| Author | Message | |||

Guido Peter Broich New User Username: guido Post Number: 2 Registered: 05-2019 |

Hi all, here I am back with a question I cannot get resolved. I did an overhaul of the rear levelling valves and the RAMs. I cleaned also the restrictor valves and checked the wiring of the solenoid. Levelling works well, but I have a problem nobody gets to help me with - while driving, when the car goes over a bump or goes up und down: 1- sometimes I hear a strong RRRRRR noise from the back, short 2- when the car bumps UP, i.e. the RAMs are released, I feel like a short but perceivable stop, as if braking power was applied. (not on the downride of the back, only when it goes up again and the possible ram pressure should be released). Fact is that the RRRR noise comes up only rarely, over big bumps, while the braking sensation is vey frequent and comes up also without that noise. That is the reason I wonder if it could be a problem inside one of the levelling valves, when the lever goes down ... I am thinking that the noise could come from the restrictor valves? The "brake" sensation could be a short circuit in the levelling valves that at a certain position or the lever allows high pressure fluid go directly in the return pipe and builds up some small but perceivable pressure in the brake circuit? Brake action must be very short, as no heat is ever build up, also after longer rides, in the wheels. Has somebody had this problem and knows how to tackle it? Thanks, Guido | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 646 Registered: 11-2017 |

Did the problem exist before the overhaul? Put the car on a lift, release the connecting link between the valve and swing arm and bleed the rams. Did you set the gap required in the height solenoid?. You can disconnect the HS and hook up to a battery to see if it is clicking as well. This is a preliminary start. | |||

Martin Taylor Experienced User Username: martin_taylor Post Number: 185 Registered: 07-2013 |

Your car is in fast levelling mode, this will cause the system to react to every bump as it is, to prove this drive with the drivers door slightly open and it will probably be no different (it should be), this is either caused by power being applied to the solenoid or dirt or girt in the solenoid allowing pressure to the signalling line on the the levelling valves, the brakes being applied is as you suggest the higher pressure in the return lines activating the master cylinder system as it cannot get back to the tank fast enough so applies pressure via the vent line in the MC which is open to the rear callipers when the pedal is released, check also none of the return lines are dented as this restricts the flow back to the reservoir. Fast levelling should only occur in neutral, park or if a door is open. | |||

Alan Dibley Frequent User Username: alsdibley Post Number: 260 Registered: 10-2009 |

It is worth checking the only rubber hose in the return line from the HCVs, to check that it has not swollen shut, unless it is a new one. Its high up on the left rear underside. Alan D.. | |||

Jim Walters Frequent User Username: jim_walters Post Number: 326 Registered: 01-2014 |

I have come across this exact issue several times and each time it was dirt in the restrictor valves. A later Shadow without a master cylinder can also have the same problem, the last time I dealt with it was on a 77 Shadow well after the master was deleted. I'm not saying Martin is wrong, just my experience with this issue is different. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 647 Registered: 11-2017 |

Agree with Jim, There is little tolerance in the restrictors for debris. I prefer to completely remove them for cleaning and rebuilding (not much to rebuild), and when assembled make sure you can rattle the valve when assembled. This way you know the internals are not hung up in the bore. It doesn't take much. | |||

Omar M. Shams Grand Master Username: omar Post Number: 2093 Registered: 04-2009 |

When I had the the same problem my issue turned out to be the hydraulic hoses. They looked great form the outside but from the inside they were choked. The hoses acted like check valves allowing oil to flow but then choking the flow. I changed them and the difference was fantastic. The braking that would come on by itself stopped immediately after the change. | |||

Guido Peter Broich New User Username: guido Post Number: 4 Registered: 05-2019 |

Thank you all very much! I will get the car on a hoist soon and check. In effect solenoid clicks but no difference with open or closed door... Will report here. | |||

Brian Vogel Grand Master Username: guyslp Post Number: 3096 Registered: 06-2009 |

By the way, even though this appears to have been addressed, I wrote up the following some years ago to cover some of the things that can occur, and the reasons for them, as far as peculiar behavior with the brakes. I may, for all I know, have even posted it on these forums, but I kept the URL for the topic on rollsroyceforums.com. See the topic, Silver Shadow Brake Issues: Your Help Would Be Appreciated! I also made a post of my then "greatest hits" collection regarding brakes/hydraulics: SY Brakes & Hydraulics - Diagnostics and Maintenance Brian | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 669 Registered: 05-2016 |

You could try disconnecting the positive or earth wires at the height control solenoid valve(insulate the ends) and take a drive. Height control should still work in slow mode. If this solves the problems it would indicate that the solenoid valve is where the trouble lies. Otherwise look for a blocked restrictor valve (most likely the low pressure return restrictor valve) or hydraulic hose. | |||

Guido Peter Broich New User Username: guido Post Number: 5 Registered: 05-2019 |

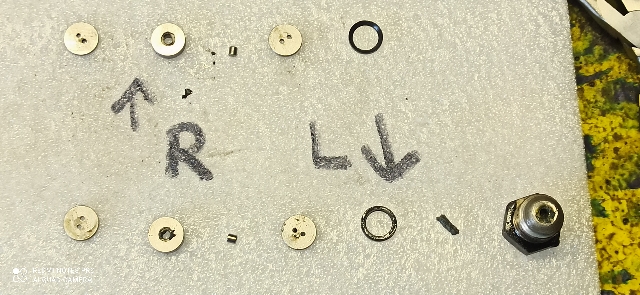

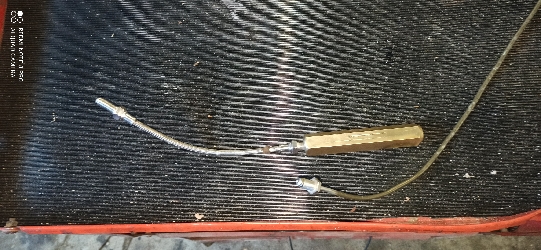

Height solenoid has wires hot on P or N, not on others. It clicks. So I took down the restrictor valvesand and the right hand one was fine and clean. The center one (left) turned out to be full of dirt. (see pictures). | |||

Guido Peter Broich New User Username: guido Post Number: 6 Registered: 05-2019 |

| |||

Guido Peter Broich New User Username: guido Post Number: 7 Registered: 05-2019 |

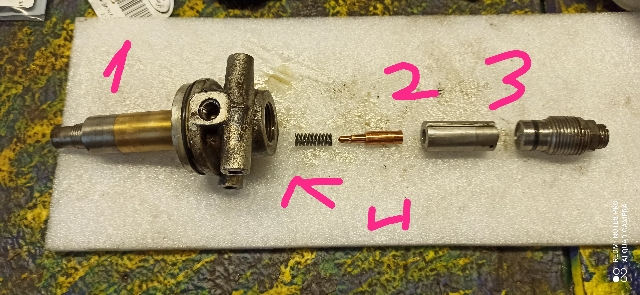

Have to shrink the pictures at home, will post more later. But now I looked at the solenoid. I got the overhaul kit from introcar. 1.coil is not short, works 2. Movement very short 3. I changed the copper plunger 4. How can I register it? Actually pressure from main input goes always through to the exit to the solenoid. When I give current, it goes also to the return exit. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 686 Registered: 05-2016 |

