| Author | Message | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3104 Registered: 06-2009 |

Gentlemen, SRH33576 has been in storage for about 5 years now, and during that time my hearing has gotten worse, so when I turn the key to run I cannot hear the telltale ticking of the dual SU fuel pump. Given that it was completely rebuilt not all that long ago, I wouldn't suspect failure but who knows. Rather than plow through the documentation to determine whether there is a place in the engine bay where I could disconnect a fuel line safely, if I have a fuel catch, to determine whether any fuel is being pumped I thought I'd ask here in hopes someone can tell me off the top of their head. Brian | ||

Omar M. Shams Grand Master Username: omar Post Number: 2098 Registered: 04-2009 |

Dear Brian, undo the threaded connection to one of the two carbs..... fuel should p^ss out as you break the seal. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3133 Registered: 06-2009 |

The pump is definitely not working, and several have suggested "not so gentle persuasion" of hitting the pump with a hammer when the key is turned to the Run position to see if that will unstick it. I've tried, but I suspect I'm being too gentle. So, this leads to several questions: 1. Is there a "preferred hammer size/weight" (I was using a relatively light ball peen). 2. Is there/Are there preferable spots for the hitting? 3. Approximately how hard. I'm not going to throw my whole arm into it, but am trying to decide whether something beyond "very gentle" rapping is required. Thanks Much, Brian P.S. I will also be posting this question on rollsroyceforums.com, as I have to get the car out of the garage she's in by tomorrow afternoon. So if you read in both places a response in either one would be fine. | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 225 Registered: 07-2018 |

The ball peen hammer should have worked if it was going to. SU pumps don't like to sit, especially if fuel with ethanol was used, the diaphragm becomes hard and brittle and it can't pump. Depends on where the new parts came for the rebuilt pump. New old stock would certainly not like ethanol, with new parts, it shouldn't matter, but still susceptible to the "sitting for too long" problem. Check and make sure it's getting 12 volts with the key in the run position first and get that off the table. If the car was stored in an unheated place, especially if it was damp with extreme temperature changes, then the points could be fused together, that's what the ball peen hammer is for. If you can't hear the pump, you can certainly feel it ticking with your bare hand. (for next time) | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3134 Registered: 06-2009 |

Jeff, So that would mean that the striking should be done more toward each end of the pump than toward the center of the body, correct? I may need to "go a bit further out" and try this again. One end of the dual pump is dirt simple to get at, but the other, not so much. I just don't want to damage it by being too aggressive with the hammer blows. I would also suppose that keeping the key in the Run position for too terribly long if it's not pumping might have the potential to damage something, but I really cannot recall clearly enough what things looked like when I had that pump apart for rebuilding. The replacement parts were not NOS. It was a Burlen SU pump rebuild kit purchased new in 2009, and it was clear it hadn't been on the shelf gathering dust for decades. I can't imagine by that time that all of the parts were not already suitable for fuel with ethanol. E10 has been more common in the USA than pure gasoline/petrol since the late 1970s. I've also never had the nightmare situations that are so often alluded to with any of my cars and blamed on ethanol, at least not so far. At this point if the pump is not getting 12V it won't matter in the very short time period I have to get it moved. We'll be pushing her out of the garage tomorrow if I can't get the pump going and her to fire up. Of the things I thought might be problematic, I had not anticipated the fuel pump. When I originally acquired the car, unbeknownst to me, one side of the dual pump had not been working for years. One day she just stopped in my driveway after backing out of the garage. When I tore the pump down to rebuild it I ended up sourcing a NOS "half" because the corrosion on the one side was so severe that there was no hope of rebuilding it. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3135 Registered: 06-2009 |

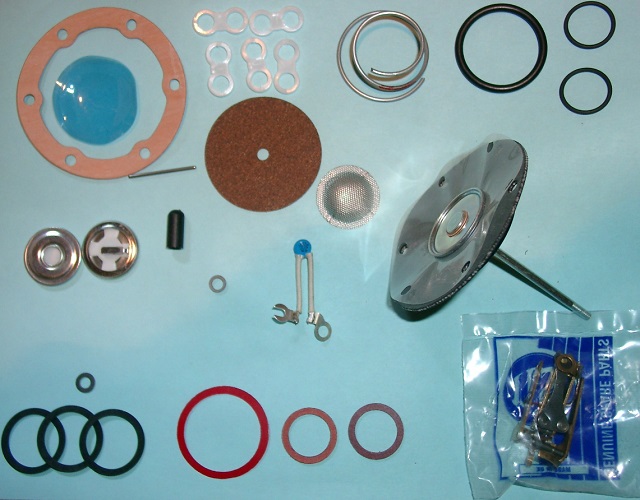

Turns out that rebuild was in July 2010. Just checked my photo archive and see that's when I took the photos related to that repair. Here were the contents of the EPK 300 rebuild kit:   | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 226 Registered: 07-2018 |

