| Author | Message | ||

Patrick Francis Prolific User Username: jackpot Post Number: 236 Registered: 11-2016 |

Hi Guys I took my Shadow 1 into the paint shop to touch up some nicks and scratches. When I picked it up, the gen light would not extinguish, and as I was travelling back home, it was misfiring, and getting worse. I know they did some welding without disconnecting the battery. I presumed that this had fried my regulator, and hoped that changing it might fix the misfire. I have replaced the regulator, but the generator light has not extinguished, so I presume the problem lies deeper. Also the misfire is still there, so I am sure that the Powerspark is also fried. I have not started digging yet, but before I do, does anyone know what else could have blown, apart from the regulator which I have replaced. I know modern alternators have the regulator as an integral part with some big diodes that can blow. Does the Rolls also have those, or is everything controlled through the regulator? I am waiting for an answer from Powerspark as to whether their units can misfire when damaged, or that they either work or not. Any suggestions on what I should check in the meanwhile would be welcome and appreciated. Thanks as always.... | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1988 Registered: 5-2012 |

Hi Patrick The alternator does contain diodes. Section M5 of the manual is very comprehensive and gives procedures for testing the alternator. I had a quick google of welding cars and disconnecting the battery. As often happens on the net, opinion is divided. Some people say they have welded many cars with no problems, others who say they always disconnect the battery. One person mentioned that exhaust shops never disconnect car batteries and often carry out welding - I suspect most would be using oxy-acetylene however. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1989 Registered: 5-2012 |

BTW - when my Powerspark failed it did so gradually with misfiring. This was confusing as I thought it would either be on or off. I therefore replaced the other ignition parts (coil, rotor, leads) before reverting back to points, when the engine ran ok again. Could you let us know Powerspark's response - it would be interesting to know. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1916 Registered: 9-2004 |

Have used arc and mig tig etc and for the last 20+ years have never disconnected the battey, have always used one of these to stop spikes etc.  | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1990 Registered: 5-2012 |

Hi Patrick (L) - I assume the Sykes Pickavant device is a large smoothing capacitor. So, logically, we can assume that car electrics are prone to spikes from MIG/TIG welders, else there would be no need for such devices. | ||

Vladimir Ivanovich Kirillov Grand Master Username: soviet Post Number: 1017 Registered: 2-2013 |

Apart from oxy welding I always disconnect the battery. I mean really how much effort does it take to disconnect the battery? I have heard mig welding will not blow diodes in alternators. I do not care. I always disconnect the battery. This thread is another reminder to me why I simply will not let any workshop near my cars. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1917 Registered: 9-2004 |

Cripes Vladimir, hope you never disconnect some moderns can be a costly time consuming job to re programme with lost codes etc. Battery disconnect went out years ago. How is the super Camargue engine coming along. I need one to put an engine in, if you need to sell at any time give me a bell. | ||

richard george yeaman Grand Master Username: richyrich Post Number: 983 Registered: 4-2012 |

Patrick F I would start with the alternator, a half charged battery isn't helping your chance of a good sparking plug, order up a new power spark and also a spare one. Kind Regards. Richard. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1918 Registered: 9-2004 |

May be beneficial to know what parts have been welded. Could be burnt loom etc. Maybe a nothing more than a fuse blown during the operation if fitted. Connection left off if removed. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 842 Registered: 11-2015 |

Patrick F, As to the welding thing, I've welded a lot of metal on a lot of vintages of cars. If it's someone else's I disconnect the battery, on mine it's cables on. Never had a problem. Of course I ground correctly so there's less chance of electrons going where they shouldn't. In both cases, never a problem. And in all the car welding I have direct knowledge of, no mig / tig induced problems. Could you get massive current flow somewhere you don't want it or induce current in something electromagnetically or create some high voltage spikes,.. sure. Even with the "running fine before shop" / "running badly after shop" clue, I would still diagnose this the same way I would any misfire. If you are more comfortable with replacing stuff, testing the Pertronix would seem easy enough, put the points back in, time them and see if the goes away. Three days ago I welded front clip back on my new mini, 1.5 hours straight welding.  Battery on, no problems. Two days ago I welded in metal to fix rusted out drivers and passengers door sills on Ford truck. 1 hour welding time ( job time four hours)  Battery on no problems. No pictures, but today I welded an exhaust on a Ford Festiva battery on, no problems except I cannot get the dignity back I lost working a Ford Festiva. | ||

