| Author | Message | ||

Pat Lockyer Unregistered guest Posted From: 81.135.122.66 |

Having delt with the correct timing up prcedure & tests on SS1 & SS2. I was most interested by the proceedure & statments that were given by a certain person no names no pack drill. As i was ready to correct the issue with guns a blazeing i was let down by forum crash. So i will state the following. Full ignition timing & advance curve with vac when fitted, should be delt with in the common way,ie running test through various figures for model of cars. Check The Dwell Angle After Contact gap set first. Electronic still have dwell. Disconnect the vac pipe to vac advance if fitted. useing the strobe start the low rpm timing first. This will tell the static timing, then with various set rpm's the mechanical centrifugal dist curves are checked. When the range is checked & 99.9%ok on Rolls Royce car are o/k & we are dealing with RR. The vac pipe is connected & total advance & vac unit is then tested. The vac units are known to fail. The distributors will last for years but must lubricate about once a year with a little engine oil. No need to remove distributor & trot to the local auto electrician for curve check as this way does it for you. Can give Strobe figures from my old updated notes SS1 SS11. | ||

Robert Chapman Prolific User Username: shadow Post Number: 33 Registered: 5-2003 |

Hi Pat, This procedure is OK if you only want to know the ignition timing and advance curve for number 1 cylinder but you will have to trot down to your local man with a distributor graph if you want to know if the rest of the cylinders have the same timing and curve.The oscilloscope(raster pattern trace) will give a general indication but is no match for the graph,this will show the true condition(accuracy) of individual cylinder firing by the distributor. The info that only a graph can give is of particular interest if the engine suffers pinging(detonation) in spite of the fact that checking the timing on number 1 cylinder indicates that timing is correct. | ||

David Gore Moderator Username: david_gore Post Number: 208 Registered: 4-2003 |

Thank you Robert, I think our guest is referring [no names; no pack drill!!] to a series of posts by myself on the Swammelstein Forum where he has obviously misunderstood the use of a distributor test bench for calibrating a distributor after overhaul. As we both know, there is a huge difference between on-car experimentation and proper calibration on a professional test bench. | ||

Pat Lockyer. Unregistered guest Posted From: 213.122.228.44 |

Hi Robert. Thanks for your reply. Regarding the dwell angle.TELLS YOU IF DIST IS OK. This is carried out first & when correct a test to determine if worn parts in the distributor is carried out,by increasing the the distributor slowly to 2500rpm. Watch the dwell meter for any change in dwell. Good = changes less than specified dwell variation. Bad =Gradual change in dwell beyond specification indicates bearings loose breaker plate,bent shaft rarely found on shaddows with correct dist maintanace. Far more precise than the raster with an oscillascope. As for the practice of heating & adjusting the wieght springs by David i just cannot believe that is good practice or fiddeling with a distributor before any dwell strobe tests are to be carried out as i stated previous posts. Hope this clarifies the easy way rather than going down an unessary route. Rolls royce to my knowlegde have never issued graphs as they would not be needed even after an overhaul as the dwell strobe test was highly used by them!!!!!!!!!& myself. Noticed Davids post was shortly after yours hope he has not misled you.keep it simple. | ||

Pat Lockyer Unregistered guest Posted From: 213.122.228.44 |

Hi Robert Forgot to say that you can check each & every cylinder for the individual timing curve just by conecting the strobe lead to each & every one. | ||

Robert Chapman Prolific User Username: shadow Post Number: 34 Registered: 5-2003 |

Hi Pat, Dwell angle measured by meter analogue or digital is the AVERAGE time the points stay closed in distributor degrees (in this case) for 8 cylinders,this will not show ether individual dwell or individual variation. Oscilloscope raster or superimposed will show individual cylinder firing point,lengh of dwell and dwell variation(but not as accurately as a gragh). If you connect the timing light pick-up to any other cylinders than number 1 or 5 you will not see any timing marks,and you will not be able to compare them accuately(this is the advantage of a ghaph, all cylinders timing and advance are checked simaltaneously degree by degree RPM by RPM. Yes R-R do issue graphs,look at your Cloud manual . To check every cylinder with a strobe light would require you to mark every cylinder T D C position on the flywheel or damper and plot the advance for every cylinder at 50 RPM increments up to 2500 ,and then compare them all .And if any adjustments or repair were required check them all again and again untill you got it accurate.Much easier and accurate on the graph. Dont understand what you mean about Davids post,I have never been misled or in any doubt about how the I.C.engine works,SI OR CI. Keep it accurate. | ||

