| Author | Message | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2333 Registered: 05-2012 |

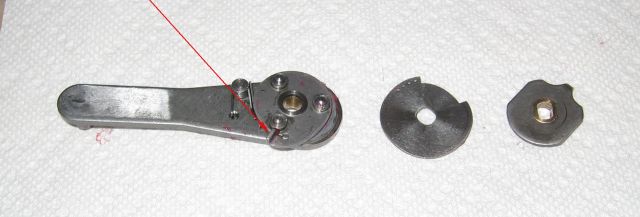

The tag on the windscreen wiper motor mechanism has snapped off - see pics.   It turns out the broken part is easily removed by pulling out the 3 bearings. I made a copy from mild steel sheet purchased from a local hardware store (Lowes) however, (as expected) the tag bends when the wiper motor is run which removes the drive to the conn rod. I was kinda hoping it would be strong enough but it isn't - no where near. My question is what type of steel to use to re-fabricate this part. Is high carbon steel too hard to file or drill? How about case hardening mild steel? Any advice would be really helpful. | ||

David Gore Moderator Username: david_gore Post Number: 4219 Registered: 04-2003 |

Hi Geoff, A question for me no doubt having been a professional Metallurgist with extensive experience investigating and rectifying component failures. Your problem is one requiring considerable thought before responding as factors other than material selection have to be considered. I am about to leave our country home to return to Sydney today and I will respond to your request on Wednesday your time if you can help with the following requests. Would you check the original part near the break with a metal file and advise if the component is easy to file or hard/unable to be filed. please try to leave the fracture surface untouched as I would appreciate a close-up high resolution photo of the fracture surface as this will provide useful information on the manufacture of the original part [see request below]. I notice a hole appears to have been drilled at the bottom of the fracture - it is important to know whether this is part of the as-installed component. or has been created during the life of the item for some reason. If possible, can you post a sharp enlarged photo of the fracture surface of the section that has broken away as this will help determine the factors that might have been involved in creating the failure. Your initial comment about your replacement part bending is also relevant as this may be an indication of other factors [e.g. binding] being involved in the cause of the failure. I can help with more specific advice regarding making a replacement if you can provide the above information. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2334 Registered: 05-2012 |

Hello David Yes indeed, a question directed at you. Thank you for agreeing to look at this problem. I had great difficulty in photographing the fracture as my equipment is so limited - just a normal camera that could not get the closeups I needed. Oh for a metallurgical microscope. So the pictures are best endeavours. I thought I'd answer your questions in the order you gave: A file barely touches the metal. Half an hour of filing would possibly remove some material but likely destroy the file. When I first discovered the damage to this part I tried drilling a small hole in order to fit a peg. I used a 1/16" titanium nitride coated drill and a cobalt drill in a drill press. They hardly made an impression on the steel - just a small mark. This material is very very hard. I am certain the small hole is part of the as-installed component. I certainly did not drill it and I doubt any previous owner did so either. In addition, it looks too well finished to been "home drilled". As I mentioned above, the attached pics are the best I could get with my limited equipment. The first pic is an overview of the two pieces and the other two pictures are cropped right down to fulfil the image size requirement i.e. the resolution is the same as on a picture that hasn't been re-sized. The replacement part is just one I fabricated in my garage. I believe it is cold rolled mild steel. The tab bent on first use. I guess another approach, given that the pics are probably hopelessly inadequate, would be if you could suggest what type of steel to use in this application. Many thanks for your help and expertise. Geoff    | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3340 Registered: 06-2009 |

Geoff, Not intending to be snarky, but weren't these wiper motors used on a very great many British marques of the era? I could have sworn they were and if that's the case, seeking the part via auto parts recyclers (AKA junk yards) might be your best bet. Brian | ||

David Gore Moderator Username: david_gore Post Number: 4220 Registered: 04-2003 |

