| Author | Message | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 309 Registered: 4-2003 |

Having drained the oil on a low mileage Shadow engine, I poked the old digit into the drain hole and felt what appeared to be a small gravel pit. Curiosity prompted sump removal and I scraped about 3/4 of a cup of sludge from the inside. The 'gravel' turned out to be large (about unrefined sugar size) lumps of cabon and the rest was very viscous black oil almost the consistency of light grease and throughout this mess a grey mess not unlike anti-seize paste. My questions to you erudite contributors is what is all this and how do granules of carbon get in the sump? The internals are almost spotless. | ||

John Dare Prolific User Username: jgdare Post Number: 99 Registered: 12-2004 |

Thank you Bill. I found the same evidence in my own well maintained (it really is!) Shadow (130,000 miles) with oil changes every 3 months; approx. 1500 mile intervals. Robert C discovered a similar alien composition (in an otherwise "clean" engine) and sent my "cup" (yes, about 3/4!) of the viscous black "oil" and "vicious" (looking) sugar sized granules, off for analysis. I will look for the results and let you know, although I dont recall them as being conclusive. Not alarming enough to sell my car though, for I simply had the sump cleaned and continued on with more fresh, well respected brand oil. But I do now "apply the digit" (as you say) at each oil change, to check for any evidence of a recurrence. | ||

David Gore Moderator Username: david_gore Post Number: 373 Registered: 4-2003 |

Hi Bill, You will no doubt remember George Shore's "sump curette" made from an appropriately formed piece of coat hanger wire which he used with great effect to drag the accumulated crud from car sumps at Self-Help Days much to the mortification of the owners concerned. I suspect the carbon "Buccyballs" are the result of coagulating additives added to the oil by the manufacturer attaching to the colloidal carbon in the oil to make them large enough to settle out in the sump by gravity rather than remaining in suspension where they apparently can result in increased wear rates. This aspect is very evident in diesel engine oil where the presence of additives to control carbon and prevent wear is a major promotional message. As to the rest of the crud; I await details with interest. | ||

John Dare Prolific User Username: jgdare Post Number: 100 Registered: 12-2004 |

I meant to mention that my sump had been previously cleaned approx. 9 years ago, when I first acquired my car (with approx, 88,000miles recorded) doing so as a pre-emptive engine "safety" condition check. The recently discovered granulation had therefore developed since that time and within approx. 40K miles of careful operation (NO "short" runs at ANY time!)meticulous serving AND more than generous oil/filter changes as mentioned above. Interestingly, I can only recall "sludge" being initially removed nine years ago, so perhaps Davids comment re some modern (and "efficient")technology oils might explain the additional presence of the "granules", details of which will follow when I locate the analytical report. | ||

Mark Peacock Prolific User Username: takemehomejames Post Number: 49 Registered: 4-2004 |

Bill& David.... what brand and grade of oil are you running in your engines ?? | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 310 Registered: 4-2003 |

Ah Mark! A slightly embarrassing question (cf when do you change your underwear?). For the past 500 miles this engine which has 106,000 miles on it has been running on Castrol GTX 2 which is a 10/50 grade methinks. When I got the car It was using plugs at the rate of a set per 30 miles and consuming/dropping/spraying/disposing of a litre oil in the same period of time. Fuel consumption was a healthy litre per mile. The problem was diagnosed by specialists as sticking rings so some magic very expensive oil was apparently dosed through the plug holes. As to what made its way to the sump that would perhaps best be left to an archiologist. Resident there was an oil the viscosity of which I would hesitate to guess at. Draining it cold was clearly a mistake as I had to tilt the car sideways about 30 degrees and leave it for 2 days. Reminded me of getting bunker oil to the ships on a cold day. Anyway with the help of Robert C much work was done on the engine which now runs perfectly and I have arranged with the owner to, among other servicing, to change the oil and filter every 3 months whether the car has done 1 mile or 1000. Even then I will follow John's advice and apply a little automotive proctoscopy each time I do change the oil. | ||

John Dare Grand Master Username: jgdare Post Number: 103 Registered: 12-2004 |

Thank you Bill. Yes.. and I would consider some kind of proctoscopy upon the previous owner of my car for not removing the sump for a thorough clean at any time during his 22 years (approx.) of ownership from new. The "sludge" amounted to about the 3/4 level of a 1 litre milk carton!. | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 330 Registered: 4-2003 |

While doing the sump I noticed the customary drip in the terminal at the bottom of the sump level unit. Is there some way of stopping this?  | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 281 Registered: 9-2004 |