Robert Chapman Prolific User Username: shadow Post Number: 35 Registered: 5-2003 |

Hi Pat, forgot to mention even if you dont have a graph for a particular model you can easily plot your own,which may well be required if any component of P L A N has been changed by design or conditions. | ||

Pat Lockyer. Unregistered guest Posted From: 81.131.174.18 |

Hi Robert. You realy have to move on from the cloud. This is a Shaddow 1/2 we are dealing with & the teaching from the sun electric corporation with which i have been taught states[dwell variation ] MAKE THIS TEST TO DETERMINE IF WORN COMPONENTS WITHIN THE DISTRIBUTOR WILL CAUSE A CHANGE IN DWELL AS THE ENGINE SPEED INCREASES. NO shaddow 1/2 has a distributor graph Regarding the the individual timing simply use a dial on the front pulley. Can explain more if you still cannot grasp it. But as you now know you do not have to make a meal out of it,would cost any customer a small fortune fiddling with the graph method on a SS even if you could. Thought you were misled into this as i thought the posting were just rather close on the replies. Happy Shaddow Days the easy way. | ||

Robert Chapman Prolific User Username: shadow Post Number: 36 Registered: 5-2003 |

Hi Pat, Thank you for your advice about moving on from Clouds,but my involvement with these cars ranges from 1950-1996 models. Re-Sun disributor Dwell test,the test you describe simply tells you if the dist bearings are worn and causing the shaft to be pulled off centre by centrifugal force,increasing points gap,decreasing AVERAGE dwell angle and advancing ignition timing. This will NOT tell you INDIVIDUAL CYLINDER DWELL DISCREPANCIES and therefore the ignition timing of INDIVIDUAL CYLINDERS even if the reading stays constant. Yes please do explain to me how you can connect your dwell meter to this engine,select 8 cylinder range (that will measure the average dwell)and read off the individual dwell for every cylinder.I'd like hear that! Thank you for conceding that in fact it is not possible to check all cylinders with a strobe light by moving the pick-up to each cylinder in turn and indeed you would be required to mark every TDC position on the damper,or as you put it "simply fit a dial"(degree wheel). How would one "simply fit a dial" (degree wheel) to the crank pulley ,and be able to see ALL cylinder timing at the same time as is posible with a distributor graph machine? I would suggest that this is making a meal of it and would cost a fortune for an incorrect diagnosis,it takes no more that half an hour to remove the distributor,fit it in the machine and properly check all cylinders and refit it. Re-no graph specs for SS1/2,thank you for conceding that in fact R-R have issued graph specs,and as I said in my last post there is no problem in plotting a graph of correct ignition advance for these engines and it may well be required if any component of P L A N has been changed either by design or conditions. Keep it civil. | ||

