| Author | Message | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 269 Registered: 4-2015 |

Re: 1968 Shadow MPW Coupe CRX2541 Thinking it would be a simply switch, today I embarked on changing the viscous fan coupling in the hopes it would have an affect on the "running hot" issue hanging over from the last time I drove the car a few years ago, since nothing else that I had tried had made any change in the symptoms. I will later try to find that thread, but for now I would like to know if anyone else has "been there, done that". Apparently the early engine did not even have a viscous coupling and it was added later per owner request and hence the scarcity of documented information. Somewhere in other prior threads I got the impression that the Hayden 2747 was a suitable current application, and even ordered one, but at that time had already tired of fussing with the car and simply parked it without installing the Hayden, in preference for the "trusty and dependable" Silver Dawn which has been the daily driver since. Time finally came to switch cars again, and I retrieved the MPW from storage. Upon removal of the suspect coupling, I found it to be entirely dissimilar to the Hayden. See photos posted below. The Hayden is larger in diameter and quite a bit taller. The larger diameter prevents it from fitting into the curvature of the aluminum five bladed fan. I neglected to take photos of the fan, but that is probably immaterial unless requested. The extra length of the Hayden would put the assembly right into the radiator core, so clearly the Hayden is unsuitable. Examination of the original showed no evidence of leaking oil, and it turns rather stiffly on its shaft, not unlike the resistance felt on the new Hayden, and so there is no real evidence that the original coupling is actually defective. Upon close inspection, I found a metal glued on tag that identified the original as "Smiths 3/70 Code FJU 3002" The "Smiths" is the same script and logo of the well known manufacturer of other instruments and components. I presume that 3/70 is the manufacture date and indicates that it was installing soon after delivery of the car and is thus presumably original and 46 years old. Car has 75,000 miles. Dimensions of the Smiths are 6" diameter, 2.5" tall. The Hayden is 7.25" diameter, 3.5" tall. Bottom line: I have found nothing on internet based on this data. I am not necessarily looking for a Smiths, but rather a suitable replacement. Does anyone have any suggestions?    | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 270 Registered: 4-2015 |

Photo of the subject vehicle, CRX2541, FYI  | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 271 Registered: 4-2015 |

Photo of the label:  | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 272 Registered: 4-2015 |

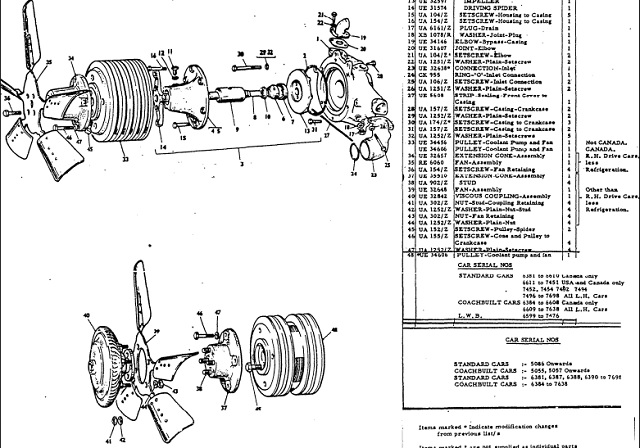

Searching the prior threads, I found this photo posted by Brian Vogel...thanks Brian. My setup resembles the bottom illustration, but I cannot see the part numbers and will look at the parts manual. I also see that in my angst about the coupling being so different that I confused the placement of the fan "wrong way around" so the diameter of the Hayden is not the issue, but the height is, as it moves the whole coupling and fan assembly right up to the radiator. So what is needed is a coupling of the same height. Diameter is not the critical issue.  | ||

Omar M. Shams Grand Master Username: omar Post Number: 702 Registered: 4-2009 |

Dear Christian, The Hayden and other viscous couplings that are proposed for this application are not the original parts that are meant to be fitted to a Rolls-Royce engine. someone has looked at readily available and cheap part and has observed that the part looks like it will fit. in terms of how effective this part will be varies form application to application. It could be that your car would sound different because the fan is engaged when it shouldnt be. In short - you are not fitting the right part to your car. In most applications this part will work with some compromise. some car owners accept the compromise if that is say noise or fuel consumption or appearance etc. In your case you have a coachbuilt car which will have the radiator perhaps closer to the engine - in your case this alternative part will not fit (physically). My recommendation given that this part has already served the car for 40 years is to replace it with a proper RR/B part. Dont assume that the lack of leaked oil means the viscous coupling is good. The only test is to try it in another car and then see if it works in another car or not. if the other car also overheats once you install your Viscous coupling then you know it is defective. | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 273 Registered: 4-2015 |

Omar... Thanks for the idea. Not having another compatible car to switch with does create a problem though. While it would not be surprising for a 45 year old and 75,000 mile coupling to be defective, I was simply looking for an expedient test before spending the big $$ for a Crewe product, only to find that against the odds, the coupling was not the source of the problem. A sign seen at an auto parts store tells that story: "If the part you bought is not the part you needed, you now have a spare." If I could rig some sort of bracket to disable the clutch entirely and make the fan direct drive again, that would also be a suitable test. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1969 Registered: 6-2009 |

