| Author | Message | ||

Udo Hoffmüller Frequent User Username: udo Post Number: 55 Registered: 2-2008 |

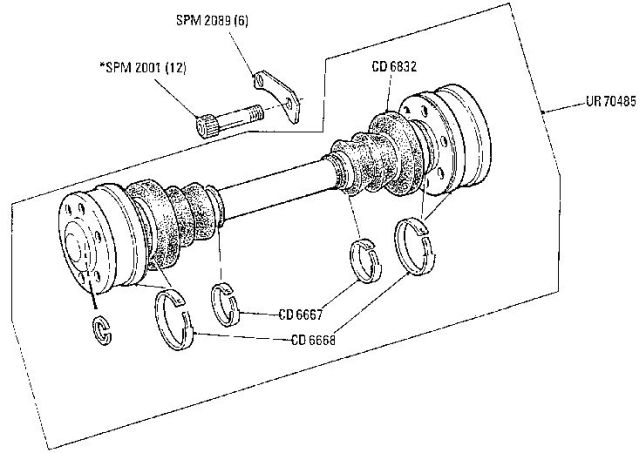

Dear friends, in the past I told you already about a rumbling noise coming from the left rear bottom end of the car. The rumble is independent of any kind of load or bad road surface, it is irregular, mostly not too loud, but always present. Observing the noise for several thousands of miles – even driving in the boot several times – I am sure that the noise is coming from the left side at the rear bottom. We dismantled the hub, but there is everything fine. We changed the rubber mounts of the strut, now perfect. I drove in the boot with one hand on top of the strut/valve body – nothing to feel (with worn out rubber mounts I could feel the knocking noise produced by the strut). The spring is not broken. I exclude the rubber mounts of the trailing arm and crossmember etc. because in this case the noise should not come clearly from the left bottom side where the spring pot/hub is located. Therefore I am suspecting the left driveshaft where it connects to the hub. In the T1 topics at no. 57 I found a picture showing the internals of the lobro shaft, but my TurboRL is MCX35566, the shaft looks different and the description in the manual does not match with the type of lobro shaft shown in the T1 topics. But what could cause the rumble if it is produced by the driveshaft? Can it have run dry and been damaged? Can the retaining clip of the shaft (see pic)  come off giving unallowed axial play/movement to the bearing and the spheres? Is there any typical kind of wear on this kind of shaft? How does it really look inside? It must be different from what the photo in the T1 topics no.57 shows – I think, the drive shaft as used in the later SZ cars could be a good task for one of the nex T1 topics. I am helpless. If the driveshaft is not the guilty part, I would have to deal with the strut itself – but I never heard that the strut produces a rumbling noise internally. Any suggestions? Best regards and thanks - Udo | ||

C Lungmuss Unregistered guest Posted From: 195.93.21.34 |

Hello Udo, Have you taken the spring out? My brief experience regarding springs is that you cannot be 100% sure there not broken without removing them. In two cases the spring was broken inside the bottom spring pot and could not be seen. I thought I should just mention this but I would be surprised if a broken spring gave off the noise you describe. Best of luck with your investigation Clive (Message approved by david_gore) | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 564 Registered: 6-2006 |

Could it be the differential output bearing? Unusual but possible if it sounds like a bearing rumble? Does the noise's frequency or level change with road speed? Not much in the shafts to rumble really unless, as you say, it has managed to rust inside and has pitted bearing faces? | ||

Udo Hoffmüller Frequent User Username: udo Post Number: 56 Registered: 2-2008 |

Dear Clive, yes, the spring has been taken out when we changed the rubber mounts of the strut because the car stood 1cm less high on the left side, we put shims in the springpot to adjust the height. Therefor I know that the spring is not broken. Paul, the noise is really and undoubtedly coming from the spring pot region, not from the center of the car. If you would drive in the boot of my car, you would be completely sure that it does not procede from the center but from the spring pot/hub region. There is no regular frequency, it is completely unregular, just arbitrary/casual/at random, on perfect road surface as well as on poor surface, but permanent. Even at 100 km/h it is there, but at 140 km/h you cannot here it anymore. If have the ARC test device fitted and can drive in "comfort", "normal" or "sport" - no difference, it does not depend on the drive mode of the ARC. The rubber boot looks perfect, I don't think that there is rust inside. The car is in Tenerife since 10 years, it does not see any water. - But what happens if the retaining clip is broken or has come off? Is that possible? When the car leaves the garage, there is a gap of 25cm where a big gate slides along. At the moment of crossing this gap very slowly you here clearly the rumble. Udo | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2105 Registered: 4-2003 |

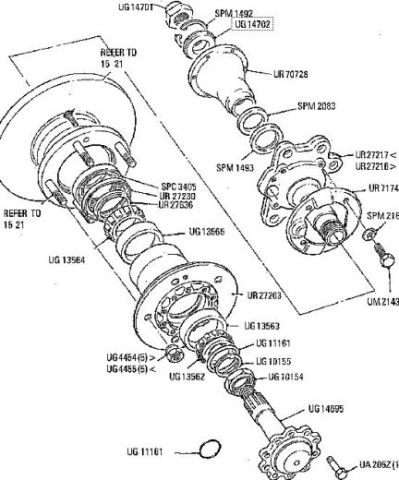

Udo, The quickest thing to do is to swap the Lobro shaft assemblies from the left hand hub to the right and vice-versa. They are identical. It only takes minutes using an Allen socket, 10mm from memory (or is it 12mm ?). That will tell all if the noise doesn't move sides. As a minimum, you may remove the suspect Lobro shaft and refit it with the flange ends swapped. Those German Lobro joints are practically indestrutible unless run dry from a split boot (Manchette). If one really needs to be opened, it may be dismantled easily on a press once the circlip holding the flange to the shaft is removed. Once dismantled, the 8mm ball bearings will show instantly whether the joint is in good condition or not. Incidentally, while near the topic: To fit new genuine boots, the joints must be dismantled. However, there are many cheap aftermarket stretchy ones which may be pulled over the flange without pressing the flange off. I hear that they perform quite satisfactorily, and save quite a lot of time and parts costs as an alternative. Once the old boot is cut away, the shaft may be washed out with petrol and repacked with special-grade CV joint grease. Crewe specifies Rocol MTS 1000, but in reality all lubricant suppliers market a suitable CV grease. RT.  | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 565 Registered: 6-2006 |