Patrick Francis Prolific User Username: jackpot Post Number: 238 Registered: 11-2016 |

Hi All So sorry that I haven't managed to thank you all for your advice and help as usual, but a combination of work and various other factors has meant that SRH 17968 has been a distant memory for a while. Geoff, I contacted Powerspark, and these were their answers: 1. Would the failure of the Powerspark unit cause my GEN light to go on? In answer to question number 1, no, failure of the kit won't cause the GEN light to come on. 2. If the Powerspark unit is damaged, could it cause a misfire, or would it just stop working altogether? In answer to question number 2, generally, if damaged, the kits would just stop working completely. Patrick L and Ross I have also done a lot of welding without any problems, but knowing how delicate Powersaprk ignitions are to electric overloads etc, I would recommend disconnecting the battery as Vladimir suggests. Richard, I have removed and checked the alternator - working perfectly with NO blown diodes. I have replaced the regulator. I have charged the battery. I still get a misfire and a permanent GEN light. I have not replaced the electronic ignition unit until I can identify the reason that the GEN light will not extinguish. I should have more time in a couple of weeks and so will start a methodical process of elimination. You will be down this part of the world around that time, so we will have a topic of discussion!! Thank you all again, and I will report back with any progress! | ||

Patrick Francis Prolific User Username: jackpot Post Number: 247 Registered: 11-2016 |

Hi Guys Richard (Yeaman) - great to see you again the other day, pity we didn't have time to battle this out together! Thanks to Alan Dibley for his reply to my "condensers" question. So, trying to get to the bottom of this problem - Generator light stays on, and car misfires to the point of nearly cutting out. I originally thought it was a welding problem when some bodywork was being done, but they used gas. So the possibility was a red hot rod puncturing the loom under the front wing where the welding was done. -not the case_ I tried all the fuses and connections, but all seemed OK. Checked the alternator and replaced the regulator box. In the process of elimination, I tried replacing the coil, and suddenly the Gen light went out and she ran smoothly. She was running smoothly on a 1.5ohm coil instead of the 3 ohm electronic ignition coil, even though I had no ballast resistor. So I changed electronic ignition and coil (borrowed from another car) - but it started misfiring again. Since she was running fine on the 1.5ohm coil (designed to run on 9v through a ballast resistor), I presumed that she was getting a dropped voltage at the coil due to resistance or a bad connection somewhere. So I ran a clean lead from the +ve of the battery, straight to the coil. She ran well for a short while, but then, again, bad misfiring, gen light on and sooty plugs! So I put the 1.5ohm coil back on and she ran like a dream for a few miles and then really started coughing badly, misfiring and the gen light came back on! The love hate relationship with the old girl was running out of love!! She finally stalled and wouldn't start! I opened the bonnet and noticed a whiff of smoke from the alternator area, and on closer examination, found one of the condensers under the compressor had a melted cable. On disconnecting it, lo and behold she started an ran like a dream!! I ran her for about 60km, and during the journey she hesitated and started misfiring a couple of times, especially towards the end of the journey, but otherwise ran well. I have not done the timing since swapping the electronic ignition pickup, so part of that may be due to that, but I suspect that it may also be the second condenser under the compressor, but I have not had time to check that. My question is, does anybody have a similar experience with these failing condensers? If they fail, does that mean a +ve is earthing and causing these multitude of problems, or is it just a coincidence? Alan says there may be many condensors around, but I presume these two that are attached to the alternator would be the ones more likely to interefe with the ignition. I am downloading the circuit diagram to see if I can make sense of it. I am a bit puzzled as to whether I have located the problem, and electrics befuddle my brain!! Hmmmm…... | ||