Omar, Now I'll have to disagree with you, but only to an extent. Viscous fan clutches are not "high tech" and, if they fit such that the fan is positioned correctly, engage, and disengage at the appropriate temperatures then they are essentially interchangeable. They are pretty much in the same class as thermostats, and are no more "precision engineered" than thermostats are, either. There's a lot of "slop" in the precise temperatures actual examples of the same item actuate when you compare them against their spec ratings. Also, Crewe never made the OEM ones, but the practice of renumbering every blessed item in a RR or Bentley with their own numbers effectively hid and continues to hide the actual manufacturer and part number (or plural of both those things) for dirt common parts like a viscous fan clutch. To my knowledge, no one has yet identified a commonly available, but fully functionally compatible, viscous fan clutch for the very early SY series cars. I have absolutely no doubt that it exists, and is what Crewe Original purchases and repackages. It will just take someone who needs one to do the necessary research to uncover what it is. The one used on these cars is "an odd bird" in several ways in addition to the ways the later ones were, too. Brian | ||

Omar M. Shams Grand Master Username: omar Post Number: 704 Registered: 4-2009 |

Dear Brian, Yes a viscous fan clutch is a simple device but they are not all the same. I was only speaking from experience where i had fitted a cheaper version of the Bentley part and the damn thing roared the whole time. I then bought the real part and it worked perfectly and silently too. To look at the two parts they almost looked identical. When I had the wrong clutch in my car I hated the car. I was only conveying a sour experience to help others not fall in the same trap. | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 274 Registered: 4-2015 |

I just received an email from a gentleman who specializes in rebuilding fan clutches...albiet not cheaply. $350 plus shipping. Albers/Zionsville has a "repro" at a cost of $450 plus shipping. Standard fan cluthces, of which there are literally hundreds of variations, are typically priced at under $100 so the extra cost is the "repackaging". If only we knew what that "repro" was!! The rebuilder's comment was that the Smiths unit (I sent him the photos) was actually an Eaton. Makes sense. Eaton built the unit and attached the Smiths name. Smith then supplied to RR. The real problem that I cannot get past is that I am not even sure beyond possibility that the Smiths unit is actually defective. To me, the only real test is to jam the coupling so that it is fixed and rotates all the time. Even a properly functioning coupling still does not rotate at full speed. If I can similate a fan rotating at full speed and the temperature remains the same, then the coupling is not the problem and I have saved $350-$450. Today I will be taking a closer look at whether this "jamming" of the unit is possible. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1970 Registered: 6-2009 |

Omar, I know there was a thread on these forums, including pictures, where emphasis was placed on not fitting "heavy duty" versions of the viscous fan clutches as opposed to regular duty ones for precisely the reason you state. I'll be darned if I can find it at the moment. All I was saying is that if you know the actual specs as far as the engage/disengage profile for the viscous fan clutch that came with a car if you can find another with the same (or very similar) specs that fits correctly it's a mighty safe bet. This is one of the reasons, over many years now, I have made it my mission to try to find out what parts, from what manufacturer(s), were actually used on our cars but given a Crewe part number. The older these cars get and the weaker support gets (and it has been getting weaker, but is still great compared to many) it will be more and more critical to know what you can pick up "from the local auto parts store" that was fitted to millions of other cars that either was used or can be used as interchangeable on ours. Even if it's not critical to some (and I know that it is not), those of us operating our cars on a budget or who are simply cost-conscious prefer to be able to source something that's a full functional equivalent quickly and at greatly reduced cost. I remain convinced that the reproduction units that are being sold are, for the most part, not reproduction units at all. Some very smart person has actually figured out what they are and what their "normal application" is, sources them, and resells them. There are a few things that we know are Crewe-specific that are almost certainly reproductions made to order in small runs. I'd be shocked if a viscous fan clutch fell into this category. Christian, if you do eventually buy the repro unit please take very detailed photographs, preferably with a caliper/ruler used as necessary to give critical dimensions. Virtually every successful parts matching undertaking I've ever been a part of starts out with matching dimensions and works out further details from there. If there are any actual manufacturers markings that have not been removed those are the holy grail. Brian | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 276 Registered: 4-2015 |

Brian... Will do, however with the vast number of viscous couplings out there, I find it difficult to accept that there is not one that will fit on the early application. If I had a source to the catalogs and dimensional specs, I would devote my time to sorting through the hundreds available, but I do not have those sources. My main concern is first to eliminate the coupling as cause or contribution to the problem and if they were cheap I would simply replace, but those available from the usual sources are not cheap. Although everyone has their own version of how to "test" a viscous coupling, mine, if possible, is the most direct and absolute. Clearly, if the viability of the coupling is in doubt, replacing it with a solid coupling and observing results gives a direct answer. If there is additional cooling, the coupling is at fault. If there is no change in conditions, the speed of the fan is not the problem and hence, the coupling, even if not working properly, is not the problem either and replacing with a properly function unit will not solve the immediate problem. I will see if it is possible to proceed on that theory. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1972 Registered: 6-2009 |

