| Author | Message | ||

John Beech Prolific User Username: jbeech Post Number: 292 Registered: 10-2016 |

How is the battery within the trunk secured to the body? Mine has been floating free since purchase, which is of course, unacceptable. Thus, yesterday I made a bar to secure it in place using 3/4" x 3/16" aluminum bar stock. In retrospect, due to how it flexes when securing the nuts, I will make it once again using steel, instead.  - Battery hold down, Mk I Meanwhile, I pondered coating the brace with liquid rubber but thought I could carefully fit it. A very large spark later I decided there had to be a better way.  - A large spark made an impressive divot - fortunately these cars don't have computers! Plan B came into being through the use of a short piece of flexible tubing as an insulator. I cheated and shaded it toward the positive post. Note how much the brace bends with tightening of the nut. This calls for something stronger, perhaps a piece of angle stock instead.  - Installed with reinforced clear PVC tubing as an insulator While this is better than nothing, I wonder this, does anyone have a photo demonstrating the OEM brace? | ||

Jeff Young Grand Master Username: jeyjey Post Number: 340 Registered: 10-2010 |

Mine had a fabric-reinforced rubber strap. Don't know if it was original or not, though. Cheers, Jeff. | ||

John Grieve Frequent User Username: john116 Post Number: 51 Registered: 4-2012 |

You're missing the battery hold down clamp that sits on top of the battery. It's plastic covered metal. The rubber/fabric strap is used to hold down the front plastic battery cover, not the actual battery. You can see an exploded diagram of this in the Rolls Royce Spare parts manuals on http://rrtechnical.info/SY/spare/start.pdf Go to electrical section, then battery box section. | ||

richard george yeaman Grand Master Username: richyrich Post Number: 737 Registered: 4-2012 |

John my Shadow 1974 has an angle shaped piece of steel that sits over the battery at the front edge it holds it very well. Richard. | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1332 Registered: 4-2016 |

Hi John, These images may also help.   | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1788 Registered: 6-2006 |

There have been quite a few Shadows that have gone up in flames due to the battery frame bolt is just floating free and welds itself to the positive battery terminal. Never good  | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2249 Registered: 6-2009 |

I have never, ever, liked the OEM method of securing the battery inside the battery box. If the frame becomes even a slight bit "free floating," at least the way the ones are cut on both my cars, the whole sparking/welding thing can easily take place. The battery is really heavy and is really not likely to move and needs very little encouragement to stay in place. If I were to be making a substitute I'd be far more likely to use a piece of hardwood much like the piece of aluminum that Mr. Beech showed and in the same manner. It should be more than strong enough to hold the battery in place and poses none of the conductivity problems of metal. That or fashion a hardwood frame much like the original metal frame. Brian | ||

John Beech Prolific User Username: jbeech Post Number: 295 Registered: 10-2016 |

Brian, hardwood frame? Think again my friend because during even a minor accident the mass of the battery will be subject to a huge force of acceleration (Newton's 2nd Law). This is precisely when you need a structurally sound method of securing the battery and why I discarded my first thought of a piece of 1" x 3/4" nylon as not being suitably stiff. Anyway, my next iteration will be a piece of 3/4" channel (the u-shape will be quite stiff against bending forces). My only concern regards fracturing the battery in a crash (e.g. because 3/4" is relatively narrow and may function in much the same manner as a garrote). Hence, the likely reason RR used a perimeter-type frame is this holds the forces where the walls of the battery are thick and function as columns (although it does mean ensuring the securing nuts never get loose). In the meantime, I have made a request of Flying Spares for pricing of the following based on the above diagram: UD18712 Battery Frame for securing top of battery UD11931 Strap for securing plastic cover over battery The strap because the one in Tootsie is a little bit frayed and I'd rather have a new one. Although if they're stupid price-wise I am prepared to substitute a piece of 1/2" webbing from the hardware store and simply reuse the existing hardware bits off the original. | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1338 Registered: 4-2016 |

John, This strap is constructed like the strap that secures your jack & tool bag. There are in effect giant staples securing the ends, just bend them straight and extract them. Then re insert into the new strap or webbing material. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2251 Registered: 6-2009 |

