| Author | Message | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2082 Registered: 5-2012 |

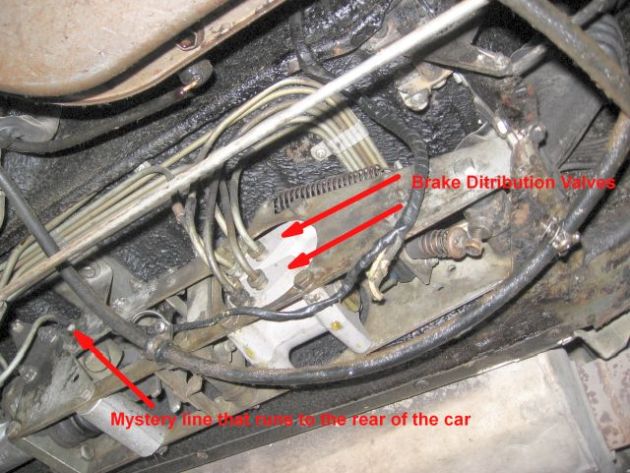

Hi Folks I am trying to blank off the height control system temporarily, as a height control valve has developed a bad leak and it will be a while before I have the time to renovate the system. I asked how to do this on the other forum and received great advice from Wraithman and Shadow II. I intend to follow Shadow II's advice and blank off the high pressure inlet to the Solenoid, Restrictor and Height Control Valves. However, I am bugged by the fact there is a single line that runs from the rear of the rat trap and appears very definitely to be the height control high pressure feed line. It would be a much more elegant solution to just blank off this line at the rat trap, and isolate the entire system. However, like Shadow II, I am wary about blanking lines on the rat trap, even though it can be seen from the photo, the proposed line is well away from the brake distribution lines. So here's my question - should I blank off the line shown in the photo (labelled as "mystery line that runs to the rear of the car) My related question is, I cannot see an inlet high pressure line for this outlet line. I don't think there is a channel running through the rat trap, more likely a high pressure line from the accumulator but obscured from view. Has anyone got any information or ideas on this?  | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 286 Registered: 4-2019 |

Do you think they would know anything about just scraping that system and replacing it with booster, master cylinder? I really really doubt you want to go that route. | ||

Robert J. Sprauer Grand Master Username: wraithman Post Number: 326 Registered: 11-2017 |

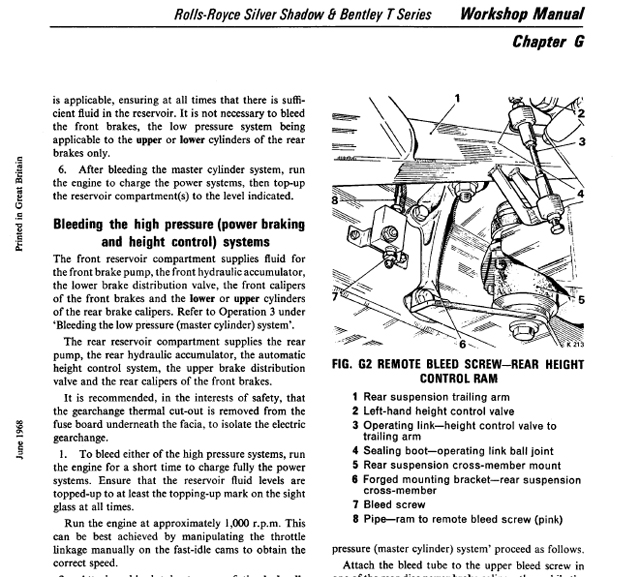

Geoff There is a line from accum 2 that feeds a T block. One side goes directly to the HT solenoid for quick response. Go to TSD4200 Chapter G Fig G2 for the piping schematic. It will be very helpful | ||

Robert J. Sprauer Grand Master Username: wraithman Post Number: 327 Registered: 11-2017 |

Go to Marinus' site and look for the hi-pressure restrictor. You can cap the incoming line and plug the port it goes into. http://www.rrsilvershadow.com/ETechn/Hydr/Schema4groot.htm | ||

Mike Thompson Prolific User Username: vroomrr Post Number: 287 Registered: 4-2019 |

Found it right away with that info.   | ||

Robert J. Sprauer Grand Master Username: wraithman Post Number: 328 Registered: 11-2017 |

What did you find? | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 418 Registered: 5-2016 |

