| Author | Message | ||

Bob uk Unregistered guest Posted From: 94.197.122.79 |

I am not very good at panel beating however I have sometimes produced a first class job. It is not an art it is an exact science and a skill. Try this get a sheet of paper and lay it flat hold one end and move the other end in a mm. The middle will bend up a bit. When sheet metal is bent the outside of the bend will stretch and the inside compress. Sheet metal stretches easier than compressing or shrinking as panel beaters call it. When the bend or dent is straightened the outside of the bend is then compressed and the inside stretched. Because the metal is stronger in compression and far weaker in tension ( stretching) the metal when straightened Will end up effectively longer. Remembering the sheet of paper if that sheet of metal say a door skin held at each end by the door frame then the panel will have a ripple in it after the dent has been knocked out because the skin is too long. Stretching is very easy to do shrinking is very hard to do in panel beating. If a dolly is placed under the sheet and the sheet hit hard enough with a hammer then the sheet will stretch. The more it is hit the more it will stretch. This means that when knocking dents out the more that the dent is hit the more the panel will stretch. So do not spend hours to knock a dent out. Because after about 5 mins of tapping the stretch will get worse and the panel needs to be shrunk. Which is the bit that I fall down on and most other people. I get close and use filler. A skilled panel beater can once the area is ready for panel beater will beat a 2 ft scape in a panel is 15 mins to perfection leaving only paint and no filter required. To prepared a dent for beating BOTH sides must be clean beating through paint and underseal doesn't work. Metal should ring when beaten. To actually learn the hand skills there are web sites. The tension and compressive bit is rarely explained and is crucial to know and understand this you will never do a good job otherwise. A job I did many years ago was complimented by a seriously very good body shop. I knocked a big dent out of a 1960s beetle front wing. The job was perfect because the wing is very curved which allowed the stretched metal to be lost in the curve. This causes the wing to be slightly different from the other side its undetectable unless actually measured. Never do this off the car because the wing may not quite fit as well. (Message approved by david_gore) | ||

Benoit Leus Prolific User Username: benoitleus Post Number: 167 Registered: 6-2009 |

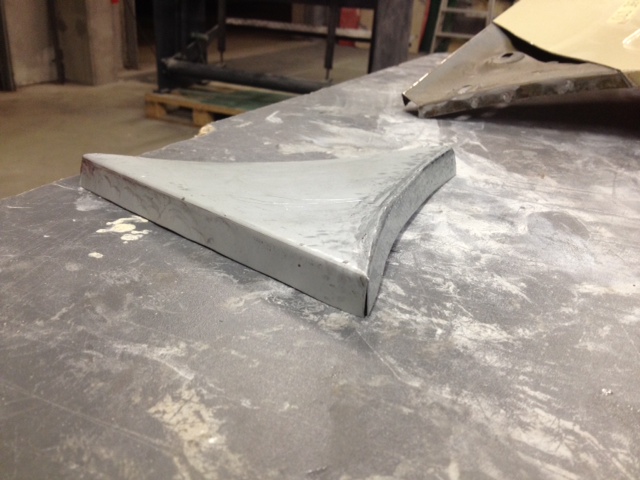

A few months ago I followed an evening school panel beating course (16 x 3hrs). It is, as Bob says, indeed a science. Before we were allowed to start we had to sit through an entire evening of theory : how does sheet metal behave and what tools do you need to get the result you want. Stretching was indeed the easy part : just hit it with a hammer. Shrinking also involves a hammer, but you have to carefully tap it in the right places. Not easy, but I enjoyed it a lot. After only a few evenings I already managed to fabricate these small panel, using only a hammer and a wheeling machine. It's not impressive but i was very proud of myself and it gave me enough confidence to tackle future bodywork issues myself. I can therefore thoroughly recommend a course similar to this one.     | ||

richard george yeaman Prolific User Username: richyrich Post Number: 186 Registered: 4-2012 |

Good job Benoit the wheeling machine is called an English wheel, Bob you are spot on, door skins and rear quarter panels are very hard to shrink one method used was to place a wet mixture of newspaper and water on the panel in a circle leaving the centre clear then heat the centre till red hot with a gas torch and then cool quickly by moving the wet paper over the heated area then repeat several times close to each other this causes the metal in that area to harden and get stiffer another method was to use a swaging dolly and a straight peen hammer you hammered the excess metal into grove in the dolly this strengthened the panel. Richard. Ps I was never a panel beater just a futterer. | ||

Bob uk Unregistered guest Posted From: 94.197.122.72 |

I have seen aluminum E type made by one man and hammers no filler no paint a perfect car. He charges thousands of pounds. You will not find the joins. The panels shown above is how he makes the bodies small panels welded together. He does it fast too one minute it's flat and the next it is a mud guard. He doesn't ever paint any thing just bare metal He is very private. Rod Jolley is also like him accept he likes the advertising. Rod is the man to see if you want a body made to better than RR standards. People work for him for nothing so that Rod is on their CV. To Rod, Boyd Coddington would be a bodger. (Message approved by david_gore) |