| Author | Message | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 135 Registered: 5-2007 |

SRH20280 Problem: Engine starts; blows smoke somewhat - although this may be early morning condensation there is a bit of black soot deposit in the pipe and on the floor under the pipe. It will not, however, go into gear. Tried: re-setting the cutout; revving the engine; checking the transmission fluid. The problem started 2 days ago although after a few tries it went into gear. Today it just won't go. Any suggestions for what to do next? | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1124 Registered: 4-2003 |

First up check that the gearbox actuator is actuating. Get underneath while someone moves the gear selector with the ignition on through its gate and the actuator lever should move back and forth. If it doesn't and you have reset the cutout you have an electrical fault most likely in the loom between the steering column and the actuator but most likely at the latter end particularly the plug and the rubber 'holed' insulator in the socket. If you have to move the car, remove the operating rod from the actuator to the gearbox and change the box manually. this is difficult to do while you are sitting in the driver's seat so you will need help and the person underneath will need to trust your brakes since the car will not start as usual unless he (the one under) puts the lever in neutral or park for starting and then moves it to drive. It is preferable that you do not drive over the helper! Refer to Topics issue 83. As to fixing the rotting things (there are no more looms available including plugs etc)a continuity check of the loom wire by wire is the first step! If the actuator does work, first pray to the gods that you have been spared and then get the car to a transmission man to overhaul the unit! | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 136 Registered: 5-2007 |

Bill, thanks. Oddly enough I have arranged to take it down to Chapman's in August for a preventative maintenance overhaul of the transmission. Reading over the archives there are a couple of things which jumped out - cold weather & too much or too little fluid. We have had a couple of heavy frosts over the last 3 days for the first time this year and there is fluid high up in the dipstick tube. Fortunately I don't have to move the car - well, no further than Melbourne - it's in the garage. In the hope that the problem is electrical I will look at the circuits first - but could you tell me exactly where is the actuator physically located so I can start testing at that end ? Is there any danger of causing further damage by running the engine do you think - I don't want to burn the thing out. If the electrics don't fix it I'll get someone in to look at it - I don't like the idea of a couple of first-time amateurs getting underneath the car with the engine running and fiddling with gear levers. Once again, thanks. Jeff | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 137 Registered: 5-2007 |

Bill - it just started first time !!! This indicates a problem with the cold I think, but the fact that it happened is no doubt indicative of something on the way out. I'll pore over the reading, test the electrics and bring forward her date with Robert - she's been so looking forward to that - here's hoping she makes it. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 138 Registered: 5-2007 |

2 little screws ! In the process of cleaning up the drivers floor pan in prep for the painting, I removed 2 little bolt screws just below the accelerator pedal. Taking the cover off the rat trap I see that these were holding a silver coloured hex shaped rod which appears to be connected to the transmission. I don't know whether to blush in shame at something so obvious or to just put it down to one more lesson learned. Hope I didn't screw anything up inside the gearbox in the process. | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1125 Registered: 4-2003 |

Sorry Jeffrey - you've lost me. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 139 Registered: 5-2007 |

Ah Bill, There is a small bracket at the end of the of the actuator lever which holds it steady. It has a pair of fixed nuts on it. The bolts screw through the drivers floor pan to hold the rod steady - I'm assuming this is either the actuator lever of which you speak or is connected to it - it's in the forward section of the rat trap enclosure right near the edge.It then travels straight across into the transmission gubbins. I'd taken the screws out because I'm re-doing the rustproofing on the pan with POR15. For this reason I checked the underside of the pan by taking off the rat trap cover and found that this rod was 'hanging loose'. Perhaps I'm on the wrong track? I'll study the diagrams tomorrow to see if I can figure it out. I'm not much good at translating verbal descrptions into facts on the ground so to speak. Also, many of the names of parts are still a foreign language to me. :-) I'll keep you informed. (Message edited by jefmac2003 on 13 June 2009) | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1126 Registered: 4-2003 |

