| Author | Message | ||

Harrison W Experienced User Username: hans3 Post Number: 13 Registered: 8-2017 |

Do the height control links just pop-off at the ball mount or must one first undo the bottom nut with the slotted screw counter hold? Bleeding the shocks of my SI Corniche didn't yield any fluid extract with weight in the boot, so I'm game for this alternate approach. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2761 Registered: 6-2009 |

My memory is that they just pop off, that it's some simple friction fit or spring pressure clip that holds it on. I know it can't be difficult since I've popped them off before to make it easier to bleed the rams. The notes in my instructions, Flush and Bleed Your Silver Shadow/Bentley T Hydraulics/Brakes the Easy Way, say, "Personally, even when I’ve done this on the ground I find it far easier to use the “pop the arm off and push it up” method." | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 336 Registered: 5-2016 |

From memory I think the slotted screw has to be loosened as it holds the link arm in place on the ball and stops it from sliding off. In order to loosen the screw you may need to hold it with a screwdriver and slightly loosen the nut first and then retighten in the reverse manner on reassembly afterwards. Be careful when raising or lowering the control link as the suspension should raise and drop as you move it and you don't want to get squashed. If raising the control arm doesn't produce bleed fluid but a knocking or rattling sound can be heard instead it usually signifies that you may have a clogged restrictor valve. Happy bleeding. | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 337 Registered: 5-2016 |

Forgot to mention that it's very tempting to raise or lower the control arm beyond it's limit and if you do you'll have to remove the HCV to remedy it so proceed with caution. You should only need to move it a small fraction. I've been there & done that and used all the expletives you can think of. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2762 Registered: 6-2009 |

Larry, Although I have not "been there, done that, cursed profusely," I know several that have. That's the reason I have the diagram from the workshop manual that shows the range of motion before internal disengagement in the instructions previously noted. You are doing the readership a huge favor by bringing this front and center, because tearing down the HCV is no fun task, and getting it off the car and on again is even less fun! Brian | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 120 Registered: 11-2017 |

The link does not snap on due to the proximity to the road surface and the possibility of it popping off. I have a 7/16 clamp on mine which is removed to free the clink. Be careful not to move the link too far...only 1-2" of vertical travel. If ther is no flow, there is a good chance both hi and lo restrictors are clogged. The "button disc" inside clog easily and the small plug of steel that opens the fluid flow hangs up easily. Overhauling them is easy and a lift is recommended. For height control overhaul visit Ronny's Garage aka rollsroycenut on Youtube. https://www.youtube.com/watch?v=3dOCE7FdkjM | ||

Avery Wise Experienced User Username: hans3 Post Number: 14 Registered: 8-2017 |

Brian, I noticed your procedure calls for putting the car in Park for the fast level. Will Neutral also allow this, since this is the gear I've habitually used when on jackstands? | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 121 Registered: 11-2017 |

Fast height solenoid is only engaged in Park or Neutral. http://www.rrsilvershadow.com/ETechn/Hydr/Hoogtediag.htm | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 338 Registered: 5-2016 |

Avery, Adjusting the height control lever while the car is on jack stands could be potentially dangerous as there will be movement in the rear suspension trailing arms which could cause the car to topple off the stands. Personally I prefer to move the height control lever while all four wheels are firmly on the ground or preferably on 4 post a garage lift and I also place a chock before and behind the front wheels. The solenoid valve is wired to give additional fluid feed to the HCVs when the gear selector is in either park or neutral. | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 122 Registered: 11-2017 |

Jack stands are placed under the car only in designated spots under the car...and those spots are on the floorpan near the round tube pan mounts in the rear and the front can be under the front subframe or under the body pan at the junction of the pan reinforcement member at the rockerbox channel. The rear suspension is therefore hanging. When the links are disconnected the body may raise only 2" or so. The solenoid is the fast acting circuit part of the leveling system. If you are not getting fluid out of the bleed ports, it is possible the solenoid is not working electrically or simply clogged with debris. It can easily be rebuilt but it must be gapped correctly to let the fluid run thru it.When it is working you can definitely hear it click. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2058 Registered: 9-2004 |

Yikes, no wing covers and the use of rubber gloves with dot 4 fluid! Robert I go along with Larry with the setting of the trim height with the car sat on its 4 wheels with weight in the boot. Hoist or pit is a must. Can't figure this with the wheels hanging [When the links are disconnected the body may raise only 2" or so]!!! | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 123 Registered: 11-2017 |

When the car is supported by a 2 post lift or jack stands in the recommended spots, the rear suspension will only drop the length of the rebound or limit straps on the trailing arms and the prop shaft is only 1/4" above the rear swaybar as well. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2059 Registered: 9-2004 |

