| Author | Message | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 272 Registered: 6-2009 |

I want to synchronize and adjst the carbs on my Shadow 2 myself after the "specialist" who did it previously messed up. However I have a question about synchronising them. the workshop manual says to use 2 gauges on top of the dashpots. But how do I install them : is there an adaptor piece available that sccrews intothe dashpots ? Benoit | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1471 Registered: 5-2012 |

Hi Benoit Yes, you will need an adapter for both gauges. You can purchase them for $50 the pair from here: http://www.sherbournemews.com/shop.htm An alternate and cheaper method is to use a Unisyn Carbalancer for around 30 bucks. There is a very good thread here: http://www.rollsroyceforums.com/forums/26-sy-series-i-ii-1965-1980/4314-carbs.html This is worth reading through. The highlight is a picture of Jim Walter's set up on page 4. Geoff | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1472 Registered: 5-2012 |

It's just occurred to me that Kelly could probably make the adapters. If this is the case, I will have two as well for future use. Geoff | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 423 Registered: 8-2012 |

See this thread for my gauge setup: http://au.rrforums.net/forum/messages/17001/17638.html | ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 127 Registered: 7-2004 |

Geoff, these adapters have long been on my list of things to make and offer, but my tool production keeps me constantly busy. I can certainly make them for less than $50/pair. I can include the extension rods and indicators as well. If anyone wants them soon, let me know, otherwise keep an eye on the For Sale and Wanted section. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1473 Registered: 5-2012 |

Kelly I will definitely have a set when you get round to making them. It is not urgent for me as I can get by with my airflow meter. It is a definite though - will make the job of balancing the carbs so much easier and more accurate. If you decide to supply the adapters only could you advise which dial gauge to use. I note Harbor Freight sell them for just 18 bucks each, but I have no idea whether they would be accurate enough. Geoff | ||

Omar M. Shams Grand Master Username: omar Post Number: 913 Registered: 4-2009 |

count me in for a pair too. Omar | ||

Jeff Cheng Frequent User Username: makeshift Post Number: 57 Registered: 2-2016 |

Kelly, I too would love a pair. I've been toying with the idea of using rubber stoppers with cheap ebay dial indicators through the middle but this would be a much nicer solution. | ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 128 Registered: 7-2004 |

Well, alrighty then. At the moment, I'm elbows deep in steering wheel hubs (which are turning out nicely, thank you very much), and other tools for friends, but I'll put these carb bushings at the top of the list. Harbor Freight indicators are perfect for this job. The heights of the carburetor pistons are not being directly measured but compared. These indicators are great for comparing. BTW, I exclusively use cheap China indicators for almost everything. I've had several expensive Starrett indicators for 20-25 years that have been used probably twice each. I never dare to take them out of their cases because of the cost. And they're not any better. | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 273 Registered: 6-2009 |

Kelly, great that you're willing to make them. I'd be very interested in a complete set, dials and all. Benoit | ||

Omar M. Shams Grand Master Username: omar Post Number: 914 Registered: 4-2009 |

Dear Kelly, I too am very grateful for your support with this project. If the whole set is an option then that is exactly what I would also like instead of just the caps. Now if I am not mistaken, the same tool would work for both the Shadow I and IIs...... can someone verify this? thanks Omar | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1048 Registered: 9-2004 |

Synchronising setting the correct mixture on a Shadow is another story will let David G or Bob R fill in on that! The colortune is NOT an option. | ||

richard george yeaman Grand Master Username: richyrich Post Number: 658 Registered: 4-2012 |

Kelly, I too not to be outdone would like to purchase a complete set Thank you. Richard. | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1188 Registered: 5-2015 |

Power balance test Disconnect A1 cylinder with engine at idle note rpm drop reconnect. repeat with B1. adjust carbs so that rev drop is the same. | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 424 Registered: 8-2012 |

"Adjust carbs so that rev drop is the same." And what do you adjust? The mixture or the airflow? And on which carb? | ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 129 Registered: 7-2004 |