Solenoid is probably OK. Clean the restrictor valves well with brake cleaner or methylated spirit. If you reassemble the restrictor valves without using the seal and shake them near your ear you should hear the small centre piece moving. If they're moving freely insert new seals and they should be good to go. If the flexi hoses have not been replaced within the past 8 years it's time to do it now. That crud in your restrictor valve is probably coming from a hose that is disintegrating or a seal that is perishing. Take the lid off the reservoir and see if there's any crud lying on the bottom, crud indicates perishing flexi hoses or seals. . | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 653 Registered: 11-2017 |

The small slug must be able to move freely in the centre hole of the discs in the restrictor valves The height solenoid has a critical gap within, that has to be adjusted and set. It will transmit a click when power is applied. | |||

Guido Peter Broich New User Username: guido Post Number: 8 Registered: 05-2019 |

Yesterday I colud not post all the pictures, as they where too big. Thanks to all and a few updates: I did a complete tubing change about 7-8 years ago, in fact the rubber hoses where blocked on the brakes. I changed them ALL, also the high pressure tubing from the accumulators to the brake cylinder. At that time I cleaned one restrictor (right) but left the left one alone (I did not see it probably) so the dirt can be from before or now. At that time I checked the solenoid valve which was clean. Not the solenoid was clean, al rubbers look ok, no leaking. One first question: the rubber seals from the Introcar kit are much less thick than the originals, so I am tempted to leave them alone not to get a leak now. Solenoid magnet works, but the inside plunger "hops" only for a very small amount. (I did a video but don't know how to attach it). Furthermore the pressure applied to the high pressure inlet (air) comes out of the outlet at al times, both if current applied or not. Return outlet is open only when current applied, so the plunger reaches the outlet opening and closes. On Fig. G29: Always form C-->B, only when current from B-->A and C-->A. Is this correct???? Robert: how much should I screw the return outlet in, to register correct? I hear a clicking if I just screw it in a little bit, than it stops (too compressed). I did NOT find ANY shims in the plunger assembly, both not between the thick plunger parts, nor on the copper one (see fig. G29, shims X and Z). I feel I have two different problems: the RRRR sound coming from the restrictors and the braking from the always open (fast levelling) solenoid. If C- to -->B is always open, pressure goes to B at all times and I am in fast levelling with or without current to the solenoid. Guido, the best way to post the video is to put it into a Google Drive folder and create a link to the video file for forum members to access and view the file. If you need help to do this, please send me an email: drh144334@yahoo.com.au . | |||

Guido Peter Broich New User Username: guido Post Number: 10 Registered: 05-2019 |

by the way: Maunal shows high pressure restrictor valve OUTSIDE the levelling valve with three pipes. In my car it has three pipes but is sitting right under the right hand valve. The low pressure restrictor valve is on the center of the car (see picture) and has also tree pipes, NOT four as stated in the manual .... Position of the hogh pressure restrictor, removed:  Low pressure restrictor on site:  (this was the dirty one - there are only three pipes, the 4th thing you see is an earthing lead). Another difference from the drawing is (I have a late LHD LWB car) is that the RAM drains are not at the sides of the car, but come together in a single terminal block at the center of the car. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 687 Registered: 05-2016 |

Hi Guido, The ram bleed screws on my Silver Shadow 11 are on a terminal block also but the right hand bleed screw bleeds the left ram and vice versa. The high pressure restrictor valve is the one nearest to the solenoid valve to the best of my recollection. The old seals in your solenoid valve may have swelled and it's not a good idea to reuse seals when reassembling a component. The solenoid valve should work in slow mode all the time when driving and only goes into fast mode when gear selector is in "P" or "N". On early Shadows fast mode was also wired to the driver's door switch but that may have been deleted prior to your model. It sounds to me that your solenoid is working correctly, best way to be sure is put everything back together and go for a drive, if you still have a problem then you can disconnect and insulate the solenoid wires and see if the braking problem goes away when the self levelling is limited to slow mode. I reckon that cleaning the restrictor valves has probably solved your problem but the hydraulic hoses are near the end of their life and you should be thinking about changing them especially if there's rubber powder particles in the bottom of your reservoir. Don't let the outer appearance of the hoses fool you as they decay from the inside first. After bleeding the rams I always switch off the engine and then bleed the No.2 pressure switch while there is weight still in the trunk as that releases any residual trapped air in the height control system. . | |||

Guido Peter Broich New User Username: guido Post Number: 12 Registered: 05-2019 |

Hi Larry, thank you very much! In fact the door switch must have been removed, I did test the wires and they are hot in P and N, but not in R, D,1,2 regardless of door open or not. Also I have the central ram purge block with right line going to the left nipple and left line to the right! I will reassemble and test it as you suggested, but I still need to know how much I should screw in the central return line connector... can you give me some suggestions? I wondered only how it can be that it never closes completely, but maybe it does under high pressure on the inlet. I will change the rubber hoses on the brakes, in effect they have some years now. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 654 Registered: 11-2017 |

The workshop manual clearly shows how to carefully dis-assemble, replace parts and SET the gap with a feeler gauge. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 688 Registered: 05-2016 |

When you run the engine for a few minutes to build up full hydraulic pressure and then turn off the engine and turn the ignition back on you should hear a faint click from the solenoid valve when you detach a wire, this indicates that the electrics are OK in the valve and that the valve is working. However, if you also hear a light hissing noise when you disconnect the wire it indicates a problem with the valve seat. So a click but no hiss when a wire is detached should mean that the solenoid valve is good. Section G 11 in the manual TSD 4200 in the technical section near the bottom of the topics menu gives details of the gap settings. I haven't serviced a solenoid valve myself yet, when mine became defective a few years ago there was no clicking noise when I disconnected a wire so I took the lazy option and replaced it with a reconditioned one from Flying Spares. When doing the wire disconnection test don't leave the ignition turned on for long as the electronic ignition module could fry. . | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 655 Registered: 11-2017 |

You can also test the solenoid by unplugging the 2 wires and testing with a stand alone 12 battery. | |||

Guido Peter Broich New User Username: guido Post Number: 13 Registered: 05-2019 |

I said before that the wires are ok. So that's done. Questions are two: 1. Is it ok that the solenoid valves lets pass fluid from high pressure input to levelling valve output both with magnet on and off, because very short plunger travel? 2. How can I figure out how much I should turn the inlet screw in? I hear a clicking noise up to a certain piint, than going further it stops. . | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 690 Registered: 05-2016 |

Have you read Section G11 in the manual. It gives details of all the settings. Assuming that the gaps are correctly set and the valve seat and spring have been inserted screw in the adjusting sleeve until the valve seat touches the nylon seat of the bobbin (I presume that's the point when the ticking stops). Then you will need a dial gauge or depth gauge to measure the distance you screw the adjusting sleeve back out, the distance to back off the adjusting sleeve should be between 0.508mm and 0.635mm. Then fit and tighten the large lock nut while you hold the adjusting sleeve from moving. The system for testing the solenoid valve fluid output is also in Section G 11 TSD 4200 which is available to download on this site. I haven't actually serviced a solenoid valve but if I was to do it I would follow the step by step guide in G 11. I had to read it a few times before the procedure became clear. . | |||

