| Author | Message | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 45 Registered: 3-2016 |

Hello, After a substantial break fluid leakage on the front right of SRH25085, I checked the hoses and I could see that they were seeping with liquid (picture 1). I removed them, cleaned and dried them and looked in vain for craks or holes. So I left them in the shed, and after three days, they were seeping again...(picture 2) It's no medieval miracle ;-) Have you experienced such an issue ? picture 1  picture 2  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1996 Registered: 5-2012 |

Hi Jean I take it these are the return hoses from the accumulator control valves to the reservoir, since they have no end fittings. It looks to me that a previous owner has used the wrong type of hose, probably fuel hose. If this is the case, the brake fluid will be absorbed into the hose and will gradually sweat out, even if you wipe it dry. The correct hose to use is 1/4" (ID) EPDM rubber hose. It is very cheap and readily available. | ||

Jean-christophe Jost Experienced User Username: jc_jost Post Number: 46 Registered: 3-2016 |

Geoff, Its nice to talk to you after some time, you are right, I forgot to mention that the hoses were the return hoses. Thanks for the specs ! | ||

Jeff Young Grand Master Username: jeyjey Post Number: 375 Registered: 10-2010 |

I've had this happen to fuel hoses (on a Formula Ford) and power steering hoses (on a T2). Both were correct hoses, but decades old. | ||

David Gore Moderator Username: david_gore Post Number: 2981 Registered: 4-2003 |

A good example where time-based part replacement is essential. I use an 8 year life as the maximum for non-critical hoses and 5 years for critical fuel and brake hoses. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 849 Registered: 11-2015 |

David, Those numbers sound good considering the heat you guys get. I bet you could extend them a bit elsewhere. I just removed two gas lines that were so parished you could peel the outer casing off by hand. That could have ended badly. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2589 Registered: 6-2009 |

Not that I don't agree with time-based part replacement, but the amount of time needs to be directly based upon the composition of the item in question. Conventional hose materials age much more rapidly than some of their modern replacements. (And even conventional materials tend to have long service lives.) | ||

David Gore Moderator Username: david_gore Post Number: 2982 Registered: 4-2003 |

Brian and Ross, The service environment plays a major role in determining the changeover period. In a hot and high UV radiation climate like ours, the service life is significantly reduced compared to a cooler, less aggressive climate and my suggestion is based on my experience both personal and industrial over 5 decades. Hoses consistently exposed to direct sunlight usually have a markedly reduced life compared to ones in permanent shade. Hoses consistently in hot environments usually have a markedly reduced life compared to ones in a cool environment. . | ||

Jeff Cheng Prolific User Username: makeshift Post Number: 115 Registered: 2-2016 |

If they are indeed the low pressure accumulator return hoses, I had mine 'fail' in the same manner only a month ago. I use the term fail loosely, as I would much rather them begin to weep, then break apart catastrophically and leave me stranded. Mine leaked 2 drips per 24hrs. The hoses were dry before I had the car in for it's annual service, where an accumulator was overhauled. I believe disconnecting the brittle hoses to get to the accumulator caused them to crack. I had an outstanding Flying Spares order, so I just added the hoses to it. To me, the minimal price difference of the FS hoses (compared to locally sourced hose) was worth the peace of mind of a warranty of sorts. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1997 Registered: 5-2012 |

I'm not sure the price difference is minimal. They are listed at around 15 uk pounds per hose. That's $19 here in the US. With shipping costs from the UK for two hoses - about 60 bucks. Compare that to the $8.49 I paid at a local store for a 10' hose. The spec is more than adequate for a low pressure return hose, EPDM, 150psi and temperature range -20 to 195F. The main advantage however is it is so convenient to buy it locally, rather than having to wait a week+ for it to be shipped. https://www.tractorsupply.com/tsc/product/abbott-rubber-epdm-rubber-spray-hose-1-4-in-id-x-10-ft?cm_vc=-10005 One thing I noted is the longer return hose for the series II cars is listed at $52. Since my car is a "series 1", I don't know if this is the same type of hose. I suppose if that hose is twice as long the rationale is - twice the price. So potentially greater savings for series 2 owners, once you've verified that the EPDM hose above is suitable. | ||