"Now if I am not mistaken, the same tool would work for both the Shadow I and IIs...... can someone verify this?" Omar, according to Jon Waples site mentioned above, Shadow II's have HIF7 carbs while the Shadow I's have HD8's They take different damper caps with different threads, so they will each need their own bushing. I only have my set of HD8's to measure from. My damper cap has 11/16"-27 threads. Judging by the dimension that Jon provides on SherbourneMews, HIF7's have a 15/16" thread but I don't know the pitch. My damper cap was very hard to measure having only two threads to count. If you can measure the pitch on your caps, that would be a big help. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1049 Registered: 9-2004 |

[adjust carbs so that rev drop is the same.] Bob this in its self will not set the mixture to the CO specifications within acceptable limits and the CO reading taken by itself without a HC reading can be misleading!!!!!!!!!!! | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1192 Registered: 5-2015 |

First adjust air flow then mixture then repeat. Until rev drop is same and when the pistons are lifted the rpm picks up and then stumbles. if when lifted the rpm drops then the mixture is weak If when lifted the rpm goes up and doesnt stumble then mixture to rich. This method is as per SU workshop manual. My car is 1974 and not subject to emission apart from visible smoke. However last test showed 3.2% CO. which is about right. On LG the CO is much lower as expected. In 1974 the test was visible smoke only so the car cannot be tested to newer standards. always do the ignition before doing carbs. Most problems start when people interfere with the linkage between the 2 carbs. This is set in the factory and should never need adjustment. To set from scratch remove piston so one can view the throttle plates. Unscrew the main throttle stop at the front of A bank carb so that the throttles are closed then insert fag papers to make sure the throttles are closed. Unjust link to suit. open throttle and fag papers should release. Screw out 1 turn only both air bleed screws on the carbs. Adjust main throttle stop so that the fag papers are released. start engine and adjust mian throttle stop for about 700 rpm then do a power balance test etc etc. Note if when applying throttle from rest the delivery is too abrupt. adjust the throttle linkage so the very first bit of movement opens one carb before the other only by a small amount. When the throttle is closed the balance is still correct and the slight imbalance on pick up wont show. Its an old trick I got from Jags and other brit iron with twin SUs | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1474 Registered: 5-2012 |

Hi Kelly I've just checked my HD8 damper caps. As expected I get the same, 11/16 - 27. Just thought I'd double check to make sure there are no variations. Geoff | ||

Omar M. Shams Grand Master Username: omar Post Number: 915 Registered: 4-2009 |

Dear Gents, My measurement of this very small dimension is outwith the tools I have. Does anyone know what the thread dimension is for the HIF7? Thanks Omar | ||

Nick Adlam Frequent User Username: crewes_control Post Number: 77 Registered: 12-2015 |

Gents My Shadow once suffered from the dreaded miss/lumpy idle in gear and general below RR standard running when I became custodian. In my quest to nail the issues I fabricated manometers, setup dial indicators, read books/forums, pored through the workshop manual, etc etc but no luck. The carbs had been rebuilt and ALL ignition components replaced, even the relay- still no joy. In the end it came down to simple trial and error- I would inspect the plugs, tweak the mixtures, inspect the plugs, tweak the mixtures, etc etc until I finally came to a good result. Theoretically my carbs seem wonky (but still close) but the engine now runs beautifully and the plugs show a reasonably even colour, just slightly on the rich side. Piston/bore/rings wear (often unevenly), valve stem seals, coolant hotspots and sundry vacuum leaks all play a part in the way they run, especially as many of our cars still sport the original untouched engines, like mine. I was not keen on suffering sailor's disease. This might sound heretical but I say that you should tune your car to the situation, not to specs and theories. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2111 Registered: 6-2009 |

Nick Adlam wrote: This might sound heretical but I say that you should tune your car to the situation, not to specs and theories. Not heretical in any way. Things like engines behave not that unlike human bodies in certain senses, particularly as they age. Specs and theories dwell in the arena of ideals, which sometimes apply and sometimes not. It's the result that you're looking for. This is not to say that one should not try to fix anything that's obviously wrong. As you say, though, there are array of things that can be, at a given point in time, practically undetectable that can have an impact that simple other adjustments compensate for until it becomes obvious enough to fix. One of my favorite quotations, which I unfortunately have no attribution for, is: In theory there is no difference between theory and practice, in practice there is. Anyone who's lived long enough knows this to be an absolute truth. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2112 Registered: 6-2009 |