David Gore Moderator Username: david_gore Post Number: 212 Registered: 4-2003 |

Pat, I really do not understand why you have some obvious resentment to my comments regarding this topic and to imply Robert Chapman was "misled" by me into posting information that supported my opinion is grossly offensive to both me and I respectfully suggest this is also defamatory to one of Australia's recognised and well-respected expert professional R-R/B mechanics. I suggest that you recognise the fact that there is a healthy diversity of opinion on the merits or otherwise of almost every diagnostic/repair technique for mechanical equipment. It appears to me that you come from a formal hierarchical background where one never questions the advice/practice of one's superiors and slavishly follow the prescribed procedure regardless of whether there are alternatives available. Here in Australia we have a different philosophy where we consider the advice/views of others and then use our own experience and judgement to determine how we go about solving the problem - we are not afraid to think "outside the square" and our reputation for being able to fix/maintain/enhance mechanical equipment has arisen as a consequence of this philosophy. I request that you restrict your comments to technical matters only and do not descend into personal innuendoes/denigration otherwise I will use my moderator privileges to edit such material. I have not exercised this privilege so far in the interests of free speech however the innuendo concerning Robert Chapman is not true as there has been no contact between Robert and myself on this topic and Robert's character and reputation is such that he would not compromise himself anyway. I am quite capable of rationally discussing opposing points of view to my own without having to descend to personal attacks to justify my opinion. I apologise to Robert on behalf of all other participants for an unjustified and inappropriate comment by our guest. (Message edited by david_gore on February 29, 2004) | ||

John Dare Unregistered guest Posted From: 144.138.195.170 |

Even as an owner/driver/amatuer D.I.Y mechanic/tinkerer I can understand what Mr. Chapman is saying and conclude that dist. test bench mnfrs. such as "Sun" etc., MUST have had sound and technical reason/s to design such dedicated test machines in the first place. If a "string and plum bob" approach were 100% effective then quite simply, dist. test machines would have never been conceived let alone built. I have personally seen such a unit (forming part of a multi-test console) mnfd. by "Ford" USA, circa 1938, some sixty five years ago! Accordingly, it does seem rather POINTless to DWELL on this "debate" of machine v plum bob any longer. | ||

Pat Lockyer. Unregistered guest Posted From: 81.131.118.74 |

Hi David. My original reply to your statement about taking the distributor off & heat stretching or what ever the springs & trotting to the auto shop for graph check,without the first dwell strobe test. As we are dealing with shaddows,you then said you were talking cars in general. To clarify the position. ONE. early cars not shaddows, were in need of distributor graph checks as the strobe dwell set up was not readily available,it came in universally with the SS1,s TWO.Because the strobe test carried out the curve test up to total advance with vac after satisfactory dwell.RR engineers passed this test the way forward. Thee.Hope i can let you have my update settings for your car as the figures you gave me differ from records stated also let me no the rest of your stobe timing setup could well be your distributor is incorrect for yor car. Regarding Robert i will get to him with my answers as soon as i can. Hope you can respond as quick as your fist posting on the shaddow forum as i'm taking the wife out in ofcourse the RR. | ||

David Gore Moderator Username: david_gore Post Number: 216 Registered: 4-2003 |

Pat - the settings for my car are based on the factory recommendations and also reflect adjustments for local conditions. The engine performance [like the power output quoted by Crewe] is more than adequate and the fuel consumption/spark plug appearance is consistent with my driving style. What you are not be aware of is the fact that the engine is the higher output UK Corniche specification and not the standard UK Shadow or Australian delivery low compression engine specification. You have misinterpretated my comments and taken them out of context to suit your own mindset - it is not your role to "to correct the issue with guns a blazeing [sic]". I remind you that your way will be only one of a number of ways in which the problem may be addressed. If you keep an open mind and be cognisant of the fact that you may actually benefit from the experience and knowledge of others; you might find better outcomes can be achieved. The role of this and other forums is to allow opinions and experience to be shared - it is the responsibility of the individual to determine what course of action they will take after reading what has been said on a particular topic and possibly seeking professional advice as well. For obvious legal reasons, the role of the forum is to provide the opportunity for participants to freely express their opinions and share their experience; specifying the "right" way of doing something is a role and/or responsibility that the forum WILL NOT assume. | ||

