| Author | Message | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 220 Registered: 5-2013 |

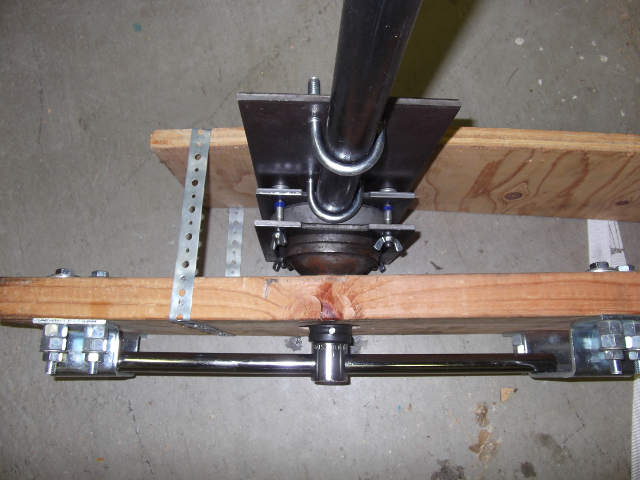

Hi Folks, I solved my recalcitrant sphere problem...     I win. Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 461 Registered: 5-2012 |

Chris Congratulations. Geoff | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 221 Registered: 5-2013 |

Hi Geoff, Thanks Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1004 Registered: 6-2009 |

Hey, hey, HEY!! This looks like a clear case of infringement on the Vogel Vice System®, first published on October 31, 2012. Pay up!! Brian | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 222 Registered: 5-2013 |

Brian Vogel has so many vices that I lost track... Yeah, well my lawyers think it is a "Fair Use" derivative work which extends the excellent work of one Brian Vogel, with a kick-ass winch. But, I'm willing to settle for an undisclosed amount of beers, as long as they are paid in Sacramento. (-: Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1005 Registered: 6-2009 |

I, like Tallulah Bankhead, am as pure as the driven slush. Beer, puhleeze. Beer is for lightweights!! Brian | ||

Jeff Young Prolific User Username: jeyjey Post Number: 195 Registered: 10-2010 |

He he... that's a man-sized sphere wrench. Well done. | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1539 Registered: 4-2003 |

Chris/ Heath Robinson will never be dead, as they say, while you're around. Recently I had a batch of spheres to overhaul and among them were some related to your trial sample! My equipment base is bolted to the wall of my garage. the pins in my spanner are piano steel and the base is of 5/8" steel! I will have to secure my garage however as I have jad two changes of postcode! | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 223 Registered: 5-2013 |

Hi Jeff, Yeah. And it worked! You can't see from the pictures, but it has a five-foot handle and I am 165 lb, which means that I can put 825 ft.lb. of torque on a sphere. That was not sufficient to open either one. The "come-along" was. It takes less than ten minutes to strap an accumulator in and open it. One of them "popped". This was a surprise. I heard a "pop" and then everything went slack. My first thought was that something had broken or slipped, not that the sphere had opened. Chris. | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 224 Registered: 5-2013 |

Hi Bill, Sounds massive. If you can stop your garage from shuffling along long enough, I think we need to see pictures... Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 462 Registered: 5-2012 |

I second that. It would be interesting to see Bill's setup. Geoff | ||

Bob uk Unregistered guest Posted From: 94.197.122.77 |

I would have put the hex bit of the sphere in a lathe 3 jaw Chuck. The pin wrench in the tool post. Lathe in low gear 50 rpm and slip the clutch. A triumph mascot lathe will go to 1200 ftlbs on a 12hp motor. I had one of these lathes ploughing 3/4 deep cuts at 10 thou per rev feed and cutting speed of 120 ft per minute using ceramic tips. The swarf comes off at 600 centigrade. The machine will do this all day with no strain. Material was EN 40 steel. My garage would probably fall down if I put a 1000 ftlbs sideways on the walls. (Message approved by david_gore) | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 228 Registered: 5-2013 |

Hi Bob, Well, if I had such a lathe, I suspect I'd've tried something like that. But why stop there? Lets assume a specially built, hydraulically operated accumulator sphere opening machine, which I also don't have. I'd've used that, too, if I had one. I bet someone could make a really good pneumatic approximation with a tire changing machine, if they had a spare tire changing machine lying around... Can't use what ya ain't got. For plywood, 2x8 Douglas Fir, and nylon straps, this worked pretty well. And is probably a design that is easy to copy. Chris. | ||