Guido Peter Broich New User Username: guido Post Number: 14 Registered: 05-2019 |

Thanks Larry! G11 in the workshop manual is about the master brake cylinder ... At page G46 there is the procedure, but it does not say how far to screw it in, but the dimensions of the shims to put in X and Z ...as I told before, I did not find any shims in the valve opening it and Introcar does not have shims in the kit. So now I will try to screw to contact and back up 0,503-0,653 mm, to see if it works. I feel that the shims are necessary to assure good closure of the side holes and inlet pressure, which would not be affected by this procedure as you follow what shown in fig. G29. I will give it a try. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 691 Registered: 05-2016 |

Hi Guido, I think we are looking at different manuals, you are reading TSD 2476 while I'm reading TSD 4200 Section G 11. TSD 2476 doesn't explain how to test the solenoid valve but TSD 4200 gives a good description of the procedure. Your car seems to be a very late Silver Shadow that has some of the parts from a later Silver Shadow 11 installed, the position of your restrictor valves and ram bleed screws are more in keeping with Silver Shadow 11 design. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 656 Registered: 11-2017 |

Early Shadows had the ht solenoid high up on the rear subframe and almost impossible to reach the top union. Later cars were lowered. As Larry mentioned, the ht solenoid info/pics is a bit different in both workshop manuals. I have rebuilt many and prefer use the SII manual. I have a 1976 Shadow and a 1980 Silver Wraith II. | |||

Guido Peter Broich New User Username: guido Post Number: 15 Registered: 05-2019 |

Hmmm, will search for TSD 4200, is it in the tecnical section? Yes, it's one of the last shadow 1s | |||

Guido Peter Broich New User Username: guido Post Number: 16 Registered: 05-2019 |

GREAT... I never looked at the shadow ii manual, it explains much better, now I see what you where talking about. I have to disassemble also the last part inside the magnet to test the gaps. Will do it and make pictures. Thanks! | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 692 Registered: 05-2016 |

Pictures would be great Guido, it might help others at a later date. It would be a valuable addition to Tee-One Topics. | |||

Guido Peter Broich New User Username: guido Post Number: 17 Registered: 05-2019 |

GREAT... I never looked at the shadow ii manual, it explains much better, now I see what you where talking about. I have to disassemble also the last part inside the magnet to tedt the gaps. Will do it and make pictures. Thanks! | |||

Guido Peter Broich New User Username: guido Post Number: 18 Registered: 05-2019 |

I just cannot understand how to measure the shim Z, it is inside the housing at 4. Should I try to disassemble at point 1? There are no points to grasp the thing. Same for distance Y, as it is inside the upper plunger at point 2. Distance at 3 can be measured by measuring the distance screwing in the valve seat.  | |||

Geoff Wootton Grand Master Username: dounraey Post Number: 2235 Registered: 05-2012 |

Hi Guido Have you watched Ronnie Shaver's youtube video on the height control solenoid. It starts at 5 1/2 mins in. https://www.youtube.com/watch?v=KtkT68vxRts | |||

Guido Peter Broich New User Username: guido Post Number: 19 Registered: 05-2019 |

Geoff, thanks it's a nice video, I got the locknut adjustment, that's ok. My problem is that the small shim you could see in the video (from fig G29 there should be one between the two valves or in top of the copper plunger, Ronny puts it under the spring) is absent. | |||

Tim North Unregistered guest Posted From: 31.53.68.145 |

I don't have the references available at the moment but if you can get hold of the late Chris Browne's articles, published in the RREC bulletin, about overhauling the hydraulic systems of his Shadow II I think you will find them very useful. (Message approved by david_gore) | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 693 Registered: 05-2016 |

Hi Guido, The shims are part number UD 15129. Introcar Ltd have them available to order on their site at approx £3.50 each or about €4. According to their exploded diagram there would appear to be 2 shims. I'm guessing that the shim thickness should be 0.50mm to 0.63mm since that is the required gap at "Z" but it's not very clear in the instruction manual. I note that Ronnie in the video said that he simply puts things back the way they were and doesn't make any adjustments and does the final measurement using a feeler gauge. | |||

Alan Dibley Frequent User Username: alsdibley Post Number: 272 Registered: 10-2009 |

Note that, when you get to set-up stage of this saga, "Ronnie" ignores the manual and thus misses the point of the chassis height adjustment This leaves the car with half-shafts NOT in line. Follow the manual. HTH - Alan D. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 694 Registered: 05-2016 |

Hi Alan, That's true, Ronnie sets up the height control levers on the height control valves to a point where they are ready to activate when weight is added to the trunk on the assumption that the car is already sitting correctly on good coil springs with the drive shafts settled horizontally. Many cars with saggy bum syndrome due to weak coil springs have their height control levers adjusted to compensate and in my opinion this helps to achieve the correct ride height and to keep the drive shafts horizontal but it renders the rear suspension spongy and adversely affects handling. If originality is to be adhered to when saggy bum syndrome takes hold then quality replacement coil springs or additional shims and correctly set height control valve levers is the safest solution, otherwise the Harvey Bailey upgraded springs, shocks and stiffer anti-roll bar and deletion of the height control altogether is probably an even better choice. | |||

Mark Aldridge Frequent User Username: mark_aldridge Post Number: 709 Registered: 10-2008 |

Larry, I am puzzled as to why riding on the rams affects handling. My Shadow 1 rides about .25inch on its rams, but with Bilstein shocks all round and a TurboR front rollbar, the handling is on a par with my MulsanneS which is on original Shocks. i wonder, could the height control system require bleeding, or are the Shocks getting tired. Mark | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 696 Registered: 05-2016 |

Hi Mark, I'm not sure why raising the height control to compensate for weak springs affects the handling, I did it once and noticed that the rear end tended to float affecting the overall stability. Maybe if the rear is raised by adjusting the height control levers it takes some of the pressure off the springs so the car would be riding higher on weak springs rendering the springs less effective especially when there's no extra weight being carried in the back. If the shocks were also weak it would add to the problem. I'm no expert nor engineer and my theory could be off the rails. | |||

Graham Phillips Frequent User Username: playtime Post Number: 325 Registered: 03-2019 |

G'day everyone,... Larry, you may find that in your experience the rear 'floats' because the springs were weak, they are losing their ability to resist compression as new springs would have that capability. The ride height rams would have nothing to do with the ride itself. Graham. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 698 Registered: 05-2016 |

Graham, I reckon you are correct about my springs needing replacement, that's next on the to do list. However, as a temporary exercise I raised the height control levers slightly, that corrected the ride height but the rear felt even more spongy. I found that the rear seemed to float more with the rams slightly raised, I think that the handling with weak springs on a raised suspension is worse than the handling on weak springs with the height control set back to normal, I reckon it has something to do with the difference in raised or lowered centre of gravity but that's just a guess. | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2396 Registered: 09-2004 |

Larry you mean king pin inclination. BTW set my car up with the correct height with spring helpers and HCL running on the rams, no floating and good for towing! | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 700 Registered: 05-2016 |