Bill two probs one is the earthing brass washer with seal. In the picture it is at the bottom,the lump of solder has come off of it stopping the unit from sending a reading. It has a seal under the lug. This is why i have done a repair,and it leaked as well. I will get to you as soon as i have completed my write up on the pitman arm. As i have just done repairs to mine.  | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 282 Registered: 9-2004 |

This is the seal underneath.  | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 283 Registered: 9-2004 |

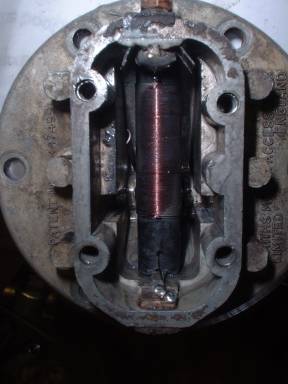

view inside the sump. More on the proceedure later, in haste. PL.  | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 285 Registered: 9-2004 |

Hi Bill. Well the second pix is peaning the rivet to tighten the seal,should have melted the solder off first as it broke the fine wire. Removed the resister core and repaired it. It now works ok. The other problem can be over tightning the unit it is made from dia cast and can distort and leak. With the sealing part use a silicone. The synthetic oil does the business in the sump and LPG.   next mods to rear crossmenber mounts etc. | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 332 Registered: 4-2003 |

Patrick. Many thanks you have confirmed what I suspected in the design. i agree with the distortion through overtightening of the flange - almost every car I have seen has this damage. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 296 Registered: 9-2004 |

Bill this is after some rather hard driving,Hot and not one leak. The sealant has to be tieded up. The wire earth i soldered on to make goog contact to the lug.  | ||

Stephe Boddice Unregistered guest Posted From: 84.66.74.118 |

Gentlemen, Going back to the original title subject of this thread: - 10 or 15 years back there was a similar problem identified in the UK relating to the Rover 3.5 Litre V8 engine. Engine failures occurred due to the build-up of what was referred to as 'the black gunge' in the camchest of these hydraulic tappeted engines. I do not know whether your problem is related. The diagnosis, as I remember, was something to do with swapping from mineral oil to synthertic or semi-synthetic oils. The oil swap was not, in itself, the problem: it was the mixing of residues of mineral with the additive-enhanced newcomer. My question is: - has anybody checked their tappet chest to see if this granulated residue is about to cause blockage problems in this area as well? Forewarned is forearmed. I may be paddling up the wrong creek without a paddle but the story sound familiar. Stephe Boddice (GB) www.boddice.co.uk | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 333 Registered: 4-2003 |

I don't want to talk to you Stephe!!! The offending Phantom had the rocker cover removed to do the valve stem seals and the heads were very clean ie no gunge just discoloured oil. I hope that the valley is in comparable condition. I would hope that the tappets/cam followers would not be gunged as they sit fairly clear of the base and as I remember the valley is fairly well drained. It is all back together now and as I am just about finished with getting that rotten silicon out of the brakes I am not keen on going back into the deep engine mining business. But I will open the chest with another car if there is one. PS Praeclarvm hopefully out next week I'll airmail a copy to you. Cheers | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 554 Registered: 4-2003 |

Just a few comforting words. At around 190,000 miles I had the sump and tappet cover off our T-Series at the same time a few years back. That was in a successful campaign to eliminate all oil leaks, including the fitting of a Spirit series PTFE rear main oil seal and housing. The sump had a reasonable but not alarming build up of gunge. Nothing to worry about. The tappet chest was spotless. Last year I changed a pitted tappet on a SSII. The tappet department was spotless. It has been the same story on other Shadows too: all spotless in the tappet department. Good news that the silicone fluid has been sent packing. It sounds as if some bureaucrat of the 1970s swallowed the Dow advertisements, or maybe too much Burgundy at a sales launch or lunch. | ||

Bill Coburn Grand Master Username: bill_coburn Post Number: 334 Registered: 4-2003 |

Thank you Richard. My enthusiasm levels are at such a pitch at the moment that if Wisteria was growing out of the breather I would simply reach for the secateurs. I think you are spot on with the genesis of the silicon noting the accompanying reports etc with the initiating letter. What is now giving me the Jeremy Brits is the odd fellow who on hearing my plight says ' Oh yes - you can't use silicon with those seals etc etc' and waxes on as if I had been in solitary confinement for the past 20 years! the latest gem I have had is that the seals changed in composition in '88 "or was it '98" and the new material was definitely not happy with silicon. Anyway..... every cup in the system it seems has been on the point of jamming and every cylinder has been garnished with shaved seals. That the whole thing did not seize up is amazing. |