: david_gore Post Number: 3402 Registered: 04-2003 |

Yes - I cannot see any obvious risks and I would not be heating the calliper as the bore actually decreases in diameter due to thermal expansion of the housing into the bore cavity. I would freeze the piston with dry ice if available otherwise spray the piston with acetone/ether whilst evaporating it with a gentle blast fron a compressed air gun to cool the piston below 0deg Celsius [32deg Fahrenheit]. This will shrink the piston in the bore hopefully enough to make it easier to push out. If you do not have access to an air compressor, take a couple of your road wheels to a local fuel outlet and pump them up to 40/45psi and use them as the source of compressed air [make an adaptor with a shutoff tap to attach to the wheel valve stem after removing the internal valve of course] with another valve-less stem to allow both filling with air, attaching the air gun and use the tap to control the filling and release of the compressed air. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 786 Registered: 04-2019 |

Success! It wasn't until plan "D" that I finally got the stuck piston out. As one guy said: even if plan "B" does not work you still have 24 more letters to go. Here are the plans: A. Take a vice grip and lock it firm on the piston and hit it back and forth with your hand, with your thumb on the vice grips to wedge it out. That worked on 7 pistons. Fail B. Hook air to the piston to force it out. Fail C. Drill tiny holes in the lip with a 1/16 in drill bit (about the size of the lead in a mechanical pencil). Drill the holes close enough that you can move the drill bit back and forth to cut through the in between space to form a slot. I made it just big enough to put a long narrow screw driver in the slot to move it back and forth until it broke free. Fail D. Take a screw driver that the handle broke off, stick it in the slot at an angle and hit it with a hammer several times until it moves the piston enough the vice grips can move it (with hitting the vice grips with a rubber hammer). Success ! | ||

Alan Dibley Experienced User Username: alsdibley Post Number: 200 Registered: 10-2009 |

Quote:- "the bore actually decreases in diameter due to thermal expansion of the housing into the bore cavity." No, the expansion is uniform across the whole object and the bore increases too. Think of what happens to the metal forming the ring around the bore - it gets longer. Alan D. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 788 Registered: 04-2019 |

Alan OBE, while in principle I agree with you on that point, but if you can get the piston out of thermal equilibrium it could decreases in diameter. Thermal equilibrium is: "Two physical systems are in thermal equilibrium if there is no net flow of thermal energy between the two systems when they are connected by a "path" permeable to heat." Without brake fluid the only path would be the rubber seal, the rust and some places the piston is in contact with the caliper bore. Although I am not sure the decreases in diameter would be significant, that would be from experiment the actual doing it, which would be called experience. For the caliper to then be in thermal equilibrium with the piston, the entire caliper body would have to come down to the same temp as the piston. David then said: "This will shrink the piston in the bore hopefully enough to make it easier to push out." Which seems to mean the experiment to his knowledge had not been conducted. As stuck as my piston was I doubt it would of had an effect. Possibly heat and a hammer and possibly thermal shock, putting water in the piston alone might have freed it. I would not do that, because it could make the metal weaker, and possible cause damage to the caliper. | ||

David Gore Moderator Username: david_gore Post Number: 3405 Registered: 04-2003 |

Alan, The form of expansion in hollow metal objects is largely a function of the dimensions and mass of the item. You are correct in situations where there is not much difference between the internal and external diameters and this is easy proved by the method of heat shrinking tyres on railway wheel centres which I observed many times when I was a Metallurgist with Australia's largest manufacturer of railway wheels, tyres, axles, bogies and associated items. Where a considerable differences between the external and internal diameters and large masses of metal are involved, constraints on free expansion may arise and the item will self "stress relieve" by contracting the internal bore and outwards for the exterior shape. In my opinion, the calliper housing comes into this category and this is appears to be confirmed by Mike's comment that heating had not been successful in freeing the piston. My advice to "freeze" the piston to facilitate removal was based on my opinion that the calliper bore was either shrinking or not expanding for this reason when heated. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 840 Registered: 04-2019 |

How long are rubber brake lines supposed to last? | ||

Alan Dibley Frequent User Username: alsdibley Post Number: 203 Registered: 10-2009 |