John, If you wish, I can post close up pictures of the 2-finger forks that are at the end of the metal frame that comes OEM. I can virtually guarantee you that these would flex and break a lot more readily than a hardwood strip done like the metal strip you showed, but somewhat thicker. I have never been worried about the battery remaining "in place" in a massive accident because I don't believe the OEM system would achieve that (nor would most in any car I've ever driven). The material used for the battery box strap cover does not, to put it mildly, age gracefully. I would be far more inclined to use modern black nylon strapping or, as I actually did do, heavy inner tube rubber cut to the correct length and secured with "Shoe Goo" and staples (which is more than the OEM used, which was just staples. That works to hold the cover in place better, too, as it has elasticity that the original straps don't. The original material seems to be some sort of slightly rubberized fabric of some sort and I suspect the fiber is of some sort of natural origin. Brian | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1339 Registered: 4-2016 |

Brian, The strap is very strange indeed. It is of the same construction as the Jack/tool holder. As you say, not elastic in any way shape or form, I have a broken piece I got from a wrecker. I will see if I can photograph it in detail. Its like a rubberised covered canvas that seems to have a type of copper wire like hair in consistency running the length of the strap. Quite strange. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1790 Registered: 6-2006 |

John, I've never seen a damaged battery cage. I think even tightening the nuts way way past the torque required to hold it safely upside down after a fall would be fine. If loose it will build up momentum much more easily than a correctly fixed one. I can probably find you a good used one here if you have trouble finding one. "The battery is really heavy and is really not likely to move and needs very little encouragement to stay in place." The heavier something is, the more momentum it will have and the more it will want to move out of place in case of an accident . . . the battery leads are strong enough to hold it there . . .but far from ideal!! The straps are like the ones used in upholstery. Strengthened rubber. Like a cross ply tyre. Try an upholsterer or trim shop? A digression . . . A client pulled up outside our workshop once. We were standing chatting when I noticed his paintwork had bubbles forming on. I Quickly realised what was happening and surely enough - - no cage and the fixing was welded to the +ve clamp and the whole area was glowing red hot and about to burst into flames. Good job we were standing that side. Seen quite a few bolts with arc welded ends! | ||

John Beech Prolific User Username: jbeech Post Number: 296 Registered: 10-2016 |

Felt pretty good today (4 epidural injections in my lumbar spine yesterday and if things go according to past history I'll feel bad tomorrow). Anyway, taking advantage of the fact I was having a pretty good day, I made a revised battery hold down bracket. And in honour of British-English, instead of referring to it as version 2, I'm thinking of it as the Mk II. This, by using some 0.125" wall 3/4" aluminum channel stock. A lot stiffer than Mk I and works pretty well.  - Battery hold down bracket, Mk II In fact, I actually made two! One for me, and one for a friend in need. If that's you, raise your hand and send me the address. Price? Raise a beer to me!  - Bracket Mk II installed | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1341 Registered: 4-2016 |

Nice nice work John. Hope you feel ok tomorrow mate | ||

Jeff Young Grand Master Username: jeyjey Post Number: 341 Registered: 10-2010 |

Looks good, John, but I thought it would have your signature electron-erosion notches in it. ;) Cheers, Jeff. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2253 Registered: 6-2009 |

John is a quick learner. He now knows that an insulating condom (but I repeat myself) is essential in a "bar across the center of the battery" hold-down arrangement. The opportunity for "an unfortunate incident" secondary to a slight bump before tight without it is just huge. It's actually not insignificant with the OEM arrangement, either, and a lot of these frames have lost quite a bit of paint over the years and don't stay in place at all well until both nuts are tightened down. That's why I've run black electrical tape along the inside edge of the frame that's closest to the battery terminals and a bit around the corners on that side, too. Brian | ||

Omar M. Shams Grand Master Username: omar Post Number: 1165 Registered: 4-2009 |

Dear John, Your car is such a masterpiece with everything in it so original - with that in mind - why mess about with a home made battery clamp? Buy a real Rolls-Royce part. They are cheap and made exactly for the job. I still have mine on my cars. They have been on the cars from the day they left the factory. They are good and work very well. Yes webs and straps and cable ties and hoses and wood and a multitude of options will all work. But the factory original is what I would choose. take care Omar | ||