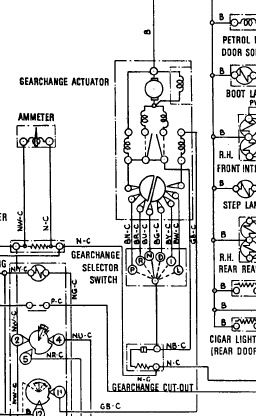

As Murphy would have it I do not have an SY or SZ car here at the moment. But I have found a poor picture of the gearbox,which I will try and post. The rod I am talking about is the one running front to rear on the left hand side of the box. The actuator is at the rear end.  | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 140 Registered: 5-2007 |

A very useful photo Bill - I'll look again and I'll take some photos of what I'm looking at and post them in the morning. I think what I'm looking at is not this. The lever in your photo seems to be facing front/back on the axis of the car. | ||

John Kilkenny Frequent User Username: john_kilkenny Post Number: 80 Registered: 6-2005 |

Jeffrey, For a quick check of the actuator, turn on the ignition without starting the engine then move the gear selector between the gear positions. You should hear the actuator operating. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 343 Registered: 6-2006 |

Jeffrey, I think the hex linkage is the accelerator, that has a bush in a bracket held on with two screws. It also runs left to right. Maybe that's it? (wouldn't affect the gear change though) Also something to check is the gear shift quadrant in the steering cowling. Make sure that there is a feed to the finger and that it is being transfered to the quadrant contacts. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1731 Registered: 4-2003 |

Assuming that the actuator makes a clickety-click, and that the fuse is not blown etc etc, what happens when you select R, I or L ? Does it drive ? If so, when you knock it back to D does it still drive ? If so, there is one main possible cause. The linkage wears over time, and eventually fails to pull the lever fully into Drive. 2mm out of adjustment, and it will not work especially when cold. It is quickly sorted out by adjusting the lever length so that the clevis pin slides gently and directly into the lever at the transmission when in D without fiddling the lever or linkage. Search this site and you will see posts on this. Worst case, if you have drive in I or L but not in D, unfortuantely the first gear or second gear sprag clutch inside the transmission may have failed. They are often actually roller clutches, but usually referred to as sprags anyhow. That is uncommon with these bullet-proof transmissions, but not unheard of on aged transmissions. When I and L are selected, the bands hold the epicyclic drums. In D, the bands do nothing and the drums rely on the sprag clutches instead. Fear not, parts for these transmissions are common to Holdens, Jags, Chevs, Astons, Hummers, army tanks, fire engines and sundry, and are available anywhere at negligible cost. Even sump gasket and filter kits retail for less than A$10. If there is no movement in the actuator, which surely you have now eliminated or confirmed, usually a relay has failed inside the actuator or the connectors in the loom, toeboard or actuator are corroded. On one occasion, our T actually had a broken wire inside the loom, and it was missing reverse intermittently. RT. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 141 Registered: 5-2007 |

1 - John: I tried the check with the ignition on - no sound of actuator operating. 2 - Paul: Yes that link is not the problem, it's the accelerator 3 - Richard: When it fails, it fails in all gears, which makes me suspect electrical. My first check will be the steering cowling connections. I have checked the connector with the rubber cover underneath - it seemd clean & no obvious breakage. The lever with clevis pin to which you refer I'm assuming is the one in the second photo, near the actuator itself and below the little gold cylinder. Yes? Thanks for helping with this guys - it failed again this morning but I'm hopeful of getting it at least to the garage in Tumbarumba (1 hour away) if it needs to go up on a lift.   (Message edited by david_gore on 14 June 2009) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1733 Registered: 4-2003 |

Jeff, thase are the lever and clevis pin. However, your issue is almost certainly electrical. Time to pull out the multimeter. R. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1735 Registered: 4-2003 |

ps: to drive the car, chock the wheels and press the lever shown into drive with the engine idling. That'll let you go to an autoelectrician armed with the schematics (better than a general mechanical garage, a specialist or a transmission shop for this one) if you can't sort it out at home. R. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 142 Registered: 5-2007 |