With regard to the thread dimension for the HIF7. One of the carbs on SRH33576 has never had the little brass clip that holds the plastic cap and rod in place clipped, and since the car has always run perfectly (when the ignition isn't dead - which is fixed), I can withdraw it. If someone can give me a reasonable guesstimate of likely threading, I could grab a couple of bolts with the candidates at the hardware store and see which threads in without any resistance. Not knowing whether the size/pitch is a likely "dirt common standard" I don't know how practical this proposal happens to be. Please advise. Brian | ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 130 Registered: 7-2004 |

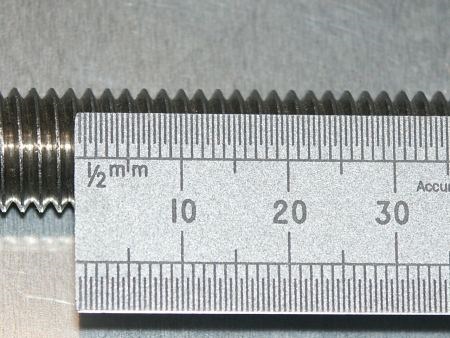

Brian, there are a couple of obstacles in the way of easily measuring the pitch on these caps. The first is the very short length of the usable thread itself. I had to use a magnifying glass and a machinist's rule/scale to try to measure across two threads. If the pitch is something really ridiculous like 27 1/2 TPI, i may still be off. The other problem is that these are proprietary threads. Neither 11/16"-27 nor 15/16"-? are standard thread sizes. You will not be able to screw your damper cap into any available nut anywhere to test for fit. Definitely do not try to screw anything into your fuel bowl. Your local hardware store might have a pitch gage available or it might be included in a tap and die set.  If you can't find one of these, you can try a series of bolts and see if the threads line up. Try these available bolts as pitch gages. In ascending order: 1/4"-20 NC or 1/2"-20 NF 5/16"-24 NF or 3/8"-24 NF 1/8"-27 NPT (this is a pipe thread - try an 1/8" pipe or pipe plug. Usually brass.) 1/4"-28 NF 10-32 machine screw If none of these clearly fit, you can try what I did and measure it with a rule.  The simplified definition of pitch is the measurement between the crests of two adjacent threads. Try to measure the distance across as many threads as possible and divide by the number of complete threads. Hopefully the HIF7 cap has more threads to measure than my HD8's. I have also sent an email to Burlen asking them for the specs. We'll see if that gets us anywhere. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 419 Registered: 4-2015 |

Kelly... Good luck getting a reply from Burlen. My past attempts at simple questions, let alone something vaguely proprietary like this, have been resoundingly ignored! | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1050 Registered: 9-2004 |

Has anyone set the carbs up doing it this way? Shut down one carb completly bring the other into play opening the butterfly enough to run the engine so it wont stall, set the CO at 3.0% Shut this carb down and do the same with the other Ajust both carbs with the synchonizer tool and set idle, re check the CO and ajust the same amount to each carb with final idle speed of 600rpm. End of play with low hydrocarbons being desirable. All done with first a correct dwell and timming set up. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 178 Registered: 11-2015 |

Patrick I synced mine in a similar way using a tach hooked to the engine. I also have a wide band O2 sensor hooked up for setting the mmixture. Setting mixtures without WBO2 or flame window is a little scary these days with alcohol gas everywhere. You can make up a simple HG H2O or ATF manometer. Take ten feet of clear hose, put in 5 feet of ATF, plug the ends into matching vac ports on each carby. Hold the hose in a U shaped loop so you can see the level in each side adjust until the sides match. I have video of me doing this on a BMWR37 somewhere, though theR37 had mechanical slides, no vacuum ports and could be adjusted by rpm or with the finger trick just as accuratly. People often tune rich by ear which is bad for many things, the biggest is more gaswashing of the cylinders while the choke is on. But as always extra HC's are way better than extra O2 so if you are going to be off, don't have anything running out lean. Best of luck. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 179 Registered: 11-2015 |

Kelly, I have a set of HD8's sitting in a box on my desk, I' ll try and pull one and take a closer look today. Are dial indicators even air tight, I would think air would bleed into the bell from the vacuum leaky indicators. What about using a rubber stoppper of some kind, or a piece of 3/8 fuel hose. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 180 Registered: 11-2015 |