We are, again, in violent agreement! I just don't have the motivation, nor the original to use as my template, to try to find it. It's also possible that its application is not "conventionally" automotive. There are viscous fan couplings that get used for all sorts of water cooled engines. I am blessed that we have several "old school" parts shops in Staunton, specifically my local NAPA outlet and the Fisher Auto Parts store. Both have proven invaluable over time in helping me to find that needle in the haystack, since they have the catalog knowledge I don't have from having needed to look this stuff up innumerable times. I have also had folks willing to take the time to try to physically match to stock when a catalog search was fruitless as a starting point. This can often lead to a more focused catalog search, if still needed, afterward. Brian | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 277 Registered: 4-2015 |

Zeroing in on the problem, if not the solution. Applying the endlessly useful technique involving duct tape and bailing wire, I reassembled the fan, original fan clutch, and nose cone with pieces of wood and plastic jammed between the two sets of four nuts, then wrapped in duct tape in order to create a fixed fan. What I found was encouraging. Because fan is running constantly, at starting temperatures there was significantly more air flow. I left the engine idling and coolant heated up as expected, thermostat opened and coolant temps seemed to stabilize at about 190F or less, no matter where I measured...top tank, top of radiator core (much less at bottom of core) bypass to water pump, thermostat housing, etc. Gauge temperature also stabilized where I would prefer it to be, in the middle of the white band. As far as the alleged additional "noise" from the constantly running fan...I did not notice that at all. After about 10-15 minutes of idling, no variation in temperatures, and encouraged, I took a six mile drive, all at city residential area speeds of 20-25mph, or less, with the first mile or so down a gentle hill. No change in gauge indicated temps. Then level for about a mile and then a three mile climbing grade. Climbing the grade, I was a bit disappointed that the gauge indicated temp gradually rising towards top of white band. At crest of hill, I turned around, retraced the route and over a one mile descent to where I live, the gauge temp quickly dropped back to the normal range. Stopping the engine and measuring the heat soak temperatures found them to be back to the 185-190F and not overheating as had previously been the case with the suspect viscous clutch. Ambient temperataures were about 75F. While not conclusive, this test is encouraging. Temps did not get as hot as before, and once hot, temps dropped faster than before, and heat soak conditions did not seem to be as bad before. The wood and duct tape "fix" is temporary at best and I hope that it will hold together to do the test again. The interim conclusion seems to point to the viscous clutch as not being properly functional. What with the complete absence of additional percieved nose created by the constantly running fixed fan, and the $450 quoted price for the "repro" coupling, I am seriously thinking of having a solid coupling machined to adapt the fan straight to the nose cone. I suppose that decision depends on the cost. Fall back position is the pricey repro coupling. Will report more as the project progresses. | ||

Jim Walters Frequent User Username: jim_walters Post Number: 89 Registered: 1-2014 |

I wish I could remember which one it is. I think it was either a Triumph TR7 or a Jaguar XJ6 that uses the same viscous coupling. It definitely is the same as one used on another British car as I had one in stock I put on a Shadow about four years ago. I haven't had to replace one since then so it's not fresh in my memory. SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 278 Registered: 4-2015 |

Jim... Both Brian Vogel..for inclusion in his Parts Compilation...and I, because I need one...will be grateful for any recollections that do come to mind. Are you sure it was for the early (pre-about 10,000 chassis number) and not the later engines? Even though the parts diagrams show the SAME illustration for both early and later couplings, the parts are definately different as shown in the photos posted. The part numbers shown in the parts manual reflect the change...but not the illustration, which is for the early style coupling. FWIW...early coupling part # is UE32842 and later part # is UE37061, which apparently interchanges with the Hayden 2747. What is missing from our collective data base is the substitute for the early number. I will take a look at couplings for TR7 and XJ6 to see if anything clicks. Meanwhile, I will be looking into having a distance piece made up to allow the fan to be attached directly to the cone to create a fixed assembly as was original to the very, very early Shadow engines...like mine. I just came in from my nightly 6 mile trip into town to the grocery store and results are same as before...NO alarming increase in coolant after pulling the grade on the way home. Upon arrival home, IR temps were, at the most, 185F at radiator core top at inlet from thermostat, thermostat housing, and lower everywhere else. That is good news! Gauge did reflect an increase from midpoint on the scale to about 1/16" below top of white band, probably due to the temperature sender on those early engines apparently being not at the thermostat housing, but rather at the rear of one of the cylinder banks and up against the bulkhead where, due to aging circulation in the cylinder head, the temperature is most probably higher there than at the thermostat housing...at least that is my explanation of why the increase shows on the gauge, but not confirmed by IR heat readings. I like these results A LOT more than previously when that trip home and up the grade would raise the IR readings to 210F and more. I think that the problem has been located. The duct tape and wood jamming the assembly seems to be holding up for now, and I hope to do another test in the heat of the day tomorrow, then remove the "temporary fix" as I do not want it disintegrating and throwing several 2" long pieces of wood (the jamming devices) around the engine compartment! Once the confirmation is in, I will go back to the defective coupling while awaiting a permanent resolution. Also confirmed is the complete lack of additional noise caused by the fixed fan. Whether or not the argument regarding the extra power needed by the engine to drive the fan all the time is academically valid, I will live with it. While perhaps factually true, I cannot believe it to be either signficant in quantity, or relevant in practical reality. Put that thinking and recollection cap on, Jim! Thanks for the tip just the same! | ||

gordon le feuvre Prolific User Username: triumph Post Number: 123 Registered: 7-2012 |

