| Author | Message | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2153 Registered: 4-2003 |

I always thought that all Turbo Rs lack torque. Perhaps our resident metallurgists would like to comment. Is this metal fatigue ? The shaft is the input shaft of my Turbo R's transmission after 300,000km, a 3L80 (same as a THM400), as fitted to most SY and SZ cars. This transmission is the favourite of drag racers and hot rods due to its immense strength. The shaft snapped at the forward clutch end. The converter end is intact. By the way, it happened on the motorway near Picton at 5:30am, about two thirds into my weekly trip to Sydney from Canberra. RT.    | ||

Omar M. Shams Prolific User Username: omar Post Number: 144 Registered: 4-2009 |

Wow.. what a failure!!! I am not a metallurgist - let us be clear about that. There are many factors here: the failure took place at a natural weak point ( the pin hole). There seems to be more than the failed crack that have eminated from the source of failure. 300,000 kms is a significant number of mechanical cylcles. Take also into account the temperature-cycles, and the case for low cycle fatigue looks very good indeed. You will need to carry out detailed microscopic examination to know the exact cause of failure. The GM400 boxes are also used for truck applications as you rightfully point out. They should therefore be able to take anything we can throw at them. Having said that, have Rolls-Royce modified this shaft in any way? could there have been a defect in the case hardening of the splined area? was the shaft subject to any mechanical intervention since original manufacture (has there been a human giving it some argy bargy at any stage of its life). your big question should be: what else is this close to failure in my drive train. good luck. Omar | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1254 Registered: 4-2003 |

Omar/ It may be a bit malevolant of me to point out that these events traditionally have been kept well under wraps in an endeavour to maintains the public's perception of the invincibility of the marque. God knows how many fine cars have been destroyed through this nonsense, sheer gullability and ignorance. Apochrypha has it that in 1966/67 the Factory replaced two engines under warranty in North America delivered fledgling Shadows because the owners sincerely believed that a Rolls-Royce should not have to have water added to their cooling systems between services. This was not burgeoning altruism on the part of the Factory but their very well recognised need to maintain the image in the one market that promised survival of the whole enterprise! Australian cockies wrecked quite a number of immediate post-war chassis' using their vehicles to round up sheep and hit outback unmaintained roads at great speeds under the delusion fostered by the spin merchants of the day that their cars were invincable. Well thanks to people like Richard and forums such as this, this aura has been largely diluted and new owners hopefully will have a realistic expectation of their vehicles' limitations and needs for care and maintenance. As the Factory Supervisor said to me in 1980, 'They are only a car you know!!' | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1255 Registered: 4-2003 |

I took the liberty of forwarding this discussion on to my favourite Master of Automotive Engineering, a graduate of Shrivenham. He offered the following comments which readers might find of interest, Interesting. Only a few thoughts. The RR or Bentley GM400 box is not necessarily the same as the GM400 box they stick in some other car. Manufacturers normally require small modifications to meet specific requirements eg. space claims, software protocols etc... So comparing ones GM400 box with one from another model of car may be an error. However, the input shaft is not something an OEM would normally modify lightly. They are designed very carefully, (should be) manufactured very carefully and on the whole perform very well. Knowing very little about the design, the Turbo R or the previous owners here are two plausible causes. Every quality system inevitably allows a few failures to pass right through it. This may have occurred here. Eg. The shaft may have been inspected on a Friday afternoon by someone who was thinking about the weekend and let it pass because the previous 1000 shafts had had no problems. Also possible is a very early over loading of the shaft I have seen how easy it is to do this in this model of car you think you are in gear you press the accelerator realise you are not and select drive or reverse before the engine properly settles in idle again shaft experiences a higher load than normal and a tiny piece of damage (in the form of a micro-crack) is done which 300,000km later has grown enough to fail completely under normal load. The science of this is well known and well documented. The loads on mechanical systems early in their life have an inverse hyperbolic effect on their service life. In short do not buy a Turbo R if the original owner was exuberant! Or if ever there were a car to buy from a little old lady who drove it to church on Sundays it may be a Turbo R. | ||

