| Author | Message | ||

Vladimir Ivanovich Kirillov Prolific User Username: soviet Post Number: 220 Registered: 2-2013 |

Does anybody know anything about Cunifer or Kunifer brakes lines and if this product is sold in Australia ? Prior to information I received on the Silver Cloud tech page, I had never heard or seen this type of brake line. There is some talk on the net in forums on other makes that this type of brake line does not comply with Australian Design Rules and unbelievably Porsche, Aston Martin and Audi fit it as standard. I have placed a call my states machinery department inspector and am waiting for a call back. It looks like a good product and its reportably not subject to corrosion being an amalgam of copper nickel and manganese but I don't want to spend time making up the Camargue's new brake lines just to have an inspector say I can't use it. | ||

David Gore Moderator Username: david_gore Post Number: 1573 Registered: 4-2003 |

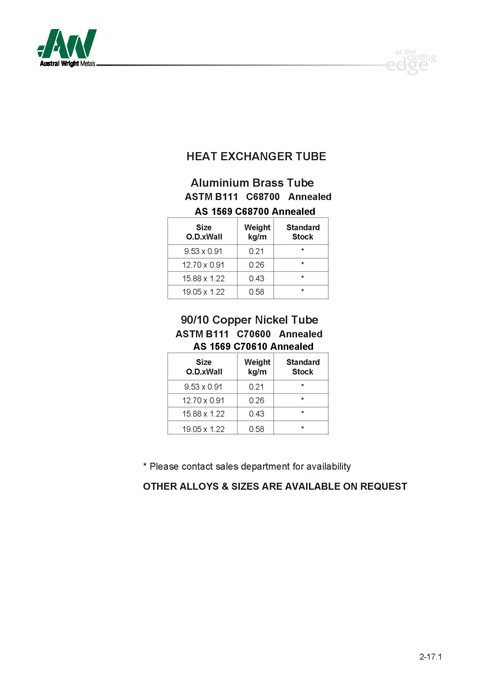

Hi Vladimir, All you need to know about 90/10 CuproNickel alloy: http://australwright.com.au/copper-nickel-alloys/ Austral Wright Metals Products would be one source: http://australwright.com.au/astral-wright-metals-products/products-copper-brass-bronze/ The Austral Wright stock sizes are as below:  Another possibility would be CuNi a subsidiary of MEI: http://www.cuni.com.au/ If either of these suppliers do not stock the tube size you require and they continue the practice from my time in the specialty steel distribution industry of referring you to stockists who would carry the size you require, a simple request should give you the information you need or one of our members may have personal knowledge of an Australian supplier. I suspect Austral Wright is a supplier whose parents were Austral Bronze who had a non-ferrous plant just up O'Riordan Street in Alexandria from where I worked as a Service Metallurgist with Comsteel and Wright & Co who were the Australian distributor of International Nickel alloys and later a competitor of ours in the stainless steel market who were located a few streets away from both of us. For this reason, their heritage is one which I would expect to continue the past practice of the Australian specialty metal distribution industry. I am at a loss to explain why this product would be banned in Australia, if this is correct, as IMHO, it is a far better and safer material than steel for vehicle brake lines. | ||

Trevor pickering New User Username: commander1 Post Number: 6 Registered: 6-2012 |

I have used this material several times in the past and not had any problems with inspections here in WA regards Trevor | ||

Randy Roberson Grand Master Username: wascator Post Number: 365 Registered: 5-2009 |

I understand some higher-end European cars use it for brake lines; it is fully approved. Copper-Nickel-Iron alloy, hence CuNiFer I buy it at a BrakeQuip dealer. Very easy to work with, bends well, yet retains its shape nicely. Corrosion resistant. Not too expensive. I did some replumbing of SRH9391's brake system with it and I recommend it. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1282 Registered: 6-2009 |

This stuff is God's gift to anyone who's replumbing brakes. I think Volvo was the company who first introduced this to production cars, and given that their reputation is built on safety, that says something. As Randy says, it bends very well without losing its shape and its a lot more forgiving if you need to push/pull a tiny bit to get the ends where you need them to be to finish off the connection. The difference in price is well worth it, at least to me, given the vastly increased ease of working with the stuff and the fact that it doesn't corrode. Brian | ||

Jan Forrest Grand Master Username: got_one Post Number: 793 Registered: 1-2008 |

I have never used anything else - and have no intention of doing without it in future. I replaced a lot of brake pipes on SRH24518 3 years ago and they're still clean and shiny. | ||

Vladimir Ivanovich Kirillov Prolific User Username: soviet Post Number: 229 Registered: 2-2013 |

Thanks all, I am still waiting for the Machinery Inspector to call and confirm there will be no scallywag objections to my use of Cunifer lines on the Camargue but as we pay taxes here to have our government staff hide behind phone answering robots, that call may never eventuate. Facinating that after 40 years on the spanners I have only just learned about this type of brake line after all the years of hell bending up steel brake lines for mine vehicles with corroded pipes that have to be replaced. You can never learn everything in the trade and that why this forum is so much value for money even though its free to use. | ||

Jan Forrest Grand Master Username: got_one Post Number: 795 Registered: 1-2008 |

I first used the stuff in the 70's when I replaced the whole braking system on a Standard Vanguard. Why it should have taken so long for the word to get out baffles me. | ||

bob uk Unregistered guest Posted From: 188.29.164.184 |

Bundy tube is steel and tape rolled 720 degrees to form tube. It is not very good but lasts about 10 years. I have been using copper and cunifer. for fuel and brake for over 30 years. I have never had a problem. When making shadow pipes remember to fit the id colour sleeve. Heat shrink Could be used or paint. My lpg system is copper clad in rubber. This is made for lpg stuff. (Message approved by david_gore) |