Maybe that's it Patrick, I'm not very familiar with suspension geometry. Today I've been reading articles and the best term I can identify with is "rear end sway". I've now discovered that rear end sway is normally a side effect of worn shocks. Like you I fitted spring assists and found that they improved the ride height a little and I temporarily raised the height control after which the rear end sway became noticeable. It was a bit like driving a fish with a swishing tail. Perhaps my problem is worn shocks combined with weak springs or maybe it's shocks alone. While I'm at it I think I'll just replace the lot. That should keep me busy for a while, it might even see me through the pandemic at the rate at which I work. | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2397 Registered: 09-2004 |

Larry, first quick check I would carry out is to measure the distance between the wheel centers one side of the car at a time, should be equal with the front wheels in the straight ahead position. This will cancel out any incorrect alignment of the sub frames etc and worn compliance mounts. BTW my shocks are still the original! May be the w/s manual has a better check, Dare I say! David. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 702 Registered: 05-2016 |

Thanks Patrick,I'll do the measurement check you recommend. If there's a discrepancy I'll delve further regarding compliance mounts condition and sub frame alignment. The compliance mounts look perfect on cursory visual inspection. There's no evidence of any uneven wear on the tyres but there's only approx. 5000 miles on the current set. I reckon my shocks are still the originals too but I can't be certain, the car has genuinely done only 70,000 miles. | |||

Mark Aldridge Frequent User Username: mark_aldridge Post Number: 710 Registered: 10-2008 |

Larry, assuming your Shadow is a 1 , have you checked the oil in the steering damper and adjustment of the steering box. They make a dramatic effect on the car stability. Mark | |||

David Gore Moderator Username: david_gore Post Number: 3840 Registered: 04-2003 |

Patrick, You, I and a small group of long-time participants in the various R-R/B forums around the world are the only ones who will understand your cryptic message  . . For those not in the know, it refers to past events on various forums involving personal attacks on myself, Patrick and others for disputing the veracity of posts by an individual who no longer participates in these forums. Onwards ever onwards wins at the end of the day.  | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 703 Registered: 05-2016 |

Hi Mark, Mine is a Shadow 11 (SRH37125) 1979 with steering rack.Steering wheel feels good, no play but the rear end appears to sway a little. While cruising on main roads it isn't noticeable but on undulating, winding back roads I sometimes sense that the rear end has a mind of it's own. If I'm travelling at a reasonably sensible speed and meet an oncoming car on a narrow winding road I tend to slow down a bit more than usual to be sure of measuring the gap. I was overtaking a truck on a motorway recently and when moving from the outside lane back to the inside lane the car appeared as though it was floating like a boat. I hadn't been smoking any illicit substances or drinking at the time but the feeling was akin to the side effects of such a practice (or so I'm led to believe). I know my description isn't very enlightening from an engineering perspective but I think that "rear end sway" as a result of worn shocks is the most likely fault but I'll check all the above mentioned possibilities too. | |||

Mark Aldridge Frequent User Username: mark_aldridge Post Number: 711 Registered: 10-2008 |

Larry, the Shadow 2 handling with the Rack steering is similar to a Spirit, my money is on tired shocks. Is the back end soft when you" bounce" the car .The downside of replacing the rears is that the fronts will appear weak. Been there , done it etc etc.and had the bill . | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 704 Registered: 05-2016 |

I reckon that the back end feels soft Mark, it has always felt soft to me but it settles quickly after I bounce it. I had assumed that the softness was a design feature to give a soft ride but it does appear very soft. I think I'll remove the shocks and bench test them or get a second opinion from a friendly local mechanic. If they're shot I might as well replace the springs too while I'm at it. | |||

David Gore Moderator Username: david_gore Post Number: 3841 Registered: 04-2003 |

I would be checking the condition of the rear subframe mounts as well. The "sway" may be a consequence of failing mounts. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 706 Registered: 05-2016 |

Thanks David, I'll check the mounts too. I hope to get started on the job within a few days, luckily I have access to a pit. If I run into difficulty I'll start a new topic as I feel that I'm inadvertently hijacking Guido's thread on the height control solenoid. | |||

Guido Peter Broich New User Username: guido Post Number: 20 Registered: 05-2019 |

I started changing the tubing today as i got the set plus two solenoid shims from introcar. 0.1mm each. But now I still have the problem that giving current to the magnet, the valve goes down less than 0.5mm. So when mounting the inlet with wire hot as in tsd4200, it screws in only a few turns and touches the valve and closes. Backing of is not podsible, too small room. How much should the valve go in when magnet starts? Magnet is NOT SHORT, but get warm after a few minutes working. Can it be that it looses its power, also if not shorted? | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 708 Registered: 05-2016 |

Hi Guido, take another look at Ronny's Garage you tube video video "Silver Shadow height control part 7 of 7. It will give you a visual idea of how far in the inlet should go before the feeler gauge adjustment is done. Also take a look at the parts diagram on Introcar site to see the sequence for inserting all the valve components into the valve body. It appears that something is stopping your valve from fully activating when you give it electrical power, it might have something to do with the way the components have been inserted. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 709 Registered: 05-2016 |

Hi Guido, Is it possible that you have inserted the valve cone or bobbin the wrong way around in the solenoid body? If that's the case it might explain why the inlet end piece is not screwing in far enough. | |||

Guido Peter Broich New User Username: guido Post Number: 21 Registered: 05-2019 |

Hi Larry, ho the valve is in ok and goes all the way down when pressed by finger. I checked both the steps for having the cone valve going into it's body and going into the bobbins seating hole (where the shims are). I saw the video from Ronny's garage, he actually does not measure anything and just puts the shim (one only) in as it came out. The weired thing in the video is that he puts the shim in BEFORE the cone valve. Probably he did it again right, as cone valve has to go with the spring in the valve body, and the shim goes between cone valve and bobbin. TSD4200 says to ACTIVATE the coil, so the spring is compressed and the bobbin is sucked inside the solenoid body. So space should be given to screw in the inlet screw. I see that in my case giving power to the electrical coil the bobbin just makes a smal hop and does actually go in for less than a millimeter (pushing it by hand it goes in all the way down). So now I took the expensive step and ordered a new coil from Introcar, in case it is working bad. In fact it becomes quite warm after only a few minutes working. Magnetic characteristics of the bobbin can be the other reason, but I think they put in an iron piece and not a magnet that can loose its strenght! (hopefully, otherwise I have to get also a new bobbin ... ) It's becoming a costly affair, it I had to start it all over I would have got a new solenoid from Introcar right away! | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 711 Registered: 05-2016 |

I feel your pain Guido, when I was in the same predicament a few years ago I ordered a reconditioned solenoid as I needed a quick fix. I had a niece's wedding coming up within a few days and I needed to get it sorted urgently. The replacement solenoid has worked perfectly since. | |||

Guido Peter Broich New User Username: guido Post Number: 22 Registered: 05-2019 |