Daniel Diewerge Experienced User Username: didi13109 Post Number: 11 Registered: 11-2009 |

Torquey engine, heavy car, heavy mileage. Solution for heavy right feet is available here: http://www.transmissioncenter.net/hardened_shafts_and_drums.htm | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1256 Registered: 4-2003 |

Daniel/ Thanks for that information I must pass it on to the cucumber sandwich group when I see them! I have to guess that this mob are in America?? Their site has only toll free numbers no email and no 'contact us' button. So where is it? | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2157 Registered: 4-2003 |

The OEM input shaft is common to all THM/3L80 transmissions except for the rare switch-pitch type on very early LHD Silver Shadows, 1965 Buick Rivieras and a few others. Spares are plentiful in Australia, as many Holdens, Chev vans and Jaguars were sold with these transmissions. Of course, there are Aston Martins, Ferraris and the like with them too. The OEM input shaft is more than sturdy enough for almost any application, and I am not at all concerned that my new one was sourced from Holden. Some Statesman and Monaro cars with the local 308 cid V8 use the THM400. Mine was probably poorly manufactured by the look of it, and it is the first my shop in Canberra or the ones known by its proprietors has seen like it. The people from other shops came for a look. My preferred shop does many THM400/3L80s and 4L80Es (4-speed 1992-onwards Crewe cars). Canberra Chev ambulances feature the 4L80E. Only the mapping differs from the 4L80E in a Crewe car. The Crewe transmissions share the casing bellhousing pattern with early Cadillacs and big-block Buicks such as the 425 cid Riviera. The innards are shared with the rest, so a Holden will make a good source of spares in as long as your casing is OK. Aftermarket input shafts are available from TSR Racing, B&M and Automatic Choice (see http://www.automaticchoice.com/Catalogue/th400.pdf for an illustrated parts list, and also Ron Sessions Turbo 400 repair bible). The OEM ones are out of production. The best aftermarket ones are called 300M and Vasco. They are expensive at around $400 or more, and are only really useful for drag racing when the transmission is suddenly locked for a burn-out. The ones in the link of the last post are not reputed to be very good. I also have a new set of planet gears in my car now, along with all-new bushings, bands and clutches. The planet thrust washers were worn, and as Ron Sessions states, it is better to fit a complete new set than to make the tedious repair for a small saving. The 3L80 in my car is an RJ series. Earlier cars have the RR series THM400 transmission. These are all bog standard THM400s with no fancy bits, and the RJ refers almost exclusively to the change point mapping. Until 1971, they all have a 16-element intermediate sprag, and a roller thereafter. Dragsters prefer the sprag type, and uprate them to a 34-element unit. All the upgrade features are known to be irrelevant for all our cars. Only minor details of no significance came with the name change to 3L80 in 1986. However, synthetic transmission fluid is a must, so I continue to use Elf G3 SYN. Anyone who has a converter removed for any reason is wise to take the opportunity to have it cleaned out, drained, and then switch to synthetic. Unless the converter is drained, only a portion of the fluid can be changed. Flushing in-situ is effective but not very thorough. Castrol Transmax Z is perfect, but it is green to confuse leaks with the hydraulics. Elf G3 SYN is red. Synthetic fluid will only add around $200 to the costs. Its life is almost unlimited in these cars, so in the long run a service costs just $6.95 for a filter and gasket kit, thereby making synthetic fluid a cheaper option than Dexron III.. Crewe did some assembly work on the THM400s until the introduction of the Silver Shadow II. There were no changes made to the transmission, and their efforts were a waste of time in reality. From then onwards, they simply opened the box in Crewe and fitted the transmission. Surprise ! Warranty claims virtually disappeared overnight. RT. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 212 Registered: 5-2007 |

Just slightly off topic. The Transmission in my 1974 Shadow one is going in to have the front seal replaced in a month or so. I know it is recommended to wait for an overhaul to do this but I'm just tired of the fluid on the garage floor all the time. I have what puports to be a new OEM seal, if it isn't is a new correct one easily available in Australia? Last November the fluid was changed and the pan seal replaced and the mechanic (an experienced RR one)said he could see no tell-tale evidence of problems. It works fine as far as I can tell. While I'm having the seal replaced is there anything else I should ask them to do while they're at it or is it best to just leave well enough alone? Jeff | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2158 Registered: 4-2003 |