Pat Lockyer Unregistered guest Posted From: 81.131.185.93 |

Hi David. Read old post on the Swammelstein site. Your statement com 9-1. I am always learning somthing new every day. usefull things i pass on, wrong statements i pass on to whoever is concerned. I am also ready to except when i am wrong. On dwell strobe timing for shaddows i am not. Learn the dwell strobe system a running test simple & quick. | ||

ted gaulke Unregistered guest Posted From: 81.135.10.45 |

regarding the statement that a dwell meter, be it analogue or digital measures the average time that the contact breakers are closed is not correct.it is only a basic meter that you are using and it has no means or program to be able to find the mean and display it.if there is a problem with the distributor then it will definitely show up as either a high reading or low reading depending on what lobe the contact breakers where set initially.this will tell you that you do have a problem with the distributor but not which cylinder or cylinders but this fairly easy to asertain.pinking on individual cylinders that i have come across have mainly been caused by valve stem seals or the valve guides been badly worn for some reason.i have never heard of retempering bob weight springs,how do you get the variable spring rate?what do you think of the distributors that use two sets of contact breakers,one for starting and the other for normal running. | ||

David Gore Moderator Username: david_gore Post Number: 217 Registered: 4-2003 |

Hi Ted, To answer your questions: 1. The mechanism/circuitry in a meter measures whatever input it is receiving and transfers it to a display - inherent in this process is averaging arising from the response time of the mechanism to the input. I have just purchased a new multimeter that is able to log data against time and download to a computer to allow measurement of peak/minimumum values and any time-dependent build-up/decay of the input - I just have to learn how to use it and find its limitations! 2. I never mentioned retempering of the springs; I mentioned heat treatment which involves annealing, hardening and tempering to achieve the desired mechanical properties. The spring rate is a function of both the way in which the coils are wound and the wire/rod diameter not the mechanical properties from heat treatment. The purpose of reheat-treating is to ensure the yield stress of the metal is above the working stress encountered by the spring and to relieve any stresses present in the metal from past problems/service conditions. Annealing also allows the spring to be rewound if necessary to eliminate any permanent set from over-stressing. 3. My understanding of twin-point distributors comes from a Falcon V8 I once owned to which I fitted a twin-point distributor to overcome point "bounce" and inability of the OEM distributor to provide consistent timing as a consequence of the breaker plate bush wearing excessively due to the loads imposed on it by the vacuum advance mechanism. This was due to the conditions under which the car was driven [hard and fast in the days when we had no absolute speed limits on the open road]. No amount of lubrication could prevent this wear; the contact stress was more than the OEM bush was designed to withstand. The role of the twin points was for one set of points to open the circuit to the coil and the second set of points closed the circuit thus reducing the effect of point bounce at high revs - the distributor had a fixed breaker plate and used centrifugal advance only; there was no vacuum advance. I put over 250,00 miles on the car after this modification! | ||

Bob Uk Unregistered guest Posted From: 195.93.33.11 |

The centifugal advance curve is never the best one for any engine. I have found from testing engines using a dynameter that when I joint the dots up on the advance graph using a fixed dizzy that you get far from a smooth curve. The centifugal advance cannot replicate the shape of the graph. So the calibration ends up as a compromise. This means that calibrating the dizzy to the N degree is a waste of time. Providing it roughly follows the design curve it will be fine. More important is timing scatter which is where they intervals are not equally spaced 90 degrees on a V8 at the crankshaft. Timing scatter is cause by worn brgs and cam. Coverting the dizzy to electronic with no points solves the cam and having no mechanical points load on the cam helps the brgs run true. The photo electric cell type works very well in worn dizzy. The only way to get an advance curve spot on for any engine is to use a dynameter, fixed dizzy and program a Eprom chip to match. The RR V8 is a low tuned engine. I have fitted quite a few wrong 25D Lucas dizzies in quite a few wrong cars with no difference to the way the engine ran from when new. I suspect that if I fitted a Dizzy from a Rover V8 that my RR would run fine. | ||

ted gaulke Unregistered guest Posted From: 81.135.49.19 |

hello david i get your point about the meter reading but how do you explain that the meter definitely fluctuates when there is a problem with the distributor,either bearings or shaft distortion the springs i dont know about as i am not into mettalurgy at all but i am sure that the two springs are odd ie:one light and one a lot stronger so that you get a quick acceleration in the advance curve and then as the speed of the distributor increases the stronger spring comes into effect.this is,i thought,shown by your graph on the other posting. the two point set i was refering to was where one set was used for improved starting and then when the temperature was at a certain level the other set took over, sorry for not explaining what i meant before. a lot of miles done in the old falcon ted gaulke | ||

