| Author | Message | ||

Darryl Watson Experienced User Username: inox Post Number: 98 Registered: 04-2015 |

Hi, 1990 Mulsanne S. I am pulling my hair out refitting the distributor(s). Because I forgot to mark the rotor arms position before removing the distributors, I am having to use TDC to re-fit them. I put a TDC timing tool in A1, (front right looking from the driverís seat), plug hole. When A1 is on the compression stroke, (the indicator pops out of the tool guide), and reaches the top of the stroke the TDC mark on the pulley approx. 180 degrees away from the pointer on the block. The mark that I assume to be BDC is near but not exactly near the pointer. Fit the distributor with the rotor arms pointing at the markers as per the service manual. The engine runs but is a little uneven. The plug leads are wired correctly. As are the Ignition amplifiers and coils. Any advice please. Regards Darryl  | ||

Darryl Watson Experienced User Username: inox Post Number: 100 Registered: 04-2015 |

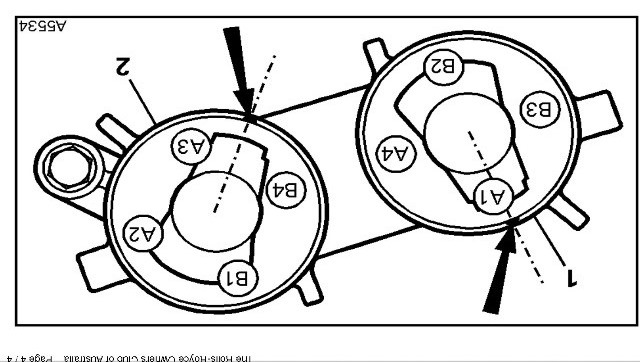

To add a little more information. Section TSD5001-B2 of the manual, (item heading "Ignition distributor to remove and fit"), reads: Position of Distributor rotor arms at TDC with A1 cylinder on itís firing stroke. This is adjacent to a diagram of the distributors (viewed as though youíre sitting on the roof of the car looking down). The rotor arms in the attached photo are in the position of the drawing. I am assuming that the firing stroke referred to above is the compression stroke. Regards | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 596 Registered: 07-2015 |

Hi Darryl They look wrong to me, see attached diagram Mike  | ||

gordon le feuvre Frequent User Username: triumph Post Number: 323 Registered: 07-2012 |

Darryl, are you sure you are on firing/compression stroke for A1. The only true way to confirm is to remove A bank rocker cover, get A1 cylinder valves on "rock" that is to say exhaust just closing and inlet opening then turn engine over in correct direction of rotation so the piston goes down bore, then next time it comes up that is firing/compression stroke. Then align tdc and refit distributor. Don't forget that if you have changed belt connecting the two distributors these have to be set correctly relative to one another as well as indicated in Michael Vass's pic! | ||

Darryl Watson Experienced User Username: inox Post Number: 101 Registered: 04-2015 |

Hi, Michael, I think that the diagram is printed "upside down". Referring to the fixing bolt turn the diagram to the right a little over 90 degrees and it aligns with my photo. If Iím correct it caught me out when I first looked at it. Gordon, Thanks for that valve tip. I'll give it a go. Regards | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 597 Registered: 07-2015 |

Hi Darryl Ah see what you did there , your view is from the other side the car lol you got me lol Go With gordon  Good luck Mike | ||

Darryl Watson Experienced User Username: inox Post Number: 102 Registered: 04-2015 |

Hi Gordon, Carried out your suggestion this morning. I get the same results in that when the valves are on the rock the pulley is approx 180 degrees out. The same with compression stroke TDC. I guess it has been like this since before I bought the car and it's run for 1000s of miles since purchase. Regards | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 598 Registered: 07-2015 |

Hi all I wonder is it possible to fit the pulley on 180 deg out? Mike | ||

gordon le feuvre Frequent User Username: triumph Post Number: 325 Registered: 07-2012 |

According to TSD 4700- spirit w\shop manual, the pulley\damper can only be fitted one way because of locating pin. If timing was out so much engine would NEVER run. Lets double check. If engine is on compression\power stroke at TDC (easiest way is to have 'A' bank rocker cover off to expose valves) 'A' bank is right hand one as viewed from sitting in car, whether Rh or LH steering. Remove No.1 spark plug(front one) and "feel" piston rising with long screw driver until the piston pushes the screw driver out of plug hole to it's highest position. Is TDC mark on crank aligned with pointer or very close, which it should be? The next step, is to confirm it is on compression stroke. To confirm whether piston is on power\compression observe whether one or other valve on No.1 moves when coming up to TDC. If it does, then piston needs to go back down bore (in direction of engine running/cranking) then come back up bore to TDC position. Then get distributor assembly and offer up in position that it should be fitted (with A1 pointer at mark and other rotor at mark on second rotor. At this point you should be able to fit distributor fully and Rotor(s) should not have moved- as Michael Vass's illustration. If engine is definitely on power stroke A1, but distributor cannot be fitted without rotor for A1 being moved one way or other, the assumption must be that the skew gear for the distributor drive must have been incorrectly assembled at some point??. There is no normal timing adjustment with this system, if both parts of distributor are aligned correctly via toothed belt, engine is on A1 power and distributor body fits crankcase fully home with A1 mark rotor mark in correct A1 position-timing must be correct! Sorry to go on a bit, but am attempting to cover off everything. Hope this might be some help. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2227 Registered: 09-2004 |