Patrick Francis Prolific User Username: jackpot Post Number: 253 Registered: 11-2016 |

OK Guys The saga continued. I spent a couple of hours trawling through bthe forum and following every instance of stalling and misfiring. So thanks to everyone. I am sure that I have read every permutation and combination of problem solving this sort of issue. So after my last 60 Km journey where she ran like a dream until near the end where she started her usual misfiring and stalling. I only just managed to get her to a parking space that I have in the centre of town. My shots in the dark were a bad connection to the coil positive, a fault in the weakener system, or a problem with the electronic ignition. So I put the original points and coil in and retimed her - she seemed to be running reasonably well, and so I decide to try and risk taking her to the workshop. I drove her to the top floor of the garage and back down twice and she didn't miss a beat. Bingo! it was the electronic ignition! I arrived at my garage, about 2 miles away, and as I drove up to the gate, she stalled again, and would not start - misfiring and backfiring. She seemed to be failing when she got warm. I was blocking and entrance, so in desperation, I ran a clean lead from the battery to the coil, and she started perfectly and I drove her into the garage. So there it was - as I thought - it was a bad or weak connection somewhere leading to the coil positive. This comes from fuse 12 which also supplies the fuel pumps. Maybe something was failing when hot and affecting the coil and fuel supply? Of course! So I traced the cable through the loom, disconnected and greased all the plugs on both sides of then bulkhead, took the fuse box to pieces and checked feed from the ignition switch, which fed fuse 12 and 5. Tried to crank her, and she would fire whilst on the starter, but not further - which hinted an a ballast resistor problem. So put the spare resistor on- but still nothing. By now, I had changed coils, changed pickups on the electronic ignition, converted back to points and original coil, changed ballast resistor. Taken apartb the weakener system, took the cap off the float breather so that the weakener is bypassed, checked fuel flow, removed and checked carbs. I checked for spark by having a spare plug visible whilst cranking. The symptoms were still the same - Car will start whilst cold. Car will not start when hot, unless I put a clean positive feed from the battery onto the coil (9v points coil). But then would run for a while and then start to misfire and stall again. The next step was an enjoyable breakfast with Richerd (Yeaman) and friends. After discussion with Richard, we decided that it had to be electrical. Richard said that the backfiring and sooty plugs shows we are getting fuel. We agreed that I should continue my saga with a direct 12v feed to the 12v coil, through the mechanical points. Then to run separate feeds to each individual item that played a part in the running of the engine ie fuel pumps, ignition system, weakener system etc This I did, still with doubts as to whether we had a combined ignition/fuel issue from the 12V feed. Well, after another couple of hours of investigation and head scratching, I finally found the problem!! Happy, happy day. So this is the challenge: Whoever guesses what the problem was gets a pint on me at the Car show in Birmingham! And if you are not coming, we'll think of something else. Pleased to answer any questions. All will be revealed!! Patrick | ||

Larry Kavanagh Prolific User Username: shadow_11 Post Number: 228 Registered: 5-2016 |

Bad connection at oil pressure switch causing fuel pumps to cut out? | ||

ross kowalski Grand Master Username: cdfpw Post Number: 869 Registered: 11-2015 |

Patrick, With a free pint at stake, it must be something really impossible to guess. I'm going broken choke stuck in closed position. | ||

Patrick Francis Prolific User Username: jackpot Post Number: 255 Registered: 11-2016 |

Larry - good guess and one I checked whilst trawling the forum. Mine doesn't have that switch. Ross - I checked that and went deeper. Had the carbs off, choke solenoid, stove pipes etc - all good. | ||