Jeffrey, I have a little personal experience and frustration on this one. It is rare for a new seal alone to stop leaks. In fact, a new seal alone often makes the leak dramatically worse, as a bad seal is usually a symptom and not the cause. The converter neck develops a groove over time. Every time you accelerate or decelerate, the converter neck moves in and out over the seal as the flexplate flexes. When there is a neck groove, the seal chops to bits in no time, and especially a sharp new one which often tears. Usually, with a new converter, the seals last very well until a noticeable groove develops, and once the groove is there a new seal will last a day or so only if you are lucky. The three remedies are: 1. Place a 4mm spacer washer behind the seal to bring it forward past the groove (cheapest) (this was even the subject of a service bulletin for the fluid flywheel seal on S2 cars) 2. Have the converter neck skimmed on a lathe. If it is not too deeply grooved , then a standard seal may do. If much material needs to be removed, then a standard seal may be used with its tensioning spring lassoo tightened accordingly. A transmission shop knows this method. 3. Have the converter overhauled, fitting a new neck, and fitting a new roller clutch while you are at it. RT. | ||

David Gore Moderator Username: david_gore Post Number: 962 Registered: 4-2003 |

Hi Richard, Have just come back onto the forum after a week in Sydney. Would you please PM me with your phone number and I will call you about your failure. I would like to discuss it with you first before venturing an opinion publically. Kind regards David | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 213 Registered: 5-2007 |

Righto Richard, That advice will at least save me the labour cost of replacing the seal to no effect! | ||

Omar M. Shams Prolific User Username: omar Post Number: 145 Registered: 4-2009 |

Jeff, I had the same issue with my Wraith II and it left stains on the floor at an embarrasing rate. My solution to the problem was to run the car with slightly less oil than the max level (do not rely on the guage inside the car). The actual max. level on the disptick minus 3mm solved the problem. No gearbox removal, no seal replacemnt nothing. Good luck. Omar | ||

Peter Colwell Frequent User Username: peter_colwell Post Number: 93 Registered: 3-2005 |

"...you think you are in gear you press the accelerator realise you are not and select drive or reverse before the engine properly settles in idle again shaft experiences a higher load than normal and a tiny piece of damage (in the form of a micro-crack) is done which 300,000km later has grown enough to fail completely under normal load." Hi Bill, that type of driving is so common, but it defines the difference between a carefully driven car and the rest. Anyone who has spent any time driving a heavy truck learns the value of patience with things mechanical, and how it pays off. My own personal mechanical wince, is watching people wrench the steering wheel while stationery. As you say, each time stresses things that little bit, and we don't want to stress the steering linkages do we? I think we are born with that fine mechanical feeling, or not, and it can't really be taught? What I do know is that it pays off big-time. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2159 Registered: 4-2003 |

Omar, Surely you are referring to engine oil and drips past the rear main engine scroll (there is no seal on almost all SYs) ? On our 1972 T, in 1985 I fitted the PTFE lip seal and housing as fitted to the SZ cars and the very last few Californian injected SYs. I bought it all brand new, at a cost of $750 at the time. However, you can machine out the scroll on the original housing and press in a new PTFE. Once the trabnsmission is out, the flywheel removes and the small housing removed, all that is needed is to clean up the crud on the surface of the crankshaft at the scroll using 1200-grit sandpaper. A slightly blocked flame trap will cause an SY to leak engine oil too. By the way, on many SY cars when new, York Motors in Sydney routinely shortened the dipstick tube by 1cm so that the dipstick reads full when it is 1cm down, equating to about a litre or so. The sump level sender needs recalibrating then too. RT. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 214 Registered: 5-2007 |

Thanks Omar, By chance, during last October's service I had the flame trap checked out and a new cover installed. The leaking fluid is red so I'm fairly sure it's the transmission. It is the last major system on the car that hasn't been overhauled in the last six years (starting with the engine block and linings) so its proably best to do it now and be done with it. Depending on the size of the government's end of financial year largesse I'll probably have the converter overhauled (Richard's option 3). Meanwhile I'm honing my wood veneer skills: obsessive compulsive disorder is so helpful sometimes... Jeff :-) | ||