Geoff, The photos are exactly what I needed. Your comment about the component being "file hard" is most important as it confirms the high strength requirement for the replacement. FYI this indicates a hardness of 52+ Rockwell C scale which is characteristic of a high strength cold work tool steel. The component would have been machined from annealed cold work tool steel and subsequently heat treated. It may have been hot forged and not machined from rolled sheet metal. What is interesting is the presence of what appears to be an internal defect in the parent metal which would have been responsible for the subsequent part failure. The appearance of this defect is suggestive of either non-metallic inclusions being present in the parent metal arising from initial melting and casting of the molten metal or an internal rolling or forging defect during manufacture of the feed stock used to manufacture the component. Hope this helps - my only concerns are the local availability of suitable feedstock for you to make a replacement component and a heat treater competent to heat treat the machined item without distortion and/or decarburisation of the metal surface which could lead to future failure. Now where do we go from here? My first suggestion would be to try and find a local RR/B dismantler who has a used Shadow windscreen wiper motor [probably a Lucas unit] and install this complete otherwise strip it down and just replace the component itself. I am assuming the wiper motor would have also been installed on other UK assembled vehicles and consequently available from a car dismantler otherwise the expensive option would be a specialist RR/B dismantler. If this is not feasible, I have concerns about the availability of appropriate new metal plate suitable for manufacturing a replacement. I suggest you contact the UK tool steel specialist below to see if they can analyse your part to determine what grade has been used and the availability of a suitable equivalent in regard to alloy and feedstock availability. https://www.akmsteels.co.uk/grades/cold-work-tool-steel/ The component will have to be machined from annealed feedstock and heat treated to at least 52 Rockwell C scale to match the original component. Any heat treater should have a hardness tester to determine the actual hardness of the component and an "old timer" might even be able to "spark test" the original component to give an indication of the likely steel grade used to make the original component.  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2335 Registered: 05-2012 |

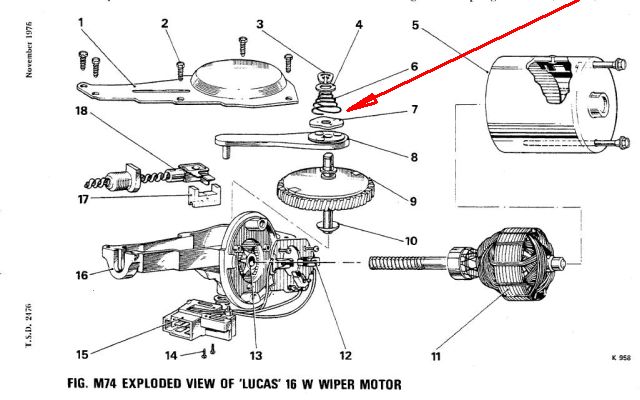

Hi Brian I didn't take your comment as snarky at all. It's a good point. The thing is I've researched this wiper motor (Lucas 16W) and the part that's failed in my car isn't present on most of the British marques of that period, even though some of them are listed as having Lucas 16W wiper motors. It is a bit of a mystery to me. Even the workshop manual for the pre-1976 models does not include this part in the exploded diagram - I include a screen grab to prove this. Flying Spares sell replacement windscreen wipers for $406.24 and I'd be happy to pay that, but they are sold "less gear" which means the conn rod assembly is not included. They did have the replacement gear a couple of months ago but it was priced at over $900, which led me to think in terms of making my own part. In fact fabricating it is just a simple job of filing and drilling the holes in the right place but the catch is it is practically impossible to get the right level of hardness for the part to function, as outlined by David in his post. I will keep my eyes open for a replacement on ebay and buy one if I'm satisfied the 16W motor does in fact have the part I'm looking for. There is another solution to this problem and that is to use a microcontroller to carry out all the functions of the windscreen wiper system. I have an Arduino and have already programmed it up, however it does make the windscreen wiper system totally non-standard. If I can't source a replacement part I may well take this route. BTW - the red arrow in the pic points to the position where the missing part should be.  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2336 Registered: 05-2012 |

David I really appreciate your having taken the time out to give me such a detailed reply. It has convinced me that I need to source a new part or use an alternate system, as detailed in my previous entry to Brian. I need to go, but will respond more fully tomorrow. Again, Many Thanks. | ||

AdrianJ Unregistered guest Posted From: 82.132.247.163 |

I have a 1974 UK RHD Shadow I am scrapping. I have looked at the wiper motor, a 16W, and it appears to have that tab on it you require. I have close up photos but do not appear to be able to post them. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 4221 Registered: 04-2003 |

AdrianJ, If you do not wish to become a member, you can email the images to me at: drh14434@yahoo.com.au I will post this for you with attribution.  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2337 Registered: 05-2012 |

Hi Adrian Since you are scrapping the Shadow I would be interested in buying the part from you, plus P&P. Regards Geoff | ||