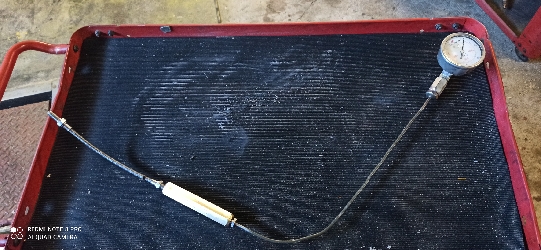

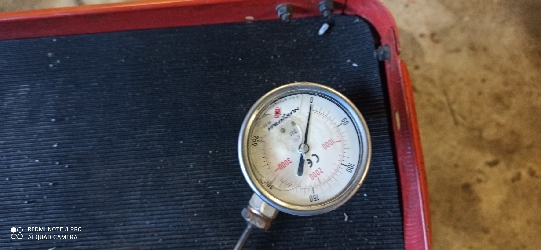

HI, so I finished the job. Changed all tubing, brakes and height control. Than I changed the coil. I found out that one must not only give current to the coil, but push the bobbin until it clicks and stays blocked to the end.IF you do not do it, it stays too much out and regulation cannot be done. So give power to the coil, push the bobbin in, screw the inlet valve in until end, measure the piece that stcks out (or me about 20,7 mm), back up 0,5 to 0,6 mm (to 21,3) and fix the counterscrew. It click well now in P and N. Now I will have to go to a ride to check if the noise is gone and if the brakes still block when height valve opens! Since I was working on it I changes also the front circuit accumulator, as it held only a few brake strokes. So I did clear the air of both circuits and the front accu. At this point I hear my 1st circuit (front) pump making a quite loud clack clack noise, which goes away after a few seconds, but comes back on if I push the brakes or also every minute. I fear the pump is going! | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 716 Registered: 05-2016 |

Hi Guido, If your pump was OK before you changed the front accumulator the chances are that it's still OK. There may still be some air trapped in the No.1 system. I would recommend that you depressurize the hydraulic system, then attach a long bleed hose with a collection jar to the No.1 accumulator valve and open the bleed screw slightly, then start the engine and watch for any air bubbles, run the engine for about 1 minute and if the pump is pumping correctly you should have about a 1/4 litre of fluid in the jar. Then close the bleed screw, top up your front reservoir with fresh fluid and bleed the rest of the No.1 system (top bleed screws on the rear calipers and front bleed screws on the front brake calipers and hopefully your pump noise will have gone away. Are the rear height control and brakes now working OK? Good luck. | |||

Guido Peter Broich New User Username: guido Post Number: 23 Registered: 05-2019 |

Hi Larry, I did as you say. First bleeded the accumulator, with running engine. When bubbles stopped, I topped up and went to the back, then the front calipers. FAct is that now the accu hold pressure well (over 40 strokes to get the light on), but the pump's noise is strong. Actually it made noise also before, and altready thought about having it serviced (I don't have the special tools to get it out), but the guy told me it was fine ... I think noise it too much. Normally do you hear the pump? I don't have other shadows for comparison | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 717 Registered: 05-2016 |

or your No.1 accumulator control valve may be releasing before sufficient pressure has built up so the pump has to work extra hard, best way to check is with a pressure test gauge at the ACV as per the manual. A hydraulic pump is usually a bit noisier until sufficient fluid pressure is accumulated in the sphere and then gets quieter when pressure builds to approx. 2500 PSI and the ACV bypasses fluid back to the reservoir, then at approx. 2250 PSI the ACV release valve should close again as there's optimum pressure in the system. Hydraulic pressure test gauge reading will let you know what's happening in the system and what the likely fault is. Without a pressure test gauge accurate diagnostics is virtually impossible and you could find yourself replacing parts unnecessarily until you get to the root of the problem. | |||

Guido Peter Broich New User Username: guido Post Number: 24 Registered: 05-2019 |

Unfortunately I have no over 2500psi measuring device... Will have to build one. At which point do you measure? High pressure output or sensor? I checked again the system and accus, brakes and levelling is free of air. Both accus take over 40 brake pushes. As pressure builds up very fast and well and keeps that way I am wondering if the noise could not come from an hydraulig tappet. It is syncron to the camshaft (about 282 clicks/min at 560 crankshaft rpm with strobo) I will try to post an audiofile here. The click has a base frequency of about 1kHz in spectrogram with 1900/3400/5700 main harmonics.

| |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 725 Registered: 05-2016 |

Unfortunately I can't download your attachment. You could be hearing a hydraulic tappet or sticking valve or it could be the pump. The pump is activated by a push rod from the cam. Sometimes adding a 1/2 litre of automatic transmission fluid to the engine oil will free up a sticking valve. The ATF won't do any harm. I made my own hydraulic pressure test gauge but by the time I had it assembled and various parts threaded etc., it's not easy to find metric/UNF adapters so I had to buy a UNF 3/8 x 24 tpi threader and cobalt drill bit, it would have worked out just as cheap to order one ready made from Kelly Opfar at Britishtoolworks.com in Utah from where I have purchased other great tools at very reasonable cost. The first place to test for hydraulic pressure is at the bleed screw hole on the accumulator control valve and if everything is good there you will know that your pump and ACV are good. If things aren't OK you move on to the ACV outlet and keep moving to various components as required until you isolate a fault. The test procedure is outlined in the manual TSD 4200. In your case if you think your pump is ticking, the best way to find out if the noise is actually coming from the pump is to place a long narrow metal rod, screwdriver or similar on the top of the pump and put your ear to the other end, you will be able to work out if the noise is actually coming from the pump. Sometimes the high pressure pipe between the pump and the accumulator can vibrate against the side of the engine which will also create a tapping noise and that's just a case of bending the pipe away slightly. I had a ticking pump a few years ago and it went silent when I depressurized the system and opened the bleed screw at the ACV and started the engine and let the pump dump fluid into a jar for about 30 seconds. When I closed the bleed screw the ticking reduced a lot. Sometimes air can get trapped at the pump outlet even though the rest of the system is properly bled and this will cause the pump to tick, the air stays at the top of the pump outlet pipe and won't move along until the ACV bleed screw is left open for a while. Most of these cars have ticking pumps, they tend to be louder on initial start-up and quieten down when the system has reached optimum pressure but it shouldn't be very noisy. Is your height control self leveling now fixed? | |||

Guido Peter Broich New User Username: guido Post Number: 25 Registered: 05-2019 |

Larry, I have put the noise file here: www.guidobroich.it/auto/SS-engine-noise.mp3 please have a look. It seams now too strong form me to come from the pump. I did actually bleed the accu for several seconds for three times, and it flows now clean without bubbles. I will try to take the old high pressure pipe I changes about 10 years ago and did not throw out, for the british threading, in making the pressure meter. Range of the dial 0-3000psi should be fine, right? | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 726 Registered: 05-2016 |

I could download your engine noise this time, it does sound more like a hydraulic tappet or valve but it could be a pump pushrod, it's hard to know. If it's a sticking valve a 1/2 litre of ATF added to the engine oil might free it. Have you tried placing a long screwdriver on the top of the pump and listening to hear if the tapping is in sequence with the pump vibration? 3000PSI hydraulic pressure gauge would be perfect, one filled with glycerine is best because it will give steadier readings, the pump pressure reaches 2500PSI. I also used an old braided high pressure hose with the gauge. Once you use the gauge with DOT3 RR363 you will never be able to use it on a later LHM car or any other hydraulic fluid except DOT3, DOT4 or DOT5.1 as the fluids are not miscible. The difficulty is finding a metric to UNF female to female adapter to join the metric tread on the gauge to the UNF tread on the hose, I couldn't find such an adapter or even a combination of adapters so I drilled and treaded a metal block to make my own. | |||