Omar M. Shams Prolific User Username: omar Post Number: 146 Registered: 4-2009 |

Flame trap!!!!............... hmmmmmmm would I be really thick if I did not know what that is??? does anyone have a photo? thanks. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 613 Registered: 6-2006 |

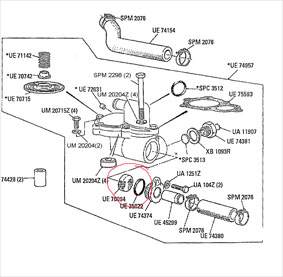

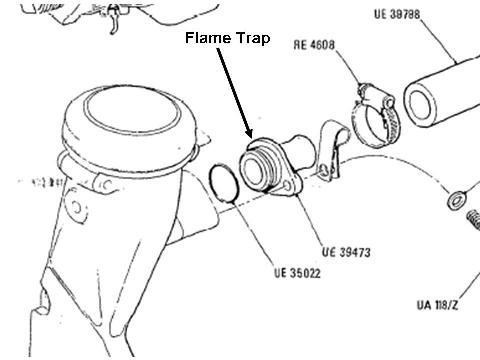

| ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2160 Registered: 4-2003 |

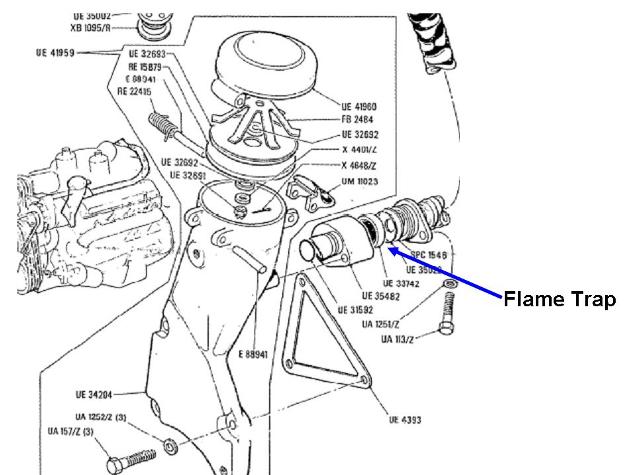

The above diagramme is an SZ or possibly the same on a late Californian SY (but I dont thinks so). The SY flame trap is quite different. The SY flame trap is the gauze in the short pipe at the oil filler. See below. This is scheduled by Crewe to be cleaned at every oil change. It has always been a fundamental service item specified by Crewe for good reason. It is often overlooked for decades, and unknowing owners assume the worst as the garage floor stains or floods with oil from the front and rear crankshaft scrolls on SYs. After not too many miles, especially on cars without upgraded valve stem seals, the gauze becomes partially or fully blocked. Even partially blocked, the crankcase will no longer be under a vacuum, and the rear main seal or scroll will drip or even pour oil. In severe cases (about 25% of SYs serviced by the local mechanic) the crankcase pressurises and blows oil from the crankshaft scrolls and even from the weep holes. A quick clean of the flame trap, and bingo its all OK again. RT.  | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2161 Registered: 4-2003 |

Sorry, the above picture is of a car with a Solex carburettor. Below is the flame trap for an SY with carburettors or fuel injection. The flame trap (gauze element) is UE 31006 for vert early SY cars until Chassis LRX 8697 and UE33742 for cars from Chassis 9001 until the end of the SSII series. RT.  | ||

Nigel Johnson Experienced User Username: nigel_johnson Post Number: 42 Registered: 12-2008 |

Well, thats another job to do on CRH11939. Regards, Nigel. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 614 Registered: 6-2006 |