Chris Browne Grand Master Username: chrisb Post Number: 301 Registered: 2-2010 |

A cautionary tale. Three years ago, I was out in my Shadow 2 when I became aware of a very strong fuel smell inside the car. I stopped to investigate and found the flexible fuel line which bends over the right side rocker cover had split and was dripping fuel very close to the hot exhaust manifold. The pipe looked and felt normal but it had split and delaminated at the top end and had become hard and brittle beyond the jubilee clip which fixes the flexible hose to the rigid metal pipe which delivers fuel to the carburettors. The cause, I assume, was the engine bay heat and the close proximity of the hot exhaust manifold. I replaced the hose straight away with the correct grade of fuel hose. Problem solved. This week, I was fettling under the bonnet, actually fitting Iridium spark plugs as recommended by some of the gurus on this forum. I happened to check the fuel pipe in passing and again found it wet with fuel at the same place-this time with a cold engine thankfully. I have replaced the fuel pipe with a new one again. I have now included a check on the condition of this pipe into my annual maintenance schedule as it has now happened twice. Iíd be interested to hear if any other Shadow 2 owners have had a similar issue, particularly in hotter climates than the dear old UK. Kind regards, Chris | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 557 Registered: 10-2008 |

Chris, the replacement of flexible fuel hoses where there is heat present is an annual job. I have had this problem on my Carb Bentley Mulsanne and the Spirit before it also on my MG s.I use Pirtek for hose, as this seems better than some of the fuel hose available. Mark | ||

Chris Browne Grand Master Username: chrisb Post Number: 302 Registered: 2-2010 |

Hello Mark, Good to hear from you. Yes your annual change makes complete sense and I will adopt the same habit. Iím a little surprised this topic has not had more of an airing before as it canít just be you and I that have had issues. Just out of interest, what spec of Pirtek hose do you specify? Kind regards, Chris | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 558 Registered: 10-2008 |

Chris, I use either 100R6 (EN854) from Pirteck ( I have had no deterioration problems with this ) or J30R6 fuel hose. I have found the cotton braided fuel hose worse than useless. I also use 100R6 for power steering returns, LHM low pressure, etc. Mark | ||

Omar M. Shams Grand Master Username: omar Post Number: 1614 Registered: 4-2009 |

Not all hoses are hoses. Just like one of our famour friends from Mount Coolon once said "not all hookers are hookers". It is the same concept. there are fat ones long ones short ones etc. Also there are ones that work for short periods and then there are those that last for a very long time. Can you imagine life in the 70s if our cars had to go in for hose changes every year? No way. The right hose will last at least 5 years. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 559 Registered: 10-2008 |

Omar, totally agree with you in theory, but in practice both my son and I have had similar failures to Chris and the cotton braided "hose" is a disaster waiting to happen. You cannot see the problem till it splits. ( over an MG exhaust !)Ethanol may be the problem but hose is cheaper than fire extinguishers.It seems only underbonnet hoses are affected. Mark | ||

Jim Walters Prolific User Username: jim_walters Post Number: 182 Registered: 1-2014 |

100R6 hose is not suitable for DOT 3, DOT 4, or RR363 glycol based brake fluid. It is for hydraulic oil or fuel systems. Look up the specs on it. You must use an EPDM hose for glycol fluids. Coolant and heater hoses are composed of EPDM. If you're using 100R6 it is dissolving inside and contaminating the brake fluid. Sooner or later it will fail. Some cheap 100R6 will start to weep in a couple weeks. I can't tell you how many times I've replaced leaking pump feed and return hoses where some mis-informed mechanic has used fuel hose for this application. I see it all the time. 100R6 is OK for use on SZ mineral oil based brake systems. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Omar M. Shams Grand Master Username: omar Post Number: 1615 Registered: 4-2009 |