Mike, I have seen hoses with the surface covered in dimples rather than "stripes" as on new ones. The dimpled hoses were original fitment I think, and should be scrapped immediately. Most common failure mode is closing till they become blocked because Dot4 attacks the rubber making it swell. I suspect that modern materials have a practically indefinite life (someone with rubber/plastic expertise might confirm this). Alan D. | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 361 Registered: 03-2012 |

I think they suggest changing ever 9 years on a silver shadow?. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 854 Registered: 04-2019 |

I had the calipers sitting around for months now, and I did not think about the virgin metal would flash rust on me. Now I have to get into the piston holes and get all that powder rust out. No wonder I just can't get the motivation to work on them. Haven't touched the car in two days. | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 497 Registered: 11-2017 |

Original hoses have a braided look to them. The stripe on replacement hoses is to be aware of any twist when installed. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1200 Registered: 11-2015 |

Mike, Lowes sells metal prep which does a bang up job of keeping things from flash rusting. It's phosphoric acid and leaves a phosphate coating behind preventing rust after it etches the rust off the surface. There will be lots of internet instructions about how to use etch for both derusting as well as flash rust prevention. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 858 Registered: 04-2019 |

I'll give it a try, see video how to do it with a tooth bush. https://www.youtube.com/watch?v=BoPlsitDZ9Q | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 865 Registered: 04-2019 |

Ross I went Lowes and they don't carry that here, so I went to other places and they don't either. Something about they use in the Meth process. Just kidding. | ||

David Gore Moderator Username: david_gore Post Number: 3438 Registered: 04-2003 |

Mike, Any auto shop that carries touch-up paint would have Phosphoric Acid based rust convertors as well. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 867 Registered: 04-2019 |

David, The only things I could find are primers etc. or a gallon for $119. I'll probably just melt a brush into a [ shape to get into there. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 868 Registered: 04-2019 |

Here is the above first picture arrangement with brake lines on and the wire braces holding it. The back one I miscalculated and had to bend it as seen. I will make a cover for it if it works. (Remember it is a test.)  | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 944 Registered: 04-2019 |

It has been a while since I have worked on the RR, because of working on my land, and bone tired working some 4 hours in the morning then another 4 hours in the evening after it cools down a bit. But I found an easy way to get the pistons into the caliper. Get a piece of metal to cover the hole in the piston and use a C-clamp to screw it in. As they say in Texas, it went in as slick as snot.   | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 980 Registered: 04-2019 |

I have been poking along on the brakes, but finally I put one together and can now confirm that the caliper rebuild kit: BrakeBest part number 15002 (an O'Reilly's Auto Parts brand) does indeed work. Except the square split ring, does not come with the kit. https://www.oreillyauto.com/detail/b/brakebest-hardware---hydraulics-2968/brake-systems-16456/brake-hydraulics-16513/brake-caliper-repair-kit-11264/d3a58bb0a88a/brakebest-repair-kit/15002/2557763 | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 989 Registered: 04-2019 |

Finely I got the front brakes on the car. All new lines and half way to make the experiment. Can a master cylinder and brake booster work on existing original Rolls calipers, without changing everything from scratch. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 990 Registered: 04-2019 |

How do you get the metal rings on the rubber dust covers on the back brakes? They are hard to get to and littler than the front, and it seems stronger as well. I have yet to find a successful way to get them on. | ||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 501 Registered: 05-2016 |

From memory the callipers need to be split in half and then the metal rings can be placed on the dust covers. Once you split the callipers it's advisable to fit new gallery seals on reassembly. | ||

Vladimir Ivanovich Kirillov Prolific User Username: soviet Post Number: 1660 Registered: 02-2013 |

Mike try rubber grease and a heated air drier but don't put the air drier too close or it may melt the rubber. | ||

Jim Walters Frequent User Username: jim_walters Post Number: 268 Registered: 01-2014 |

You need fingernails to do it, actually thumbnails, and push them down with your fingertips as you spread them with your thumbnails. Easier to do when the calipers are split but it can be done without. No grease, that will make the circlips slide off when you're trying to get them to stay on. Heat won't help. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 991 Registered: 04-2019 |

Larry and Jim since do not have the gallery seals I am very reluctant to break apart the calipers. My thumbnails are thin (maybe not enough iron or protein) but I will try that again. Thanks Also I have been thinking about a cap on something, and putting the ring on that cap, then slipping it onto the rubber in place. | ||