The early cars were fitted with a fixed fan not sure about world wide, but in UK there were customer complaints of heterodyne, similar to a twin engine prop. plane being out of phase. The factory published a Service Bulletin to retrospectively fit viscous fan in cases of complaint. We did a few cars. The parts manual page might have been updated at that time to reflect that a car might have one or other. Cannot remember year, but seem to think it was around 4000 series, 1968? The way to test the viscous operation is to FIRST remove gearbox safety switch with box in neutral (4 speed) park (3 speed). Start car from stone cold, leave on fast idle i.e do not kick choke off. Initially you will hear fan roar. After 3-4 mins, should gradually decrease until No fan roar. After 15 or mins, fan will be heard to start to drive, which means wax has melted and starting to drive as a fluid coupling in auto box does. The fan roar will then gradually increases to level first heard from cold. Kick off fast idle and stop engine. Might take a couple of times to tune one's ear into this. There MUST be some one out there, with abulletin book, really usefull. My ex. company skipped the lot!! | ||

Alan Dibley New User Username: alsdibley Post Number: 6 Registered: 10-2009 |

""There MUST be some one out there, with a bulletin book, really useful. My ex. company skipped the lot!!"" I have a bulletin SY/L11 which states that, to improve cooling at low speeds, a smaller pulley on the water pump was fitted along with a larger viscous unit to cope with the increased speed (1.2:1). This applies to 4-door saloons after 11224, long-wheelbase saloons after 11288, Corniche after 11284 and all Corniche fitted with "the increased performance engine"(???). New parts are not mixable with the parts - The viscous coupling is bigger, the fan is modified to fit this, and the pulley mounting is changed to four-bolt, and the water-pump impeller is smaller to prevent cavitation at high speeds so the right impeller must be fitted to the appropriate pump body. I suppose this might not apply directly to this thread but does illustrate the point that there are different couplings for early cars. There are also different belt part numbers. That should muddy the water a bit more. Regards from Alan D. | ||

richard george yeaman Grand Master Username: richyrich Post Number: 533 Registered: 4-2012 |

Hi Alan very useful information these early cars had a lot of upgrades from year to year and also changes made by owners sometimes make it hard to make sense of what should be there and what isn't I always try to keep everything as it was, Maybe you have a lot more of these gems of information hiding away somewhere. Richard. | ||

David Gore Moderator Username: david_gore Post Number: 2087 Registered: 4-2003 |

A similar situation reportedly applied to alternator pulleys - cars delivered to countries where city driving predominated were fitted with smaller diameter pulleys to ensure the alternator would keep the battery charged in stop/start slow speed city driving whereas cars delivered to countries where highway speeds were more common were fitted with a larger pulley to increase the life of the alternator brushes and bearings. It is my understanding all "colonial" specification vehicle were fitted with the larger pulley. | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 279 Registered: 4-2015 |

Also of interest, and as alluded to by Gordon, are specifically the changes included in the "kit" installed into the "very" early Shadows that were originaly delivered with a fixed fan that was used to convert to a fan clutch. The coachbuilt MPW may or may not be representative of the standard saloons, but the space between the front of water pump and rear of radiator core is very limiting. The inclusion of the clutch, which added only 1" to the length of the assembly, puts the fan to within about 1/2" of the radiator core which is a bit tight for my liking. This distance could have been increased by using a shorter cone on the water pump as there are several inches to spare in the direction of the engine before interference with other components. I suppose that the "kit" as used was considered "good enough" until the entire system could be redesigned for the post-11,000 engines. Today's test on the same hill, this time in 85F heat, confirmed that the fixed fan seems to lower the IR temps to a much more reasonable level, and thus confirming that the existing 45 year old clutch is not operating up to snuff. On direction of another member whose thoughts are most appreciated, I believe that I have found a suitable "substitute" clutch that simulates the dimensions of the "very early" clutch and which was used by Jaguar. It was under $50US delivered, so I have ordered one for verification. Meanwhile, for the amusement of everyone else, especially those who hate front end clutter...Robert Noel Reddington, will go apoplectic!...I have included a few photos of the front of CRX2541. I used to collect badges and had them displayed on a bookshelf, and upon being told (this was years ago) that they belonged on a badge bar, I purchased the MPW for that purpose and fabricated the additional lower license plate frame with another badge bar incorporated. The license plate of the MPW really is "68RR"! The Flying Lady is no longer lonely, and has plenty of good company!    | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1978 Registered: 6-2009 |

Christian, If said viscous fan clutch proves to be suitable both for fit and temperature regulation I fully expect the details on the maker and the part number!! Brian | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 281 Registered: 4-2015 |

Brian... Absolutely. While photos and described specifications are one thing, actually fitting remains to be seen. We shall see. Hope springs eternally! | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1979 Registered: 6-2009 |