Robert Chapman Prolific User Username: shadow Post Number: 37 Registered: 5-2003 |

"If someone says something to me which has no meaning,it jars my mind.I worry about it, and I lose the next ten sentences". Keith Duckworth. (designer of the worlds most successful racing engine). | ||

John Dare Unregistered guest Posted From: 144.138.194.245 |

Thats right- K. Duckworth often boasted that his "B.S" meter (which was permanently engaged) could detect automotive technical NONSENSE at a range of 50 yards and with glazed eyes recalled the old adage that "none were so blind as those who could not see" and would therefore silently withdraw from a given "debate". Incidentally, Mr. Duckworth was not a poultry farmer but a person who began modifying "Ford" Zephyrs and less than 30 years later sold out his world renown engineering/consultancy business for hundreds of millions of pounds. | ||

Ted Gaulke Unregistered guest Posted From: 213.122.150.180 |

to all having been away for a deserved break i thought i would check on the site to see the postings. David,a dwell meter does fluctuate quite a lot when there is a problem with it and when checked after repair or replacement does not! Robert the distributor springs in c/b distributors are different,the weaker spring is slightly shorter than the heavier spring so that is why you get the quick advancement to start with for a quick power boost.Keith Duck worth did design a very successful race engine along with Mike Costin. john Fiat and Lancia used the double contact system on 124 spyders, beta's etc,the reason i put this up was that reading about the use of LPG as an alternative fuel it usually needs the timing to be slightly altered so this way you could keep the right distributor for petrol and LPG,just using a switch to go from one setting to the other as needed.i don't know about Keith Duck worth being a chicken farmer but i do know that he went to imperial college London and then to Lotus as a transmission development engineer where he met Mike Costin who was the technical director of Lotus cars,first engine they modified was the good old ford 105e push engine hence their association with Ford and Lotus.so please less of the b/s meter theme Ted Gaulke | ||

Robert Chapman Prolific User Username: shadow Post Number: 41 Registered: 5-2003 |

Hi Ted. I dont understand why you are talking to me about springs as i have not mentioned them and certainly dont need any explanation about their purpose(by the way they are call primary and secondary ). The reason you see a fluctuation in the dwell meter(if the distriutor has a worn base plate or bushing ) is because the AVERAGE dwell is decreasing as you increase engine speed, you are not seeing individual dwell this is not possible with a normal dwell meter.Example,if you checked the distributor condition with a dwell meter only, when you fit a new set of points and you have a worn cam lobe,when you test the dwell you will have a false AVERAGE.This one worn lobe will increase the average dwell angle,and by setting the dwell to the makers setting you will be decreasing the dwell on all other cylinder to compensate,therefore all cylinder will not have the same ignition timing.This is why the dwell variation test should always be performed in conjunction with a scope,this will show individual dwell variation and ignition timing. Keith Duckworth did not "design a very successful racing engine" he designed THE most successful racing engine in the history of F1. | ||

Ted Gaulke Unregistered guest Posted From: 81.135.12.49 |

Robert sorry about the springs,it was not you that i meant to explain to. regarding the dwell meter i have spoken to a cryton calibrater and a auto electrician who has been in the trade 40+years and they both say that if the meter fluctuates it does indeed mean wear in the distributor,normally the bearings.they also said that it is a live reading and so that every time the contacts open and close that affects the reading,but also a digital meter does not show this so well as it does not respond so quick to the input,something to do with the moving coil in the analogue meter. yes Duckworth and Costin deed design the best F1 engine but this was a little bit of nick picking don't you think? Ted Gaulke | ||

