| Author | Message | ||

dave turner Unregistered guest Posted From: d137-186-236-123.abhsia.telus.net |

about two years ago my 87 spur had a front shock lockup solid , the suspension would not move at all.All was well when the car was parked but the following day a solid suspension . i replaced both front shocks and all has been good, that is until today when the same has happend again , i have just removed the shock and i can get the shaft to move smoothly when pressed against the floor but only about an inch and a half travel before a solid knock and no more movement . What is with these shocks? i do lift the car on my wheel free hoist for its weekly tinkering but i cant see that having any detremental effects lastly any sourse for cheap replacements ?? thanks Dave (Message approved by david_gore) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1110 Registered: 4-2003 |

There are two brands of shock absorbers to suit your car correctly: Boge as originally fitted, or Bilstein B46-1429. The general consensus seems to be that Bilsteins are the preferred replacements. Just about any shock absorber shop in the world will order them in for you in a day or so. They are not ridiculously expensive, but fitting them is a true pain. It's strange that you have had problems as the Bilstein and Boge units both have an extraordinary life expectancy unparalleled in any other make of car. My '87 Turbo R and '72 T-Series both have the original Boge units in good shape (the Turbo R is tested on a computerised rig every two years in the roadworthiness test and there is only a 5% performance tolerance allowed here). That's at 270,000km and 330,000km respectively. Are you sure that the tower cap is not shot ? The hole for the shock absorber top fixing is known to wear if the shock absorber is incorrectly tightened. If the shock absorber becomes a loose fit as a result, then the shock absorber works at an angle and is soon destroyed. If so, you may buy a new cap, have the existing one sleeved, or have it weld-filled and redrilled. Lightning never strikes twice: don't blame the shock absorber, but rather find the cause of failure or it will only happen again. RT. | ||

david turner Unregistered guest Posted From: d137-186-236-123.abhsia.telus.net |

both shocks assys are now out an dissasembled, all the mounting hardware is is as new condition as are the spring rubbers, the lower joints were rebuilt during the last go round. i just went and had another good look at the top mounts and they are slightly oval (about 0.010") on both sides .although not significant i will sleeve them anyway. i shall order some Bilsteins and if i can let the gas out safely i will cut the shock in half and post some pictures. Dave (Message approved by david_gore) | ||

david turner Unregistered guest Posted From: d137-186-236-123.abhsia.telus.net |

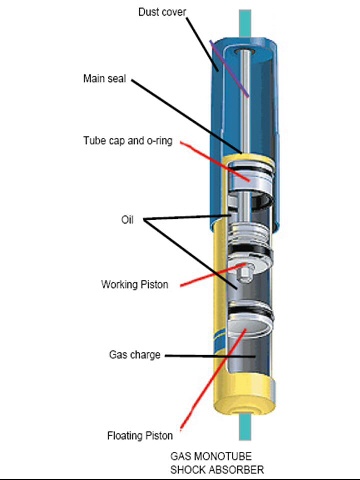

problem solved after some serious pondering, the only reason i could accept was that some oil had been lost from the shocks, which would allow the gas in the bottom of the shock to expand and raise the floating piston which would then contact the bottom of the shaft and cause the shock to lock up as any movement by the shaft would have to compress the gas and not just move the piston / valve assy through the oil. after constucting a sturdy jig the shock was compressed and which exposed the snap ring, following removal of the top cap and the seal below, the shock was compressed competely (very high pressure)it was then refilled with shock oil, readily avaliable at motorcycle shops, the seal and cap refitted and both shocks now work as new all for the cost of a liter of oil.I am a very happy camper. But while this was a succesful endeaver i must caution everyone that the presures dealt with are enough to propell shock absorber parts straight through the human body so any one wishing to attempt this sort of foolishness should be extremely carefull. Dave (Message approved by david_gore) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1114 Registered: 4-2003 |

That all makes sense, except why did it leak in the first place ? Sure, the working piston should never come near the floating piston or indeed it may lock solid at the point of contact. I imagine that you replaced the cap outer o-ring, but the cap seal must be nigh impossible to replace. Given that the gas charge pressurises the oil to around 20 atmospheres, you are brave indeed to open up a Monotube shock absorber. A concern is that the floating piston seal will have been subjected to very high pressure differentials in the vehicle, and to even more during refilling (50 atmospheres ?), whereas it is subjected to none at all in service. Are you confident that the repair is permanent ? Were there signs of oil leakage around the cap ? Also, it may be worth approaching the manufacturer and asking for a free or heavily-discounted replacement given the very early failure. Surely they would agree that two years is a very short life. A word of warning to anyone else handling a Monotube shock absorber like these: even the slightest dent in the tube will ruin it. Many are ruined by dropping or mishandling them during installation. Twin tube conventional or gas types are far more tolerant to dents as the outer tube only holds reserve oil and air or gas. Only the inner tube is active on a twin tube shock absorber. | ||

david turner Unregistered guest Posted From: d137-186-236-123.abhsia.telus.net |

yes i am confident in the repairs . There is no seal in the cap or "o" ring in the tube all the oil sealing is done by a quarter inch thick flexible rubber washer the outer part sealing against the tube and the inner hole sealing against the rod, oil presure will force it against the tube and rod to provide the seals. the cap has only a dirt excluder. where did the oil go ? well when the shock is at full extension the top side of the piston contacts the rubber seal and probably distorts it slightly allowing some oil to pass by. this will only happen when the shock is left at its max extension not in normal use. Well my car spent a considerable time last winter at the body shop undergoing a complete repaint where it was on a hoist with the wheels hanging. this i think is when most of the oil slowly escaped as it has since covered a very limited distance and has spent more time on my hoist at home a further small oil loss brought the problem to light, it been two days now with no leaks at all so i will remain quietly confident. ps perhaps thats why new shocks often come with a stap around them keeping them compresed, and i thought it was so they would fit in the box! best regards Dave (Message approved by david_gore) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1116 Registered: 4-2003 |