David Gore Moderator Username: david_gore Post Number: 3849 Registered: 04-2003 |

Hi Guido, I am certain the noise is coming from a collapsed hydraulic lifter and not a brake system pump due to the frequency of each tap when idling. This noise usually diminishes as the engine warms up and pressurised engine oil makes its way into the lifter. If the noise dies not diminish after 5 minutes driving or is still audible; this suggests the hydraulic lifter piston is jammed in the bore of the lifter either due to wedging from misalignment of the piston or a permanent blockage in the engine oil feed to the lifter. The first non-dismantling "fix" I would try is to add about half a litre of automatic transmission fluid to the engine oil after the engine has been warmed up, let it idle for 5 minutes. You will have one of two outcomes; the first being the tapping should go away completely and the second is a continuation of the tapping. If outcome 2 applies, I would try taking the car for a 15 minute drive whilst keeping speeds below 80km/hr to apply full oil pressure to the lifter to "blow out" any crud that might still be blocking the oil feed to the lifter or the lifter itself. If "Maxwell's Silver Hammer" as described by the Beatles in their song is still present, the next step would be to remove all lifters from the engine for stripping down, inspection for wear/mechanical damage, cleaning and reassembly for testing prior to being put back in the engine for final testing to see if the problem has been solved. If the lifter shows signs of excessive wear especially in the bore, you might have to consider replacing the lifter with a reconditioned or new lifter if available. Fortunately, the ATF addition has a high success rate in freeing stuck lifters. Of course, if there is a successful outcome with the addition of the ATF, you should change both the engine oil and oil filter immediately afterwards to minimise the possibility of oil-borne crud blocking the lifter again. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 661 Registered: 11-2017 |

After determining which bank the noise is coming from, remove the rocker cover and inspect and check push rods and rocker arms for the source. If there is a collapsed lifter, it would show up with an obviously loose push rod. | |||

Alan Dibley Frequent User Username: alsdibley Post Number: 281 Registered: 10-2009 |

Quote - "The difficulty is finding a metric to UNF female to female adapter to join the metric tread on the gauge to the UNF tread on the hose," For future reference Automec.co.uk can supply 10mmx1.0 to Unf 3/8 x 24 brass fittings in M to F in both directions and M to M (though not F to F). Bit pricy though. Alan D. | |||

Guido Peter Broich New User Username: guido Post Number: 26 Registered: 05-2019 |

Thanks to all, will go with the ATF tomorrow!!! And for the UNF to metric ... well, I took an old braided hose, than took about 15 cm of the bronze rod I used to drill my new wheel nuts and got a UNF tap for one side to match the hose male part, and a metric tap to the other, to connect the gauge. Now I will have to get the gauge! Thanks, will tell you how it goes on. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 728 Registered: 05-2016 |

If you like you can also tap into the side of the bronze rod for a bleed screw (not essential but handy if you want to bleed while doing various pressure tests). I hope the ATF trick will free your hydraulic lifter. | |||

Mark Aldridge Frequent User Username: mark_aldridge Post Number: 725 Registered: 10-2008 |

I usually add 200ml of ATF to the oil on my cars as an insurance policy every oil change. | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2401 Registered: 09-2004 |

IMO this is a classic restrictor valve failure through whatever cause, allows the pump piston to stick "up" through low pressure. Note .28 of the recording the pump instantly goes quiet! Lifter would go quiet slowly! BTW the engine would run not as smooth as it should if the hydraulic lifter was stuck. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 729 Registered: 05-2016 |

I see Patrick's logic. Quickest way to establish if the the problem is in the height control area would be to temporarily blank off the height control fluid supply before the height control solenoid and detach the electrical power feed to the solenoid and see if that eliminates or reduces the noise. However, I'm not ruling out a stuck hydraulic lifter. | |||

Guido Peter Broich New User Username: guido Post Number: 27 Registered: 05-2019 |

Mmm, I see. Tomorrow I will do the ATF trick and change the oil, it must be done anyway. I had a less strong clack noise also before, which I considered from the pumps (mainly 1st circuit as the rod-auscultation gives it louder there) and now I mounted the new accu and valve assembly on the 1st circuit. I serviced the restrictors and the solenoid, so I actually touched both circuits. Patrick, I serviced the redtrictors, changing ALL inside bits with new from Introcar. High pressure restrictor was ok, low pressure was stuck with black debris, that's why I decided to change the brake and levelling rubber tubing. Patrick, how would you proceed? | |||

Guido Peter Broich New User Username: guido Post Number: 28 Registered: 05-2019 |

Mmm, I see. Tomorrow I will do the ATF trick and change the oil, it must be done anyway. I had a less strong clack noise also before, which I considered from the pumps (mainly 1st circuit as the rod-auscultation gives it louder there) and now I mounted the new accu and valve assembly on the 1st circuit. I serviced the restrictors and the solenoid, so I actually touched both circuits. Patrick, I serviced the redtrictors, changing ALL inside bits with new from Introcar. High pressure restrictor was ok, low pressure was stuck with black debris, that's why I decided to change the brake and levelling rubber tubing. Patrick, how would you proceed? If it is height control, I could block the whole system by detaching the main line and screwing a bleed screw. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 730 Registered: 05-2016 |

If it's a blocked restrictor (from crud still left in the pipes) you should feel and hear a knocking in the pipes in the restrictor/solenoid area, the knocking would probably be even more obvious in those pipes when a height control valve lever is pushed up or weight is placed in the trunk to activate the height control. However, if the pump is knocking because of a blocked restrictor valve it would be heard in the No.2 pump at the rear of the engine. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 731 Registered: 05-2016 |

A 3/8 x 24 TPI UNF plug is best to block the height control, you will need to follow the inlet pipe at the solenoid valve back to the brake distribution valve and plug it there. You will also need a female plug for the end of the pipe that will be detached from the brake distribution valve. A bleed screw to plug the hole is not advised because the pointed end of the bleed screw could distort the sealing face in a valve outlet hole. The plugs to use should be the same shape as the existing pipe fittings. Some people simply unscrew the pipe and insert a 3/16" ball bearing into the hole and then refit the pipe but one needs to be careful not to over tighten or the steel ball bearing could distort the softer fittings in the valves or pipes. Personally I use male plugs at the solenoid inlet and the restrictor valve inlets and female plugs on the pipes, not forgetting to detach the electric wire to the solenoid. I find it easier that way as there's good access at the rear cross member. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 662 Registered: 11-2017 |

Kelly @ British Tool Works has a nice block off kit. Remember..never over tighten | |||

Guido Peter Broich New User Username: guido Post Number: 29 Registered: 05-2019 |