So how may the body lift 2" or so when the links are disconnected with the wheels hanging. And with a two post how are you going to set the trim height? | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 124 Registered: 11-2017 |

The original post was in regard to bleeding. Setting the height: All 4 wheels have to be on the ground or same plane...and assuming the springs are fine. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2060 Registered: 9-2004 |

So I take it "ground" means pit or 4 post to bleed! However in your posting "The rear suspension is therefore hanging. When the links are disconnected the body may raise only 2" or so"?????????????????? What the heck are you on about????? | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 125 Registered: 11-2017 |

If you haven't noticed there is a strap from the floorpan to the rear swing arm.When the car is on a 2 post lift the strap will limit the downward travel of the swingarm. The height control linkage can be disconnected from the swingarm to manually purge the height cylinder. Pretty clear. | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 340 Registered: 5-2016 |

I was visualising a situation where the car was resting on axle stands in their appropriate locations with the car wheels being barely off the ground. Then when the HCV lever is raised the wheel moves downwards and may touch the ground and cause imbalance and/or movement of the car. I wouldn't personally like to be lying underneath in that scenario and would feel much safer in a pit or under a 4-post lift. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2763 Registered: 6-2009 |

I've done bleeding of the rams on the ground with no pit. I seem to recall reaching in from the side to actually activate the height control mechanism and I had long tubing on the bleed screws. I know I did it once, and definitely was not under the car when I did it, as I couldn't even fit under the back end in that circumstance. There are certain things that are really hard to document in the moment and to remember much later when you're the one-man crew. Brian | ||

Larry Kavanagh Grand Master Username: shadow_11 Post Number: 341 Registered: 5-2016 |

That's how I normally bleed the rams too Brian, all wheels on the ground and reach my arm in from the side. It helps if the wheels are resting on large flat wooden blocks as that allows a little more space for reaching in. I'm not saying that a 4-post lift or a pit are essential (though either would make the job easier) but I wouldn't risk leaning in to the bleed screws while manipulating the HCV lever if the car was on jack stands for fear that the pressure from ram would move the wheel downwards and cause the car to raise off a stand and upset the balance. It's scary enough without adding risk to the job. Furthermore, I prefer not to have the trailing arms resting on the straps as I don't trust the straps to take the weight. Somewhere in the manual, I think it's the section on servicing the rear hubs, it recommends not to have the trailing arms resting on the straps. | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 126 Registered: 11-2017 |

If you place a trolley jack under the rear diff and place blocks or jack stands under the body at the correct points then lift the front end at the triangle arm junction on the front subframe and support accordingly, you will not have issues and you will easily access the bleed points since the tire has dropped down from the wheel well. I have a Mohawk 2 post lift and really do not use a trolley jack and stands anymore like I did decades ago with my first Shadow. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2764 Registered: 6-2009 |

All of this drives home, again, that there is seldom any single "right way" to do many tasks, though there can be a multitude of wrong ones. There are plenty of techniques that get the job done while maintaining the safety of the individual doing the job. None is more "right" than the other, though there can be distinct differences in convenience. Brian | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 127 Registered: 11-2017 |

Totally agree Brian. Another simple effective way to support most cars is the use of a wide tree trunk. I used these back in the day. Easily sourced, cut to fit. Very stable | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2061 Registered: 9-2004 |

Yes safety is the key when working on the self levelling. a pit or 4 post hoist is the easy and safest way. If the system has failed by whatever reason the rams can still hold the car partly up under pressure. Crack a bleeder and the cars body can drop trapping the person under the car. | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 128 Registered: 11-2017 |

Keep in mind the rams only compensate a couple inches and the restrictor valves control erratic flow back to the reservoir. I never had a car suddenly drop. Remember the cars have springs and the rams were designed to compensate for additional load in the rear. Being cautious is always paramount. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2062 Registered: 9-2004 |

"I never had a car suddenly drop" Try it next time when failed, with of course the weight in the trunk test! But on a 4 post or pit for safety! | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2765 Registered: 6-2009 |

It really doesn't matter if it suddenly drops if you are not under it. They do not drop enough to pin the arm of anyone I know. If one wishes to be under the car then they'd be insane to be doing this work without a pit or lift. If the manipulation of the lever is from reaching in from the side it really doesn't matter. Due caution must be exercised that is directly dependent on the technique being used, and not just for this particular activity. Different techniques require different levels and types of caution. It's that simple. I fail to understand why people seem to believe that perfectly safe techniques that are not their own chosen ones must be pilloried as though they pose huge risks when they do not. The whole point of the "lever manipulation" technique is to obviate the need for weight in the trunk to begin with. It's a different route to get the same result during the bleeding process. Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2065 Registered: 9-2004 |