When I temporarily blanked my height control I think I went for overkill and blanked both restrictors and the inlet to the solenoid valve. Richards suggestion to just blank the inlet to the high pressure restrictor valve should do the trick as all high pressure fluid from the No.2 accumulator to the height control components appear to go through it. I disconnected and insulated the power feed wire to the solenoid valve at the same time as I was concerned that it would activate while dry of fluid when park or neutral gears were selected. I think I blanked the low pressure restrictor too because I was concerned that the reservoir would drain back through it and into the leaking HCV. | ||

Robert J. Sprauer Grand Master Username: wraithman Post Number: 330 Registered: 11-2017 |

Larry.. On point with disconnecting the electrical connection at the solenoid since it will be triggered. I forgot to mention that in my previous post, Thanks | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 420 Registered: 5-2016 |

Sorry Robert for referring to you as Richard by mistake, old age is advancing my attention deficit disorder. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2834 Registered: 6-2009 |

Geoff, Something that I included in the, RR & Bentley Parts, Repair, Restoration & Other Resources Compilation, ages ago: Blanking Off the Height Control System – [Updated 2/20/2015- Purists Skip This Paragraph] Should you decide that you no longer wish to deal with the height-control system (and the headaches that often go with it), this entire system can be easily blanked off while having no detrimental effect on the braking system. Determine which is the high pressure feed line to your height control ram and work backward to the T connection that splits the fluid source to feed each height control valve. Then working your way backward from the input to that T connection to find the connector where it and an input line to the “rat trap” both receive high pressure input from the accumulator. Consulting the workshop manual that applies to the series of Shadow/T or derivative you own beforehand is helpful in getting some idea of where these connectors are located. All are available at http://rrtechnial.info/sy/04_sy. After assiduously following appropriate cleanliness precautions, undo the connection to the height control rams where it exits the connector that serves to feed both the rat trap and the height control system. Be certain that you do not blank off the line that feeds the rat trap itself, only the one that feeds the height control ram, otherwise you will be disabling part of your braking system!! Secure a small ball bearing that is the correct size to block the entrance to the steel tubing (3/16” diameter ball bearing) and place it at the opening of the tube, then close up the connection, being careful not to over-tighten the connection. This blocks all circulation of fluid through the height-control system. --------------------------------------------- You might want to use a plastic rather than metal bearing to avoid bending the flares since this is a temporary measure for you. Brian | ||

Robert J. Sprauer Grand Master Username: wraithman Post Number: 336 Registered: 11-2017 |

Instead of a ball bearing or plastic "ammo" used in airsoft guns I would highly suggest buying the "line blank off set" from Kelly at British Tool Works. I have used them over and over and can't live without them when doing hydraulic work. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2083 Registered: 5-2012 |

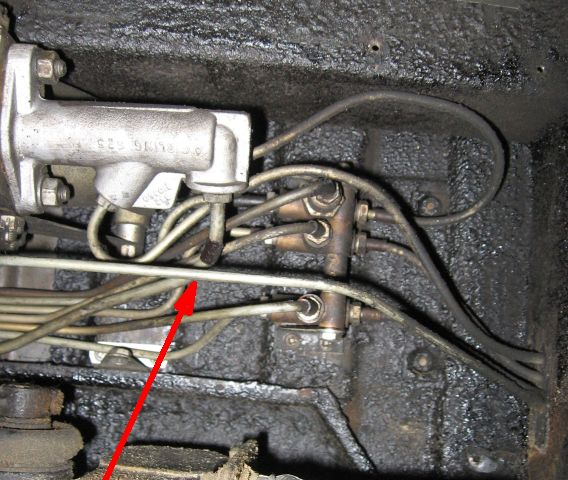

Hello Brian Many thanks for your reply. I consulted the resource file first of all before starting this project. The problem I am having is identifying the rat trap to T connection line, as so much is obscured by the various parts of the car e.g. the triangular box of the exhaust system to name but one. I've consulted the manual in detail but find the schematics will obviously not point to the actual physical line on the car. What is quite tantalizing is I can actually see the four lines at the rear of the rat trap (see photo). I will see which of those T junctions connect to the distribution valves and master cylinder and blank off the remaining line. Robert - I have already received the blanking set from Kelly - arrived last week.  If you check out the photo at the start of the thread, the line I have red arrowed to is the same as the one labeled "mystery line to the rear of car". I think this is the one to blank, but can't be sure. | ||

h_kelly Grand Master Username: h_kelly Post Number: 312 Registered: 3-2012 |

Geoff, just a side note, I have resealed the outer seals of the old 68 shadow,(now sold) on more than one occasion, it went(the seal) where the adjustment rod enters/exits same. It's a 5 minute job to do same,( if the unit is off car). I see Ronnie has YouTube video on same. P's about hours work to take off/replace same(unit). Good luck | ||

h_kelly Grand Master Username: h_kelly Post Number: 313 Registered: 3-2012 |

P's if you disconnect the power to the fast idle solenoid , would this be a quick solution?.. I'm sure others will advise ye/nay?. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2084 Registered: 5-2012 |

