| Author | Message | ||

David John Stacey Yet to post message Username: staceyd142 Post Number: 1 Registered: 11-2019 |

I removed the head over the course of a week (a serious use of wedges required due to corroded studs) and noticed a small stub protruding from the centre of the block that I can’t find any reference to. It would appear to have snapped off at some point in its life and looks like a locating dowel that is hollow to allow the passage of coolant between the head and the block. Any ideas about its purpose? I attempted to remove it by unscrewing but just mangled it. I can drill out the remains and make a replacement or get it skimmed off. The only thing that concerns me is that the corresponding hole in the gasket has no sealing ring. Any advice much appreciated. David.  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2163 Registered: 05-2012 |

Hi David An absolute expert on these cars is Norman Geeson who occasionally posts into this forum. His website is: http://www.kda132.com/ He has a contact email listed on that site, so this may be a line of inquiry worth pursuing. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2201 Registered: 09-2004 |

Oil low pressure supply to rockers, type of dowel. | ||

David John Stacey New User Username: staceyd142 Post Number: 2 Registered: 11-2019 |

Thanks Geoff, I’ll give Norman a shot, David | ||

Jeff Martin New User Username: jeff_r_1 Post Number: 9 Registered: 07-2018 |

On my MK VI (4 1/4) I have an external low pressure line that feeds the rocker shaft. It bolts to the side of the head at the centre on the carb side, the oil is fed through there, around a collar on the centre head bolt and eventually leads to the rocker shaft. If your head doesn't have the external oil line, then that dowel in the block is probably an oil feed. If in fact it is an oil feed, it should be pretty easy to trace the path in the head to the rocker shaft. At any rate it will be interesting to see what Norman has to say. He'll probably be able to tell you how the dowel is held in there so you can repair it, if need be. | ||

Christopher Carnley Unregistered guest Posted From: 109.156.10.48 |

You must drill it out and make a close fitting, ie interference fit,replacement, it is the oil supply dowel to the rocker shaft. (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2202 Registered: 09-2004 |

Looks dry inside the oil way dowel! Other things to do of importance while apart. Disconnect the oil feed connector at the top of the block and at the bottom on the relief valve, clean and leave undone until new type dowel fitted. Remember gauge oil pressure shown is not what is going to the inlet rockers. This is low pressure regulated by the slots in the seat of the high pressure valve. Also make sure low pressure oil is making its way to the engine gears! | ||

Norman Geeson Unregistered guest Posted From: 81.99.138.38 |

Patrick "Looks dry inside the oil way dowel" You are correct you would be waiting a long time for oil to issue from that E50362 dowel because it is the centre cylinder head locating dowel. Interesting the O/D of the dowel hole is 9 mm, and the correct oil feed does have a sealing ring. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 3519 Registered: 04-2003 |

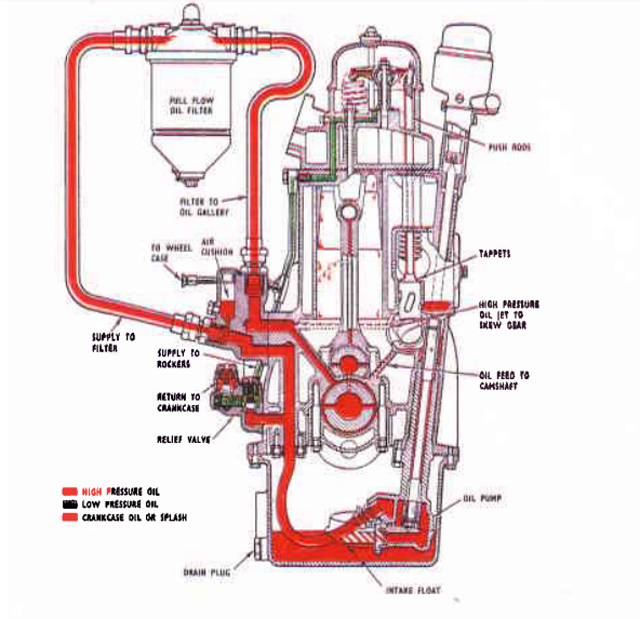

Christopher Carnley has forwarded the following oil flow diagram relevant to to above post for my inclusion on his behalf:  "One picture is worth many words" | ||

Jeff Martin New User Username: jeff_r_1 Post Number: 10 Registered: 07-2018 |

What is the need for a locating pin with all those studs ? Once the head is in place, how much movement can there be to effect the proper alignment of the head and gasket ? It seems like another RR overkill and redundant function of something. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2203 Registered: 09-2004 |