Thanks Richard, I just reset the cut-out otter switch on the fuse board and it got it started - First I pressed it with the engine running; no go. Then I pressed it with the engine off and it worked. The problem I'm 99% sure then is electrical. I'm heading off to Melbourne anyway for some other work and a service, as well, as I said, for a transmission overhaul (seals etc). I might just bring forward the date. Meantime I'll just check as much as I can with the continuity tester for a week or so and see what I find. Most inconvenient timing - I have the entire interior out and have half the floors pans half stripped ready for POR15 painting. I'd hate to put it all back in before that job is completed just to find out it's a wiring problem I could fix myself. Fortunately I've got a couple of weeks off work. Cheers, and thanks, Jeff | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1129 Registered: 4-2003 |

Maybe it's the Otter Switch? They do fail!! | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 143 Registered: 5-2007 |

Now that's a thought. I wonder how available they are. | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1130 Registered: 4-2003 |

They should be at least from a wrecker but meantime consider using a fused link. Rather than poking a bit of wire in the two appropriate slots and risk burning the loom out if there is a short, make up two short bits of insulated wire with male connectors one end and female the other. The latter are pushed on to a modern blade fuse of suitable amperage and you can make the connection. Step one of course as Richard points out is to put a multi meter across the terminals of the cut out to see if they are connecting when you push the button. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 144 Registered: 5-2007 |

I'll try that Bill. With a 5amp first and work my way upwards - unless anybody knows offhand what the correct amperage is? | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1131 Registered: 4-2003 |

It would be quite high I have always expected since parked on a steep hill in 'P' and not held by the parking brake (not that that is necessarily much help)it takes quite a bit of pull to get that parking pawl out of the notched cone!Instance the effort pulling the gear selector out of 'R' on the old hydramatic on a steep hill. | ||

John Kilkenny Frequent User Username: john_kilkenny Post Number: 81 Registered: 6-2005 |

Jeffrey, Because the problem is intermittent I don't think it is likely to be a faulty gear change cut out though it is possible of course. The next time it occurs do not reset the cut out, but pull it out and check for continuity between its two contacts. Tap it with a screwdriver with the meter connected to check for an intermittent connection. If OK, you need to look elsewhere, I would start with the connections to the gear change switch itself. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1738 Registered: 4-2003 |

Why not just duplicate the SZ 20k setup and ditch the Otter switch ? A standard 20A Littel fuse, the type used on most SZ cars, is fine. Those fuses are used on everyday cars like BMWs, Audis and Holdens etc. I wouldn't bother with HRC or any special type of fuse. The 20A Littel fuse does the later cars well, and they have the same actuator. Littel fuses fit to standard blade inline sockets as sold at service stations in packs of 20 for $2. See http://rrtechnical.info/sz/sz87/tsd4701/23.pdf for the SZ 20k wiring diagramme. A 5 Amp fuse would evaporate. 20A is the right size. RT. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 344 Registered: 6-2006 |

The finger contacts inside the actuator also wear out. This can give intermittent faults as well. Try putting it in gear and giving the actuator a light tap and see if then goes in gear. Try moving the loom gently. If you need to manually put it in gear, remove a clevis pin and tie the rod up. Forcing the actuator lever with it connected will stress and may permanently damage the gear inside. Remember that if you do put it in gear manually, it will start and already be in drive. A note on the screen is a good idea to remind you and anybody else that gets in. | ||

John Kilkenny Frequent User Username: john_kilkenny Post Number: 82 Registered: 6-2005 |

I would not replace the cut out with a fuse unless the cut out was proved to be faulty and a new one was unobtainable. The question is why was the cut out used in the first place ; a fuse would be cheaper. It would be to detect the situation where current was drawn for an excessive time rather than an overcurrent condition or a short circuit For example, if the actuator was not turned off by the gear selection switching circuit, which would lead to overheating and damage. Later cars may have a different arrangement but in my car the dual relays for the actuator are fed straight from the battery and would not be de-energised by the ignition switch. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1740 Registered: 4-2003 |

Well, John, if the fuse is good enough for SZ 20ks onwards, when for the first time ever Crewe engineers were given a decent budget to upgrade any cars from top to bottom mid-series, dragging them into the late 1970s by 1987, it can't be too bad ! The cutout version was a first attempt, and dates back to the design concepts of the 1950s. Of course, a cutout offers inferior protection to that of a fuse. They didn't even need to select a Slo Blo. RT. | ||