Christian, This was the route I ended up taking when circumstances required me to find an alternate viscous fan clutch and fan blade set for LRK37110. I know I went through at least 2 different sets of fan blades and, I believe, 3 viscous fan clutches until I came up with a combination that worked. I now have a metal fan like the earlier cars, but not with the asymmetrical placement of the blades. If I could have determined an alternative source for the original plastic blades I would have gone with those, but that search came up empty. All the money spent, combined, didn't come close to the asking price for a single used set of the fan blades. If you added the original fan clutch, well . . . Brian | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 282 Registered: 4-2015 |

Brian... Yes, while I would dearly prefer to be able to "solve the problem" of the smaller early clutch, for the good of all who will in the future benefit from that information, I find solace in the fact that there is always the back-up of simply eliminating the clutch entirely and converting back to a fixed blade set-up, so one way or the other, I will get the car working again. | ||

Patrick Ryan Prolific User Username: patrick_r Post Number: 276 Registered: 4-2016 |

All I can say to those images Christian is WOW! | ||

gordon le feuvre Prolific User Username: triumph Post Number: 124 Registered: 7-2012 |

Please do not forget that if you are worried about fan to radiator clearance, check the front engine mount. this incorporates an adjustable physical stop that stops engine moving forward under braking. Details are on workshop manual under engine section. | ||

gordon le feuvre Prolific User Username: triumph Post Number: 125 Registered: 7-2012 |

Please do not forget that if you are worried about fan to radiator clearance, check the front engine mount. this incorporates an adjustable physical stop that stops engine moving forward under braking. Details are on workshop manual under engine section. | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 287 Registered: 4-2015 |

Gordon... Forgive me but I miss the point. Are you suggesting to check the stops because they may have already allowed the engine to move forward which is the reason why there is only 1/2" clearance, or are you suggesting that I check the stops to be sure that they are tight and do not allow the engine to move forward and damage the radiator. While it is certainly prudent to check and verify that the stops are tight and functional, the mere theory of the engine moving forward confuses me. Since the engine is connected to the transmission and the transmission to the drive shaft and rear axle, essentially the entire drive train is one unit and that entire unit would be moving if the engine were to move. Certainly there are more "hold down" points on that entire assembly than just the engine stops at the front? If I am correct in that assessment, before the engine (and entire assembly) would move forward under hard braking, there would have to be a lot more amiss that simply a loose front engine stop. Of course I will try to check it, but what am I missing in terms of the "entire assembly moving" picture? | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1558 Registered: 6-2006 |

The engine weighs a ton and is mounted on rubber. It will move forward as far as it is allowed to . . . And happily chew a radiator if it can. With a viscous coupling it will just chew the rad . . With a fixed fan it will swallow it to. There is nothing behind the transmission to anchorus it because of the splined sliding joint on the output shaft. | ||

gordon le feuvre Prolific User Username: triumph Post Number: 126 Registered: 7-2012 |

Christian, there is a correct(small amount)that the engine/gearbox assembly is designed to flex on the three mountings under braking and of course to do their job of absorbing vibration. the prop shaft/diff is not designed to "hold back" the engine/gearbox assembly under braking as the prop shaft on 4speed (pre gm400) or the tail shaft flange on gm400 is designed to absorb the changes in overall length between rear of gearbox and diff input flange caused by everything being rubber mounted and moving under torque/load. This all means that the mass of engine/gearbox needs to be controlled under braking to avoid fan hitting rad. The way of doing this is to have a stop as part of the front mounting positioned under timing cover. The mounting is bolted to lower timing cover "foot" and other part is bolted to subframe. These bolts also hold an adjustable bracket that will limit the forward movement of engine for the reasons above. Sorry to ramble on, hope I have clarified! | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 288 Registered: 4-2015 |

Paul and Gordon... Yes. Thanks both. With a bit of reflection it should have occured to me about the splined shaft. Bottom line is that I am having the MPW in to ACME for some minor issues on Wednesday, and while we have it on the rack, will observe those mounting points to see if they are functional and if they have perhaps moved to their full forward position already, and generally assess the situation given that all the the rubber mountings everywhere in the chassis are now 50 years old, dry, hard, cracking, etc. Better to check and be sure than find out about the problem later, when the movable object encounters the immovable object! Ouch! | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 289 Registered: 4-2015 |

