| Author | Message | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3296 Registered: 06-2009 |

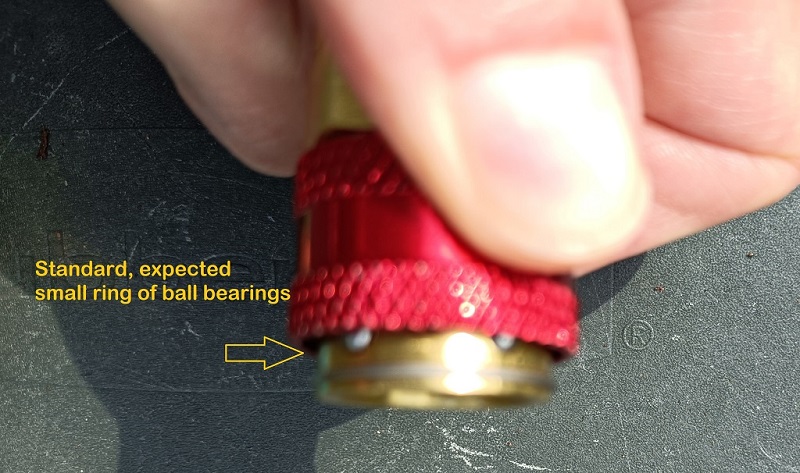

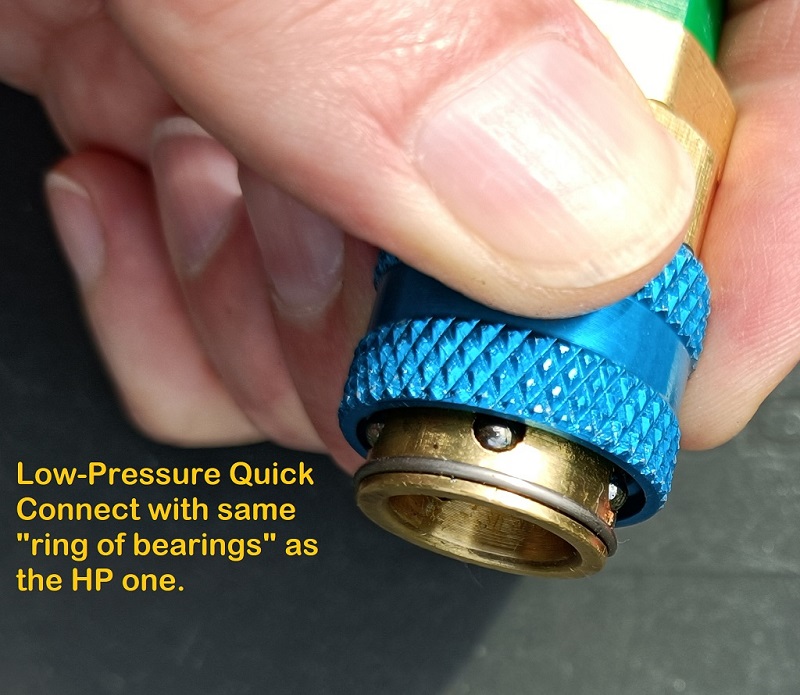

Hello All, This question could be considered non-model specific since it involves a tool that is often used if one wishes to do some DIY diagnostics and/or topping off of the refrigerant charge in one's AC system. I received a brand new AC manifold gauge set yesterday with all the little side bits needed to use it. All was going well with getting everything together until I noticed something odd about the quick connects, which I have documented with photos below.     Both the high and low pressure quick connects seem to suffer from the same defect, and that is the seat where those little ball bearings sit and are supposed to protrude through and act as "finger grips" when the collar descends entirely, were not drilled out far enough to allow them to be pushed through by the collar and do their jobs. I've used fittings of this type on many occasions (not AC specific) and in all cases the collars always dropped such that they covered the exterior part of the little ball bearing completely and pushed it through such that the ring would act as a grip on a corresponding extension on the valve they connect to. Is there some secret here that I'm unaware of, or did I get 2 defective quick connects in this set? Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3297 Registered: 06-2009 |

Scratch this question. Someone on ToyotaNation saw something I couldn't/didn't, and that's that the final photo of the inside of the quick coupler probably shows an anti-blowback valve that pushes up into the quick connect as you push it down on to the Schrader valve on the AC system, allowing the exterior collar to drop and push in those small bearings (half of the round hold on the interior is covered by the collar on that anti-blowback valve in the photo). After a bit of checking his theory proved to be entirely correct. Brian | ||

David Gore Moderator Username: david_gore Post Number: 4102 Registered: 04-2003 |

Brian, Please do not be concerned about posting this issue. The outcome will be of great assistance to other forum members acquiring a tool of this type. I certainly will use this information in the future. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2319 Registered: 05-2012 |

Hi Brian A review would be really helpful, once you've had a chance to use the gauge set. I will need one in the future and will probably buy one from Harbor Freight, unless I'm advised against it. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3298 Registered: 06-2009 |

Geoff, I certainly will. On the whole, these sets are all pretty much the same (in terms of what's included and how you use them - quality is really more than a bit of an unknown). The one thing I was looking for was a refrigerant can tap and valve, as I won't ever be using a "propane tank sized" tank of refrigerant. When it comes to stuff like this, I have learned that price is not always a good indicator of either utility or quality. In my case, since this is something that will be used infrequently, and because it had good reviews on Amazon, I went with it. I have lots of Harbor Freight tools that I find way more than "just adequate." Most tool breakage (including my own) comes from using a tool to do something it was not intended to do or exerting forces on it that it was not designed to handle. I have "cheap tools" that are decades old, and well-used, because exercising reasonable care is something I try to do at all times. Brian |