Hi all, some news: I did a further bleeding from accu down, all ok. Solenoid clicks ok. Levelling valves work with detached arms, bleeded Then I added 500ml of ATF in the hot engine and left it run for 10 minutes. The major click did go away quite immediately. The less strong click remained. Then I took the car to a ride, ca 20 minutes. At the end the engine did run smoothly and the light click did come on and off, but for the first time I had times click-free. Second, the braking effect at levelling ram discharge went away and no noise from the back any more! Definitely the blocked low restrictor was the cause and is now definitely open and working. So I am convinced now that the noise comes from a tappet that opens and blocks, the ATF was a miraculous hint! Thanks David! I changed the oil and filter now. One question at this point: as there is still some minor blocking, should I add some ounce of ATF just for normal use, as Mark suggests? . | |||

David Gore Moderator Username: david_gore Post Number: 3851 Registered: 04-2003 |

Hi Guido, Great news - I suspect the click still present is coming from the hydraulic pump and may be from air trapped in a hydraulic circuit acting as a cushion [a full system bleed should fix this]. A second cause could be a worn push rod on the hydraulic pump requiring resetting of the pump. A hearing test using a long screwdriver or metal rod with your ear on one end the other end placed on the pump housing will confirm this - a distinct loud "clicking" will be heard if this is the case. I cannot claim responsibility for the ATF addition suggestion as this had been suggested earlier by Larry Kavanagh and I only added some information on the procedure involved.  | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 734 Registered: 05-2016 |

I've added ATF to the engine oil in the past and it had the effect of quieting the valves, it actually went so quiet that I could barely hear the engine at tick over and I could clearly hear the time clock ticking on the dashboard with the engine running. I change my engine oil more often than the service recommendation and usually add a 1/2 litre to the engine oil about 300 miles before I do an oil change and I believe that this helps to clean out any sludge. I drive the Silver Shadow less than 4000 miles per year but change the engine oil and filter at least once a year. I think your best option, given that you still have some top end tapping noise, is to add another small amount of ATF but don't overfill or you could cause rear end seal leak. Drive on and see if the engine quietens more with use. If it gets to the point where it's virtually silent change the oil and filter again and see how it goes without ATF added. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 735 Registered: 05-2016 |

I'm wondering if you remembered to bleed the No.2 pressure switch after you had bled everything else. The pressure switch is bled last and with the engine off. I usually find that the pump gets quieter after the pressure switch has been bled. | |||

Guido Peter Broich New User Username: guido Post Number: 30 Registered: 05-2019 |

Yes, I did actually bleed both accus serveral times. (this time I used up 5 bottles of precious rr363!) Larry, un effect when ticking is if, engine runs very smooth and silent. When it comes up it is still audible. Revving up the engine it goes away, but comes on back after a few seconds. Having the engine running idle at about 560rpm it sometimes goes off, sometimes on. Probably there is still some sludge there. And I still feel that part of the noise may come from a pump's rod: screwdriver tells me that pump is clicking, but since is the only SS I have, my ear has no comparison value. Anyway the pump that clicks more is the number 1, front pump, whuch I bleeded several tiles letting the fluid run a lot. I was thinking now to drive the car a little bit more around, do the ATF trick again and sacrifice 9l of oil for an extra change...  | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 736 Registered: 05-2016 |

I think your plan to drive for a while and then add 500ml of ATF is a good plan. I would add the ATF and drive gently for about 300 miles and then change oil and filter. Maybe 560 RPM is a little too low for your engine idle and is not allowing oil pressure to build sufficiently. 650 RPM is recommended in the manual but I have mine set at 600 RPM. You might have a worn pump or push rod or the gap settings could be shimmed wrong but don't rush to remove the pump until you see if driving around for a while and another ATF flush helps. Have you checked the ignition timing? The timing figures in the manual are based on 97 octane petrol so you might have to adjust a little to find the sweet spot if your fuel octane is below 97. When flushing the hydraulic system I use regular DOT4 brake fluid and only use RR363 when I'm happy that everything is OK. Sometimes I make my own mix of 90% DOT4 with 10% pharmaceutical grade castor oil and that is a lot cheaper than RR363 especially when I can buy a 5 litre can of DOT4 for less than €30. | |||

Guido Peter Broich New User Username: guido Post Number: 31 Registered: 05-2019 |

Here are pictures of the pressure device I made. I will do the longer drive as soon as the weather gets better. Dot4+castor oil is a good idea, which do you use? Have to buy it over internet, here it seems nobody knows what I am talking about...     . | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 738 Registered: 05-2016 |

Hi Guido, gauge set up looks good. I buy pharmaceutical grade castor oil from my local pet store, he has it in large containers and drains off 500ml into a clean bottle for me. Your local chemist/pharmacy would probably have some too. | |||

Jim Walters Frequent User Username: jim_walters Post Number: 332 Registered: 01-2014 |

Ask at a model shop that sells remote controlled aircraft, they will have it. It's used to mix with the fuel for lubrication. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | |||

Guido Peter Broich New User Username: guido Post Number: 32 Registered: 05-2019 |

Hi all, here I am back. I had a broken hoist electrical motor, so I could not use it. Obviously it shorted with the Shadow up in the air and the security blocks did not allow even to have it coming down by loosening a bit the oil pipes. COVID blockage of the shops and driving restrictions did the rest. (my electric shop is in a different region ad I could not drive over that internal border!!!) So now I got it all set again and have the car in my garage. First a resume: Patrick, I cleaned the restricotor valves, the low pressure one was stuck of dirt. Since I was on it, I took the opportunity to change all hydraulic tubing, brakes and levelling, and got a new front accumulator. The braking effect on bumps disappeared and the car is runnig fine now. So taht confirms that dirt in restrictor valve was the cause of the braking on bumps. For the tappet noise I did the ATF trick: 500ml and a short run. Noise got MUCH better, now it comes up sometimes but disappeares others. It comes up more when the car is idling, unader acceleration it goes away most times. Braking is fine, pressure goes up immediately (switch off, 40 or more pushes for the back and now over 50 front, sometimes 100, then switch on, light goes off after one ore two seconds.) So I now would give the ATF a second try, putting 500-1000ml ca in and drive about 200-300 km, and then change the oil again. Larry, would that be ok? browsing through the forum, I read about adding diesel fuel to the oil on a ormal basis. What is nbetter, ATF or diesel? how much for a fill? Best wishes and stay away form COVID!  Guido PS: Larry, I ordered Castor oil from the UK! should arrive mid february to stock up my brake fluid availability  | |||

David Gore Moderator Username: david_gore Post Number: 3876 Registered: 04-2003 |

Guido, I suggest a second treatment with a new oil filter and a fresh ATF/oil combination before a weekend trip involving a 500 to 800 km round trip travelling continuously to the destination, an overnight stay before returning followed by another complete engine oil and oil filter replacement. This should clean out any recalcitrant muck in the oil circulation system and hydraulic lifters that remained after the first treatment. I have used the ATF/oil treatment with excellent results - I have reservations about the diesel/engine oil combination as my experience with my turbo-diesel 4WD suggests the miscibility of the diesel fuel and engine oil can leave a lot to be desired. | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 759 Registered: 05-2016 |