Re: CRX2541 Further on the "faux" fixed fan tests: For the past several days while awaiting the arrival of the possible replacement coupling, I have closely monitored the IR heat readings of the engine. I had also been a bit reluctant to take the car up to speed, but after adding a few more wraps of duct tape, gave it a try today while doing errands. I had been told that the "fan noise" was most noticeable, rather than at low speeds, but instead at higher speeds and I can report that even at 60mph I could not detect anything unusual or annoying. The wind noise with windows partly open, the leaking weather stripping wind noise with the windows closed, and the exhaust rumble were all sufficient to mask any fan noise, so if necessary, I have no problem with the conversion back to a permanently fixed fan. The before and after heat readings at radiator core and thermostat housing, even in today's 85F heat (heat wave for San Francisco area), have been very encouraging. Whereas before with the old coupling (and consequently not full speed fan) the temperatures at core and thermostat got up to 240F, and the gauge hovered at just shy of critical, which were certainly cause for alarm and kicked off the entire episode, with the fan working full time and full speed, those readings now seem to stay in the 190F to 210F range, the later when climbing a 3 mle long hill that I chose for that "hill climb" test, and that highest temp dropped off immediately to 185F upon turning around and descending the hill. Clearly the low fan speed was a contributing factor to those prior higher temperatures. Now...here is the latest question: I do notice that even with the lower temperatures, the gauge reading does still eventually climb up to the top of the white band. Not as badly as before, but still a concern. When I take IR readings at the prior locations however, the reading are still in the 190F-200F range at all tests taken during today's various errands, irrespective of the guage "indication" of heat. I took the readings at every stop. As noted elsewhere in these threads, I surmise that the reason the gauge reads hot, but the IR readings do not, is the location of the temperature sender on these very early engines being at the rear of the head where the circulation is the worst and consequently the heat the worst. So...that baits the question of whether there is any way to get better circulation to the rear? Possible exterior water lines going directly to the rear, blanking off others to force the flow to the rear, descaling of the interior passages, et cetera. All ideas are solicited. Even though the fan issue seems to have materially affected the temperatures at the radiator, I would still like to address the higher temperatures at the rear of the heads, which over the long run, are less that desirable. Ideas? Thanks. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1298 Registered: 5-2012 |

Hi Christian I can't help with any ideas for exterior water lines going to the rear area of the engine, although I absolutely agree with your diagnosis. I just wanted to mention, as an aside, that I too had a lot of wind noise from my windshield rubber seal and effected a total and lasting repair using Permatex windshield sealer. If the wind noise on your car is coming from your windshield area, it's definitely worth trying. http://www.autozone.com/sealants-glues-adhesives-and-tape/windshield-repair/permatex-tube-flowable-silicone-windshield-and-glass-sealer/552992_0_0/ Geoff | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 290 Registered: 4-2015 |

Geoff... No, not windshield, but rather the old, original, dry and cracked rubber door weather stripping between the door and window frames and the body. The noise is not horrendous, simply noticeable. I rarely drive with the windows closed anyway as here in the SF Bay Area climate it is seldom, if ever, hot enough to even "need" air conditioning (just stay out of the interior valleys!) and for me, it is much more pleasant to have the flow thru ventilation, with brings with it the attendant noise anyway. In the very mild winter here (if it gets to the low 40s, it hits the news!) the fan from the heater is almost noisier than the weather stripping noise. Accordingly, wind noise is the least of my worries. It was simply an observation regarding the allegedly annoying "roar" of the fixed fans. Given a choice, I will take the cooler radiator. | ||

ross kowalski New User Username: cdfpw Post Number: 6 Registered: 11-2015 |

It is good to hear you seem to have the overheating problem fixed. Better yet, for short money. I have one of the early cars with the clutchless flex fan. It sounds like all flex fans, (read loud) Fixed flex fans are louder than broken clutch fans for the same reason people fit them in the first place, .. air. Flex fans have more steeply raked large blades that move A LOT of air. They do work really well to keep things cool and are as reliable as stone, but they are louder, they use lots more HP, and (not that it matters on a RR/B) they instantly get pulled into your radiator when fording deep water. I like them as it is one less thing to break, and a little engine noise lets you know the engine is still running at stop lights. | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 291 Registered: 4-2015 |

Ross... I would be interested to see a photo of your "flex fan" as that description is at variance with how I would describe mine. I will post a photo of mine later, but it is neither flexible material (plastic), nor of flexible pitch (variable pitch). Steel, not plastic. The blades are very wide and quite steeply angled, such that the length/depth of the fan (front to back, not side to side) is about 5"-6". As noted, it is NOT loud or noisy, at least to my ear, neither stationary with bonnet open, nor at speed, windows open or closed and hence is not practical as a meter for the engine running at stop lights, given that it cannot be heard. Whether or not it actually consumes much more horsepower I do not know, but given that it is not really that heavy, and once revolving, only requires enough power to keep it revolving (like a flywheel) and given the capacity of the engine to begin with, I cannot imagine that the "loss" is significant, only academically arguable, nor does fuel mileage seem to suffer. As to "for short money" I will not go into all the things that were suggested or replaced before getting to what I would now consider the FIRST thing to check, rather than the last: Thermostat, steam valve, top tank cap/gasket, faulty gauge, faulty sending unit, cumbustion leak into water passages, "those high temp readings are normal, you don't have a problem", water pump, clogged engine passages, hoses, belts, radiator R&R twice, first to rod out (no change in results), then to replace with new heavy duty (improved flow rate, but no significant change in results). The wake up call regarding the various "tests" for a fan coupling is that they are basically useless when compared to the absolute positive test (inconvenient as it might be as it must be removed and jammed with wood/plastic dowels and wrapped with duct tape) of converting to a fixed drive and comparing the actual temperature changes. NONE of the other traditional tests gave any confirmation of the condition of the coupling, seemed to indicate that it was operating as expected, and at best, one observer's comment (covering their bases) was that perhaps it was a bit weak. So the takeaways are twofold: 1) The fan clutch is the FIRST thing to replace, not the last 2) The only AUTHORITATIVE test for a fan clutch is to convert to fixed setup and observe the results. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1988 Registered: 6-2009 |