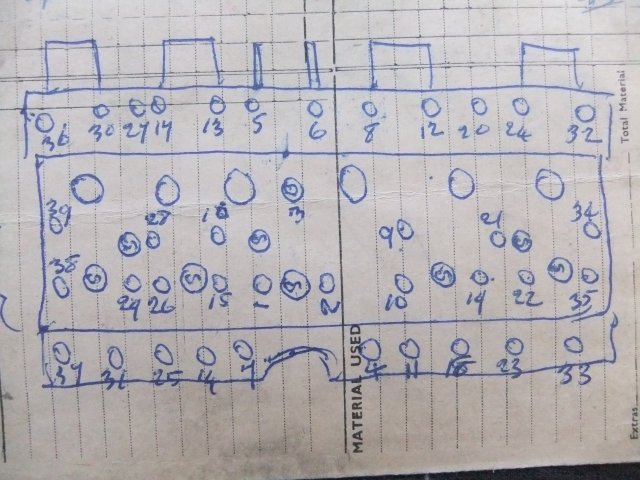

Having to use 39 studs IMO is pointing to a weakness in gasket sealing life that had to be over come, from the distant past the torqueing of the 39 nuts was carried out three times allowing the gasket to settle, last was after a run up warm. The correct tightening was a must, from my distant past a copy of the order may help.  | ||

Trevor Pickering Experienced User Username: commander1 Post Number: 114 Registered: 06-2012 |

This is just a locating stud Part No. is E50362 I think Just rebuilding my 1953 4 1/2 ltr engine and had the same in the center of the block | ||

Trevor Pickering Experienced User Username: commander1 Post Number: 115 Registered: 06-2012 |

Woops!!! Just seen your post as well Norman Sorry for the duplication | ||

Jeff Martin New User Username: jeff_r_1 Post Number: 11 Registered: 07-2018 |

Patrick, I think it's much more then that, the aluminum alloy the head is made from is no where near as strong as todays alloy's. Torqueing down the bolts to todays specs would crush the head, so RR relied on many bolts and lighter torque specs to do the job. | ||

Christopher Carnley Unregistered guest Posted From: 109.156.10.79 |

Follow the Green Line. Without the oil way stub, the pressurized oil forces it way out though the gasket core. (Message approved by david_gore) | ||

Norman Geeson Unregistered guest Posted From: 81.99.138.38 |

The position of the oil feed hole and the location dowel is still confusing a number of people here. I would first of all draw your attention to the position of the ignition distributor in both images now submitted. Let us take the initial image of David Stacey’s first. Note the ignition distributor drive poking out of the cylinder block at twelve O’clock. Now, note the rocker oil is fed from the pressure valves to a point OPPOSITE to the distributor side of the block. At this point also note the cylinder head stud hole positioned exactly on the centre line between cylinder 3 and 4. Anyone suggesting the dowel position is the oil feed needs to explain to me how the oil supply is going to pass from the 6 o’clock position where it enters the block (just out of the picture at 6 o’clock) RIGHT THROUGH the head stud between cylinders 3 and 4 and terminate at the dowel. Of course, that cannot happen, and both images show the position clearly, as we shall see. Locate the head stud hole between cylinders 3 and 4 in the initial picture, as you move down towards the 6 o’clock position the FIRST hole you meet is the OIL SUPPLY hole. Note this hole is on the opposite side from the ignition distributor as the supply cannot pass across the cylinder centre line as there is no room to do so. Keeping an eye on the previously mentioned cylinder head stud hole, it will be seen that the location DOWEL is positioned in the next hole moving towards twelve O’clock. In short, from the cylinder centre line head stud hole, the DOWEL is position in the first hole in the direction of the distributor and the OIL FEED is the first hole away from the ignition distributor. Now let us examine the image submitted by Christopher Carnley, with the notation “One picture is worth many words”. That is only true by the way if the picture is studied. In our case it shows clearly that the dowel is not an oil feed and how the (Green) oil feed comes into the side opposite the distributor and passes vertically before it reaches that centre head stud. (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2205 Registered: 09-2004 |

"Torqueing down the bolts to todays specs would crush the head, so RR relied on many bolts and lighter torque specs to do the job." Todays use of stretch bolts may well solve the gasket sealing 100% with much torque fettling etc. | ||

David John Stacey New User Username: staceyd142 Post Number: 3 Registered: 11-2019 |

Thanks all, it definitely links the water jackets, block and cyl head but the tiny drilling in it seems unlikely to contribute anything to cooling. Introcar want £45 for the thing, definitely a DIY machining job at that price! I note from their crankcase diagram that there’s a rear dowel available (only £1) but my block doesn’t have one of these. | ||

Christopher Carnley Unregistered guest Posted From: 109.156.10.115 |

All of the necessary printed information for the above, and for each and every enthusiast is available from the Library on this site. "Better is he who is both practical as well as theoretical, for he is doubly armed" Vitruvius, Bk IV. (Message approved by david_gore) | ||

Bill Vatter Experienced User Username: bill_vatter Post Number: 84 Registered: 09-2004 |

Jeff Martin posted on 11/25 2019: On my MK VI (4 1/4) I have an external low pressure line that feeds the rocker shaft. It bolts to the side of the head at the centre on the carb side, the oil is fed through there, around a collar on the centre head bolt and eventually leads to the rocker shaft. Jeff, look again. That connection is on the block, not the head. The oil flow path under discussion in this thread is about the oil flow between that attachment point to where it passes through the upper portion of the block to the cylinder head. | ||

Jeff Martin New User Username: jeff_r_1 Post Number: 20 Registered: 07-2018 |

Yes Bill, thanks, I posted from memory, the feed is indeed connected to the block. I was seeing the access plug on the head where it was machined for the oil gallery within the head. |