"The whole point of the "lever manipulation" technique is to obviate the need for weight in the trunk to begin with. It's a different route to get the same result during the bleeding process." Well I can see that a quick job of bleeding and setting the trim height on a hoist or pit safely, but could turn into days months by the so called its "that simple"! Well maybe you have a way of resetting the trim height after you fiddle with the HCV levers after a bleed with the car on the ground? | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2766 Registered: 6-2009 |

Yes, Patrick, I do. Reconnecting them. Moving them for the purpose of bleeding does nothing to change the linkage configuration when they're popped back on. If you didn't have issues with the trim height before, you certainly shouldn't after. Good God, but you're a PITA and insist that yours is The One True Way at every turn! Please, for the love of God, give it a break! Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2066 Registered: 9-2004 |

Brian, if the levers are being able to be popped off then you have either worn or bent ball joint or body. There should be no movement slop on the ball joints if there is as in your case as confirmed by the joints being popped off the car would travel like a lop sided duck out of water. The transmitted movement is very fine to the HCV and so setting and bleeding is SAFLEY carried out with weight in the boot on a 4 post hoist or a pit. BTW the only way to remove the lever correctly is to slacken the lock nut and the undo the adjusting screw. The tolerance of the ball joint when refitting the adjusting screw is with grease and no tight spots when the lever is swung.  | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 134 Registered: 11-2017 |

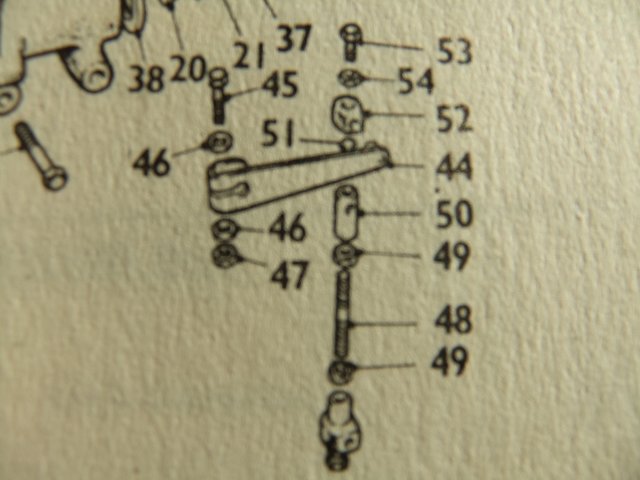

Here's a pic of the linkage. There are to ball joints that should be cleaned, openings chased with an axial brush (they collect debris) and waterproff grease is what I use. The stud with the ball end can be left mounted on the car side and no changes to the height will occur since the stud has not moved. It so easier to purge the air in the height system when the links are disconnected especially when working solo. Experience has shown this.  | ||

gordon le feuvre Prolific User Username: triumph Post Number: 293 Registered: 7-2012 |

When refitting it is very easy to push arm onto ball joint too far, especially as the boot covers every thing. If this happens, as you tighten adjusting screw it will pull arm towards threaded shank of ball. Just take a bit time, and tighten adjuster so that there is no excess movement but arm should swivel 90 degrees on cone in arm and adjuster. Like everything, easy on bench! | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2767 Registered: 6-2009 |

That some cannot understand "popped off" may require loosening of a lock nut or other retaining fastener is really not my problem. I presume that anyone who's working on this stuff has looked at the workshop manual or consulted reference materials here and/or elsewhere and knows the steps needed to allow something to be freed correctly - often colloquially referred to as "popped off" when it can be done with one's fingers. Popped off doesn't mean brute force pulled off without any consideration of anything else. It just means that the removal process is quite uncomplicated and requires very little force to achieve. It was a simple matter to remove the linkage at the ball post end, manipulate it as needed to do the bleeding, and return it to its prior state afterward. That prior state is awfully "wiggly" compared to certain other linkages. Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2067 Registered: 9-2004 |

Well that confirms with the car on the ground is fraught with a dangerous procedure, the use of a 4 post hoist or pit is the safe and quick way. After bleeding the rams it is good practice to check the levelled height settings as per manual with a load in the boot and carried out on a 4 post hoist or pit, do take heed or else be heedless! | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 135 Registered: 11-2017 |

Well said Brian. I think we shredded this topic to no end. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2768 Registered: 6-2009 |

Robert, I'm done, that's for sure. You couldn't please certain people if you hung them with a new rope. (As my dear, departed Aunt Lila used to say.) And crystal clear isn't clear enough for those convinced their own way is The One True Way! | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2068 Registered: 9-2004 |