AdrianJ Unregistered guest Posted From: 146.200.18.105 |

Have hopefully sent 3 images from a Proton account so you are o.k with opening it. Sender details will start with 'tax'. Have a look and see if it is the correct unit Geoff requires. It is not that I do not wish to be a member but more that I am not IT savvy. Additionally I prefer not to leave a trail over the Internet for anyone to see my 'activities' which will occur as my name would appear instead of a username. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 4222 Registered: 04-2003 |

Have received the images from AdrianJ - I just have to Photoshop them for posting which will be tomorrow morning [Saturday] our time. | ||

David Gore Moderator Username: david_gore Post Number: 4223 Registered: 04-2003 |

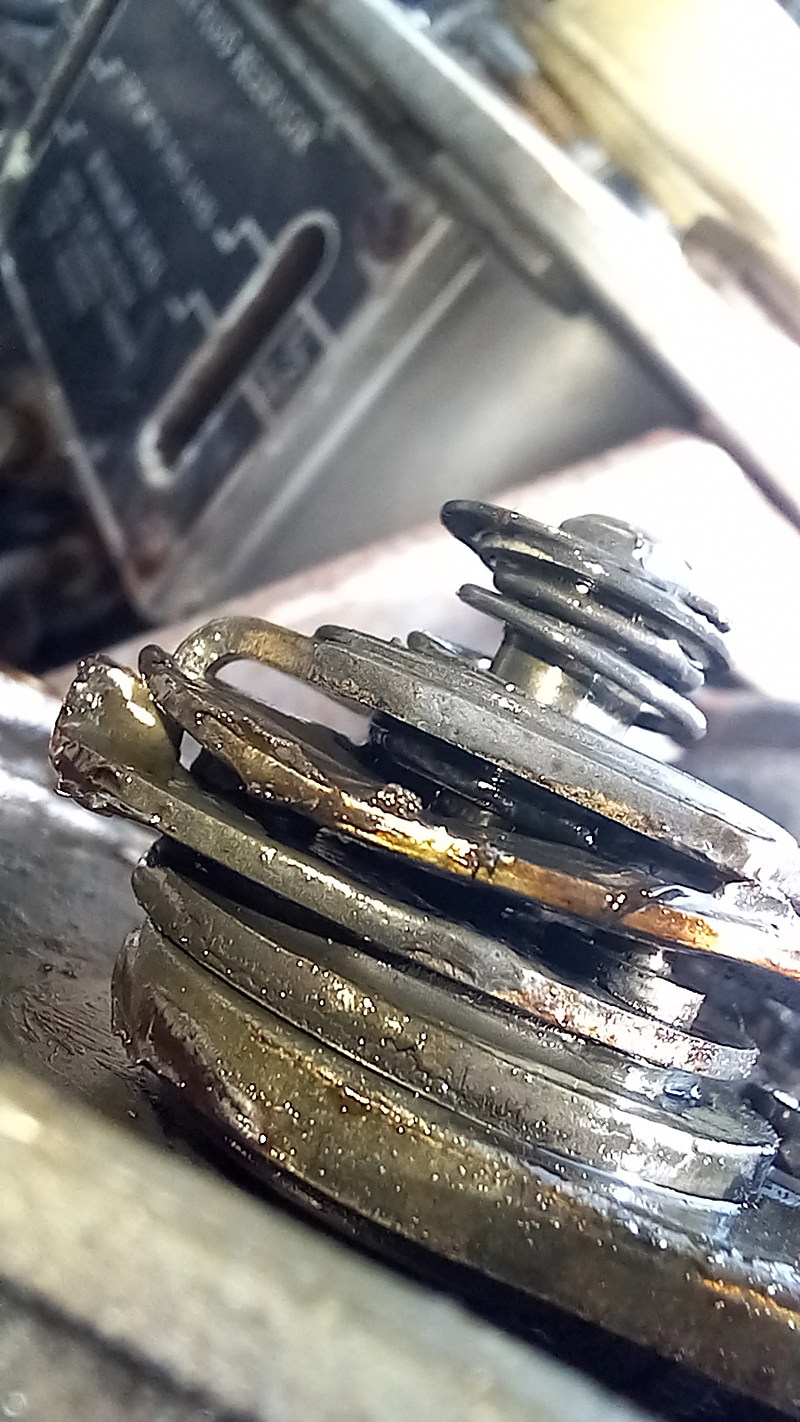

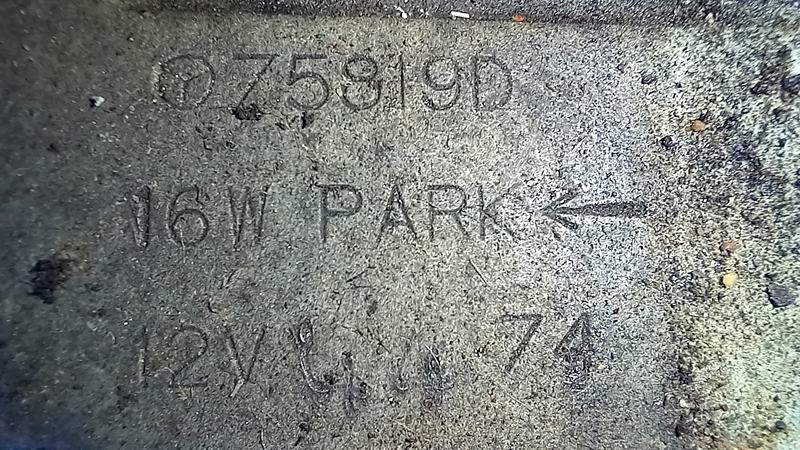

Here are the photos from AdrianJ - thank you for providing these for the benefit of our contributors:    | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2338 Registered: 05-2012 |

Hi David Since AdrianJ is not registered on this forum, could you email him to see if he is interested in selling this part, or the wiper motor. He did mention he is about to scrap his Silver Shadow so he may be interested. Regards Geoff | ||

David Gore Moderator Username: david_gore Post Number: 4224 Registered: 04-2003 |

Hi Geoff, Have passed your request on to AdrianJ as requested.  | ||

AdrianJ Unregistered guest Posted From: 146.200.18.105 |

Geoff, If this is what you are needing then yes happy to send you the motor. Will not fit my 1980 Shadow 11 anyway I don't think. Make me an offer. I will get a postage quote Monday / Tuesday. David can pass you my e-mail address (which I rarely use) to communicate a delivery address. Are you happy this is what you require? Ref the hole previously mentioned, this too has it but appears more of a 'comma' shape with having a little tale. That could be a stress point resulting in fracture, remember the early DH Comet with non radiused windows? (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 4225 Registered: 04-2003 |

Hi AdrianJ, Have passed the relevant details on to Geoff and he will contact you direct. I am reasonably certain Geoff's failure was initiated by an internal non-metallic inclusion reducing the ability of the component to withstand the loadings applied to it in service and not fatigue cracking. I am very aware of the Comet window frame fatigue problem from my University Metallurgy degree course in the late 1960's; we spent some