John Kilkenny Frequent User Username: john_kilkenny Post Number: 83 Registered: 6-2005 |

Richard, The cut out in this case offers a different type of protection, not an inferior one. I suspect the later cars have a different circuit for controlling the actuator, rather than just replacing the cut out with a fuse. Of course if the actuator on my good old four speed should fail I can change gears with my tyre lever ! John | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1741 Registered: 4-2003 |

Compare them in the links below: they are the same. However, a fine point, late cars switch to Park when you remove the key. Early cars prohibit key removal unless in park by way of the solenoid in the switchbox. They just finally rid the system of the breaker for 1987. I can do the change manually by hand by the way: no lever or brute force required provided the electrics are isolated by removing the fuse, or by forcing the breaker open on early cars. http://rrtechnical.info/SY/TSD4200/m/m4.pdf see page 39 of the download. http://rrtechnical.info/sz/sz87/tsd4701/23.pdf http://rrtechnical.info/sz/sz80/4400m/7.pdf | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1742 Registered: 4-2003 |

For completeness, 4 speed gearchange (pre-1968) and early 3-speed. http://rrtechnical.info/sy/tsd2476/14.pdf 4-Speed  3-Speed  | ||

John Kilkenny Frequent User Username: john_kilkenny Post Number: 84 Registered: 6-2005 |

Richard, Yes, it does appear that the 20A fuse has replaced the cut out, although the difference with the later cars (later than mine that is) is that the forward winding of the actuator is connected via the ignition switch which provides some degree of safety. I assume the actuator itself is identical in all cases ? The fact remains that the 20A fuse will really only blow in an overload situation and will not detect constant energising of the actuator windings. I'm impressed that with a non-operating actuator on your three speed you can manually change gears without getting under the car. I believed that was only available on the four speed. Regards, John | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1744 Registered: 4-2003 |

John, I must be careful. A bit of a retraction here ! All SZ 3-speed cars, even those with the circuit breaker, have a switched-armature permanent-magnet actuator motor, as do the SSII cars. At least the early SYs, and maybe until the SSII (??) have hybrid separately-excited motors (series/shunt). The greatly increased line inductance of the earliest ones may warrant a breaker or Slo Blo fuse. Just a thought for discussion. RT. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1745 Registered: 4-2003 |

ps: to actuate the selector manually you do need to reach under the vehicle to push the lever with the electrics isolated. When the selector is left in Park, on later SY and on SZ cars, the selector motor activates to resist shifting from park without the ignition turned on if you try to move it without isolating it electrically. On earler ones, the selector will try to shift back to park as soon as you insert the key. That‘s why the later ones are safer when left unattended or when savaged by a pet from underneath ! RT. | ||

Dennis Akerman Yet to post message Username: dennis_akerman Post Number: 1 Registered: 5-2009 |

Hello from USA. I hesitate to post this suggestion among the techincally advanced ideas, but here it is for what it's worth: On my '75 Corniche, occasionally and intermitently the actuator would not function. I tried pressing the red button on the Otter unit which did not help. Then I wiggled it in its position, and all was well. Thus encouraged, I removed it and cleaned both the male and female spade connectors. Problem solved. Has not failed since. Could your situation be the same? I enjoy this forum and the whole website with its wealth of information. Many thanks. Dennis | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 145 Registered: 5-2007 |

I thought I'd follow this up with a few photos for the benefit of those like myself to whom this is uncharted territory. The problem indeed turned out to be the Otter switch. There was no continuity between the terminals on the transmission circuit. Taking it apart (with the help of a Stanley knife) I was able to remove the 3 little fuses and observed a couple of interesting things. The reset spring was missing from one of the fuses - but not the transmission one! Also the 3 fuses are interchangable - I removed the spring from the one that was dead and put it on the otherwise okay one. I then put the dead one temporarily on the door lock solenoid circuit - you can always use the key to open the doors. I could just as easily have left it out entirely. I've ordered a couple of spares from a wrecker in the UK and am fairly confident that I should be able to cobble together a reliable switch if either of those has one or more dead fuses - otherwise I've got some spares on hand for the future. Otter still make switches by the way - and say they will make the terminals in any configuration requested - although I suspect you'd need to order in bulk. http://www.ottercontrols.com/products_motor_protector.php The Otter switch in question is the little black box in the fuse box - there is another under the glove box for the window motors: Photo 1 What it looks like inside: Photo 2 One of the fuses: Photo 3 I've also included a photo of my floor pan fully stripped and ready for its final clean; etching and painting - I obviously have too much time on my hands... (The black area which had the worst rust has already been done with several coats of POR15 paint, seam sealer and their refinforcing filler - ready for a final 'cosmetic' coat)     (Message edited by jefmac2003 on 30 June 2009) | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 351 Registered: 6-2006 |

