| Author | Message | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 17 Registered: 12-2003 |

SSII 1977 I am pulling out the heads to replace gaskets. Question: Is it neccesary to remove the exhaust manifold from the head or is it possible to remove the manifold in situ, with the head by disconnecting the exhaust pipe? Kind regards M K | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 581 Registered: 9-2004 |

I would remove the manifolds you will need to work round the head for in most cases for the removal. Steady with the stove pipe fixings on the manifold. Which side head is failing? Did you do the tests? | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 18 Registered: 12-2003 |

Mr Lockyer: I am unable to remove the manifold nuts because one of them already has a slippery head. I will have the car towed and have a mechanic do the work. I did not carry out the tests because the coolant was boiling after a few miles. It is my guess that it is either the gasket or there is a hairline crack However, the spark plugs on the B bank came out perfect while the A 1 and A2 were a little oily. No coolant in oil or on the plugs. The radiator was dirty but did not require rodding, only a professional power flush. I donít think radiator is the cause of overheating. MK | |||

David Gore Moderator Username: david_gore Post Number: 592 Registered: 4-2003 |

Hi Mujahid, Sorry to hear of your mutilated manifold nuts however this is not uncommon. There is a range of tools sold around the world known as "Metrinch" being spanners and sockets than can be used interchangeably on metric and imperial fasteners. They also have a special advantage that they apply load to the centre of the nut/bolt head instead of the corners and can be used to undo damaged fasteners. On very badly mutilated items, it may be appropriate to use the mechanic's trick of putting a suitable shim between the fastener flat and spanner face to keep the contact lobe bearing on the centre of the flat instead of being offset towards the "rolled-over" corner reducing the possibility of the applied leverage further damaging the corner to the point the spanner/socket will no longer fit [time for the "last resort" nut breaker to come out with the attendant problems of getting it into a suitable position!!]. I expect your mechanic will use this type of tool on your vehicle. The following link might be of interest to you: http://www.metrinch-tools.com/ I am a very satisfied user of these tools especially as I have cars which use fasteners from both systems depending upon where and when they were manufactured. Best wishes David (Message edited by david_gore on June 15, 2006) | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 19 Registered: 12-2003 |

David: You made my day. I had almost given up, but I woke to your post and used the old forgotten Metrinch. The stubborn nut accepted defeat in two minutes. MK | |||

David Gore Moderator Username: david_gore Post Number: 593 Registered: 4-2003 |

Hi Mujahid, You also made my day with your feedback on your success. To paraphrase Bill Coburn; "feedback makes our time looking after the forum worthwhile" as we learn something new each time we hear of a successful outcome to a problem. | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 20 Registered: 12-2003 |

David: Indeed, the Aussie forumís help has been tremendous for an individual who has no training. To further the story of manifold bolts, the few at the top which had weathered 27 years of service were rounded and decided to stay put even to the Metrinch. But, a trip to the Sears solved the problem. Members will be delighted to note that there exists a special set of tools (Craftsman), which costs 20 bucks; this set of tools is capable of removing any rounded bolts. I removed all of the bolts within 30 minutes, and what a relief. I think we should all have this set. MK | |||

Bill Coburn Moderator Username: bill_coburn Post Number: 662 Registered: 4-2003 |

MK I still want to hear how you get on with actually getting the head off! | |||

David Gore Moderator Username: david_gore Post Number: 595 Registered: 4-2003 |

Hi Mujahid, I would be very appreciative if you could advise the Craftsman item description for the tool and I will put the details up for all to see. I have tried briefly to find it on the Sears website without success. Kind regards David | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 21 Registered: 12-2003 |

David: http://s7.sears.com/is/image/Sears/00952160000 www.Craftsman.com item # 52160 Bolt-out damaged bolt/nut remover I hope this helps. I love this tool. MK | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 22 Registered: 12-2003 |

Bill: I will keep you all posted on the progress. Work has slowed down a bit at present. Which issue of T-one covers the heads? I will also open the brake pumps while I am at it. Any pearls will be highly appreciated. MK | |||