...............?  No end cap sealing ? Yet the piston was fouling the seal ? Good luck. Also, the heat of a paint oven (never used these days anyhow) is less than that of parking in the street on a sunny day. If oil leaks out once from anywhere it will leak again unless you stop the cause. | ||

david turner Unregistered guest Posted From: d137-186-236-123.abhsia.telus.net |

Nice picture of a shock richard. but nothing like mine i think you are assuming that mine are bilstien. when in fact they are original equipment Girling de Carbon according to the stamp on the tube tht is . as i said a snap ring holds the metal cap in place, directly below the cap sits the rubber seal with the presure holding against the cap and forming the seal. if the cap were sealed then any oil that passed the first seal,to be retained by the seal on the cap, would would equalise the pressure on both sides of the seal rendering it useless and left to float in the oil. in the picture you show the shock could rest at full extension with the working piston against the tube cap without ant ill effects a better idea all round if there is ever a need i shall have to insist on bilstien . but when they came from a RR dealer in R packaging you tend to trust the design quality . perhaps they moved this designer on to steering racks. Dave (Message approved by david_gore) | ||

Larry Halpert Prolific User Username: larry_halpert Post Number: 100 Registered: 9-2003 |

I didn't know Girling even made shocks for these. I wonder what Girling part number is stamped on them. I thought original equipment was only Boge into the '87-'89 20,000 series, etc. Larry | ||

david turner Unregistered guest Posted From: d137-186-236-123.abhsia.telus.net |

Larry the stamping on the shock says GIRLING DECARBON 70056379A 4GP9. I doubt if that can be converted into a RR part #. after studying the picture that Richard posted i may dissasemble the shocks and make a new top cap with different seals similar to the bilstien system i could also fit a filling port for the nitrogen and change the oil for a slightly thicker spec to stiffen the damping.if i do then i will post some pictures. Dave (Message approved by david_gore) | ||

david turner Unregistered guest Posted From: d137-186-236-123.abhsia.telus.net |

Well i did go ahead and make some new top caps. they carry a lip seal around the shaft and an "o" ring to seal to the tube, a teflon bushing on the inner bore lets the shaft slide smoothly, and a fill port was added to the botton of the tube to enable refilling of the nitrogen. the gas pressure was calculated from the effort required to hold the shock at the half compressed position while the oil viscosity was increaced to 10w which gives approx a 10% increace in the damping rate. I have attempted to include pictures but they all seem too big to be accepted . if you can explain how to do this i will post them. well off to the garage for the next project Regards to all Dave Moderator's Advice: David, you have to register on the Forum before you can post pictures etc - this is a simple process by using the "Register" button in the top right hand corner of the webpage. I am following your work here with a great deal of interest especially the results you achieve when the shocks are installed and settle in. (Message approved by david_gore) (Message edited by david_gore on November 02, 2006) | ||

David Turner Yet to post message Username: silver_spur Post Number: 1 Registered: 11-2006 |

Finaly! I think i may have sent some pictures. Picture1 shows the original top cap ,just a fancy washer realy  Picture2,the shaft assy with the working piston on the left and the seal and top cap where they would be ,mid stroke.  picture3, shows the seal squashed between the top cap and the full extension stop, as when the wheels would hang when on a hoist.  Picture4, the underside of the seal  Picture5, the top of the seal with marks from being squashed.  Picture 6, the underside of the top cap.  Picture7. a great way to unwind with the lathe, one of my favorite toys.  Picture8.One of the finished caps with a bushing for the shaft to ride on.  Picture9. The two top caps with the lip seals for the shafts, the grove around the exterior will carry the O ring to seal the cap to the shock tube.  Picture10. a Nitrogen fill port with a Shrader type valve was added to the bottom of the tube below the floating piston.  Picture 11. All assembled, filled with oil and charged with Nitrogen. ready to go back on the car.  best regard to all Dave | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 617 Registered: 9-2004 |

I will post again! Dave that is spot on and brilliant. Please let us know the best running pressure with regard to the nitrogen, don't i just love the being able to alter the nit pressure with the shrader connection. Are you happy with just the snap ring holding the your machined modified top caps in place even though they were originaly like that. | ||

David Turner New User Username: silver_spur Post Number: 2 Registered: 11-2006 |

Hi Patrick I dont anticipate any snapring problems ,If you look at the cap on the left of pic 9 you can see that the cap has two different diameters, the lower and greater diameter is a nice snug fit in the shock tube ,while the smaller upper dia is a snug fit inside the snap ring when its in the grove in the tube. To assemble, The oil and the top cap is pushed down the tube well below the snapring grove and the snap ring is installed with a small ammount of Nitrogen added the oil and the top cap are pushed up the tube and into position where the top caps smaller dia is now inside the snap ring which will prevent it from escaping is grouve Dave | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 619 Registered: 9-2004 |

Dave, yep i now understand,so if future repairs are needed i assume the nitrogen is let go with ease now you have the shrader valve the and the cap is removed without the need for the press! I must say i do love these mods when not in the book,keeps my brain ticking. |