Mike Thompson Frequent User Username: vroomrr Post Number: 999 Registered: 04-2019 |

How I got the back brakes off. They were so tight I could not budge it so I put the breaker bar on there and screwed it up with a jack.  | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1004 Registered: 04-2019 |

Now all the calipers are back on the car, I have all the brake lines on. All I need now is to buy a hose for between the small reservoir and the metal brake line to the master cylinder/slave cylinder. Then fill both systems up with brake fluid (RR master cylinder/slave cylinder, and the master cylinder/vacuum booster) bleed the brake lines, and check for leaks. Then it is test day. 6 months from the time I bought this car. With really 2 months off working on my land. 533 posts 1 + 2 | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1007 Registered: 04-2019 |

So I am at the point that I am filling up the reservoirs and looking for leaks. Found two so far, one because I did not tighten the 3rd connection on a 3 way connector. The other is again on a 3 way but I think it was tightened too much (I did this one before told on bubble flares you can't tighten it too hard). OK so the question is I put brake fluid into the little reservoir for the slave/master cylinders and no fluid is making it to the bleeder screw I made with a 3 way connector. The manual says the input is the one shown with the red arrow (original brake line), is that correct? And if so why is there no fluid making it to the bleeder screw? I have pumped the pedal a million times and nothing. And I blew air through that line before I put it together to make sure crud was not in there.  And the new line goes to the bleeder screw, then to the slave cylinder.  | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 549 Registered: 11-2017 |

Confirmed, Inlet (reservoir) is the rear connection. https://www.rrsilvershadow.com/ETechn/Hydr/Compmstr.htm | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 371 Registered: 03-2012 |

Mike see the second line, put a bleed screw here to check if master cylinder is good, ie. fluid in reservoir depress brake pedal, open bleed screw and bleed as you would a caliper, if you get a good solid pedal the cylinder may be considered a "good one" failing same may require new seals/cylinder | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1008 Registered: 04-2019 |

There should be fluid getting to the inlet as confirmed, and the only reason I can think of that it is not making it to the bleed screw is that the valve is stuck, ie whatever clip or whatever that holds it has come off or rusted. So is not opening. I sure don't want to take all that off again and open it up and hope to find parts for the master cylinder. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1009 Registered: 04-2019 |

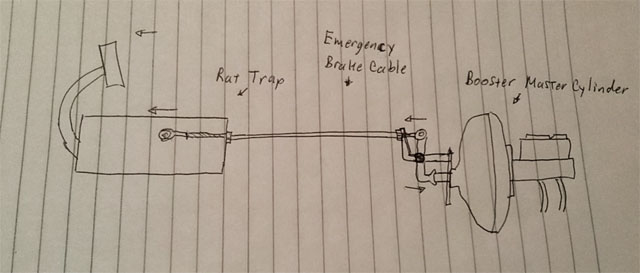

To add to above, I also just tried to use a funnel and a hose hooked to the bleeder screw to back flow fluid to the master cylinder to hope to pump fluid to the bleeder screw on the slave cylinder, and nothing. Also after 50 pumps on the pedal. No fluid is going anywhere. I believe this says the original RR master cylinder is not functioning. (After sitting for 15 years.) The funnel is above the rat trap and the bleeder screw is opened. Something should be going somewhere. ??????  | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 372 Registered: 03-2012 |

Mike my method of testing the master cylinder as outlined above is simple and definative as I have used same to test a master cylinder on old 68 shadow. The test can be done with master cylinder in situ, open drivers door depress brake pedal with one hand while you bleed the bleed screw when fitted to master cylinder with other hand. Naturally if it doesn't work the seals are defective. This is a tried and tested method.. | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 373 Registered: 03-2012 |

P's if you decide not to try my method consider putting a bleed screw at the other side of the brass T piece and try above method as described | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1254 Registered: 11-2015 |

Mike, Here's a good animation about how the MC on the RR works. https://www.rrsilvershadow.com/ETechn/Hydr/Compmstr.htm Looks pretty straight forward, but looking at how it works, you should be able to pull output fitting out and let fluid flow through, that being observed, hand actuating the brake with your thumb over the output port should confirm the thing CAN actually move fluid to bleed it. I would certainly make sure the MC is pumping before trying to bleed it. For instance if fluid doesn't come out, the inlet is plugged. Good Luck | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1255 Registered: 11-2015 |

