| Author | Message | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1938 Registered: 5-2012 |

After over a year and about 3000 miles the points on my car are slightly pitted. This incidentally is with the ignition system running a high output 12v coil through points without a ballast resister. Pitting may have been less running at 9v however on my mileage replacing the points once a year is, in my view, a small price to pay for the benefits of bigger sparks. I am wondering what the groups opinion is on filing ignition points. I read conflicting views on the net. Some people say to always replace points as they are case hardened and sanding/filing them removes the hardened faces. Others say not to, as microscopic traces of sanding material, even after meticulous cleaning, leave high spots. On the other hand, points have traditionally been filed/sanded and the fact auto stores sell points files seems to also indicate it's ok. I'd be interested in any comments on the above. i.e. to file or not to file. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 776 Registered: 11-2015 |

Geoff, You can file points and they will work but because you are removing the plating ( not hardening) they won't be as durable. Just make sure they are parallel when you are done. | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1901 Registered: 4-2016 |

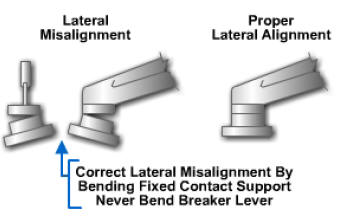

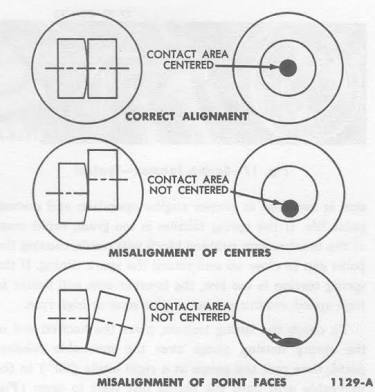

Geoff, I agree with Ross. It was one of the most important things I trained apprentices A) always confirm new spark plug gap before installing B) check alignment of new points before installing This is a plan view of misalignment.  Also view from the side elevation as well as shown below I pretty much always had to “tweak” points alignment before instillation. A lot of people always install new plugs & points straight out of the box without checking the above.  If a car I have been working on has not had points changed in years, I would always remove the distributor, clean and service it as well. Many times I would find the shafts seazed or frozen not allowing any vacuum advance to happen. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 786 Registered: 4-2015 |

Geoff.... If you do try to file, I would be interested in your observations. On a pre-war 20/25 that needed its points cleaned up I tried hand filing and found that they were SO hardened that the file did not have the least affect on them. There was no obvious evidence that they were plated, but were clearly VERY hardened. I then tried a Dremel with a steel cut-off wheel as a filing/polishing tool and even it barely had any results although did slowly smooth the surface out. I was impressed with how tenacious the surface of the points were which is logical since they spend their time resisting electrical sparking for hundreds of hours and simply pit a bit rather than completely disintegrating. . | ||

David Hughes Frequent User Username: wedcar Post Number: 74 Registered: 7-2004 |

Gents "Filing" is a generic term. The use of a fine carborundum stone or fine (1000 grit) emery paper is best for this job, remove as little material as necessary to remove the pitting. As Patrick says the alignment is also very important. | ||

Maxwell Heazlewood Prolific User Username: tasbent Post Number: 183 Registered: 9-2017 |

Ah....takes me back to my motorcycling daze when filing points etc was regarded as the norm  These days you can by very slim 'stones' not much thicker than a knife blade and slip it between the points faces and they will clean up the faces very well. As has been pointed out, points face alignment is critical to a solid 'make and break' situation to give good coil 'saturation'. You can also tell if a coil's polarity is wired wrongly by the direction of the 'pip' on the points face....which causes the pitting in the first place. It's always best to have a new set of points and a condenser on hand anyway....making sure all the associated wiring from the distributor to the coil is all in good clean condition. The whole ignition system is a chain of events and any weak link in that chain will cause grief. Save a lot of bother and go electronic  | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 279 Registered: 6-2005 |

For a points system there will always be some degree of pitting and this can be minimised by ensuring the points gap and plug gaps are to spec. Because of the usual intermittent use, our cars should go for years before the points need filing or replacement. Points files are OK but as Ross says ensure the points are parallel and the gap is correct when you've finished. The condenser is a critical component as in simple terms it maintains the circuit until the points are far enough apart to minimise arcing. While failure is not common it has to withstand 200 to 300 volts. It is cheap so can be replaced if suspect. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1939 Registered: 5-2012 |

