| Author | Message | ||

whunter Frequent User Username: whunter Post Number: 14 Registered: 10-2003 |

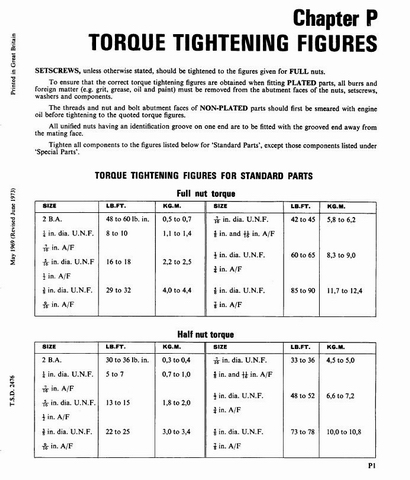

proper torque values for the water pump on 1985 Silver Spur. Use at your own risk, Best possible copy of fuzzy fax, just finished keying in the Torque Tightening figures. Can someone please check these? Thank you. whunter Torque Tightening figures Standard torque tightening figures Tighten all setscrews, full nuts and half nuts to the figures given in the tables. Setscrews should be tightened to the figures quoted for full or castellated nuts. Plated parts should have all burrs and foreign matter (e.g. grit, grease and paint) removed from the abutment faces of the nuts, setscrews, washers and components, to ensure that the correct torque tightening figures are obtained. The threads and abutment faces of none plated parts should be smeared with engine oil before being fitted. All unified nuts having an identification groove on one end, are to be fitted with the grove away from the mating face. Certain items should not be torque tightened and these are as follows. #1. Nuts that are locked by riveting. #2. Wood screws. #3. All threads less than 2 B.A. Components used during manufacture of the vehicle have different thread formations (Metric, UNF, UNC, etc.). Therefore, when fitting nuts, bolts and setscrews it is important to ensure that the correct type and size of thread formation is used. UNF = UNIFIED THREADS (SAE FINE) A/F = ACROSS THE FLATS (BOLT HEAD SIZE) FULL NUT SIZE________________NM_________KGF_M______LBF FT 2_B.A.______________6-6.5______0,6-0,7____48-60_LBF_IN 1/4_in_dia_UNF______11-13______1,2-1,4_____8-10 7/16_in_A/F 5/16_in_dia_UNF_____22-24______2,2-2,4____16-18 1/2_in_A/F 3/8_in_dia_UNF______39-43______4,0-4,4____29-32 5/16_in_A/F 7/16_in_dia_UNF_____57-61______5,8-6,2____42-45 3/8_and_11/16_in_A/F 1/2_in_dia_UNF______82-88______8,3-8,9____60-65 3/4_in_A/F 5/8_in_A/F_________116-122____11,6-12,4___85-90 7/8 in A/F XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX HALF NUT SIZE_______________NM_______KGF_M_____LBF FT 2_B.A.____________3-4______0,3-0,4____30-36 LBF IN 1/4_in_dia_UNF_____7-9______0,7-0,9____5-7 7/16_in_A/F 5/16_in_dia_UNF____18-20_____1,8-2,0____13-15 1/2_in_A/F 3/8_in_dia_UNF_____30-33_____3,0-3,4____22-25 5/16_in_A/F 7/16_in_dia_UNF____45-48_____4,6-4,9____33-36 3/8_and_11/16_in_A/F 1/2_in_dia_UNF_____65-70_____6,7-7,1____48-52 3/4_in_A/F 5/8_in_A/F________99-105____10,1-10,7___73-78 7/8_in_A/F XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX METRIC-FULL NUT SIZE______NM________KGF_M______LBF FT M_6______11-13_____1,2-1,3_____8-10_LBF_IN M_8______28-29_____2,8-3,0_____20-22 M_10_____56-59_____5,7-6,0_____41-44 M_12_____95-98_____9,7-10,0____70-73 M_16____240-249___24,5-25,4____177-184 XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX Thank you Have a great day! _________________ whunter RROC, Lake Michigan, Motor and Ohio region. ASE Master Mechanic Bloomfield Eurotech 45671 Woodward Avenue Pontiac, MI 48341 Work Phone 248-334-6400 Fax 248-334-2363 asemastermechanic@juno.com | ||

David Gore Moderator Username: david_gore Post Number: 134 Registered: 4-2003 |

WHunter, I have a similar chart in my archives at home but as I am not there at present; I cannot check these for you until later this week. Hope this request is not urgent otherwise I hope Bill Coburn can help on my behalf. | ||

whunter Frequent User Username: whunter Post Number: 18 Registered: 10-2003 |

Thanks David. Not urgent, just a lot of work, concerned it may have errors. Thank you. whunter | ||

David Gore Moderator Username: david_gore Post Number: 146 Registered: 4-2003 |

The following general fastener torques apply for Shadow I vehicles UNLESS SPECIFIED OTHERWISE. High tensile [eg SAE Grade 5/Grade 8] fasteners are capable of higher torques provided the tensile strength of the material holding the fastener is adequate. Torque values are set by the design engineers based on the mechanical properties of the materials used and the thread dimensions and are calculated to ensure the yield point of the material has a safe margin above the stress imposed by the fastener when tightened. There are no special torque figures for the water pump mounting bolts so these will be determined from the data below:  | ||

Richard Treacy Prolific User Username: richard_treacy Post Number: 72 Registered: 4-2003 |

Also see: http://www.jag-lovers.org/xk-lovers/library/torque.htm | ||

whunter Prolific User Username: whunter Post Number: 50 Registered: 10-2003 |

Hello Everyone  Thank you all for the information. This is a Great group to participate in.  Have a great day. Whunter |