Benoit, Specialists, they are fewer and farther between than the label it seems. Is it possible your specialist swapped the vacuum bells between the carbs? The piston bell fit is properly precise and matched on SU's, and if you swapped them it would ruin your sync in some very unpredictable ways. It cartainly would lose silky smooth off idle power on. It might not be noticable cruising. | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 425 Registered: 8-2012 |

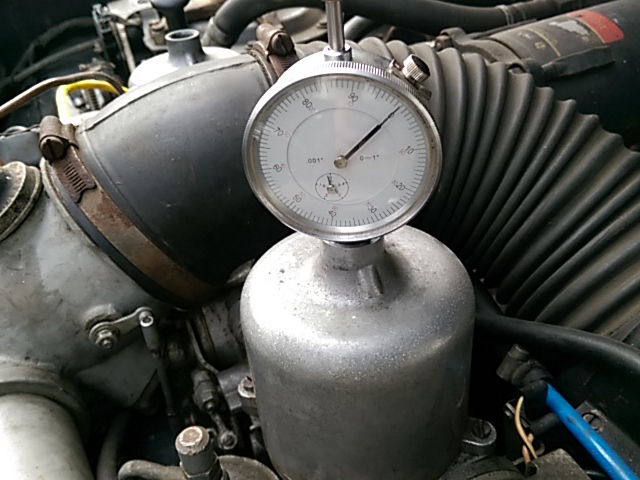

"Are dial indicators even air tight, I would think air would bleed into the bell from the vacuum leaky indicators. What about using a rubber stoppper of some kind, or a piece of 3/8 fuel hose. " The dial gauges don't need to be airtight. They are just measuring the lift of the piston. The carbs will still work when the dashpot caps are removed. In fact I have noticed that some caps have a breather hole in them anyway. As I said in the other thread, it's not even necessary to have a screw thread on these adaptors. Just drop them in and the weight will easily hold them in position. All that is necessary is a fairly close fit in the dashpot to stop them wobbling about. The upward force on the gauge is only a few grams. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 364 Registered: 10-2008 |

I have successfully balanced carbs airflow for years by just listening to the hiss either from the intake throats or in the case of RR carbs the hiss from the dashpots with the caps removed. It is possible to compare piston heights , running ,on multi carb setups using a vernier as a depth to measure the amount of rise on each carb piston. To synchronise mixtures, measure the distance between the jet and the bridge in each carb and adjust to equal, then set mixture running by adjusting each carb mixture screw equally. Mark | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1054 Registered: 9-2004 |

Mark have you tested the CO and HC after your method, the engine may seem to run OK but the specifications of CO and HC may be well out. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 365 Registered: 10-2008 |

Patrick, yes the HC and Co have been tested at Mot at my request on all of my cars even when exempt.( I detest the MOT exemption) and I have a CO meter. However I tune to max performance up a local steep straight hill.(approach bottom of hill at 20mph,floor accelerator and check speed at top of hill. I generally find the Shadow 1 best at about 4% co.If we had a suitable rolling road facility handy, I would use this everytime. | ||

Hubert Kelly Prolific User Username: h_kelly Post Number: 206 Registered: 3-2012 |

13:56 Carburetor Tune Up - Rolls Royce Silver Cloud 2 or 3 YouTube - Jul 21, 2016 Hi, check this video out, he makes it look easy. You will need to copy and paste first line(from above) into Google, I was unable to paste a direct link. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 181 Registered: 11-2015 |

Here's the link https://youtu.be/3ih5h1J-AN4 | ||

ross kowalski Prolific User Username: cdfpw Post Number: 182 Registered: 11-2015 |

Bob, You must be the uncle to which they refer! I should have read the other thread. If air lekage isn't an issue making these things should be cake. I would think most people would be using cheapo import dials which seem to have pretty strong springs so gravity fitting would probably be boarderline. I would think an anular groove with a o-ring loise fit to the fine threads or something would hold it quite nicely. Hmm. | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 427 Registered: 8-2012 |

Well, I am using the cheapest dials money can buy, about £5 each from ebay (at the time). The force required to move the plunger is virtually nill. Just a few grams at most. Certainly nowhere near enough to lift the gauge up against its own weight. | ||

ross kowalski Prolific User Username: cdfpw Post Number: 183 Registered: 11-2015 |