Patrick Francis Prolific User Username: jackpot Post Number: 256 Registered: 11-2016 |

Now that she is good, she is purring with her electronic ignition back in, timing done and carbs reset and tuned since I had had them removed. A while back I had a problem with a fuse disconnecting when it warmed up due to a dry solder, so not that. All my fuses resold ered and working well. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 2068 Registered: 6-2006 |

Suppressor at the coil going down? Coil terminals iffy? One end of the pumps down, second end starting to fail? | ||

Alan Dibley Prolific User Username: alsdibley Post Number: 168 Registered: 10-2009 |

Poor contact in key-switch? | ||

Jeff McCarthy Grand Master Username: jefmac2003 Post Number: 553 Registered: 5-2007 |

Leaking vacuum hose or stovepipe? | ||

Patrick Francis Prolific User Username: jackpot Post Number: 257 Registered: 11-2016 |

Paul Supressor disconnected-so no Tried 3 different coils Fuel pumps were a major concern and would gave been my next investigation, but no. Alan Supply from key switch fed fuse 12 and 5 and all feeds from 5 were good such as fans - so no Jeff Stove pipes and choke and weakener working as should. | ||

Trevor Pickering Frequent User Username: commander1 Post Number: 74 Registered: 6-2012 |

Sounds like a problem I had and it turned out to be Carb main jet rubbers had split alowing too much fuel and thus a very rich mixture. | ||

Patrick Francis Prolific User Username: jackpot Post Number: 259 Registered: 11-2016 |

Hi Trevor Took the carbs apart- which had been recently serviced 18 months ago, and they were perfect. Had to rebalance and retune them when I found the problem though. | ||

Larry Kavanagh Prolific User Username: shadow_11 Post Number: 229 Registered: 5-2016 |

Vacuum leak at gasket between carbs and inlet manifold? | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1964 Registered: 9-2004 |

Condenser failing in the distributor, look at the contact faces to confirm. Incorrect dwell causing the coil to over heat! | ||

Omar M. Shams Grand Master Username: omar Post Number: 1693 Registered: 4-2009 |

rotor arm | ||

Omar M. Shams Grand Master Username: omar Post Number: 1694 Registered: 4-2009 |

i can smell the hops already......... | ||

Jim Walters Prolific User Username: jim_walters Post Number: 200 Registered: 1-2014 |

As Omar said rotor. I have posted an easy checklist several times in the past on how to quickly pinpoint an FTP. One of the checks on the list is to test the rotor by holding the coil high tension lead close to the centre of the rotor and have someone crank over the engine. If a spark jumps to the rotor, the rotor is faulty. We see them fail fairly often, it's the third thing I check for after confirming power to the coil, and spark from the coil lead to ground. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 2042 Registered: 5-2012 |

My favorite for this kind of fault - engine gets hot and misfires - try something and engine runs again, is fuel vaporization in the float chamber. It is based on the notion that whilst trying a new idea to remedy the fault, the fuel cools. On cranking the engine again, fresh fuel adds further cooling and the engine runs smoothly again. It is a known weakness on these cars and Introcar have a thermal insulation kit for this. However I think this is only likely in a hot climate (ambient 100F +) and I know Gibraltar (if you are still resident there) is very mild. So I suspect my guess will be wrong. Interesting quiz - I look forward to the answer | ||

Omar M. Shams Grand Master Username: omar Post Number: 1695 Registered: 4-2009 |

i must admit - my experience with VW air cooled engines led me to my conclusion. Their rotor arms fail in the same way and fairly frequently. Most VW owners carry spare rotor arms. | ||

Patrick Francis Prolific User Username: jackpot Post Number: 260 Registered: 11-2016 |