These would seem like a good replacement   | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1010 Registered: 04-2019 |

Hubert I have already put a bleeder screw on the master cylinder. Not sure what line you are talking about "second line". The original line is the Inlet coming from the reservoir. The new line goes to the 3 way connector (T) with a bleeder screw. No fluid is coming out of the bleeder screw. Ross "I would certainly make sure the MC is pumping before trying to bleed it. For instance if fluid doesn't come out, the inlet is plugged." That is the whole point, in every car I have ever done you fill up the reservoir pump the pedal and then open a bleeder screw to see if fluid is coming out. Nothing is coming out. Nothing is clogged. The only thing it can be is the valve that acts as a one way valve is stuck closed. So no fluid is coming into the master cylinder, and/or it is not pumping. Regardless of whether the MC is pumping or not there should be some fluid coming through, it is basic hydrodynamics. That is why I tried to back flow fluid to the master cylinder to see if the MC would pump, hoping that would open the valve from the reservoir. Are there rebuild kits for the RR master cylinder? . | ||

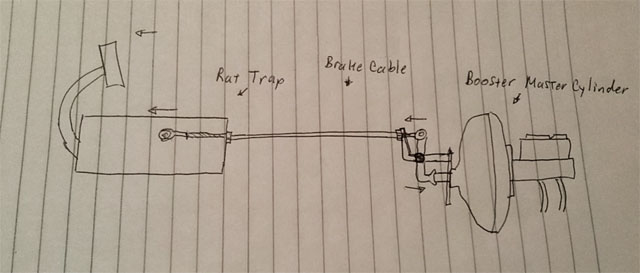

Mike Thompson Prolific User Username: vroomrr Post Number: 1011 Registered: 04-2019 |

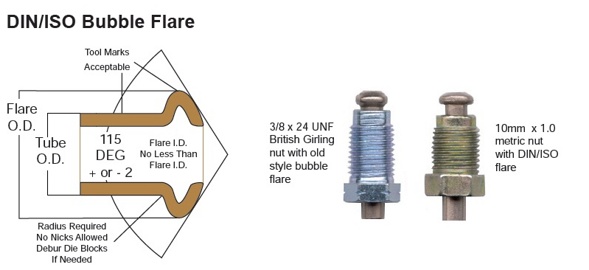

Here is a schematic of how the system is set up.  | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1256 Registered: 11-2015 |

Mike, If the reservoir is located above the clutch slave cylinder (the higher the better), and the internal valving on the MC being what it is this should probably self bleed. Have you tried leaving the bleeder open on the slave and waiting? | ||

David Gore Moderator Username: david_gore Post Number: 3477 Registered: 04-2003 |

Mike, The master cylinder is a standard Girling item [? my memory is vague as it is two decades since I last refurbished this item but it is a standard item fitted to many UK made cars in the early 1960's] and overhaul kits should still be available. It is an easy overhaul job although the bore may need honing if it is pitted. I note you have not shown the anti-lock device that was fitted to the Shadow 1 master cylinder discharge so we can eliminate this item as a possible "trouble generator". | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1012 Registered: 04-2019 |

Ross I left it open overnight and not a drop. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1013 Registered: 04-2019 |

Does someone know the part number of the master cylinder? Or better the rebuild kit. There are cheap MCs at the below link but it says it is for a Triumph. https://rimmerbros.com/Item--i-122167ORIG?gclid=EAIaIQobChMIys2k4JuO5QIVw8DACh27TAhEEAQYAyABEgK3uvD_BwE | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2157 Registered: 05-2012 |

Mike The substitute part for a Shadow 1 master cylinder is: Land Rover Series 2 2A & 3 SWB88 3/4" Bore Center Valve Brake Master Cylinder Note this is the 3/4" bore as opposed to the original 5/8" bore. You can pick them up off ebay for around 35 bucks. https://www.ebay.com/p/896875885 | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 374 Registered: 03-2012 |