Some numbers, I just started the car, then pulled one of the caps on the pistons. The car ran fine so vacuum leaks are not an issue. I stuck a soda straw down the top to get a sense of how far it is to measure. I got 4.75 inches from the top if the piston cap openung to whatever it toucges in tge piston. I looked into a spare hd8 vacuum piston cap hole and noted there was a flat just below the threads that a o-ring might fetch up on. Or whatever might fetch up on, other than the threads.  This is sort of how one times a diesel pump so I pulled those out of the diesel timing coffee can in the shed.  One of my diesel timing dials has a 5 inch extension witch would work perfectly for testing. I have to put an axle in the wifes car this afternoon, but i'll bring the bell and dial with me and maybe I can check out some off the shelf parts at the hardware store. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1475 Registered: 5-2012 |

And as you pointed out on the other thread, if the engine is not running smooth the gauges can be lightly pressed down with your fingers when you actually take the reading. NB - this comment refers to Bob's previous entry - I posted it at the same time as Ross | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1476 Registered: 5-2012 |

I have to put an axle in the wifes car this afternoon Ross - hope you've some good heaters in your garage. Geoff | ||

John Beech Experienced User Username: jbeech Post Number: 35 Registered: 10-2016 |

I'm with Mark Aldridge on this, using your ears plus a piece of water hose and simply listen to the hiss the carbs make is far and away less trouble than breaking out the Uni Syn, believe me when I say this because I have a gracious plenty of experience in balancing carburetors.  - Quad Weber Weber 48IDA carbs are perfect for feeding Lulu's ferocious appetite | ||

ross kowalski Prolific User Username: cdfpw Post Number: 186 Registered: 11-2015 |

Geoff, The torpedo heater was used, but only so my breath didn't fog my glasses. I use cardboard when under the car witch is softer than concrete, lower than a creeper, and insulates. You apparently can use vw 1.6 diesel timing kit to sync RR carbs. Before I did the axle, I synced the carbs to get a better idea of the process with a dial. I just took the first section of one kit and put in the rod from the other and presto RR sync tool.  I just pulled the tool out and moved it back and forth between the two pistons. It worked fine. turns out I had synced them with .005 using lesser means. John, Nice. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1477 Registered: 5-2012 |

Ross - good tip about using cardboard as an insulator. I intend to do some work on my car this winter, when road salt enforces the winter layoff. I'll put down a couple of layers. Mark and John - you are better men than I. I have never been able to balance carbs by ear. Maybe my hearing is just not finely tuned enough to pick out the volume differences. I am looking forward to when Kelly has time to make the carburetor adapters as the idea of just removing the dampers and fitting the two gauges really appeals to me. So much easier than having to remove the U shaped air ducts. It means I will be able to check the carb balance regularly with minimal effort. Also, it looks cool. Anyone entering the garage will think I know what I'm doing. Geoff | ||

richard george yeaman Grand Master Username: richyrich Post Number: 659 Registered: 4-2012 |

Geoff I am like yourself one hiss just sounds like another, The U tube video that Hubert referred to and that Ross supplied the link was very good in setting out the procedure using the gauges and as you say it looks like you know what you are doing. Richard. | ||

Omar M. Shams Grand Master Username: omar Post Number: 917 Registered: 4-2009 |

I get to deal with lots of hissy fits at home so I am tuned out of hearing hissing of any nature..... Like you Geoff, I like the idea of accurate but convenient measurement of carbs using the dial gauges. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 366 Registered: 10-2008 |

John, those quads look an interesting challenge to set. Setting hiss by ear is purely practice and that 40+ years ago when I had my first multi carb setup it was the normal method; some of us do not change. My son usually also sets SU's by ear at least it keeps the tradition alive. Mark | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 428 Registered: 8-2012 |

I have tried setting the carbs by the listening method, and got nowhere. You have to remove the air horns, which takes half an hour before you can even start (unless you can do it through the dashpot). You have to make sure that you are holding the tube in exactly the same spot in each carb; because if you move the tube at either end the sound will change. As you can't hear both carbs at the same time, you have to compare by memory. And I was never sure whether you have to compare the volume or the pitch? But in any case, this method can only be hit-and-miss at best, compared to the dial gauges. Using the dial gauges, a fraction of a turn of the volume screw will send the needle shooting round the dial. The screws can be set with absolute and measured accuracy. I was a bit confused by the chap on the video synchronising the carbs by adjusting the butterflies. This should be done by adjusting the volume screws. (Workshop Manual Section K). | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1478 Registered: 5-2012 |