" (easiest way is to have 'A' bank rocker cover off to expose valves) 'A' bank is right hand one as viewed from sitting in car, whether Rh or LH steering. Remove No.1 spark plug(front one) and "feel" piston rising with long screw driver until the piston pushes the screw driver out of plug hole to it's highest position" To save time, the use of a whistle in the spark plug hole to sound as the piston comes up to TDC! | ||

Darryl Watson Experienced User Username: inox Post Number: 104 Registered: 04-2015 |

Thanks to every one for their input. I have now checked the timing 5 times incorporating all of the suggestions received. ē Rocker cover removed ē TDC indicator tool in Al plug hole (Front plug right hand side viewed from the driverís seat). ē Turn crank in direction of engine running (clockwise viewed from the front of car) ē A1 piston rises ē Indicator rises ē A1 exhaust valve opens then closes ē A1 inlet valve opens then closes as ē Indicator drops ē Indicator rises and indicator rod pops out of body due to air being expelled. (Compression stroke) ē At the immediate (next) TDC the timing pointer does not line up marks on pulley (approx. 180 degrees out) Distributors fitted as per photo with reference to diagram now aligned in the same plane. Engine usually starts then runs a little unevenly but occasionally will kick back (indicating timing slightly off?) Have taken the opportunity to give the ignition components the once over replacing plugs (Denso iridium), Leads (Lucas), both distributor caps (Beru), and replaced coils with two from a 43,000-mile car. I have carried out the Mototronic fault finding procedure but found nothing untoward except one earth point resistance slightly high, (now rectified). I guess itís now time to seek help from the RR-B specialist thatís about ten miles from home. £££s Regards. Darryl    | ||

Omar M. Shams Prolific User Username: omar Post Number: 1930 Registered: 04-2009 |

Do you have a failing rotor arm? If you swap them around does the car behave exactly the same or is there a difference in the kick back? If you have a spare rotor arm - it may be worth trying it in each distributor one at a time. It is clear that at least one of those must have failed in the past - that is why your two rotor arms are different colours. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3008 Registered: 06-2009 |

Omar, Interesting. I was wondering if the two colors were OEM and meant to make it easier to instantly differentiate which set of 4 cylinders one was looking at. Were I to be in a position to need to replace one, I'd probably try to find a different color, as I'm big on using color coding and it would be handy in this instance. Brian | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 614 Registered: 07-2015 |

Hi Darryl I found 2 cars that "kick back" had bad engine earth's try an additional earth strap from body to block. Mike | ||

Darryl Watson Experienced User Username: inox Post Number: 105 Registered: 04-2015 |

Thanks for the input, I wondered about the rotor arms especially as the distributor caps jumped off because I didnít fit them the right way around. (Only made that mistake once). When I replaced the belt, I used a generic belt so I have ordered a couple of rotor arms and a Gates 100 XL 025 belt. I checked the fairly new and rather substantial the earth cables from the block to the body and the bolts are tight. I also cleaned the five (or six) wiring eyelet connectors and metal work on the inside of the front wing. If the rotors and belt donít help, Iíll run a couple parallel earth straps to the block. Regards Darryl | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 615 Registered: 07-2015 |

Hi Darryl Good luck, what is strange is the SY's had 2 earth straps but SZ's only one. I fitted mine from the psa reservoir bracket bolt to the suspension top ok cheers Mike | ||

Darryl Watson Experienced User Username: inox Post Number: 115 Registered: 04-2015 |

Have now replaced most things in the ignition circuit and rectified three ďfaultsĒ that showed up during working through the Motoronic fault finding chart. Replaced, plugs & leads, dizzy belt, rotor arms, dizzy caps, air flow pot and ign. coils, (used from a 43,000 mile car). I still think that there may be a timing issue as a couple of times since the above it has still kicked back slightly. I think itís time to take to the experts* for their opinion because Iím stumped. In the decades Iíve been playing with cars that hasnít happened very often. Thanks to all for your input. *Thereís a Bentley RR specialist about twelve miles from my home. Regards, Darryl | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 622 Registered: 07-2015 |