No hastle Mike,from my experience with the master cylinder on my 68 shadow ( now sold),it drove me to distraction, I wanted rid at the time.The only thing I found benefitical was putting bleed screw on master cylinder. Anyway sounds like you need a new one | ||

Jim Walters Frequent User Username: jim_walters Post Number: 269 Registered: 01-2014 |

Absolutely get a 3/4 inch bore new one like Geoff has linked. I think you will still not have enough volume to operate the system though. Remains to be seen I guess. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2191 Registered: 09-2004 |

On a car of this size braking with a single controlled master cylinder with this configuration is madness. To start the procedure IMO it must be operated by duel m/c. Maybe the experts on here know different than me though! | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1014 Registered: 04-2019 |

I would think a 3/4 inch bore would exacerbate the problem of travel hence volume. But the travel of the vacuum booster from the top of the original pedal was only maybe an inch. The slave cylinder can easily move that far. I still worry once the engine is started and vacuum is applied that the slave spring will overcome the vacuum booster spring and apply the brakes as discussed. We all have our comfort levels on safety. Some have no problem driving on 30 year old tires with a very heavy load. I would not do that. As said statistically speaking the single versus duel MCs are statistically equal in safety. The park brake is the second system, which had worked on cars for 70 years before the duel system was used. My 1964 Chrysler Imperial is much bigger and much heavier than a RR SS but has a single master cylinder. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1015 Registered: 04-2019 |

SUCCESS ! The master cylinder is now working. So I was taking off the inlet line for two reasons, to see if indeed there is no clog in that line, and to take off RR master cylinder to repair. As I was about to take the line off, all of a sudden a good flow of fluid was coming out of the bleeder screw. Theory, if you remember the worms in the original RR reservoir and these same worms were in the brake pumps. It is not hard from this to conclude the worms were in the master cylinder as well. So caused a clog in the master cylinder and why there was no flow. Also when I reattached the inlet line the flow dropped to drips. So I put my mouth around the remote reservoir fill and blew hard. [censored] Again the flow returned and whitish stuff was in the brake fluid (arr there be worms in them thar parts, matey). And some pumps later fluid came out, at the back at the slave cylinder bleeder screw. Worms !  | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1016 Registered: 04-2019 |

Well it seems to be a case of premature evaluation. I got out all the air in bleeding the line (as far as I can tell). And no joy in getting a hard pedal. And as far as I can tell no movement in the slave cylinder. Back to the master cylinder needs to be rebuilt. Anyone got a rebuild kit part number for the RR master cylinder? | ||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 507 Registered: 05-2016 |

Master cylinder seal kit CD4151 from Flying Spares | ||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 508 Registered: 05-2016 |

A topic started on another site yesterday under "early ss brake bleeding with master - solved". If you google it you may find it helpful. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1017 Registered: 04-2019 |

I just thought I did not bench bleed either the master cylinder nor the slave cylinder will it bleed by pumping it? Thanks Larry | ||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 509 Registered: 05-2016 |

My car is a later model without a master cylinder so I don't have hands on experience but I would imagine that it should bleed by pumping although I note that a lot of owners experience problems getting it to bleed. I think the vacuum suction method described in "early ss brake bleeding with master - solved!!!" should sort your problem by sucking the brake fluid through the master cylinder to the rear callipers but you might need to blow the pipes through with an air line first to expel the "worms". I've also read somewhere of folk using Land Rover master cylinders to good effect on their Silver Shadows but I can't seem to find an article on it just now. | ||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 510 Registered: 05-2016 |

Hi Mike, I just found a reference to the Land Rover master cylinder that has a bigger bore but is a direct replacement fit. It's for a Land Rover Series 2 and has a 3/4" bore. I think it retails for approx. $40. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1018 Registered: 04-2019 |

I looked in google for "early ss brake bleeding with master - solved" it does not show up yet. Geoff Wootton beat you to the Land Rover MC above. Land Rover Series 2 2A & 3 SWB88 3/4" Bore Center Valve Brake Master Cylinder. But thanks | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1259 Registered: 11-2015 |

Mike, I just looked at a report that the national highway and safety folks did in 83 looking at the safety effects of dual circuit brakes vs single circuit. The statistics they used showed that dual circuits do reduce brake related crashes over single circuits. So Patrick L is correct that dual circuit brakes are safer than single circuit ones. report here Also running single circuit brakes on the car and documenting the fact that you are doing it despite the fact that it is less safe would seem to make the lawyers job that much easier when something goes south. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1019 Registered: 04-2019 |