Hi Bob The video is for the Silver Cloud. It does show the principle involved however. Geoff | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 429 Registered: 8-2012 |

It is for the Silver Cloud, but those carbs still had volume screws (after 1955 as he says). He just screwed the volume screws out 2.5 turns and left them there, then did all the volume adjustments with the butterflies. Very strange. I do not have the Silver Cloud manual, so this may be the official RR method for all I know. But on carbs fitted with volume screws, they are the best way to adjust the volume! | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1479 Registered: 5-2012 |

Hi Bob I stand corrected. I had just assumed the carbs did not have volume screws however you are right, he screwed the volume screws out 2 1/2 turns and then ignored them. My experience is adjusting the carb balance by loosening the clamps on the butterfly spindles is very difficult, particularly on older cars where the spindles are worn slightly and the clamp tends to reposition itself when the clamping bolts are tightened. This should only be used for coarse adjustment. The very reason the volume screws are there is to facilitate the fine adjustments. Following the video makes a simple job much more difficult. I would go as far as to say the video is just plain wrong. Geoff | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 430 Registered: 8-2012 |

I agree. Although it is still a useful video if you are aware of this anomoly. And there is also the eccentric pin that you pointed out to us on the other thread. Something that most of us never even knew existed! This can also be used to adjust the butterflies, but I think the least said about that method, the better! | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 367 Registered: 10-2008 |

Bob, on the later carb set up as on Shadow2, I believe, but certainly on Spirits, the only volume adjustment between carbs is via this eccentric adjuster and the most successful way I have found of setting this is to slacken the adjuster and hold one carb open with feeler gauges under the stop ( which is a redundant casting with no adjusting screw)and then synchronise air flow via the idle adjustment screw on the other bank and then relock the eccentric ! If the eccentric comes loose, one carb shuts down completely at idle : it happened to me. Air hiss is checked via damper caps, and is worth rechecking whilst someone holds the throttle open at say 2000 rpm. Mark | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 431 Registered: 8-2012 |

I freely admit that I know very little about the later HIF7 carbs as fitted to the Shadow 2. Seems like a retrograde step to me! If I had a Shadow 2 I would probably try and fit the earlier carbs! | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 368 Registered: 10-2008 |

Bob, It is poor compared to the Shadow 1 setup. A conversion would be a good idea. Anyone done it ? Mark | ||

John Beech Experienced User Username: jbeech Post Number: 36 Registered: 10-2016 |

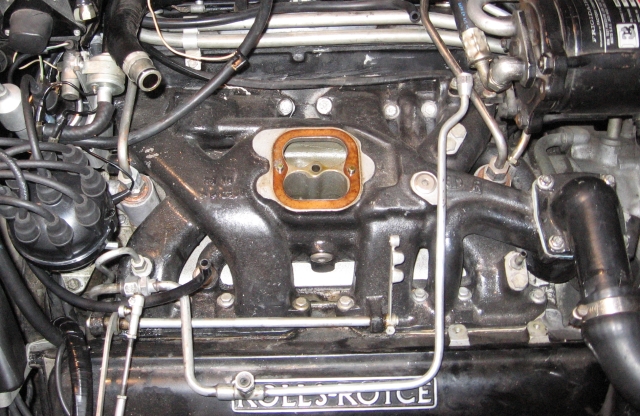

Does anyone have a photo of the intake manifold with the carburetors removed? | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1481 Registered: 5-2012 |

John I took this when I first bought the car and had not at that time cleaned the engine. It was covered in Las Vegas dust. I have other pics if this one doesn't answer your question.  Geoff | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1482 Registered: 5-2012 |

| ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 136 Registered: 7-2004 |

To put a little button on the end of the saga and also to aid future searchers, the threads on the HD8 caps are 11/16"-26 and the HIF7's are 15/16"-26. | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 276 Registered: 6-2009 |

Kelly, if ever you decide to make a kit for the HIF7's I'm ready to buy one. Benoit | ||

Kelly Opfar Prolific User Username: kelly_opfar Post Number: 138 Registered: 7-2004 |