David Gore Moderator Username: david_gore Post Number: 1451 Registered: 4-2003 |

Chris, I do not think this type of comment is appropriate on our forum - Bob is quite within his rights to post alternative ideas to yours for consideration by all. Just because his ideas are different to yours does not entitle you to belittle him in what I consider to be a sarcastic manner. I personally know a number of members of this forum who have workshop facilities that would be amenable to Bob's suggestion of using a belt-driven lathe as a mechanised jig to open accumulators if needed. If Bob had suggested a geared direct drive lathe, I would have advised to the contrary as it would give rise to possible motor burnout if the lathe stalled whilst trying to separate the spheres; a belt-driven lathe will "fail-safe" with the belts slipping if the lathe stalls thus preventing overheating of a stalled electric drive motor. I strongly emphasise this forum IS NOT AND NEVER WILL BE RESTRICTED TO BEING A MUTUAL ADMIRATION SOCIETY - we encourage the expression of different points of view and reasoned, robust and, most importantly, courteous discussion about these opinions. We are Australian with an ethos of a fair go for all who take the time and effort to contribute; you have been a beneficiary of our ethos and your extending the same privilege to other members with different ideas will be appreciated by all. There are certain international members of this forum who have had problems with having posts published in other forums who now appreciate being able to post without being rejected or censored because they have different points of view. | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 229 Registered: 5-2013 |

Hi David, So, Bob wanted to explain how he would solve a problem he didn't have with a machine he didn't have. That is sort of a pointless "Angels on the head of a pin" discussion, isn't it? But, being a good sport, I humored him and accommodated his discussion by musing how I would solve a problem I did have with a machine I didn't have. And then I went further, by explaining that the original post showed how I solved a problem I did have with a machine I did have and that anybody else could have, too. The point was that this tricky problem of opening spheres need not defeat anyone with a little ingenuity. If your shop is already suitably equipped with massive machines, then this thread was not for you anyway. Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1013 Registered: 6-2009 |

This comes back to a "how you read" issue. In this case, I agree with Chris as far as how comments such as Bob's read in context. They don't come across as being of the helpful, "If you happen to have . . . here's another way," but carry the impression of a criticism, delivered indirectly and slyly. There is a reason that the phrase "read between the lines" came into being. Most of us, if we had access to some of the more elaborate machinery, would use it (and come up with creative uses, too). However, being able to accomplish what seemed to be an "impossible" task, using only really commonly available "scraps" that are lying around in a multitude of homes and garages, has far wider applicability. Brian, who's "been there, done that, got the slaps" and doesn't apologize for reacting to them | ||

David Gore Moderator Username: david_gore Post Number: 1452 Registered: 4-2003 |

Chris, You have missed the salient point in Bob's post; he DOES have a suitable machine in the lathe he mentioned using for other work in the above post. He just hasn't had the need to use it in this fashion yet as I recall from another post elsewhere in this forum. I still regard the tone of and the expression in your post as being below the standards that should prevail on this forum. If Bob had intended to criticise your point of view, I am in no doubt he would have done this directly and courteously and not as suggested by Brian above. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1016 Registered: 6-2009 |

David, You and I have had, and I hope we shall continue to have, a friendly and mutually beneficial relationship. That being said, I'm finding it more than a bit unnerving that chastisements regarding tone and style of expression are not being offered evenhandedly, and right now they are not. Brian | ||

Chris Miller Prolific User Username: cjm51213 Post Number: 231 Registered: 5-2013 |

Hi David, You have missed the salient point of the entire thread! "Here's a way to open a sphere, that anyone can do without the use of any special machines. Anyone can copy this jig." My response to Bob was gentle guidance that offering tips on how to use an expensive, heavy and uncommon machine is not only unhelpful to most, it is a distraction to the discussion. If you have such a machine, then you probably know how to use it and if you don't have such a machine, then do you really care? Are you going to go out a buy a lathe to open an accumulator sphere? Had Bob offered comments improving my technique or other similar techniques available to everybody, like Bill Coburn's post-code hopping garage, then I wouldn't have had to remind him that his remarks were probably out of place. If Bob really has such a burning desire to talk about all the clever things he's done, or can do, with a lathe, then there is nothing stopping him from starting a thread discussing that. And if you were actually "moderating" and not "proclaiming", then you'd have given equal weight to my opinion that Bob's comments were not in their best place. Two ideas to keep in your moderator's mind:

Chris. | ||

David Gore Moderator Username: david_gore Post Number: 1454 Registered: 4-2003 |

Brian and Chris, As always, there are two or more sides to this discussion and everyone is entitled to their opinion. I leave it to all to make up their own minds in this regard. I have not been "proclaiming" as I wish to remain neutral and not take sides however I have been "moderating" in pointing out deviations from what I regard as appropriate standards for this forum and relying on the individuals concerned taking appropriate corrective action to avoid the need for future editing of their posts to conform with our standards rather than editing [censoring] these deviations without explanation. What may be regarded as acceptable in one country may not be acceptable in another and it is presumptuous to lecture me on what standards must apply in our forum especially those derived from beliefs and practice that are not necessarily in accord with our own. Offensive speech is exactly that; offensive and more speech is not a remedy but a provocation for even more offence leading to entrenched opposition and antagonism rather than reconciliation and/or acceptance of the merits of alternative points of view. Governing least does not govern best as this benefits the powerful and disadvantages the weak. Governing for all on equal terms is the optimum in my opinion and my moderation has always been based on this belief. | ||

Jeff Young Prolific User Username: jeyjey Post Number: 196 Registered: 10-2010 |

I have enjoyed the technical content on this thread: Chris' original "man-wrench", Brian's and Bill's variations on the theme, and Bob_uk's "man-lathe" (which I do happen to have something similar to). But, the rest of the thread? Not so much. Cheers, Jeff. | ||

Bob uk Unregistered guest Posted From: 94.197.122.81 |

Lathes are very common I should think that most people are within 2 miles of a lathe. I am 10 yards from a lathe as I write this and 1 mile away is a big 24inch swing Mitchell lathe. Which is capable of snapping spheres in two without unscrewing the ring. A tyre machine hasn't got that sort of torque. My lathe hasn't got the torque however it has back gears which I can lock off and give it welly by using my 1 ton floor crane and a big hammer. So while the method shown above worked there is more than one way to skin a cat. Another way is to simply machine the locking ring off the sphere and make a new locking ring from steel. And if room make it bigger and put c spanner slots. So the tightening torque is in the middle of the ring. Or lay the sphere on a anvil and hit with a hammer with will stretch the ring a couple of thou" Also blows will causes the flanks of the threads to bounce against each other. Hit the ring hard and turn the sphere a bit then hit again. It must ring. When the ringing changes to not so resonant the jobs done and then unscrew the ring. Using a concrete floor won't work. It will just dig holes and Mark the sphere up. When my spheres needed changing it took 2 hours plus 1/2 hour to get them. That afternoon the car was back on the road. I don't bother trying to hard to remove very tight nuts because one can damage tools and often the nut that is very tight ends up so damaged that it needs replacing so I machine or drill and chisel off the nut and buy or make a new nut. I have done this.with many drive shaft nuts. Drill parallel to the thread and then sharp cold chisel to split the nut. Sometimes the nut splits as is being drilled. A lot of these drive shaft nuts are less than a fiver so spending hours saving one is pointless especially when the New CV joint comes with a new nut. The Shadow has a 500 ftlbs nut on the rear drive shaft which is 'king tight. It has a nylock cap which will make drilling harder to align. Another way is to hit the flats hard with a cold chesil with a smooth rounded edge instead of a sharp one. This will stretch the nut side ways. On half shafts sometimes a press fit collar is used behind the bearing. To get the collar off lay the collar on an anvil and hit hard with the blunt chisel and it will stretch side ways and go loose on the shaft and fall off. Also there are torque multipliers that can give ten times the input torque so 1000ftlbs is child's play. So while I commend Chris for his ingenuity it's all been done before. Such as a spanner so big it needs a crane to support it while a fork lift truck pulls it. Using rams to stretch a shaft put the nut on handtight then release the shaft and the nut is 'king tight. (Message approved by david_gore) | ||

Jeff Young Prolific User Username: jeyjey Post Number: 197 Registered: 10-2010 |

Yeah, cutting is often the right answer. I spent hours getting the half-clamps apart when re-doing my T2's exhaust recently and ended up with junk nuts and bolts anyway. I cut the last few off, which went much quicker. But I wouldn't do that with a sphere locking ring. All these other methods look like too much fun not to be tried out. ;) Cheers, Jeff. | ||

Bob uk Unregistered guest Posted From: 94.197.122.73 |

I wouldn't bother with a part such as an accumulator . I would just get a recon which is what most RR repairers do. All of my methods for getting tight stuff undone I have learnt from other engineers. It's not me being clever it's the engineers of old who did it first who are clever. (Message approved by david_gore) |