Hi Darryl When you say kicks back ,do you mean when trying to start it? Mike | ||

Darryl Watson Experienced User Username: inox Post Number: 116 Registered: 04-2015 |

Hi Mike, A few times the engine has coughed/moved slightly when switching on the ignition. Likewise, a few times when starting the engine, it kicks back and doesn't run and then starts when the key is turned to start the engine again. It happens about 10% of the time at an estimate. Regards, Darryl | ||

Jim Walters Frequent User Username: jim_walters Post Number: 292 Registered: 01-2014 |

Daryl, that kick with turning the key on and off is characteristic of a failing ignition module on the earlier cars with OPUS ignition. Yours has two Bosch modules, one for each distributor. I have not come across one of those failed yet on the cars that come in to me but as the symptoms are the same as a failing Lucas OPUS I would be looking at those modules. I believe, but am not positive, that the Bosch modules in your car are the same as the ones fitted to 4 cylinder Porsches and BMW's. One module for each distributor. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 623 Registered: 07-2015 |

Hi just remind me of your chassis number. Have you tried another earth strap yet? Cheers Mike | ||

Darryl Watson Experienced User Username: inox Post Number: 118 Registered: 04-2015 |

Hi Jim, Mike, I hadn't considered the ignition amps. I had one fail about five years ago Ė it was intermittent - 8 cylinders then 4 then 8. Quite entertaining. It appears that the amp, UD70829, is unique to RR-B and itís a Bosch 0 227 100 146. The MBís are 0 227 100 114, (1/3rd of the price so whatís new), and I couldnít find a Porsche amp that looked similar. Iíll get a used amp and try that. There are two 3-way earth leads and both are in very good/shiny condition. I did remove them and clean the ends and the associate fixing points to be sure. The chassis No. is 32556. Many thanks, Regards, Darryl | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 624 Registered: 07-2015 |

Hi Darryl try a new ign relay by the fuse box | ||

Darryl Watson Experienced User Username: inox Post Number: 119 Registered: 04-2015 |

Hi Mike, Thanks for the suggestion. Swapped it over with the rear fog light relay, (same Bosch code), engine no difference. Because I have a spare I also swapped the ABS & engine management relay. It only took a couple of minutes so I thought why not? Again no difference. Regards, Darryl | ||

Udo Hoffmüller Experienced User Username: udo Post Number: 103 Registered: 02-2008 |

Do I understand well that the engine is kicking back? The only thing that can cause the effect is ignition and sufficient gas expansion while a piston is moving up in some cylinder. That small rotation determines that kickback is caused by spark, gas ignition, and burning well before top-dead-center (BTDC) piston position. In other words, the engine fires at the wrong moment. And that in turn means that the EngineECU believes it should ignite. So it "thinks" it's the right time to fire - but that's not true. The EngineECU must therefore receive incorrect information. It is "told" that it is the right moment to ignite even though it is the wrong moment. Who "tells" the EngineECU when is the right time to fire? The crankshaft sensor on the front of the engine does this, it sits on the front on a bracket above the crankshaft damper. If its distance from the reference pin is too large or its internal resistance is out of range, it delivers incorrect values ​​and the EngineECU no longer "knows" when to start firing, i.e. the moment A1 is in BTDC. The error does not have to occur continuously. So you have to check air gap and resistance. The air gap of the sensor to the reference pin should not be less than 0.9 mm and not more than 1.3 mm, adjust if necessary (an adjustment tool is required). The internal resistance of the sensor between pin 1 and pin 2 of the plug must not be less than 400 ohms and not more than 1600 ohms. If these values are within the given limits, the sensor works correctly. After all you have done already, my next question would be: Have you ever thought that the EngineECU itself could be faulty? Swap the engineECU for another one. If you don't have another Spirit pp available - sometimes you can find one for a reasonable price on eBay. Regards - Udo | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 625 Registered: 07-2015 |

Hi Udo and Darryl I was thinking the same if it kicks by just switching on the ignition, I thought maybe the relay was crackling . Try them Darryl (but hide the hammers lol) Good luck Mike | ||

Darryl Watson Experienced User Username: inox Post Number: 120 Registered: 04-2015 |