Hi Guys You have to know that I was very thorough in my investigations!! Larry I had the carbs off and back on and made sure that all gaskets were tight. So no. Patrick (L) The fault was there with both the electronic ignition and the original points and condenser etc. Made no difference. So no. Omar I tried 3 different rotor arms with both the original points set up and the electronic ignition. The original and two that came with the electronic ignition. So also no. Keep smelling the hops 'cos I'll be drinking the beer!  Jim It was not the rotor, as explained above - but you are somehow warm my friend. Geoff I am still in Gibraltar, and we get up to the late 30s early 40s in the summer. For that reason, I have the thermal insulation kit installed and functioning as it should. I think I did this following your advice originally! Omar Interesting about the VWs. I used to own a beach buggy with VW engine and remember having ignition issues. Took her out for a drive this evening and she has never run better! Happy guessing..... | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1967 Registered: 9-2004 |

Incorrect fitment of the coil low tension leads. BTW did you scope the electrics first? | ||

Patrick Francis Prolific User Username: jackpot Post Number: 261 Registered: 11-2016 |

Hi Patrick At one time I had one 12v coil and two 9v coils tie wrapped in the engine compartment and a live lead directly from the battery to leapfrog the fusebox. Trying every permutation and combination of coils and power supplies, but I never misconnected the cables on the coils. What do you mean by "scope the electrics"? | ||

Larry Kavanagh Prolific User Username: shadow_11 Post Number: 230 Registered: 5-2016 |

Worn or damaged carbon button in centre of distributor cap that should make contact with the rotor arm? | ||

Jim Walters Prolific User Username: jim_walters Post Number: 201 Registered: 1-2014 |

Distributor cap if it is misfiring. Or as Larry said carbon brush, or possibly coil high tension lead. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Patrick Francis Prolific User Username: jackpot Post Number: 264 Registered: 11-2016 |

Hey!!! Roll of drums and the odd bugle!!! Well done Jim, Larry I tried 2 distributor caps and checked the buttons on both. So no. Jim Carbon brush and Dissie cap were good as mentioned. The problem was the coil to Dissie cap HT lead. The fault was not consistent and not a total failure. When I checked for a spark with a spare plug on various HT leads, it was always there. For some reason , after running for a while, the lead would start to fail and the spark would get weaker and erratic, causing misfiring and backfiring. I checked it various times, but never tried a replacement. In the end, after I had put a clean positive feed from battery to coil, and she restarted, I was checking the spark on the end of each HT lead with an in line telltale light that I have, and noticed an occasional weakening of the intensity of the telltale, though no failure. My initial thought was a failing coil since the positive feed to the coil was direct from the battery. But I had 3 coils on the go and swapping them made no difference. So a shot in the dark was replacing the lead- and voila! The lead was a silicone lead, part of the set supplied with the electronic ignition kit from Acuspark. I have replaced it with the original copper core one, though Acuspark recommend a silicone upgrade for their system. Anyone know why? I'll be looking it up on their webpage. Well done Jim. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 2070 Registered: 6-2006 |