David Gore Moderator Username: david_gore Post Number: 597 Registered: 4-2003 |

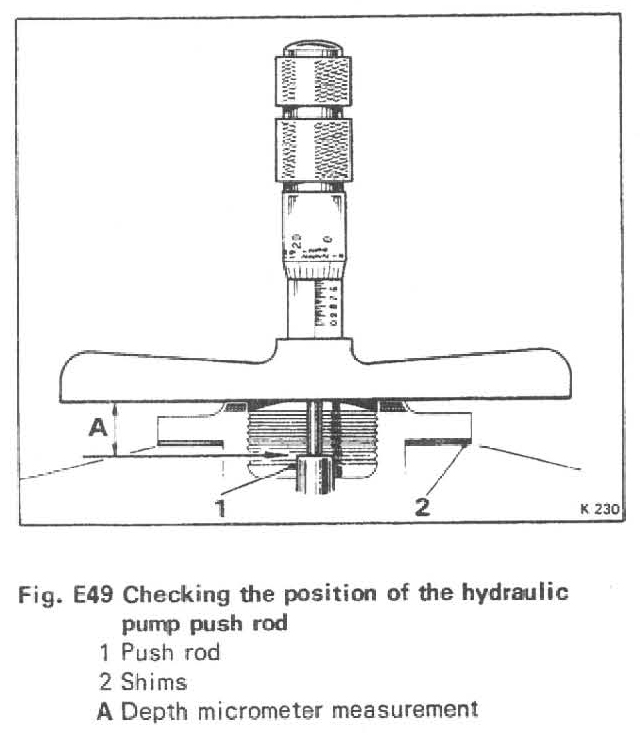

Thanks Mujahid, I wasn't aware of these tools and the price is certainly attractive - I shudder to think what Australian prices will apply for similar items. At least we can order them from the USA if they are not available locally from the Craftsman distributor. To quote a plumbing analogy, these tools are a "female" version of the common "Easy-Out" reverse-threaded tap ["Male" designation] for removing broken bolt/stud shanks. If you proceed to remove the brake pumps from the valley cover plate to do a full tear-down and rebuild; you will need a depth gauge to set the pushrod/mounting flange clearance. This is essential to avoid pump clatter [excessive clearance]/reduced fluid output [insufficient clearance/damaged pump components [piston impacting valve discs/pump body]. The type of tool required is as below;  The relevant details from the Workshop Manual are below:

| |||

Bill Coburn Moderator Username: bill_coburn Post Number: 663 Registered: 4-2003 |

MK First a confession up front. I have never pulled a vee eight down. I tried to a couple of years back and despite the most elaborate and frighteningly powerful 'pulls' the bloody heads simply would budge. We actually suspended the car from the unbolted head - no deal. I had to give the car back to the owner defeated. The obvious way to get the things off if they are stuck is a puller but that has to be able to push against the block. The studs only screw into the block with Helicoils and if you really load them up you could well shove them right through the casting. Bob Chapman our GURU in Melbourne has devised a 'puller' which I have yet to see which pushes on certain studs and pulls on other spots. The puller attachments are tightened very gradually which spreads the load, lifts the head and saves the block. As I have to whip the heads off my S2 this year I had better get details of this gadget and get a drawing into Topics and have one made up. Above all be gentle and patient DO NOT wedge belt or lever without thinking very carefully where you are putting the loads. Patrick you will have had this problem - what did you do? Lastly, you will need at least a 'C' spanner to remove the pumps from the valley cover. When you have them off get a tube spanner made up so that they can be removed without having to take the whole top off the engine! | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 585 Registered: 9-2004 |

Bill i make a type of funnel shape round each stud that has corrosion build up through a number of failings in the cars service life,then with a special fluid fill the "funnel" when filled the bubles appear as the fluid sinks into the corroded thread of the stud. Oh do jack the car so the head you are working on is level. next day top up and try for movement. Never been beat yet. Worst car "Stag" that i ever had to deal with was a car that was run on tap water and the owner kept topping up for a long time. The head moved just enough to get to hacksawing the studs,not the recomended practice and not with an alloy block like a RR. Tip on bolt removal when seized,try to tighten up first then undo. Strange but it works. | |||

Bill Coburn Moderator Username: bill_coburn Post Number: 664 Registered: 4-2003 |

OK Pat don't be coy what is the 'special fluid! The tight bolt release is a good tip, a judicious smart tap on its end will also often release stuck threads. This always works in my experience with those rotten little screws that hold the Shadow sight glass retainers on the reservoirs but you have to have the back side resting on an anvil! | |||

bob uk Unregistered guest Posted From: 80.3.64.11 |

I have had problems with parts that do come off when they should. With heads I try to remove the studs with lock nuts or a stud wrench. Another method I have used is to fill the bores with hot oil boiled up on a camping stove. I had a Jag Xj6 hanging off the roof for a week and I came in one morning delighted to see the car had fallen to the ground and the head was hanging off the roof only. I once used a sledge hammer to drive a piston up the bore to move a head of a Stag engine, the owner of the car was getting really worried by I didn't miss and the engine was scrap anyway because one of the bores had a floating piston pin which had worn through to the water jacket- explained why the engine appeared to have a badly blown head gasket. Shame I liked the Stag but that engine was truley awfull -- not to be trusted and definetly not to driven hard which rather defeats the purpose of a GT car. (Message approved by david_gore) | |||

Bill Coburn Moderator Username: bill_coburn Post Number: 667 Registered: 4-2003 |

Bob UK. I like you and I think most of us do too - won't you register. David is a timeless moderator but I am sure he would be grateful if you joined us! | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 23 Registered: 12-2003 |