Hi, Ignition amplifiers are OK. Udo, Wow! You should write technical manuals. The kick back is slight and only happens occasionaly. Spark sensor. The sensor on our car fits into the engine so you canít see the sensor body when fitted. (Similar to the crank sensor at the rear). So the method of measuring the gap is different. Looking at my test results the sensor dc resitance is 541.8 Ohms (within spec) and the cranking voltage 0.3v (should be about 0.11v). This did set me thinking. My service records show that I replaced the sensor, Blink Code Error), in March 2019 with a used unit. I first noticed the unevenness summer of that year. In the car the unevenness is only apparent at 2000 rpm plus. I have a spare and will fit that in the coming weeks (and check the gap if possible). The current on the EHA was 97m/a in series with pin 4 and 100m/a meter in series with pin 5. Should be 100m/a. I had thought of the ECU but given the price even of used ones I would rather not. I have found companies that can test / repair ECU's and if it comes to it talk to one of them. Regards, Darryl | ||

Udo Hoffmüller Experienced User Username: udo Post Number: 110 Registered: 02-2008 |

Dear Omar, I am traveling right now and cannot give any detailed explanations at the moment. I guess you have the workshop manual. There you enter "001485" in the search function. Under this number you will find a flow chart describing the test of the MAP sensor. Regards - Udo | ||

Omar M. Shams Prolific User Username: omar Post Number: 1942 Registered: 04-2009 |

thanks Udo. Safe travels. | ||

Darryl Watson Experienced User Username: inox Post Number: 136 Registered: 04-2015 |

I like to say thankyou to everyone who replied to my original post with their suggestions. The engine is now running OK (he says finger crossed and holding onto a great lump of wood). Firstly the timing mark on the pulley is approx 180 degrees out. The kick back that sometimes happened when starting the engine hasnít happened since replacing the distributors.* Our local RR-Bentley specialist, Hillier Hill, looked at the car when they resumed operations after Covid Lock down. The fuel mixture was weak. The Hillier Hill had experienced uneven running of these engines when the mixture was weak previously. The wheels also needed balancing. Iíd had the wheels balanced twice already. They must have a magic touch because once before they balanced wheels that had been balanced making a significant improvement. The day the car was returned the expansion bottle started leaking. An easy job but! MOT test next week. Onward we go. Regards Darryl *I obtained a used distributor fitted with Beru leads in v.good condition and nearly new Bosch caps. Replaced the belt and bushes on the A bank distributor. Using this for comparison I found that I had re-assembled the previous distributor incorrectly Ė one part was upside down. | ||

Omar M. Shams Grand Master Username: omar Post Number: 2059 Registered: 04-2009 |

This thread has been most helpful for me. I am setting the distributors on my 1990 Bentley Continental right now. Just for reference, the sockets mentioned earlier 1 5/16 and 34mm are not the only ones that fit. A 33mm socket also fits (rather nicely if I may add). If you can get a deep socket then it will be ideal. I will be using a compression tester to capture firing TDC. | ||

Mark Luft Frequent User Username: bentleyman1993 Post Number: 317 Registered: 10-2016 |

Omar, 1990 Continental?? | ||

Omar M. Shams Grand Master Username: omar Post Number: 2062 Registered: 04-2009 |

. | ||

Mark Luft Frequent User Username: bentleyman1993 Post Number: 318 Registered: 10-2016 |

WOW! | ||

Omar M. Shams Grand Master Username: omar Post Number: 2064 Registered: 04-2009 |

Dear Darryl, So in conclusion what was the cure to your problem? And how can it be that the TDC mark was 180 degrees out? That just cant make sense as the pulley can only go on the shaft one way. Thanks Omar | ||

Darryl Watson Experienced User Username: inox Post Number: 137 Registered: 04-2015 |

Hi Omar, I believe that there was probably no single cause responsible. Definitely the mixture was wrong resulting in uneven running and vibration at 2000rpm+. The wheels needed balancing which gave steering wheel vibration at 65 - 70mph coinciding with the 2000+rpm vibration. (The wheels had already been balanced twice previously). The kick back when starting I suspect was the distributor but canít be sure as it didnít do it every time and I replaced a lot of parts etc. The ignition leads I finally fitted are of a better quality than the new ones I purchased on a well know auction site. So who really knows. Re timing. The timing mark on the pulley is approx. 180į out. Iíve had the car for fourteen years and nothing was changed in that time. Regarding finding TDC to remove distributor. At the end of the day all you need to is put something to loosely seal plug hole A1. When it pops out thatís the compression stroke. (That tip came from this forum). I used a bit of wadded paper towel. A screwdriver or similar in the plug hole will indicate TDC. Itís not that critical for replacing the distributor. (Large gear spaces on distributor drive). Regards, Darryl | ||

Omar M. Shams Grand Master Username: omar Post Number: 2065 Registered: 04-2009 |

Thanks Darryl. My car was easy to fix. I replaced all the plugs, one broken rotor arm and two HT leads that the garage fitted incorrectly . One thing that we need to tell people (not everyone knows this)... the rotor arms are held on by a bolt. You will need an Alan key to remove the rotor arms off these models of car. |