Ha! Don't you love intermittent faults . . . Especially when it's the failure of a newish part!! Hope the beer gets there safely Jim!! Enjoy. I was collecting a Cloud III from the new Forrest yesterday. Was certainly thinking about about this post. 3 FTPs. All when hot and been driven for quite a while. Misfiring and loss of power, especially when travelling up hill. Managed to crawl to services. Petrol starvation? Fuel ok to carbs. Dizzy cap off. Check points. Ok New cap and leads had just been fitted. Looked like new points and condenser as well. Notice a washer jammed between plate and vac advance. Ahhh Fished out. Cap on. HT Lead also out of coil. Ah ha. Screw in type. Fish out brass end without loosing it. Back together. Start engine. Running fine. (At this point I should mention that when collecting the car from the dealer (classic cars but not RR&Bs) he told me to watch out with the gear shift because RRs are odd. . . You need to hold the gear shift right up high against its stop to get it to crank but it will still run forward especially on choke!! Make sure the handbrake is on whatever you do!! I assumed he was talking about that slight half lurch the Clouds do. Turns out NO!! It was fully in gear with no neutral and had to be driven in N to get top gear. So no reving it to try it once running.) Seems fine, drive around services and head out again. Half hour later same thing. Bugger. Call RAC?Still peeing down. Nurse it to next exit. Still peeing down & pitch black here. Phone torch balanced. Check points again. Notice screw on condenser is fitted at a jaunty little angle & no washer. Bit of wiggle on condenser? So screw out, fingers crossed, will it go back straight and tighten? YES!! Cap on, starts. Running ok. Result!. Back on the M4. I'm soaking. (There hasn't been a peep of heat or air from the blowers all journey, so 1/4 light now open to keep screen clear.) 15 mins later 25 miles from home. Same again. RAC called whilst nursing car to next exit. Nope. M4 hard shoulder. Pitch black. No hazard lights. RAC quoting 60 mins even after explaining position not safe. Cap off again. Rotor arm felt solid this time when removing it. Spindle or Bob weights sticking when hot?? Snaps back when given a jiggle. Stealing PAS oil from reservoir with screwdriver tip and feeding it down distributor drip by drip. Work it until it seems nice and free and springing back to centre. Cap on ( wish I had one ) start engine. Phone RAC to tell them I was going to try and drive somewhere safer. Was told the job would be passed to contractors and it would be at least an hour (on top of original time) but they would let me know if it was changed. From experience I know that the AA and RAC always say an hour. It may turn out to be less or it usually turns out to be multiples of an hour, but when you call them back for updates they will always say an hour. Wait or go for it? Seems good. 21 miles. Phone RAC tell them I've got it running, tell contractors to hold fire but not to cancel and I'll call again when I stop . . .either at home or broken down. Got home fine thankfully. Happy ending :D :D Phoned RAC before even changing out of wet clothes. I explained I didn't need them and had managed to get home safely. . Was told that the call out had already been marked as resolved and closed. Good job I didn't need them again! I wonder if I am now one on the 4 out of 5 call outs that they fix at the side of the road within 30 mins? Lol. Of course I'm still not sure if the problem is cured so another long drive needed. Daytime and in the dry next time. You can't beat a Cloud for an elegant waft around the New Forest which was as beautiful as ever in it's autumnal colours and especially in the warm and welcome sunshine. Selective memories are great! Lol. | ||