There is a slight difference but within statistical error, therefore no difference. I live in Texas these brakes are legal here. There are lots of old cars and custom cars here. Cheaper parts: Brabo Parts http://braboparts.com/cs_parts_details.php?partno=BCD4151 Flying Spares https://www.flyingspares.com/shop/rolls-royce-bentley-shadow-t1-t2-corniche-mpw/silver-shadow-t-1-2-brakes-pads-discs-fluid/master-cylinder-and-associated-parts/master-cylinder-seal-kit-cd4151.html | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2158 Registered: 05-2012 |

Mike I'd think again. From Haynes.com - By 1967, it was mandated by the Federal Government that all vehicles use a dual-brake master cylinder, with separate circuits in case of the failure of a line or other issue. As Ross has said: this thread is a Lawyers dream should anything go wrong. | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 375 Registered: 03-2012 |

Geoff, you make perfect sense, as originally the car had 3 braking systems excluding the emergency brake . As Patrick L. rightly knows in the UK and Ireland car modifications in a no no, particular when it comes to insurance.It can be done ,but one must jump through loops..engineers reports and the like.. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1020 Registered: 04-2019 |

If anything goes wrong that's why you buy insurance. And when Texas hands me the inspection sticker, that car is the same as any older car as my 1964 Chrysler Imperial or my 1965 Ford Thunderbird, "legal" with only a single master cylinder. Funny no one cares about someone running on 30 year old tires pulling a ton load on a trailer and possibly flipping over with a complete blow out from tire rot when that goes wrong. A tire on my Imperial blew just sitting in the garage, it sounded like a bomb went off in the garage. It threw shrapnel to every corner of my garage. There would be no Lawyers, and no engineers reports, this is Texas not some overly litigious UK country, or state up north. That is just not what happens here. Every state has the right to decide what their inspections must have to pass. Any ideas on how I can buy a master cylinder rebuild kit at a local auto parts store? . | ||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 511 Registered: 05-2016 |

Hi Mike, that Silver Shadow master cylinder bleeding topic was posted only a couple of days ago on https://www.rollsroyceforums.com | ||

Jim Walters Frequent User Username: jim_walters Post Number: 270 Registered: 01-2014 |

If you insist on staying with your design buy the new master linked above. If you think you can just put a seal kit in your old master you are sadly mistaken. I can guarantee you the pressure seal will fail in short order. The bore of that aluminum cylinder, with a steel piston, sitting for 15 years with water contaminated glycol brake fluid in it, will be badly pitted. The edges of those pits are razor sharp. Honing will not take out the pits, and using those cheap cylinder hones on those aluminum cylinders is a mistake anyway. They leave the cylinder too rough for the seals to seal and/or remove too much material so that the lip of the seal is too loose in the cylinder. At the most they should only be cleaned up with 1000 grit sandpaper on the end of your finger. A new seal will tear on the pits the first time you pump the pedal, probably not enough the first time to cause a complete failure but the pits will chip away at the seal lip until it suddenly fails. Your design for the brake system is just ridiculous in my opinion, absolutely not safe. You should have at least used a tandem master bolted to the rat trap as I suggested months ago. Sorry Mike but I don't think this thread should even be visible to the public lest some other misinformed soul thinks it is a good way to modify the original brake system to save money. Nothing against you Mike but I worry for your safety as well as the innocent drivers you share the road with if you ever do manage to get it to work in this configuration. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 550 Registered: 11-2017 |

Passing inspection does not mean this car modification will be exempt and out of reach of lawyers if, god forbid anything happens to the public. You can bet your last dollar that a lawyer will go after everything he can. If you had spent your time and money repairing the original system, rather than trying to cobble up a rube goldberg contraption, your car would be safer, on the road, and without doubt more valuable to the next custodian. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1021 Registered: 04-2019 |