Hi Jeffrey, I suspect the one without the spring isn't missing a spring, it may be a self resetting one. It will click out when hot, but click back once it has cooled. There are coloured paint dots on the terminals which correspond to the ampage / load rating. Make sure you have swapped like for like. Have to ask . . . what's the brown thing to the right of the steering wheel? Cheers, Paul. | ||

Jeffrey McCarthy Prolific User Username: jefmac2003 Post Number: 146 Registered: 5-2007 |

Ah - thanks for that info Paul - I'll check them first thing tomorrow. The bakelite thing is a Barnacle; I glued a magnet under the vinyl which holds it on. It's for indulging Christopher Marlowe's other vice ;-) They were very popular in the UK in the '70s apparently, also keeps the ashtrays in the car clean as it can be emptied every time I get out of the car. | ||

Jan Forrest Frequent User Username: got_one Post Number: 83 Registered: 1-2008 |

Jeffrey: One minor point you made in your second posting on this thread. You said you were worried that the transmission fluid showed Stop worrying. "They all do that, Squire"  The proper transmission fluid level can only be obtained by getting the whole box and fluid up to normal operating temperature by covering several miles of spirited driving, followed by parking on a level surface, slowly moving the gear selector from P to L and back and finally with the engine still running dashing round to the engine, removing the dipstick, wiping it, returning it and then removing it immediately to look at it. That is how you should check the TF level on all automatic cars and is necessary as the proper level has to take into account the fluid filling all the alleyways, drillings, pumps and even the torque converter. Ps. I sincerely trust your Rolls will soon be wafting you around to the barely concealed envy of all your neighbours  | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 353 Registered: 6-2006 |

Jan you said "That is how you should check the TF level on ALL automatic cars and is . . . . " That's how I've always done it on RR&B's , but not ALL makes are the same. Aston Martin in particular (well some models) need to be in drive and takes 2 or 3 pints more than when it's in Park! | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1779 Registered: 4-2003 |

As Paul states, all transmissions are not equal. Sticking to Crewe cars for now. There are dangers. For example R-Types/Silver Dawns, SC/S through to Silver Shadow/T PV, PVI Hydramatic (4-speed) transmissions must NOT be checked or topped up hot. The transmission should be cold, then run in Neutral only, and for a maximum of 5 minutes from cold before checking the fluid level. If hot, a ridiculous overreading is often, but not always, shown due to the splashing fluid in the transmission when medium-hot. Many are damaged due to serious underfilling when the readings are taken too hot. As I say, this is not always the case, but many Hydramatics are so whether in pristine condition or badly worn. The point is that a hot reading on a Hydramatic is highly unreliable. Take no chances. Many specialists simply top up Hydramatics cold and on idle in neutral, filling exactly to the minimum level as that is about equivalent to a warm reading at maximum. Note that those transmissions have no Park position as such. When in doubt, read the owner's handbook. RT. | ||

Colin Silver Experienced User Username: colsilver Post Number: 46 Registered: 8-2008 |

Oh Richard, can I come over and talk you stupid for a week, with you telling me all you know. I don't want to go this learning curve for a Royce. Learning curves are not a problem when working on a mass produced vehicle. You learn, with effort, but at low cost and knowledge there is a replacement out there. For me, only 3 years an owner of a Cloud I, it seems I'm going to have to to another Uni degree, just so I can feel confident when working on the lady. My degree pays for the family and future, but not for the inheritance. sigh. |