Christian, Not that I don't think you've found your cause, but there is a problem with your theory. If you're driving along at anything more than 20 MPH the effect of the engine fan is virtually nil as opposed to the ram supply of air being forced through the radiator. You might see sudden elevation of temperatures when you've been running at a brisk pace, the engine is already completely heated up, and you suddenly have insufficient air flow when you slow or stop. If you're driving along the highway in a "low load" situation the fan is just not a factor. You can see this demonstrated very clearly in cars with thermostatically controlled electric cooling fans. These are not generally "on" when driving at speed and usually not until you've been relatively still or stopped, and for several minutes. Hills or "high load" situations will be more sensitive depending on the amount of speed you can maintain and how much demand is actually being placed on the engine. I disagree that the fan clutch is the first thing I'd replace, but to each his own. I also disagree that your test is authoritative, but it is strongly indicative. If one were able to easily and inexpensively source a replacement viscous fan clutch (and I know that you can't) that would be my first and authoritative test. If the car is supposed to have one you are actually increasing the pull of the fan, at least slightly, by making a fixed fan. Brian | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 292 Registered: 4-2015 |

Brian... As you are aware, proper scientific procedure is to change only one thing at a time and record the results. That is what I did. I changed a questionable viscous fan clutch for a fixed fan. The result under at least similar, if not scientifically controlled, weather and road conditions was remarkable and brought IR readings (same tool, same locations measured) down from 240F to 200F. That is what I call indicatively authoritative. Of course the other side of that experiment will be to remove the jamming devices and reconvert the fixed fan back to a viscous coupling of suspect quality and see if the readings revert back to the higher temperatures. If they do in fact revert, that is double authoritative, but if they do not then the whole experiment is negated. For the time being, and until the "possible" replcement clutch arrives later this week, I am simply deriving too much pleasure driving the MPW without knowing that it is "running hot" and last year we even disagreed as to whether 240F was indeed "running hot". Irrespective of what characterization one ascribes to 240F, I would MUCH rather have the engine running at 190-200F which is unarguably "less running hot" than 240F, but to each his own. As to the issue of air flow at 60 mph, yes, that is a conundrum I admit and was one of the reasons that I just could not explain the observed circumsatances last year. At that time, I had fully expected the temps to fall as a result of that air flow, but they did not. This year all I changed was the variable to fixed fan and the temperatures did fall. So as a result, I must throw all "rationalities" as to what should or should not be happening out the window. With a fixed fan, the temperatuares dropped and I am a happy camper irrespective of the objections as to what that is or should be happening. Now I just wish I could get more coolant flow to the rear of the heads. Then I would not only be happy, but genuinely blissful! | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 293 Registered: 4-2015 |

Here is the promissed photo of the fan showing the width and angle of the blades, and which also shows the old style clutch and how it just barely fits between the blades. Hopefully the "possible" replacement will be of similar dimensions.  | ||

gordon le feuvre Prolific User Username: triumph Post Number: 128 Registered: 7-2012 |

Christian, notice from last pic, you do not have cowling around radiator that enables fan to draw air through rad. more efficiently. The parts cat. lists these as on air cond. cars only, then seems to just list them as standard. Very confusing! I think this cowl was part of upgrade kit I mentioned previously. Will take pics from my Corniche and post, although it is '73 CRH15049 The fan diameter changed on late cars, so again it is all minefield. | ||

Christian S. Hansen Prolific User Username: enquiring_mind Post Number: 294 Registered: 4-2015 |

All... YOU WILL NOT BELIEVE WHAT I DID TODAY THAT BROUGHT THE IR TEMPERATURE READINGS DOWN ANOTHER 10F. The engine now runs at 185F-190F instead of the 195F-200F as a result of "converting" the fan to "fixed". What was the "fix"?? Drum roll...wait for it...tightened the drive belts!! Yes. Ever since fussing with the fan assembly last weekend, the belts have been squeeling upon engine start up, and if the engine is revved. I assumed it was because after reinstalling the "fixed" fan assembly, I simply did not get the alternator belts tight enough, or that those belts were simply worn out. I happened to check the "other" belts that I had not disturbed that run over the crank pully, over the power steering pully, and then over the water pump pulley and they were way too loose. Tightened them up and the "squeeling" went away, so clearly that "squeeing" was simply circumstantial and had nothing to do with the work on the fan assembly. While I was happy to get rid of that annoying "squeeing", upon driving the car today on errands, I noticed that the temperature gauge reading was LOWER than it had ever been before and did not increase as much as before upon climbing the hill on the way home. IR readings prior to climbing the hill were ONLY 185F and were ONLY 190F at the top of the hill!! It is hard to believe, but the only rational explanation is that the the loose belts did not drive the water pump at full speed and thus the coolant circulation was not at 100% either!! So...bottom line is that on top of the reduced temperatures derived from the "fixed" fan set up, the additional cooling from simply tightening the belts is ICING ON THE CAKE!! The temperature gauge now runs right in the middle of the white band, and only increases a bit upon climbing the hill. I am one happy camper! The "substitute" early fan coupling also arrived in the mail today. It has exactly the proper dimensions. I will install this weekend and report. Gordon... A few comments to respond to your VERY helpful suggestions. The cowling: Yes, I had thus far forgotten to mention that. It was something that was on my original "to-do" list last year when I purchased the MPW and the "running hot" issue slapped me in the face. The very early cars not only did not have a fan clutch (had a fixed fan) but also did not have any cowling and there are not even studs on the radiator onto which they can be installed. This obvious upgrade, which would involve jury-rigging a later model cowling and installing attachment points, would further help by pulling more air through the radiator matrix. When my car was "upgraded" early in its life to include the fan clutch, no cowling was added, and I never got around to it. Now it seems unnecessary. As to the engine mounts you alerted me to, I checked them and found that the engine is in almost its furthest forward position and is barely 1/16" away from that stop, so there is no need to worry that the engine will move any further forward causing the fan to impact the radiator core. It was worth checking, just to be sure that unfortunate event will not occur, and all is well in that department. Bottom line is that it appears that the "running hot" issue has been resolved. I did not like 240F AT ALL. I could have lived with 195F-200F resulting from the "fixed" fan, but LOVE that the engine now runs at 185F-190F!! Good News! | ||