Thanks Jim a new MC is the same price as the rebuild kit so I will go for that. This is a good example why the old system would out cost the price of the car. Plus since I still do not know how that system worked I cannot see that being safer. This RR was a POS that should have ended up on ebay as parts. Not a museum piece to have a conservator. It seems some think all one has to do is open up the wallet without anything in there, and pay for an entire new system. It don't work like that in the real world. If a single system is so unsafe don't buy any car before 1967 including a Rolls Royce. Rolls-Royce Silver Cloud, Silver Cloud II and Phantom V Bentley 51, Bentley 52 and Bentley Continental 52 Description On both 51 and 52 cars, the braking system incorporates a gearbox-driven friction type servo motor which is engaged by tire foot brake pedal. The output from the servo is transmitted through hydraulic cylinders which operate Girling Hydrostatic brakes incorporating special Rolls-Royce features. In addition to operating the servo, the foot brake pedal is also connected to the rear brakes through a mechanical linkage of rods in tension, as also is the handbrake, and supplies 40 percent (Sl cars) or 30 percent (S2 cars) of the effort applied to the rear brakes, the additional 60 per cent (S1 cars) or'70 per cent (S2 cars) being provided hydraulically. The handbrake also is connected to the rear brakes through a mechanical linkage. http://webcache.googleusercontent.com/search?q=cache:QlrSAOo_-NYJ:rrtechnical.info/sc/sc1/wshop/7.pdf+&cd=1&hl=en&ct=clnk&gl=us | ||

Patrick Francis Frequent User Username: jackpot Post Number: 295 Registered: 11-2016 |

Just to put my twopence ha'penny's worth in: you might have seen on my other thread that I suffered partial brake failure on a downhill run the other day. Th brakes boiled and my pedal hit the floor. This was because the master cylinder did not have enough travel to take up the airlock that was produced. When the pedal reached the floor, the two valves that activate the two pressurised systems came into play and the pressurised systems compressed the airlock in the other two systems until the brakes were activated. Having a pressurised system is like having a limitless supply of pressurised fluid that can overcome air llocked brakes. Not possible with a puny master cylinder. When travelling in a quiet comfortable cabin, sometimes we may not be aware of the work those brakes are doing on a relatively small disc trying to stop 2 tons of motor down a long hill. Please be aware- be very aware. Said with my best intentions, having had a scary experience. | ||

Mark Aldridge Frequent User Username: mark_aldridge Post Number: 642 Registered: 10-2008 |

Mike, noting your comments on the S1 system, I had a complete hydraulic failure due to a pipe collapsing on a hot day on a 1:7 downhill with a fully laden car. The early S1 only has single circuit hydraulics. Thanks to the mechanical rear brakes, I was able to safely stop the car on an approach to a busy roundabout. If you are using single circuit on any car, the handbrake must be absolutely A1( I have a couple of sportscars with single circuit from new ). The S1 Bentley single hydraulic models system is considered by our MOT testers as having 3 braking systems ie mechanical service brake, hydraulic service brake and parking brake. From my experience with Shadows and Spirits, I have had several, the handbrake can be considered a joke ! even in A1 condition. I have driven a Shadow when the engine stalled and with U/S accumulators. The experience does not want repeating ! If driving a strange car, I always now do a pedal count check before moving off ! I would not contemplate a single circuit Shadow. Sorry! Mark | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 551 Registered: 11-2017 |

The "parking brake" on a Shadow is not considered an "emergency brake" by any means. It is strictly a parking brake. Look at the small pads and you will see why. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 1262 Registered: 11-2015 |

Mike,  Looks like the one on my Alpine. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1022 Registered: 04-2019 |

Ross I believe the original RR MC is Girling 625, if the Alpine MC is that, then they are the same, but since I have never heard of a Alpine before now (being rare I take it) I doubt that would help me find a rebuild kit locally. Which is one of my goals with these threads. Patrick Francis I still feel your pain with the brakes boiled. But in the system I am building there is no direct contact with the calipers hence no way for enough heat to cause the brake boiling event, a plus for my system. That system (the original MC/slave) is isolated from the braking system with it's own reservoir. The other is a dual master cylinder/vacuum booster system. One of the dual goes to the front brakes, the other to the back, and they are not connected in anyway to each other. And it still has the park brake that I have proven can be used to stop the car without any other braking. That is how I got it, under its own power, into the garage. It has a lot more braking power than you might think. And in the "extremely" rare event the master/slave system "might fail", there is still the park brake, which has served cars for 70 years, longer that the dual system has been around. And I know this will make no difference to some, but this is only at this time "a test". A proof of concept, it will never hit the road until it passes this test. (geez) LS swap RR SS and briefly you can see the same kind of braking system. (I would not want to shift with my left hand.) https://www.youtube.com/watch?v=j6hcBUSIV-0 Another https://www.youtube.com/watch?v=lT4R3hyB1oM My RR First start drive into the garage. https://www.youtube.com/watch?v=_Z5o1ljesno | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1024 Registered: 04-2019 |

