| Author | Message | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 36 Registered: 3-2016 |

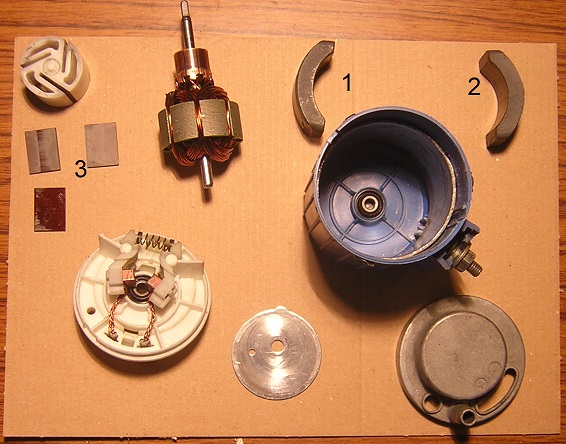

Experienced fellows, The FIAMM air horns on my SRH25085 (1976 SY) were not fonctionning due to a failure of the electric motor. So I opened the box and I could see that the stator magnets (1-2) were no longer secured to the case. I fixed them with stong epoxy glue, cleaned the brushes and the engine is now working perfectly BUT I do not have any compression, just a feeble breeze. The impellers also (3) are making a ratling noise. I have two questions : 1) Is a part missing ? 2) If no , could someone help me with the correct way to fit the upper part of the compressor ? Thank you in advance  | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1384 Registered: 5-2015 |

The vanes (3) are most likely worn out. This compressor is cheap to buy from Ebay. | ||

Patrick Francis Frequent User Username: jackpot Post Number: 85 Registered: 11-2016 |

Just a guess, but did you stick the stator magnets in the position and direction that they came out? Could be the motor is revolving in the wrong direction if you didn't, or maybe slower because the magnets do not coincide with the commutator strips? This might help? http://www.alfabb.com/bb/forums/alfa-romeo-montreal/334530-montreal-fiamm-electropneumatic-horn-compressor.html Good luck | ||

David Gore Moderator Username: david_gore Post Number: 2531 Registered: 4-2003 |

I agree with Robert, the vanes have worn probably due to running dry from lack of regular lubrication. My Fiamm compressor on DRH 14434 had an oiling cap on the top housing whereas this compressor seems to be of the "sealed for life" type. If it was my unit, it would get a couple of drops of air compressor oil "down the spout" on regular basis to provide internal lubrication [I am assuming the brushes will be protected from oil contamination by their mounting plate and armature shaft bearing.] | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 37 Registered: 3-2016 |

Thank you all. Patrick, I followed your intuition and swapped the polarity, but it did no miracle. Robert, David, The compressor box was indeed sealed for life and the inside absolutely dry.. Just for curiosity sake, what are the characteristics of a vane in good condition ? | ||

David Gore Moderator Username: david_gore Post Number: 2533 Registered: 4-2003 |

Cannot help you there as I never had to open up the compressor - the length of the vane is the critical factor; the rate of wear on an unlubricated vane IMHO would be very high but good for sales of replacement compressors if the vanes are not available as replacement parts. | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 38 Registered: 3-2016 |

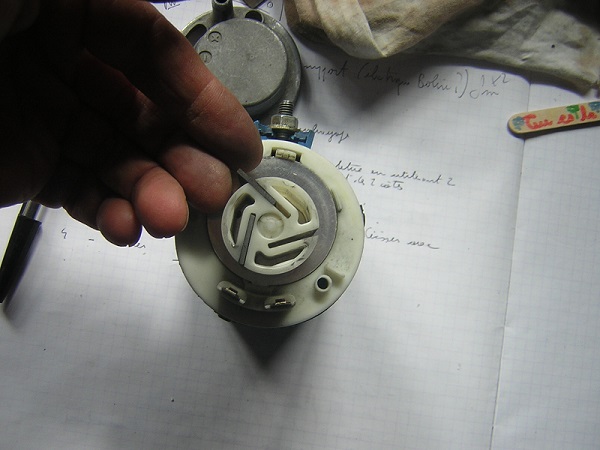

Thank you David. One last picture to document the topic, showing two of the three vanes in position. But again these compressors should not be unsealed.  | ||

David Gore Moderator Username: david_gore Post Number: 2535 Registered: 4-2003 |

Jean-christophe, One last thought - is it possible one or more of the vanes were jamming thus allowing "blow-by" giving the impression the compressor had failed instead of malfunctioning?? | ||

ross kowalski Grand Master Username: cdfpw Post Number: 396 Registered: 11-2015 |

Jean-christophe, What was the back story on this pump, was it working fine and suddenly stopped or ???. It might help diagnose the problem. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 397 Registered: 11-2015 |

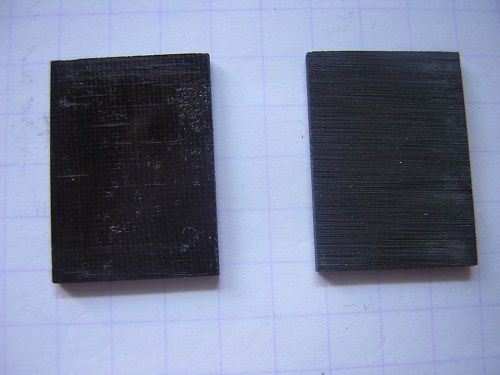

Jean-christophe, Are those vanes graphite? | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1394 Registered: 5-2015 |

Reassemble compressor and put some oil in it, suck and see. The oil might get the compression up. its a permanent magnet motor so reversing the polarity also reverses the direction. | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 39 Registered: 3-2016 |

Dear all that are taking interest in my compressed air story, thank you. Ross : As the owner of this car, I've never seen/heard the air horns working. I began by testing the electrical feed, the relay, and could see that the compressor was dead. So I opened it (broke the two plastic rivets) and what I could see inside was : - two magnets sticking to the metal cylinder but no longer fastened, - white dust, - corrosion, also, on the metal cylinder. - a dry dry place, no oil. I have no idea if the vanes are in graphite, here is a close view. On one side they are smooth (left), on the other rough (right).  Robert, David : I love the challenge of bringing this original compressor back to life. I'll follow your advices and I'll do my best to reseal the box, because I think the problem may also come from a loss of air-tighness. |