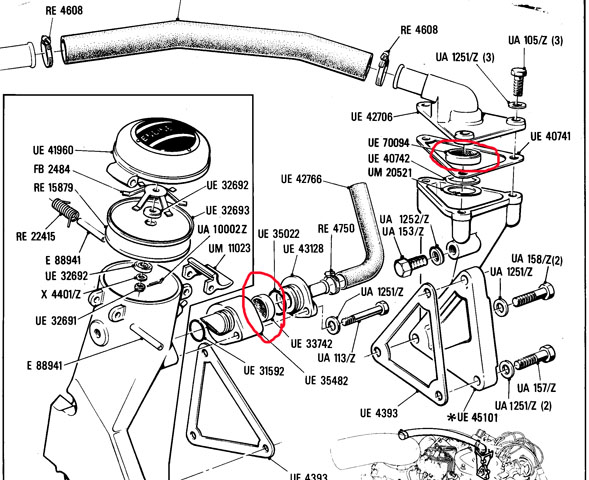

RT The picture I posted should be for Omar's (and also your) Turbo car. You should have recognised that one  It's more complicated because it needs valves to select a vacuum from the inlet manifold or the intake pipe depending on boost conditions. It's more complicated because it needs valves to select a vacuum from the inlet manifold or the intake pipe depending on boost conditions. On mid chassis Spirit cars it was moved to the rear of the A bank cylinder head. Here's a picture showing both types on a Nat Asp car. (you will have either / or , not both )  But wherever yours is, it should be cleaned.  | ||

Omar M. Shams Prolific User Username: omar Post Number: 148 Registered: 4-2009 |

Many thanks for all the support on the flame trap matter. As I only have the green Wraith at home, I took that apart and found the mesh to be a little dirty. The car only has 41000 Km on it so I did not expect it to be blocked. I will check the other cars when they come back from the garage. I was surprised to find a restriction orifice in the shape of a flat thin washer in place against the mesh thus reducing the effective area significantly. I removed it. Was that the right thing to do or will I get a bolt of lightening from the sky for doing a booboo? | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2162 Registered: 4-2003 |

Paul, he is referring to his Silver Wraith II, which has the same flame trap as our T-Series to which I was referring in that context. R. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2164 Registered: 4-2003 |

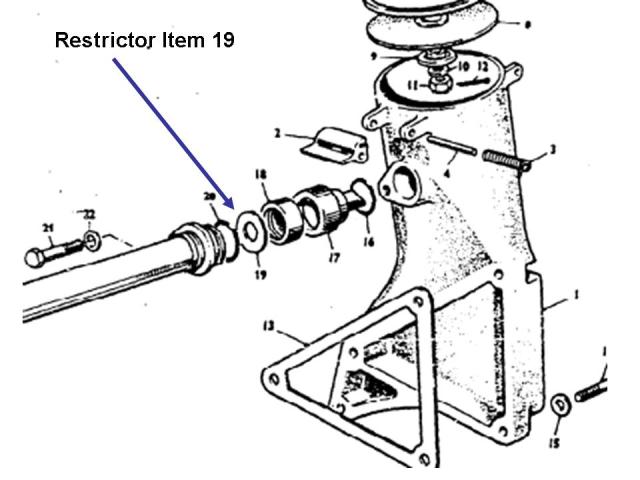

Omar, are you referring to the breather restrictor disc to the right of the flame trap gauze in my earlier post ? See below for the reversed view (from the SY I manuals, same part numbers and components as SY II). In any case, the crankcase ventilation is effected upstream from the carburettor (or injection) butterflies, and therefore makes no measurable change in fuel/air mixture or idling speed. On many other engine types (Holden, Chev, Ford, BMW etc) the Positive Crankcase Ventilation (PCV) is downstram from the butterflies and therefore at manifold vacuum, and a PCV valve is vital in controlling maintaining the mixture and volume on those cars. Not so on Crewe cars. I would not be in any manner concerned at running the car without the disc. I'll have a look at the T on the weekend to remind me whether the disc is there still. If it is, I may remove it as a trial. RT.  | ||

Omar M. Shams Prolific User Username: omar Post Number: 150 Registered: 4-2009 |

yes Richard you are spot on. i removed the restrcitor and have seen little difference. Many thanks to you, Paul and the rest of the team for your input throught this excercise. best regards Omar |