Hi Guido, A litre of ATF might be too much but I'm not certain about that, I think that .5 litre should do the job but I don't claim to be an expert. What I do is add .5 litre about 500 km before an oil change. I do that for most oil changes but sometimes I forget to do it. I always change the oil and filter often, maybe every 5000 km and at least every year whether I reach 5000 km or not. I don't add ATF to the fresh oil, I only add it roughly 500 km before an oil change so it's really only used to flush. Sometimes I use 10w40 oil but mostly I use 20w50 and I think the 20w50 makes the engine smoother but that might only be in my imagination. | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2419 Registered: 09-2004 |

I am not convinced it is a hydraulic valve lifter. I believe the coming and going of the slight tapping now is another prob, my guess is that the noise is to do with a very slight bent push rod on the pump. Listening with long screwdriver on the body waiting till the noise appear will confirm. | |||

GuidoPeterBroich Unregistered guest Posted From: 180.149.228.30 |

Hi all, I did as David and Larry suggested. The knoking noise now came up and went away, very variable, but good parts of time without it. I had also a stop for lunch with a friend. Than coming back I stopped at a second place, at start 2nd brake light came up and stayed that way all time home. BAck on the hoist with the stethoskope I can hear only a very low "rrrrr" noise from the valve covers, which should be ok. Front pum makes a slight cliccing noise, very soft. Back pump makes a loud, clear clack clack clack ...... Obviously something went bad before the second stop and at departure pressure just would not build up well again. So I was thinking of a broken pushrod. I changes the engine oil and restarted the engine, and the light went off!! Did not drive the car up to now, but the pressure build up is just residual. EVidently soemthing is worng there, but cannot be a broken ushrod, as that would give no pressure at all. Can it be just murk in the second pump? Anyway at this time I ordered the special spanner from Introcar and will have a look at the pumps. Should be arrive soon. (Message approved by david_gore) | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 760 Registered: 05-2016 |

Your pressure test gauge will diagnose where the problem lies. Why go to the trouble of removing the pump unless you have already diagnosed that it is faulty? Start with a test at the accumulator control valve bleed screw and note the readings. Then test at the ACV high pressure outlet port and note the readings. If the outlet port readings are good the likelihood is that the pump and ACV are working correctly and the pressure leak is further down the line. Whenever there's a pressure leak (internal or external) the pump is forced to work harder to maintain pressure so it ticks louder. Your pressure test gauge is your friend and can save you from a lot of unnecessary work if you use it systematically until you pinpoint the actual fault. I had to learn this the hard and expensive way and I no longer remove components on a hunch but use the gauge diagnostics to confirm what component is or isn't healthy and now avoid shooting in the dark. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 675 Registered: 11-2017 |

Study the animation link, and using your test gauge, you can accurately pinpoint your problem. https://www.rrsilvershadow.com/ETechn/Hydr/Alganim.htm | |||

Larry Kavanagh Frequent User Username: shadow_11 Post Number: 764 Registered: 05-2016 |

Hi Guido, Any progress locating the hydraulic fault? | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2518 Registered: 09-2004 |

To update on my coming and going of the tapping noise. Turns out to have been caused by a broken spring within the hydraulic pump. Pumped worked but at a reduced rate before failing completely. | |||

Graham Phillips Frequent User Username: playtime Post Number: 469 Registered: 03-2019 |

G'day everyone,.... Great news Patrick, It's always good to have resolved annoying noise's and issues. My Camilla's high pressure hydraulic pump makes a loud-ish knocking if: A) She has been sitting for at least a week when first started. B) She has had to endure time in stop-start traffic C) After a few consecutive uses of heavier braking. Initially its either there then instantly gone. Then after two or three times it will fade out then be gone. Having gone through Camilla's service records there has NEVER been any work done on the pumps in her life time. Later in the year I will have Camilla's ride leveling system re-connected and I am thinking I'll have both pumps rebuilt. Graham. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 755 Registered: 11-2017 |

Graham. Having a circuit blocked off is not good at all. The only reason to block off a circuit is to temporarily stop fluid flow and repair whatever is needed. Remember, the hydraulic fluid circulates...and what happens when it sits? You guessed it. You will have more than brake pump work when you address this issue. Hopefully ball bearings were not used for blockage. They deform whatever they touch and they are usually over tightened. Plugs and caps is the correct method here. | |||

Graham Phillips Frequent User Username: playtime Post Number: 470 Registered: 03-2019 |

G'day everyone,... Robert, I was told when I inspected Camilla that the system was disconnected. Tony at UK motors confirmed it when he inspected Camilla. I vaguely remember in the service records it mentioned. I will be having the entire leveling system rebuilt to be safe. I guess my simple comment of having it re-connected lacked depth in explanation. I hope to move on this by mid year. Graham. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 756 Registered: 11-2017 |

Ok, Hopefully just the 2 electrical connections | |||

Eric Molenaar New User Username: aussiewraith78 Post Number: 28 Registered: 06-2021 |

Graham, i will be following your progress in this matter closely as my car LRH32854 has had its rear levelling disconnected also according to the history notes i recieved when i purchased in 2021.Something i am keen to rectify. Today however i removed brake system no1 sphere and accumulator control valve, re kitted my first acv using a kit from Kelly at BTW and a few tools he supplied (fantastic service and great to chat on the phone) and ships to Australia in about 10 days. I also cheated and purchased a disposable sphere for the SY series cars from Richard at Spur parts. Tommorow will bleed the hydraulic system. Also tested the ACV operation with a gauge purchased at BTW. All good. Thank goodness or just plain lucky. Cheers Eric | |||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2519 Registered: 09-2004 |

I take it that with the rear leveling system disconnected to maintain some sort of trim height the car would be fitted with colonial or heavy duty springs. If not the strain wear on the drive shaft trunnions and rubber boots etc would be excessive. | |||

Robert J. Sprauer Frequent User Username: wraithman Post Number: 757 Registered: 11-2017 |

If the rear seat and trunk are not filled on a regular basis, there would be no adverse wear on the trunnions or boots. It is ONLY when such conditions arise that the fast acting electric solenoid kicks in, otherwise the car when sitting is at showroom height on it's springs. | |||

Graham Phillips Frequent User Username: playtime Post Number: 471 Registered: 03-2019 |

G'day everyone,... Eric, I have a few tools from Kelly myself and I have to say the tools are VERY good quality indeed. I'm not sure how Camilla's system was disconnected but Tony said It could cost up to about 6K to rebuild depending of course on what needs to be done. ---------------------------------- So far when traveling in Camilla we have traveled light, even with the boot full with couple of eskys, gas burner, gas bottle. camp chairs etc,... Three people. (not in boot) She sits level. When I get this job done it will be when I get ALL the other jobs done, I am also leaning to have her repainted as well. Graham. | |||

Geoff Wootton Grand Master Username: dounraey Post Number: 2305 Registered: 05-2012 |

I blanked off my system years ago when the left side height control valve started pouring hydraulic fluid all over the floor. I replaced both rear springs. Ride height is perfect and since the car is only ever lightly loaded I see no point in re-commissioning the system. If in the future I decide to, I realize I will have to recondition all the parts, but I would have done that in any case. The system is only really necessary if you want to fit a tow bar and trailer, transport large amounts of rubble in the boot or decide to become a chauffeur for Tammy and Amy Slaton, IMHO. |