Dear Jim, this is great stuff!! thanks for sharing this vitally important piece of information. I am also a victim of this problem. What is the right grade of rubber hose for this application? And whilst we are at it - what is the right grade of rubber hose for ethanol based gasoline? | ||

Jim Walters Prolific User Username: jim_walters Post Number: 183 Registered: 1-2014 |

Omar, automotive coolant and heater hoses are composed of EPDM to be compatible with glycol antifreeze. This means they are also safe to use with glycol (DOT 3, 4, RR363) brake fluid. We use small heater and/or radiator overflow hose for pump feed and return hoses. I'll get the number off the hose for you when I get out to the shop. The best grade of fuel hose to use is anything that conforms to SAE specs J30R9. This is modern fuel injection hose that is specifically designed to be safe to use with ethanol laced gasoline. Yes, it is fuel injection hose but it is specifically spec'd to be ethanol safe and is backwards compatible with the common J30R6 fuel hose so is fine to use with carburetor fuel systems. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 560 Registered: 10-2008 |

Thanks Jim, we have not used other than genuine "crewe" hoses for brake fluid, which are costly. The hose number that you use would be appreciated. Mark | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2590 Registered: 6-2009 |

I've posted it before, but here it is again: RR & Bentley Parts, Repair, Restoration & Other Resources Compilation There is a table in the file that lists each and every commonly available hose, of the correct elastomer and spec, for the brake system in the RR363 series cars. Search for "Hydraulic Hose Substitution Chart" and you'll go straight to it. I've used 3/8" ID EPDM heater hose for the gravity feed from the reservoir to the pumps and 1/4" ID EPDM for the return to the reservoir for years. They simply work and are available at any auto parts store cut to length (and will continue to be so). Other EPDM brake hoses that meet the SAE J1401 - 1/8 HL spec that the Crewe hoses also use are available for far lower prices. If you want to greatly extend the service life of your brake hoses then consider spending the extra money to get ones with a PTFE carrier tube. Most of the long, slow breakdown in brake hoses comes from the exposure to the fluid itself (hence the fine black sediment that shows up in the reservoir even shortly after new replacements are fitted). PTFE is chemically inert and the outer hose jackets are generally steel mesh reinforced, creating a hose with a "virtually perpetual" service life. These are quite similar in construction, except for the addition of the PTFE carrier, to the high pressure hoses that exit the accumulators, and even those without a PTFE carrier have service lives much longer than the hoses further "downstream" of the accumulators. Brian | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 561 Registered: 10-2008 |

Thanks Brian, heater hose is specified SAEJ20R3 in the Uk, is this an equivalent. Mark | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2592 Registered: 6-2009 |

Mark, I have no idea. All I did was ask for EPDM heater hose. Since pressure is not a factor in either the gravity feed or return burst strength is a non-issue. Brian | ||

Jim Walters Prolific User Username: jim_walters Post Number: 184 Registered: 1-2014 |

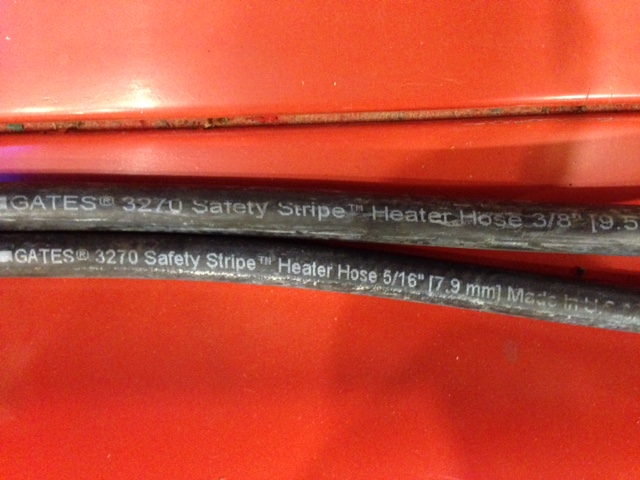

Here'a pic of what we use:  SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com |