John Beech Grand Master Username: jbeech Post Number: 303 Registered: 10-2016 |

Omar, you make a very good point and we're of like mind, which is why I've already ordered one from Flying Spares (for £30) whilst ordering some other bits. Unfortunately, they do not have the strap for securing the plastic cover over the battery so I'll have to make something work until I find one. Meanwhile, I have another question; does anyone know the proper size battery required? Tootsie presently has a nearly new Group 24 battery (10" long) but I've measured enough space for a Group 27 (12" long). | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2254 Registered: 6-2009 |

John, Group 27 is the correct size. Brian | ||

John Beech Grand Master Username: jbeech Post Number: 304 Registered: 10-2016 |

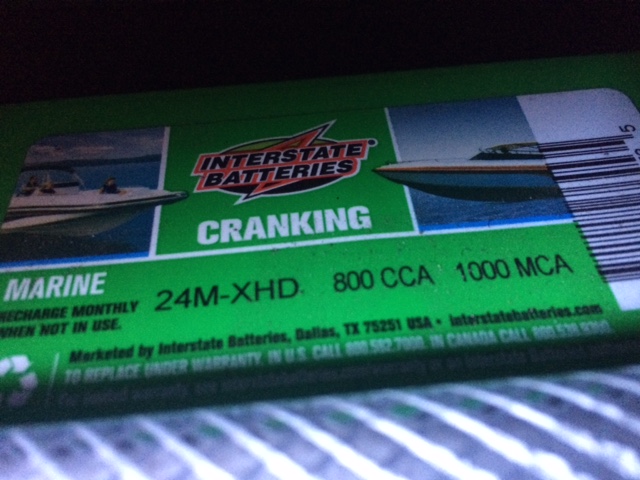

Thanks Brian, I'm not going to change out the nearly new battery but when it comes time I'll get the proper group. This despite this Group 24 battery having more CCA than the Group 27 batteries I looked at whilst measuring dimensions the other day. In the meantime, a 2" spacer x the width of the battery (7-1/2 or 8" I believe, will let me use the OEM battery hold down I've ordered from FS). In any case, all this will wait a week or so while I wait on the effects of the cortisone to take full effect on my back. Hopefully, this too shall pass (although it's been since just before Christmas and I am nearing the point of desperation).  - 800CCA Group 24 battery, which is 2" shorter than the OEM Group 27 battery | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2258 Registered: 6-2009 |

John, Also notice, though, that you have a marine battery. Not that it's not working, obviously, but that can account for some of the spec difference. I don't ever recall the figure for "MCA" ever being used on a battery intended for automotive applications though "CCA" (which if memory serves is Cold Cranking Amps) defnintely is. The note to "Recharge monthly when not in use" is distinctive, too. Brian | ||

David Gore Moderator Username: david_gore Post Number: 2512 Registered: 4-2003 |

Brian, MCA = Marine Cranking Amps http://www.offshoreonly.com/forums/general-q/46428-what-difference-between-mca-cca-batteries.html The values vary due to the different temperatures used when testing. * | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 572 Registered: 4-2015 |

Marine application batteries are also "deep cycle" which is good is it not? I always thought so and have in the past often used them in my cars for specifically that reason, or am I being delusional...again! | ||

John Beech Grand Master Username: jbeech Post Number: 307 Registered: 10-2016 |

I didn't purchase this battery but the receipt indicates it was purchased a few weeks before I purchased the car. Anyway, there are actually several different battery types in common use, e.g. car batteries, marine batteries (as separate and distinct from deep-cycle batteries, which are also for marine use, but for a completely different application). Also, there are AGR-type batteries (Advance Gas Recombinant), or AGM (Advanced Glass Mat), which is also recombinant technology. It can be confusing and to preclude battery information being lost within this thread, I've taken the liberty of starting (no pun intended) a wholly separate battery-thread. But in brief, we want car batteries - or - deep discharge batteries, while marine batteries are really better suited to use where physical abuse is a factor, e.g. a hull slapping or hitting waves and passing the shock to the lead plates. |