| Author | Message | ||

Martin Cutler Prolific User Username: martin_cutler Post Number: 150 Registered: 7-2007 |

My standard bodied MK VI stopped rolling. The left rear wheel was grabbing. Hmm, look at that tomorrow. Drove to the top of the drive, the wheel was holding tighter. Drove up to the workshop, (2km), car was hardly movable. Wound the adjuster all the way off,still no good. Took the spat and wheel off, jarred the drum with a large lump hammer, and it freed. Took it off, expecting to find a de-laminated shoe, but the shoes where fine. The "piston" part of the mechanism had jammed in the bore. Some "Rost Off", and working the handbrake, and it came free. What do you all recommend for lubing the pistons in the mechanism of the rear brakes? I was thinking synthetic grease? Cheers Marty | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2081 Registered: 4-2003 |

To answer the question, Loctite nickel antiseize is the only one to use. I have applied it and its earlier versions to my R-Type for decades. It is essential to apply it on everything from spark plugs to ball joints. Note for others: the rear brakes are mechanical on these cars. There is no hydraulic piston, rather a mechanical expander. Had an unexpected stop on my Turbo R on Monday at 5am at Marulan on the way to Sydney too. 135km/h then coasting. The good old Panel B A4 fuel injection fuse fried again. The curious thing is that the fuse plastic melts but the fuse itself doesn't blow. Next step is to install a filter circuit as the chopper load square-wave PI current drain is clearly to blame. The service bulletin shows the ineadequate fix for the 20,000-series cars, but I had modified mine around 1990 already. Luckily the delay was less than 1 minute as I knew immediately where to look. | ||

Laurie Fox Frequent User Username: laurie_fox Post Number: 76 Registered: 6-2004 |

Marty I use just a trace of HMP grease. The expanders will remain free indefinitely provided the rubber boots which stops dirt getting in are in good condition. They do split after a time and you have to dismantle a bit to get new ones on. Regards Laurie | ||

Martin Cutler Prolific User Username: martin_cutler Post Number: 151 Registered: 7-2007 |

Hi Laurie, Rubber boots? I don't have any rubber boots on the back of the MK VI, should I have? I intend to pull the back wheels off my other MK VI and check that as well. The mechanism body is alloy, I think, (did the job in double quick time, as I needed to be out on the road). Nickle anti sieze would be the way to go I think. On a hydraulic wheel cylinder, the piston is lubricated by the brake fluid, and the rubber boot keeps the dust out. I don't think there is a recess in the alloy housing to take a rubber boot. Thanks Richard for your tip. The back road from Goulburn through Bungonia and up to Marulan is one of my favourites, would be awesome fun in your Turbo. Cheers Marty | ||

Laurie Fox Frequent User Username: laurie_fox Post Number: 77 Registered: 6-2004 |

Marty In the MK VI Schedule of Spare Parts, Group J6 there are several versions of the rear brake expander as various modifications were introduced but they all seem to have the Dust Excluder RG3379. My B420EY certainly has. To replace it I needed to remove the peened over cover which closes the bore in which the expander moves and detach the expander from the rod after having undone the rod near the centre line of the car and moved it so as to allow access to the expander retaining pin. The rod is now free for the new dust excluder boot to be fitted. The new boot goes on over the end which has the expander eye - just. I hold the rod in a vice and use plenty of persuasion and rubber lubricant. Reassembly is straightforward except for the original peened over cover. I just use aluminium foil and wire it on with the wire in the groove in the expander housing so that I can get it off easily next time without any further damage to the groove. Current availability of RG3379 may be a problem for you. I have used 3 in the last 50 years and there is one more on the car which is due for replacement. I can't now do this on my own but one of the gardeners is mechanically minded and I will probably get him to help when summer comes. I have spares available but, sorry to say, not enough to let you have any. My last purchase (in 1998) was from Theo Hendrikson who took over from Appleyards and is still trading (Google "Theo Hendrikson")' If you do locate a source elsewhere then please let us all know. Girling GB1268 seems to be (or was) the Girling Part Number. Regards Laurie | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2085 Registered: 4-2003 |

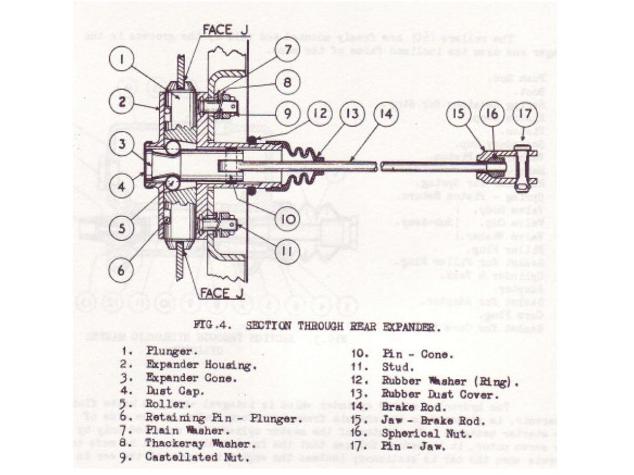

Here is the rubber boot, Item 13. If yours are missing, then you are asking for trouble. Your local bearing shop will sell you a generic to fit nicely.  | ||

Martin Cutler Prolific User Username: martin_cutler Post Number: 152 Registered: 7-2007 |

Ah, thanks for the explaination guys. Yes, I have the rubber boot as shown, the part that seized was number # 1 (plunger)in the above diagram. Funnily enough only the top plunger siezed, the bottom one was still moving freely. Is it still Ok to put nickel anti seize in this area? I will drop the rods off the back of the R Type to get a sample, and give that to our brake supplier, should be able to get them easily. I will check the condition of the boots on the MK VI. I didn't look closely at it on saturday morning. I threw it all back together fairly quickly, can't keep the bride waiting! Cheers Marty |