Hello Benoit, I have HIF7 adapters in stock now and updated my ad in the "For Sale" section. I've sent you a private message. Kelly | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 281 Registered: 6-2009 |

Mark, when you describe how you synchronize HIF7 carbs, you talk about holding a carb open with feeler gauges under the stop. What exactly do you mean and where is the "stop" on the carb as I just can't visualise it. Kind regards, Benoit | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 282 Registered: 6-2009 |

Today I installed the carb synchronising dial kit that Kelly made just to see what the results would be. Following video shows you what the dials indicated : https://www.youtube.com/watch?v=0udva7uW_R0 The A-bank dial is all over the place. I ruled out a faulty dial by switching them between caarbs with the same result. What could cause this ? | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1546 Registered: 5-2012 |

Hi Benoit I think you can rule out lack of damping oil as when I balanced my carbs I did so without any oil and they were rock solid. I think you need to remove the suction chamber and see if the spring has gone soft or is broken. Also do a piston drop test to make sure the piston is not worn. Failing that compression test the engine to check there are no faulty inlet or exhaust valves. What great devices these gauges are. This fault would not have shown up on the cheap airflow meter I used to use. Geoff | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 385 Registered: 10-2008 |

Benoit, sorry for the delay in replying but I am housebound with Bronchitis, on an enforced 10 day min rest ( Doctor was emphatic !)As soon as I can get out to the car I will photograph the setup. With regard to the video, have you got a plug or plug lead fault. ? Recently, I had a Platinum plug fail after 10k miles with no warning but on a plug tester provided a very weak spark, the others were fine. One new plug and poor running was sorted. | ||

Omar M. Shams Grand Master Username: omar Post Number: 989 Registered: 4-2009 |

Dear Benoit, Geoff is right. The suction chamber must come off. Then you will either see a perfectly normal set up or something glaringly obviously wrong. If it all looks normal, swap the two chamber assemblies and then see what happens. I am most intrigued to know whats causing this effect. | ||

John Beech Prolific User Username: jbeech Post Number: 162 Registered: 10-2016 |

Mark, Don't mess around with the 10-day rest because it can become pneumonia and then you may be in trouble before you know it. John, who has twice been in ICU for pneumonia because he didn't believe the doctor - people die of it! | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 284 Registered: 6-2009 |

I removed the suction chamber on the carb : the spring and everything else looks fine. The piston drop test didn't reveal anything suspicious : there was no difference between both pistons, although I don't know how fast the should drop (they travel quite fast, even with the holes blocked). I then swapped them over to see if this would influence the results, but the dial gauge on the A-bank carb still moves around. I then replaced all the plugs with new NGK Irridium plugs and tested the plug leads, which didn't reveal anything wrong. It's not clear for me how to interpret the dial gauges. Even with the A-bank one moving about, there is a big difference between both carbs, which would indicate that they are not synchronised. Marc, John is absolutely right. You only have one pair of lungs so follow your doctor's advice. I'll get the information when you're better. Benoit | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1548 Registered: 5-2012 |

Hi Benoit The next step is a compression test. If you have a chipped valve or one that is not closing properly on one of your cylinders, this will cause the effect you are seeing. Hopefully it will not be this, but given your carbs are ok, you need to eliminate this possibility. You can still balance your carbs. I would take the high reading on the A bank. Geoff | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 285 Registered: 6-2009 |

Geoff, I will do a compression test next. If there is a problem there I guess it will be on the A1, A4, B2 or B3 cylinder as these are being fed by the A-bank carb. In the meantime I redid the piston drop test taking exta care to plug both vent holes with rubber bungs and taping over it, just to make sure. As you can see in the video it takes about 1,2 sec to drop. I don't know if this is correct as I read that on a SU carb it should take between 2 and 7 sec depending on the type of carb you have, with HIF carbs taking the longest. https://www.youtube.com/watch?v=y059hdXvVwg | ||

Omar M. Shams Grand Master Username: omar Post Number: 990 Registered: 4-2009 |

We are all assuming that the inlet manifold is clear of any obstructions and that there is nothing in there that may be flapping around. Also we are assuming that the inlet manifold has no take off points that are being used for any other purpose. Benoit - can you verify all this when you do the compression test? Thanks Omar | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 386 Registered: 10-2008 |