ross kowalski New User Username: cdfpw Post Number: 7 Registered: 11-2015 |

Yeah, "short money" is a relative term, but I always look at the worst possible on overheating as head gasket or block and those cost a great deal more than a re-cored rad or new water pump. I just looked at your picture and that is definitely not a flex anything as it is too thick and riveted in the center of the blade. I looked at that diagram of the rolls early fixed fan and it too is not a flex fan. RR just fit a fixed pitch clutchless fan. As for mine, well ... I definitely have a flex fan. You can tell because the blades are thin like 1mm or a little less and fixed at the leading edge. I also noticed that mine appears to have a (as per diagram) #37 extension cone and an aluminum spacer ending in a decidedly non-OEM flex fan. I am posting a picture as an FYI as to what a flex fan looks like fitted to a RR engine, but with the disclaimer that this is in no way a RR factory setup. Here is a link to the decidedly non RR flex fan setup on my car. https://sites.google.com/site/rollspicturestorage/rolls-pics-1/6_28_2016_IMAG0075.jpg?attredirects=0 Some previous owner lost the clutch and went the $39.95 USD route. | ||

ross kowalski New User Username: cdfpw Post Number: 8 Registered: 11-2015 |

As Brian correctly pointed out, the fan really doesn't do a lot (nothing?) when a car is moving. Adding a shroud to the radiator would only help when the car is sitting still. Also the fact that your fan is almost touching the rad means that a shroud probabbly won't gain you a lot. On my 69 pontiac grand prix however, the shroud was essential as the radiator was a foot away from the fan. If it didn't have a shroud it would just be spinning air around in the engine bay. If your running 185~190F now, I can't see a shroud doing much. | ||

Jim Walters Frequent User Username: jim_walters Post Number: 90 Registered: 1-2014 |

Christian, was the TR7 fan clutch as I suspected the correct one? Did it fit without modification? SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 339 Registered: 4-2015 |

Jim... Sorry, for not following up closely. Health issues and a plethora of unwanted legal distractions side tracked the effort. My recollection is that I did not have any success in the TR7 avenue, and then, I forget how, stumbled upon photos in the 1980s Jaguar line that appeared to be at least visually appropriate. Ordered one, which turned out to be of the appropriate dimensions, save just a smidgeon longer (1/8" as I recall). The "hair dryer" heat test on the thermostatic bimetal coil "seemed" to indicate that it opened at a temperature of about 120F which, while seemingly too low, was fine by me as I would prefer the fan to be on prematurely, rather than only after the coolant is already too hot and playing "catch up" trying to get the heat under control. By contrast, the Hayden 2747 did not even begin to engage until about 215F which was way too high for my liking, even had it fit, which it did not since it was for the later, post 11,000 VIN engines. Also, it was not apparent whether the diameter of the recess on the (Jaguar) clutch that fits over a protrusion on the water pump extension would fit with or without an insert bushing. In any event, given that all the thousands of $$ that were spent on various items (thermostat, new radiator, hoses, etc,) did not effect the heat problem, but in the end, simply tightening the drive belts did, and thus the temperature problem, while still not ideal on the gauge, is at least under control in terms of IR readings, and in combination with the aforesaid health and legal distractions, the "substitute" Jaguar clutch has never been installed, the MPW has been rotated back to storage and I am now happily driving my Cloud I for the immediate future. Someday I will get back to the MPW and fan clutch issue and will supplement the thread at that time. | ||

Randy Roberson Grand Master Username: wascator Post Number: 686 Registered: 5-2009 |

I wore this subject out when suspecting that the clutch on my 1970 home-market Shadow was not keeping the end up. In short: although obviously the clutch was bought out, and it seems highly improbable that a special design was made only for Rolls-Royce, I was not able to identify another clutch that would bolt up. I suspected that a similar-sized British-built vehicle: Jaguar, Rover, etc., might use the same one, but never did find one. The later Cars used the same clutch as similar era Cadillacs and possibly other larger cars, and this has been well-documented. In short, I had a used fan-clutch assembly and I used this clutch with success.If someone is able to identify a source for this clutch it would be of value no doubt; at least of interest as I hate to leave loose ends. |