time discussing this failure and its causes especially the structural stress forces and the inappropriate design of the window frame creating stress concentration points that facilitated the cracking of the aircraft frame and the resultant catastrophic structural failures that caused the aircraft to crash. One of our lecturers had spent time at Farnborough whilst the Comet fatigue testing was underway and he passed on a great deal of knowledge about what was done and how the faulty initial design was recognised and modified to give us the flight safety we enjoy today. What was suitable for unpressurised propeller driven aircraft proved to be highly unsuitable for pressurised jet aircraft. We had access to the Farnborough testing reports and photographs which graphically showed how and why the window frame corner design was responsible for the subsequent depressurisation and crashes. I later investigated many major component failures due to poor design leading to fatigue cracks and advised the corrective measures required to eliminate these failures. Many of these involved motor sport as designers and drivers pushed the boundaries of design and material specification to create race-winning vehicles.  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2339 Registered: 05-2012 |

Many Thanks for your help David. | ||

David Gore Moderator Username: david_gore Post Number: 4226 Registered: 04-2003 |

Geoff, It was rewarding for me that our community responded to your predicament in a positive and successful way. Despite what is happening in our world today, there are still people who will make the time and effort to help others when they can. My credo always has been a simple "the impossible we do today; miracles take a little longer". Thank you one and all for helping to make our world a better place.  | ||

AdrianJ Unregistered guest Posted From: 146.200.18.105 |

Unfortunately Geoff is of the opinion that my component is at the point of fracture also, therefore nothing became of this. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 4227 Registered: 04-2003 |

Adrian, Regardless of the outcome, this topic still has been an excellent example of our members and visitors trying to help each other. It is this outcome that makes my 20+ years of forum participation worthwhile. I am happy to advise further on making a replacement component especially in regard to the material selection and heat treatment procedures involved in creating a suitable replacement. Remember the adage "if you don't at first succeed, try, try again"!!! |