John Dare Unregistered guest Posted From: 144.138.194.16 |

Ted.. good to see that you have bought yourself up to speed at the library since your deserved break. If you can locate the book which records the history of Cosworth Engineering you will indeed read about how Keith D. often Gauwlked at his "B.S" meter when confronted by automtotive "experts" who appeared to be auditioning for amatuer night. I once met such an individual who presented himself as a "world authority" and whilst good with "one liners" and "off the cuff" assertions (delivered as "facts") was inevitably short on any compelling documentary evidence in support of his grandiose summations which were expected to be "accepted" without question. So that this debate does not continue into the next millenium, lets invite some posting of formal decisive opinions/conclusions (on their official letterheads as opposed to simplistic "Ed on the Bus" hearsay commentary etc) from "Sun"/ "Crypton"/"Lumenition" etc. Maybe then, some people might feel obliged to review their own "facts" at which time I too might be able to enjoy a break .. a "deserved" one of course! | ||

Ted Gaulke Unregistered guest Posted From: 213.122.52.224 |

john Dare i say that is not the case here,i am just making observations on this subject gleaned over the years of practical work.i quoted from the cryton and auto electrician as they have a lot more experience in this field. | ||

John Dare Unregistered guest Posted From: 144.138.194.172 |

The points as advanced have ignited so much fueled air (hot) that this could lead to one becoming maladjusted (or even retarded) by dwelling to any degree upon highly tensioned arguments which have too many gaps and erratic curves to provide a timely conclusion. The ever professional automotive engineer, Mr.Chapman, correctly describes the distributor centrif. advance springs as primary and secondary and thats about the long and short of it. | ||

Pat Lockyer Unregistered guest Posted From: 81.131.143.10 |

Hi All. Keeping to the original topic as much as possible. Thought i would point out the dwell meter type for the way of checking the distributor and advance curve when dwell is within range. The magic name is the D'Arsonval movement meter with its inherent accuracy,no smart talk here! It is good to see some healthy technical postings on the subject by which we can all learn some things and benefit from them,i have. Ted.I was most interested in the two sets of contacts for running two different timing settings,as i have both of my shadows on lpg i will indeed look into the posiblity of useing this type of setup. I still keep the original fuel tanks for added range for long continetal trips to the Agarve. | ||

John Dare Unregistered guest Posted From: 144.138.194.173 |

Pat.. Thanks for your information, but please dont go to any trouble by locating and sending instructions etc. Early today a good friend in advertising, who has strong connections with the T.V networks (he has just landed the lucrative rights to some show about a Postman and his black & white cat!) told me that the media people have these miniaturised cameras as they had recently installed one in a car to expose some kind of consumer scam on Cowboy type car repairs, e.g work charged for but not performed etc. Anyway he said he will contact the shows producers so that we can locate the actual mnfr./supplier of these diminutive "Spy-Cam" units. Again, thanks for your input. | ||

Pat Lockyer Unregistered guest Posted From: 81.135.125.2 |

J.Dare , no trouble as i feel i must let you or the more technical Folk know that the info update regarding DWELL AND STROBE can be used on Rolls Royce cars from 1955 on wards supported by the sun electric corp yippeeeeeeee,of course they are top secret,but will be released to the Silver Cloud owners.Delco Remy,Lucas40898d, Lucas20Db For DWELL AND STROBE CHECKS. Now i know why we have not needed to use our sun 506 dist tester much in resent years. Many thanks to the people who have personally supported me on this subject. | ||

John Dare Unregistered guest Posted From: 144.138.194.91 |

Having been away for a break (a "deserved" one of course!) I thought I would check the site to see the postings. Irrespective of the method of checking dwell/timing/advance curves (being mindful of the PRACTICALITIES i.e convenience/shop time, there is no doubt that a accurate outcome should be the prime objective. Ergo, if you dont get it right your Silver ShaDDow will run like a Silver ShuDDER, so whether you drive a Rolls-Royce or a little red van, make sure you DO get it exactly right or you could be late at the office, or worse, late on your rounds. Moreover, I still cant grasp how I can conveniently check the TRUE (all cyls.) position on my 56 Silver Cloud by using the strobe dwell procedure with a degree wheel set up on the crank pulley etc., but I feel sure that the worldy and wise will be able to suitably apprise me. They usually do. (Message edited by admin on April 05, 2004) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 113 Registered: 9-2004 |