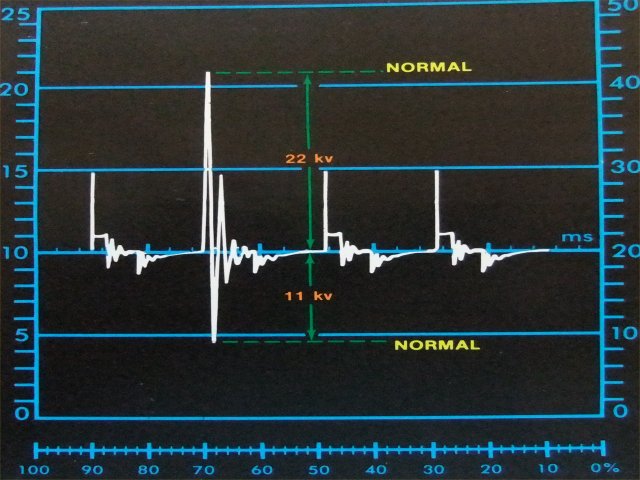

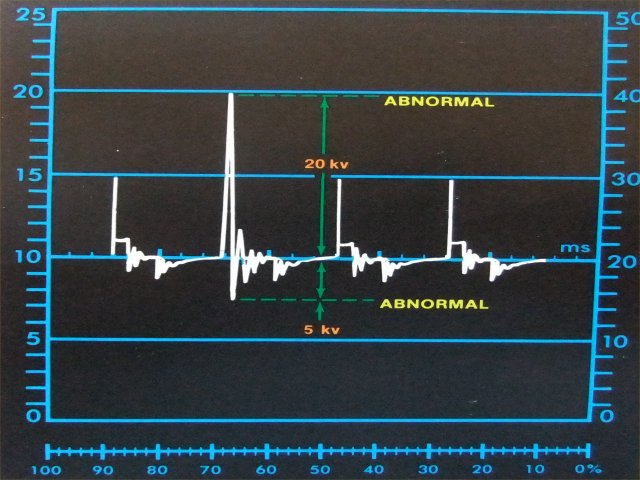

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1968 Registered: 9-2004 |

Patrick to answer your question "What do you mean by "scope the electrics"? This is the way of finding a fault with out all the trial and error of trying different parts to find the prob. When connected to the engine oscilloscope the following example is showing a normal display, this is carried out with the removal of one HT lead at a time. Look at the upward and downward voltage spikes. The trace of the downward spike should be equal to at least half of the voltage spike extending upwards.  The following example shows the abnormal failings. IMO check on rastor to confirm varriasion on different cylinders to confirm coil HT or carbon tracked coil tower ETC. OHMS test to confirm HT lead failing!  | ||

Patrick Francis Prolific User Username: jackpot Post Number: 266 Registered: 11-2016 |

Hi Patrick That sounds interesting. I think I can get a CRO on ebay for future use, but how do I connect it up? Is there anything else it is useful for? Thanks Patrick (the other one) | ||

Larry Kavanagh Prolific User Username: shadow_11 Post Number: 231 Registered: 5-2016 |

Paul's experience on the M4 reminds me of an FTP I had west of the Severn Bridge in a Mk11 Jaguar a few years ago. My AA membership had lapsed but I chanced them anyway but to no avail. I was stuck on the hard shoulder, lights getting dimmer by the minute and darkness and fog falling. I didn't know who to phone so I chanced the emergency No.112 or 999 where a very annoyed telephonist informed me in no uncertain terms that this was merely a breakdown and not a real emergency. I responded by saying OK, sorry, someone will probably crash into my rear before long and I'll phone back after the pile-up. It wasn't long before motorway towing services arrived to pull me to Cardiff Gate where I abandoned the car while I organised a trailer. | ||

Larry Kavanagh Prolific User Username: shadow_11 Post Number: 232 Registered: 5-2016 |

Faulty H/T leads may not always show up at idle or might cause a slight intermittent misfire but when they're put under load the bad connection usually becomes more apparent. Well done Jim - but since you're not going to the NEC meet at Birmingham and I am - I would be delighted to oblige by drinking that pint on your behalf! | ||

Omar M. Shams Grand Master Username: omar Post Number: 1699 Registered: 4-2009 |

Dear Larry, We will split the pint into two halves... we will each have half of Jim's for him..... | ||

Larry Kavanagh Prolific User Username: shadow_11 Post Number: 233 Registered: 5-2016 |

That's a very kind offer Omar, no doubt Jim will be most grateful to us for sharing the responsibility of looking after his interests! | ||

Jim Walters Prolific User Username: jim_walters Post Number: 202 Registered: 1-2014 |

Now if I could just get away from the shop for a few days....... I could collect on that pint myself. Larry and Omar, here in Western Canada beer is served by the pint or "glass". A glass is half a pint, so each of you can enjoy a glass on me. (Well Patrick really)  SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Larry Kavanagh Prolific User Username: shadow_11 Post Number: 236 Registered: 5-2016 |

Thanks Jim for your generous offer but I don't drink so maybe Omar would settle for a glass and I'll be happy with a packet of peanuts while you can retain the accolade as the one who correctly guessed the cause of Patrick's electrical problem. Bottoms up & cheers. | ||

Omar M. Shams Grand Master Username: omar Post Number: 1701 Registered: 4-2009 |

Gents - i am up for it.......................... a pint and a glass would be in order to celebrate friendship and good banter. |