John, Benoit Thank you for your wise advice. I am taking this problem seriously, but your wake up call is appreciated. Mark | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1549 Registered: 5-2012 |

Benoit I can't help regards the speed of the piston drop. I looked at other youtube videos and your's seemed a bit fast, but you are getting suction and the engine does run ok so I would look elsewhere. You could try cleaning the bottom of the piston where the dial gauge contact point seats. A small piece of grit or debris at the bottom might cause this strange problem. When I set my carbs I removed the pistons, tipped out the oil and used cotton buds to make sure the bottom of the hole was clean. It's worth checking - just in case. Geoff | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1550 Registered: 5-2012 |

Hi Mark Here's wishing you a quick recovery. My way of dealing with chest colds is to keep indoors at a constant warm temperature for a few days. Geoff | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1250 Registered: 5-2015 |

With damper unscrewed the piston should drop quick and hit the bridge with an audible clunk thus proving the piston is freely moving under its own weight and the force of the spring. If not then loosen screws tap with screwdriver handle and retry. Then install damper which should give resistance like a suspension shock damper. Also both engine oil and ATF work about the same so what ever is handy will do. Theres seems to be confusion about SU carbs so may I suggest reading the SU web site which explains things about carbs that one wouldnt even know about until told. Dont assume. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1079 Registered: 9-2004 |

Chronic vac leak carb etc, many things to check IMO | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 1259 Registered: 5-2015 |

Good point check the cruise control whatsit these units can leak vacuum and the hose goes very brittle. Also the vacuum module and associated pipe work. Note that there maybe a restrictor in the pipe to the gearbox vacuum module which when replacing the hose can go awol. Also the fuel weakening device and associated pipe work. Which is covered in Tee One Topics and in this forum. | ||

Patrick Francis New User Username: jackpot Post Number: 8 Registered: 11-2016 |

I read somewhere that balancing the carbs with the airscrews should be done to a maximiu on 3 turns on any carb, otherwise you get whistling- the rest should be done with butterfly adjustment? SS1 that is. | ||

Vasco Pridat Yet to post message Username: monsterbabybln Post Number: 1 Registered: 03-2023 |

old thread.. but I am having the same issues right now.. my engine shakes like crazy during idle and i tried to tune the carbs.. and get the exact same thing on the gauge on Bank A which is all over the place.. did you solve the problem Benoit ? | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 821 Registered: 11-2017 |

First make sure the ignition system, Wires, cap and rotor are fine and also NO manifold leaks. Trying to balance the carbs with any issues is a wasted effort. Full description is in the workshop manuals. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2554 Registered: 09-2004 |

Robert S, so what is your method of procedure I do it a simple way without a manometer! | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 822 Registered: 11-2017 |

My 1981 Silver Wraith II is fuel injected so no worry here and my 1974 Shadow, which has carbs, I use the dial indicators. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2555 Registered: 09-2004 |

Robert FYI your FI system can and will give you some worries if you or your car live long enough. As for the carb synchronizing another way! this was taught to me by a Sun engineer(Jim Biddle) Kings lynn back in the sixty's before Snap-on name came about! Dial indicators no good for the many carb balancing faults. Not using a manometer. So which is the best way. To start without manometer, correctly gap plugs, warm up engine and use a scope to check the firing lines, should be all even with firing order. This together with a c/o meter and RPM meter will allow you to sett and balance the carbs or show air leak failings, using the engine firing order is key with the scope RPM meter and C/O. Do remember each carb feeds A and B bank. | ||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 823 Registered: 11-2017 |

"your FI system can and will give you some worries if you or your car live long enough." Alot less maintenance than a carb system | ||

Jim Walters Frequent User Username: jim_walters Post Number: 381 Registered: 01-2014 |

Patrick, if the dial gauges are "no good" as you say then why does Rolls-Royce instruct one to use them to balance the carbs? SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2557 Registered: 09-2004 |

JIM,R Royce back in the day of shadow 1-2 the RR way was a time consuming exercise that was common with such jobs costing much expense! Often using dial gauges etc for synchronizing the butterflies the end result can be a system with other faults built in with an engine that never will run 100% Many RR dealerships did not have diagnostics with oscilloscopes let alone co meters that could do hydrocarbons Air leaks more on one inlet tract! etc etc inlet cam lobe worn just a few to mention.  |