550HP LS7 Powered '58 Rolls Royce And brakes https://www.youtube.com/watch?v=sxh40q2p-Fk The new chassis 58 Rolls  Hydroboost (?) with slave somewhere (video above LS Swap Hot Rod on street)  | ||

Jim Walters Frequent User Username: jim_walters Post Number: 271 Registered: 01-2014 |

Mike, you're not convincing anybody that your modification of the stock braking system is safe let alone a good idea. Your comparisons above are apples to oranges. Top pic: Wilwood modern tandem master with front and rear disc brakes. No comparison at all. Bottom pic: your arrow points to a remote vacuum booster like I suggested to you months ago. It is clear that they have mounted a tandem master onto the rat trap and added remote vacuum boosters to both the front and rear brake outputs.You can see the second remote booster behind the right front shock tower. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1026 Registered: 04-2019 |

What part of it's a test is unclear? And it will never hit the road until it passes this test. If you feel a single system is so unsafe you should not drive anywhere where old cars share the road (and as I have pointed out that includes Rolls Royces). That certainly does not include Texas. You cannot spit for hitting an old truck or car down here. That also includes 18 wheeled trucks that only have an emergency backup where all wheels will lock up. Air has to be supplied to unlock the emergency braking. I'm not sure how anyone feels an accumulator that can blow a hole in an engine block is safer than a dual master cylinder/vacuum booster/slave system. | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 1027 Registered: 04-2019 |

An addition to the above post: I found in his replies Lee Screaton tells what he did. And in no way am I endorsing what I do, I am only telling others, for amusement or information, what I am doing. Also as I have said in my second post in: #2 Help Restore My 1975 Silver Shadow Mike Thompson Posted on Wednesday, 12 June, 2019 - 17:32: "To everything I have said on this forum do at your own risk." This is what Lee Screaton said he did, no mention if it is a dual or single system: https://www.youtube.com/watch?v=j6hcBUSIV-0 Question Michael Nichelas 6 years ago How did you go about the brakes and accumulaters ? I know that that's a major issue when doing a Chevy conversion on these RR's Reply Lee Screaton 6 years ago So basically I bypassed it all... I installed two remote brake boosters that run off the engines vaccum line; one booster for the front calipers and one for the back. I then installed a new pedal box as the car is also manual so needs a clutch. Seems to work ok ;) Lee Screaton 6 years ago I left the disk and calipers as per RR but removed everything else. The issue I found was that the brakes (and rear suspension) are all hydraulic so work more based on valves that traditional cylinders. None of that would work without a hydraulic pump on the engine and accumulators as you say. The brake pedal assembly alone is a work of art! . | ||

Patrick Francis Frequent User Username: jackpot Post Number: 296 Registered: 11-2016 |

Hi Mike I have not followed this thread close enough to understand how you say there will be no direct contact with the calipers? Anyway, I have to say that I have the same thought train as you. I am still not sure why my brakes have boiled so quickly, twice on different occasions and locations but in similar circumstances. Once with RR363 and the second time with DOT4 YAK.. I used to race various cars. The Panther Lima used to boil it’s brakes by the 4th-6th lap of a 15 lap race. The Ford Escort Cosworth would Come into the pits with the discs glowing cherry red and never lose it’’s brakes in 20 laps or more, neither did the Sierra Cosworth, and they both used DOT4.. I share your excitement with trying to install what is a “tried and tested” system of master and slave with a servo, and I am sure there is not one person on this forum that has not wondered why RR didn’t do this in the first place. When you get it working, please take it somewhere where you can test the system safely - 4up, down a long hill, braking constantly- rather than depending on logic that things won’t fail. Good luck in you endeavors! | ||