Bob UK: I will second Bill! Swamm, is unfortunately on its last breath, or so it seems to me. I am sure Rolls owners and posterity will be delighted by your thoughtful comments. The Aussie forum is a stable and built to last piece of work. M Khan | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 587 Registered: 9-2004 |

Well Bill,here in the uk we have many oven roasts but we do have the barbecues but not as many as you as it has just started to rain dam. Any way the fluid is used as an oven or barbecue cleaner. It has never failed. Also ideal for the freeing up of the Sprinter etc injectors for removal! Some say use wheel cleaner but it may be to strong on the alloy. Bad practice to hit heads of bolts or studs on most engine parts on a RR as it can cause havock with the helicoils. But as you say it works with those small allen countersunk headed screws on the sight glass. Bob did the lower part of the studs let go on the jag, they seem to corrode in the base of the block on some early models. | |||

bob uk Unregistered guest Posted From: 80.3.64.11 |

The 4.2 XJ6 has head studs that go throu the top deck of the block and into the casting. If the core plugs are removed the stud bottoms where they screw in can be seen. The deck has expansion slots in it around the stud hole. In the case of the jag hanging for the roof two of the studs had snapped so we got a drill with a magnetic base removed the core plugs and drilled out the broken ones and retapped the holes---- straight forward engineering The best XK engine is the 3.4 litre it revs well and produces about the same power as the 3.8 (std engines like for like) providing it is reved. Over the years I have driven quite a few XK engines and I have never really trusted them. I would be happy to run a Shadow at say 80 mph for mile after mile -- but a jag would have me looking at the gauges every 10 seconds. The Yanks put 5.7 litre chevy in Jags and it transform the car. Shame Jag didn't do the same. They had a 4.6 litre V8 ( daimler magestic major design by Edward Turner who also was designed the truimph Speed twin motor bike ). This was fitted as a try and the results were very good but by this time they had spent loads on the V12 so they carried on. Also the V8 was not suitable for cheap mass production. The XJ6 was never meant to have a 6 cylinder engine right from the start it was designed with the V12 in mind but delays caused jag to pop the Xk engine in. Note the very wide engine bay. I suppose I had better sign up to this forum. and stop posting jag stuff (Message approved by david_gore) | |||

Bill Coburn Moderator Username: bill_coburn Post Number: 669 Registered: 4-2003 |

Well that is good news although after the accounts of your and Gore's shovel eggs and billy tea with loco oil I have had to revise my picture of you Bob. I had put you down to a late thirties highly experienced operator with a healthy touch of skepticism and a very sensitive bovine detritus detector! As to recounting other makes' foibles they are usually interesting and quite often catalysts for solutions to our probs! I went through a period in my life of extreme religiosity. I was talked into pulling the head on an XJ6. The thing had come loose through rotting of the head studs. With a lot of prayer and a back up of a sledge hammer as a threat I was lucky enough to get the rotten studs out (all of them actually) but then decided to clean up the threads. The tap snapped off. I stopped (nearly midnight) and went to bed with a sedative. Next night I approached the problem calmly and with two dental pics I managed to coax the broken bit out of the block. I was a very relieved young man. The end of the story was quite interesting. I put the thing together tuned it and handed it back. Six months later everything went wrong according to the reports I received and the owner who was I thought a close friend dirtied my name around town for ruining his Jaguar. I then found out that if you fix a major part in that engine you HAVE to do the whole lot. I didn't do that and the advice proved correct. I don't think I have even leaned on a Jaguar let alone driven one since! Lastly Bob I would be interested if you have any problems with registration. These are referred to in almost subliminal mutters from time to time. I believe however if we don't keep a check at the gate we well stand a chance of the fate of Swammelstein. | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 24 Registered: 12-2003 |

I am happy to note that Bob UK is considering joining the Aussie forum. We all can benefit from his experience. I have. Bovine detritus: A wholesome and useful term invented by Bill. Indeed, very few of us can detect this.But isn't life, after all, full of it?!! By the way , the heads are off. I will keep you posted. Do I need to put a "compound" on the gasket ? M khan | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 588 Registered: 9-2004 |

Muja. To your question compound on the gasket "no" Make sure you fit them correctly marked top. What did you find by visual inspection. Have you checked the "tell tell holes for liner leakage. Do check the heads for distortion after the overheating. Have you checked the valve guides while the heads are off. The fitment of new valve seals as well.[controled lubrication type of course] Tip keep water in the w.pump if the job is left for days as the seals dry out causing failure later and as some will say you will have a gusher though the fault of ageing pump,or replace if necessary at this moment in time. | |||

Mujahid Khan Experienced User Username: anjumkha Post Number: 25 Registered: 12-2003 |

Hi: The gaskets came out fine! The heads are at the machine shop to detect any microscopic crack or warpage. How does one check for the tell tale liner leakage. I will have the Valve guides checked MK |