Safety is the operative word, do it by the manual and all will be well. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2061 Registered: 5-2012 |

One slight problem with Patrick's method; I have neither a pit nor a 4 post hoist. When my height control needs bleeding I'll just pop off the control link and lean in from the side of the car, thereby saving myself 6 grand. | ||

richard george yeaman Grand Master Username: richyrich Post Number: 1052 Registered: 4-2012 |

Second post of this thread by Brian Vogel. My memory is that they just pop-off, Geoff Wooton says when my height control needs bleeding I`LL just pop off the control link. Richard. | ||

Robert J. Sprauer Prolific User Username: wraithman Post Number: 136 Registered: 11-2017 |

If the link simply "pops offf" the set screw on the end of the link is not set properly. The set screw should be turned in to tighten and backed off to let the it flex and locked with the nut. That's the way it works. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2769 Registered: 6-2009 |

Richard, Anything prefixed by me with "my memory is" can mean "my memory is wrong." I stand by the use of "pop off" for removed with ease. It has been confirmed that it isn't a friction fit, but requires the unscrewing of a fastener. Geoff's post follows this one, and I have little doubt plays off it, too. I really cannot believe the amount of discussion the phrase I used, with qualification, and that was later corrected by others (which is fine) has gotten. People are able to read, I hope, and fill in blanks where someone else, including myself, has left them. The long and the short of it is that it is perfectly safe, and incredibly easy, to remove the linkage at the ball post, manipulate it from the side of the car (not beneath it) to get the rams to bleed, and put it back on. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2062 Registered: 5-2012 |

I was absolutely using the term "pop off" in the context of Brian's previous comments, namely "I presume that anyone who's working on this stuff has looked at the workshop manual or consulted reference materials here and/or elsewhere and knows the steps needed to allow something to be freed correctly - often colloquially referred to as "popped off" when it can be done with one's fingers. Popped off doesn't mean brute force pulled off without any consideration of anything else. It just means that the removal process is quite uncomplicated and requires very little force to achieve. " | ||

richard george yeaman Grand Master Username: richyrich Post Number: 1053 Registered: 4-2012 |

Gentlemen why I just Quoted the first answer and the last answer was my way of saying that most of the in between posts were as Robert J Sprauer said shredded to no end. Richard. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 2069 Registered: 9-2004 |

[Anything prefixed by me with "my memory is" can mean "my memory is wrong."] Best to not post on such a safety issue then. See the emails are flying! Geoff are you and Brian going by the workshop manual or not regards to a safety? Do you use park with the hand brake on with the selector fuse removed when the car is not lifted without a pit or 4 post hoist? | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2063 Registered: 5-2012 |

Hi Patrick I don't normally remove the selector relay when I'm working on my car. I have a battery isolator switch which I always turn off before carrying out any work. The exception to this is tuning the engine, when I remove the relay. Handbrake is always on. I tend to be over the top on safety when under the car. I use six axle stands every time. I get a little claustrophobic with the car inches above my head. Handbrake on, wheels chocked and battery isolated. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2770 Registered: 6-2009 |

Patrick, My track record on safety is unblemished, except in your mind. For the love of God, please stop dogging my every post. It's unseemly, unnecessary, and makes you look crazy. You're definitely being willfully stupid when it comes to me, and it's been noted. Brian | ||

David Gore Moderator Username: david_gore Post Number: 3156 Registered: 4-2003 |

MODERATOR COMMENT: This thread has become repetitious and the standard of certain posts is less than appropriate for this forum. These posts do not respect the Forum's policy of enabling full and frank discussions of opposing opinions. This policy does not extend to allowing inappropriate and/or derogatory comments about those who have different viewpoints regarding the matter under discussion. Please respect the rights shared with other forum members regardless of whether you agree or disagree with their advice/opinions by refraining from repetitious comments in an attempt to "have the last say". It only detracts from your standing in the eyes of other members as well as the esteem given to the advice. Compliance with Forum standards will be greatly appreciated - lack of respect will have adverse consequences. . | ||

Vladimir Ivanovich Kirillov Grand Master Username: soviet Post Number: 1308 Registered: 2-2013 |

Gentlemen, you must try to understand that there are often many ways to perform a task and end up with the desired result. The mechanical trade like the panel and paint trade is full of tradesmen who think they know the true and only way to perform a task. My methodology is to be a vacuum cleaner and try any new method when its suggested provided it not silly like "put your hand in the door jam and slam the door hard to adjust door gaps to specification." So please chill. |