J.G.Dare. Oh yes,it can be done and other important tests,brought up to date by 21st electronics. (Message edited by david_gore on November 30, 2004) | ||

whunter Grand Master Username: whunter Post Number: 106 Registered: 10-2003 |

The most common answer in the USA is Pertronix electronic ignition conversion, or Mallory distributor, replacing the expensive worn out CREWE part. Total cost is less than $70.00 for Pertronix or $300.00 USD for Mallory. With a basic Labor rate of $100+ USD per hour, if the distributor is suspect, it is cheaper to replace than repair. | ||

John Dare Unregistered guest Posted From: 144.138.194.90 |

Thank you Patrick. Your somewhat belated reply almost EIGHT MONTHS after my post (4/4) fails to address my original concern. I indicated that I could not understand how to CONVENIENTLY check the TRUE (ALL cyls.!) position on my 56 Cloud by using the strobe dwell method combined with a degree wheel set up on the crank pulley etc. As I only have ready access (like most amatuers!) to basic, albeit "tried and proven" equipment, I would appreciate your advice that I am at least proceding in the right direction (to establish "TRUE" timing on ALL cyls.)even though there doesnt seem to be much space and clearance down there. (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 119 Registered: 9-2004 |

Whunter,you are slightly off track here. Dealing with 21st century technique. I am aways learning! | ||

whunter Grand Master Username: whunter Post Number: 108 Registered: 10-2003 |

Cost is king with many owners. If the test takes one Labor hour, and shows a distributor problem that will take two Labor hours to repair + $500.00 USD of parts, logic tells you to buy the NEW "Mallory" electronic distributor for $300.00 USD and one hour Labor. Total for OEM repair $800.00 USD+ waiting for parts. Total aftermarket repair $400.00 USD+ no delay. I have seen one award winning Silver Cloud 2 equipped with the "Mallory" electronic distributor. Most show cars use "Pertronix" because it replaces the ignition points, and looks OEM outside. I prefer to measure the OEM distributor lobes in the car, with a dial indicator. Over the last three years; the Silver Shadow 2 electronic distributors seem to be dying at an alarming rate that is part of the reason many are going aftermarket and scrapping OEM. The kits are simple DIY. If we can not keep these cars on the road, where they belong, and get joy from driving them, they will soon be in the salvage yard. Sorry to be so long. | ||

smokydave Unregistered guest Posted From: 75.117.71.64 |

I keep seeing a reference to a mallory distributor that will fit the silver shadow does any one know the Mallory part number and whether it will fit the 69 shadow? (Message approved by david_gore) | ||

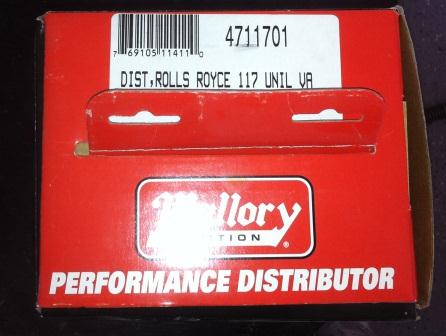

Kelly Opfar Experienced User Username: kelly_opfar Post Number: 15 Registered: 7-2004 |

The part number is 4711701. Summit Racing shows it as still available.   | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 854 Registered: 6-2006 |

I have found that many distributors are dying due to lack of maintenance. Unfortunately many cars distributors are never lubricated annually. This is especially true of electronic or so called 'maintenance free' systems. Just because a car isn't doing many miles and doesn't need points doesn't mean that the oil on the mechanics isn't draining off and waiter and corrosion stop acting on these components. I don't think that there is a problem with the quality of the distributors as much as a problem with overlooked maintenance. A car covering a low annual mileage usually needs more maintenance than an 'average' use car. A car that doesn't move at all will need even more care. A sadly unappreciated and overlooked fact | ||

Kevin D Ritter Yet to post message Username: 1025username Post Number: 1 Registered: 4-2013 |

Does anyone have source for replacement distributor advance springs part number CD5472 |