Hi Hubert Yes, I will probably end up blanking off the high pressure restrictor (which feeds the inlet to the solenoid) and the two inlets to height control valves. I just thought it would be better to blank the entire system off upstream, but since I don't want to accidentally blank a braking circuit I will probably play safe. I believe disconnecting the solenoid would leave the height control system in slow mode. I will disconnect it anyway and seal the connectors. | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 424 Registered: 5-2016 |

The solenoid sends signal pressure fluid to give an extra boost to the height control when park gear is selected. Disconnecting the electrical feed to the solenoid will eliminate the signal pressure but there will still be a supply of high pressure fluid to the height control valves from the accumulator. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2085 Registered: 5-2012 |

Hi Larry Yes, agreed. I intend to blank the high pressure inlet ports to both height control valves. Also the restrictor that connects to the inlet port to the solenoid. | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 425 Registered: 5-2016 |

Geoff, I'm sorry I can't help with finding where exactly the t-piece for blocking the height control is precisely located and that's the reason I temporarily blocked my system down stream at the high pressure restrictor valve (a female plug on the pipe and a male plug in the restrictor). I reckoned that fluid would still drain from the reservoir down to the height control via the low pressure return line so for that reason I blanked the low pressure restrictor also. That meant that there was no high pressure fluid going to the height control solenoid or the height control valves and no fluid draining down to the HCVs from the reservoir via gravity through the return pipe either. Don't forget to disconnect the electrical supply to the solenoid valve and insulate the end of the wire and tidy it out of the way with a cable tie or some such method. I think the t-piece you're looking for is the very first t-piece on the No.2 system high pressure line from the accumulator a long way before the rat trap, it could be the actual t-piece that the high pressure braided hose from the accumulator screws into diverting high pressure fluid in one direction towards the brake distribution valves and in the other direction straight to the high pressure restrictor valve but I'm not certain about this and that's why I decided to blank off the high pressure restrictor valve instead as that achieved the same result albeit further down the pipework but still before any of the height control components. | ||

Robert J. Sprauer Grand Master Username: wraithman Post Number: 337 Registered: 11-2017 |

The T junction actually sits on top of the rear crossmember and not accessible and barely visible. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2086 Registered: 5-2012 |

Larry, Robert, Brian, Hubert - Thanks for all the information. I intend to blank the system off tomorrow. I am now clear of my approach to this problem. I will let you know how I get on. Geoff | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 427 Registered: 5-2016 |

The routing of the pipework on top of the rear crossmember is a design disaster from a maintenance point of view in my humble opinion. Something as vital as brake/hydraulic suspension pipes should be easily accessible for inspection and replacement. I've replaced most of my brake lines with cunifer pipe except the pipes above the rear crossmember which I have yet to inspect. I reckon I'll eventually re-route them to a more service friendly location if possible but I don't fancy having to lower the crossmember to locate the connections. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2836 Registered: 6-2009 |

Geoff, If you have never used Glad Press n' Seal to cover the ends of the lines that will be pulled for blanking, I cannot recommend anything more highly for that purpose. This stuff was like a small miracle for being able to create dust covers in seconds that held a tight seal, and can be removed just as easily as well. Since you use very little given the size of the objects being put in a protective tent/bubble a single roll will last quite a long time. I'm still working on one I bought in either 2009 or 2010. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2087 Registered: 5-2012 |

Brian I've made a note of that for future related purposes. I have already bought a kit of caps and plugs for the high pressure lines. Kelly also supplies a lot of plastic fittings with the kit, which I have not yet explored (since I am mainly interested in the high pressure parts) but I presume are for capping off loose lines to prevent water/dirt ingress. The thing I like about Kelly's caps and plugs are I can be sure they will not deform the seats as may be the case with universal fittings. |