Udo, Are you saying the noise frequency/pitch is independent of road speed? Do you only get the noise when moving? Have you tried this? First make sure your accumulators are working properly. DON'T try it if they are not! Find a long downward hill and travel at a speed that the noise is apparent. Slip the car into neutral. Any change? Turn off engine. Any change? Listen for as long as possible, then restart the engine. F.I.P.? (Also Remember the diff is only connected to the car at the outer points of the diff carrier and the control rods. There are no mountings above the diff to transmit noise directly upwards) | ||

Daniel Diewerge New User Username: didi13109 Post Number: 7 Registered: 11-2009 |

Hello Udo! I would also say that one of your Lobro joints is the likely culprit. I now this humming sound from "wrong-wheel drive" cars with faulty joints. Do as Richard Treacy suggests and swap the driveshafts to isolate the problem. Good Luck! Sebastian | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1226 Registered: 4-2003 |

Hmmm. Assuming you don't exit your garage at high speed and assuming by 'rumble' you are talking about a vibration,crossing a 25cm rut slowly, of itself is not going to generate a 'rumble' nor make the Lobro joints rattle. Have we checked the exhaust system particularly the rear pipe hangers, the spare wheel mounts and the sub-frame dampers? | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 566 Registered: 6-2006 |

Bill - I'm not sure if Udo's rumble is a "rumble" or a vibration either. Maybe we are losing something in the description or translation. The only rumble I can think of that is not speed related, is the F.I.Pump. They have a fairly constant speed and pitch but when starting to go, do 'jump' in sound levels and pitch and often (and randomly) turn into a growl for short periods? And are also around the n.s. spring cup. ( To SZ drivers: You should always have at least 1/4 tank of fuel to avoid damaging your fuel pump. Especially on mountainous and winding roads. ) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2108 Registered: 4-2003 |

One last point. I have seen two Turbo Rs with loose inner hub nuts causing rumbles. On the last, 20122, you could lift the inner hub flange almost 5mm. The hub drive shafts (see the drawing below, Drive Shaft – Splined) and flanges have splines on Turbo cars with the retaining nut tightened to just 80 lb.ft (unlike the Woodruff key and nut at 510 lb.ft on non-turbos, where the Woodruff keys often break and cause horrible rumbles and vibrations). Note that the splined hubs incorporate a circlip – see the drawing below. If the circlip is missing or broken, I would expect rumbles and maybe vibrations. With the splined hub, we simply loosened the nut, removed the flange for inspection (only a simple puller, if any, is required) and replaced it all tight. There was no more free play or rumble afterwards. I have a new hub drive shaft and three new hub flanges at hand, but didn't need those expensive bits afterall in either case as the old ones tightened up nicely at 80 lb.ft. So, once the Lobro drive shaft assembly is off, I recommend that you open the locking point on the nut, loosen the nut, check that the circlip is in place and not broken, then retighten it all. RT.  | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2109 Registered: 4-2003 |

ps: from memory, the diagramme above is slightly incorrect. I am almost certain that the circlip is located on the other side of the washer. The nut tightens within the circumference of the circlip and directly onto the washer. RT. | ||

C Lungmuss Unregistered guest Posted From: 195.93.21.34 |

Hello Udo, Thanks for your note back re. spring removal. You have attracted a lot of advice as to the potential sources for the 'rumble/vibration'. Should I get similar I now know where to start looking. Paul, running old cars I was told many years ago not to run the tank below 1/4, but I had not given the possibility of damage to the pump much thought, thanks for the tip. Clive (Message approved by david_gore) | ||

Udo Hoffmüller Frequent User Username: udo Post Number: 57 Registered: 2-2008 |

Thank you all for your advice. Bill, the "rumble" is really a rumble, nothking like vibration. Exhaust hangers are fine, the exhaust does not bang/throb/knock against the body or something else. The spare wheel mounts are prefect. The subframe dampers are new (not orignal Bentley ones, but the new ones from Introcar, the Bentley ones were poor and noisy, kracking and rattling), the old ones have been leaking. Paul, yes I did what you describe, we suspected already the fuel pumps. A long street without traffic on sunday 2 km or more downhill, engine off ... no difference. The accus are new, I changed them to exclude them as culprits, but no effect. Richard, we suspected already the hub nut. We removed the hub to check it meticulously, but we did not found anything wrong. 80 lb ft is not so very much, only about 110 Nm, therefor not so difficult to tighten up. I do understand that a loose nut could produce just the noise I try to describe, especially passing slowly a gap of 25 cm - and I am passing the gap so that the rear wheels do not cross the gap at the same moment, but one after the other - and the knock/bang comes only from the left wheel region, not from the right side. By the way, Richard, look at the grafic copied from my manual!  If you all say that the shaft itself is nearly impossible to produce this noise/rumble I would once again concentrate on the hub nut ... I hoped to avoid this job. And what about the strut itself????? Best regards - Udo | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2110 Registered: 4-2003 |

Aha. Crewe finally corrected the drawing afterall ! Cheers from CH. |