The hammer trick will only go so far, don't start tapping on the fragile bakelite end cap, only the steel body. The steel body is pretty robust, you can't really damage it, if you hit it too hard, all you will do is damage the paint and ding it up. Don't leave the key on in the "run" position for more then 30 seconds, your ignition may be damaged, especially if you're running an OPUS ignition. If you can remove the bakelite end cap, you can physically inspect the points, as well as opening and closing them with your finger to get them to work. Any corrosion there will be very visible. You also may be able to move the diaphragm pin that the solenoid controls to see if it moves. You need a multi meter to check for 12 volts at the pump, or even just a rigged up auto lamp before assuming the pump isn't working. That has to be done first to eliminate that. Connect one end of the lamp to the 12 volt source that feeds the pump, and the other to ground. Burlen isn't going to be using material that is susceptible to ethanol, so that's not a worry. . | ||

Trevor Hodgekinson Frequent User Username: wm20 Post Number: 232 Registered: 11-2006 |

Unplug it as close to the pump as possible. Hook up a high voltage power supply , some where around 48V or better. You are not looking for high current, just higher voltage than the 12 V normal supply You can ever use a bank of 9V transistor batteries. Over time the point oxadize so will not pass current. Tapping hopefully makes & breaks the contacts so the pump starts to work again A higher voltage is the electrical equivalent of tapping with a hammer. My voltage regulators on the vintage bikes do this all the time and for them 24 V passing through seems to do the trick If you start to get a click - klack with the bateries then plug it back in and it should fire up Otherwise it is emery paper drawn between the points to clean the oxide off them. | ||

michael vass Frequent User Username: mikebentleyturbo2 Post Number: 708 Registered: 07-2015 |

Hi Brian I replied on the other forum ok Mike | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3136 Registered: 06-2009 |

I'm sure I posted this at some point in the past, but it never hurts to have another reference to it out there: Getting the SU Fuel Pump In & Out of the Car (for an SY2, pump mounted near rear final drive) | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 423 Registered: 03-2012 |

Well Brian, did ya get it fired up, I was going to suggest a cheap 12v pump, just to get her out of your way ..For now? More than likely the points are welded together, in saying that always check the fuses and power to the pump. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3137 Registered: 06-2009 |

Hubert, The fuse has definitely been checked and, in fact, switched out for good measure. Power to the pump, etc., will have to wait for post move out of the garage. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3138 Registered: 06-2009 |

OK, so I've popped the rubber boot off of the end of one side of the pump exposing the electrical connection, which I presume I can test just by using a test lamp connection on the pump and the other side to a convenient spot on the chassis. But I cannot remember if getting the bakelite cap off is as simple as removing the two nuts that are used to hold the electrical connection on to its post and sliding it off. Is it? I might try going that far if I find I do have +12V actually coming in (which I have every reason to suspect I do). I wish I had taken more photos when I rebuilt this thing, and it's taught me a lesson that I need to photo document even more than I used to! Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3139 Registered: 06-2009 |

OK, here are several more questions related to doing a diagnostic: 1. How do I test for +12V getting to the pump? I have the post exposed for one end of the pump, and if memory serves it's grounded through the chassis (though I could be wrong about that). I presumed that connecting one terminal of my test lamp cord to the post on the pump, and another to the chassis somewhere (once I find someplace "good"), would eventually result in an illumination when the key is turned to the Run position. Is this correct? [BTW, the lamp has been tested and polarity does not matter as it's not LED] 2. If #1 is correct, and I determine that I am not getting +12V at the pump, is it safe for me to run a switched line from the positive terminal of the battery to the pump post/terminal, then flip the switch to see if I suddenly get pumping action? My memory is hazy about exactly what the electrical connections involve for the pump and the photos I did take are not helping me much. Brian | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 424 Registered: 03-2012 |

Brian this might help single pump but same idea https://m.youtube.com/watch?v=jJjV33djBks | ||

Omar M. Shams Grand Master Username: omar Post Number: 2127 Registered: 04-2009 |

Dear Brian, yes i have in the past run a live wire to the pumps and got the car started that way to move it to somewhere convenient to troubleshoot the reason for no power at the pump. When you run a live to the pumps you also energise the ignition circuit - so please bear that in mind. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3140 Registered: 06-2009 |

Thank you gentlemen. I think I shall try a live wire to the pump in a few short minutes. I'll keep everyone posted. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 3141 Registered: 06-2009 |

The direct line of +12V causes an instant characteristic ticking on the side to which it's applied, and for what I need to do I only need one side! So now it's back outside to see if I can actually make her start. I also need to drop the rear end off of the jack stands, too. Brian | ||

gordon le feuvre Frequent User Username: triumph Post Number: 366 Registered: 07-2012 |

Have not read through all posts, but don't forget ss2 has oil pressure type switch next to oil pressure switch on front lh side of engine. The idea is there is enough fuel in carbs to start car, then oil pressure cuts off earth that is connected to fuel pump relay.This allows feed to then go to fuel pump. It is designed to cut off electrical supply to pump if car rolls over and engine cuts out. Just remove connector at switch, you will know if correct switch as other one the same does oil warning light on ignition. Tie wire in knot and crank engine to get started. These fail quite a lot and it such an easy fix. replace switch when convenient. |