Many thanks for all your replies. In answer to Christian's question, I too found the file just skated across the hardened surface of the points. I resorted to grade 400 sand/emery paper to remove the pitting and then 1000 grade to "polish" the surface. I wrapped the emery paper around a very thin strip of aluminum and used it between the points using the spring as a tensioner. I am satisfied they are parallel. The importance of correct alignment has been emphasized, however, as far as I can tell there is no facility for adjustment on these points. I am assuming on other cars the points can be separated by lifting the one off it's pivot and using shimming washers to get perfect alignment. On this contact set the points cannot be removed. However, they are perfectly aligned. Maxwell mentioned to save a lot of bother, go electronic. I do have a Powerspark unit sitting in my desk, however I am loathe to fit is as the first one failed. My guess is this was due to the heat in the distributor. Ambient temperatures here are often over 100F in summer and under a hot hood the engine compartment will be higher than that. It's quite possible the temperature within the distributor went higher than the design spec for the Powerspark unit, causing it to fail. This is why I am uneasy about going electronic again. I think the main lesson I've learned here for the future is, if I stay with points, buy and fit a new contact set. This has answered my original question of whether try and recondition my existing points. Thanks again for your comments. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1872 Registered: 9-2004 |

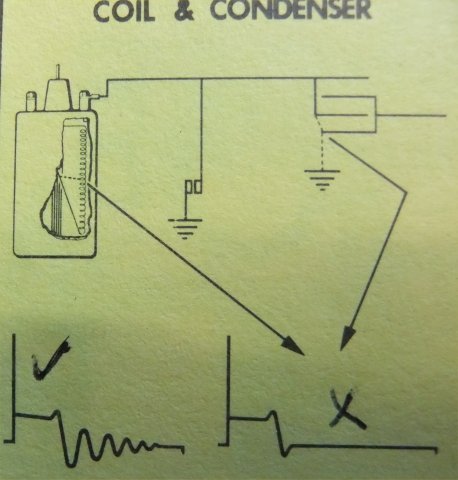

As john and Ross say ensure the gap is correct. This is set by the Dwell angle setting! When completed check the strobe timing. The contact breaker [make and break] can be ground to remove pitting, I still have a hand driven disc machine somewhere just for removing the pits. This is caused by a ropy condenser or oil fumes getting to the contacts. The condenser mfd capacity should be 0.18-024. something that not all new condenser are within limits from new. BTW for a quick clean up use 3M p1200! For those that use a scope for looking at faults.  | ||

ross kowalski Grand Master Username: cdfpw Post Number: 778 Registered: 11-2015 |

Patrick L, That wave form looks like AC WHAT.... just kidding. Geoff, I clean points all the time so I just did a little research ( a phone call actually and the internet) and turns out car points are not plated or hardened. The guy I called started by asking if I was talking magneto points or Kettering points. "So there's a difference?" I said. Read this for the internet part. Basically it looks like this. Tractors and cars used to have magnetos and ignitions that used contact surfaces on the points that were platinum or platinum / iridium alloy and could only be filed a couple times because you removed the plated surface. Modern high speed automotive points are usually made from tungsten through and through You can surface tungsten points until you run out of adjustment on the point plate without losing anything if you do it correctly. You can surface platinum points until you cut through the platinum without losing anything as well. The long and short of it is no harm in filing points, which is a good thing for me. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1940 Registered: 5-2012 |

Hi Ross Thanks for carrying out that research. It explains why there is conflicting information on the web. I'd resigned myself to a much shortened life span of the points however I now know this will not be the case. | ||

Christian S. Hansen Grand Master Username: enquiring_mind Post Number: 787 Registered: 4-2015 |

The more information generated, the murkier or more confusing or conflicting it becomes especially when considering what "used" to be and what now "is" i.e. the modern (often not to OEM standards) replacement stuff available. My experience related was with the prewar chassis and while those points originally "may" have been a plated alloy, the ones I have encountered had no obvious evidence of having been plated and while they may not have been "hardened" I suspect that source was thinking either surface hardened or case hardened rather than simply an EXTREMELY hard alloy. i.e. "hard" by nature rather than "hardened" after the fact. Even the repro points for the prewar cars are expensive (well at under $100 they are not cheap) and so the inclination is to make them last by surfacing, if not filing. Fortunately they are easily removed and that work can be done conveniently on the bench. . | ||

gordon le feuvre Prolific User Username: triumph Post Number: 245 Registered: 7-2012 |

In the sixties when I started my apprenticeship, filing points were the norm. We were accessed on surface angle alignment! Now my view is, for the cost why bother except in a "failed to proceed moment" | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1941 Registered: 5-2012 |

Hi Gordon I agree with you. I think my notion of filing the points being the norm was based on my previous experience of maintaining my classic cars back in the 70s. Nowadays, just replace them. It took me ages to sand them down and I still have a small crater on the one of them. However, the engine is running well at the moment - will be interesting to see how long they last. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1873 Registered: 9-2004 |

Not very long if your condenser is shot! | ||

ross kowalski Grand Master Username: cdfpw Post Number: 779 Registered: 11-2015 |

This should solve the condenser problem. http://www.brightsparkmagnetos.com/easycap/universal/index.htm | ||

Maxwell Heazlewood Prolific User Username: tasbent Post Number: 187 Registered: 9-2017 |

>>>>....Maxwell mentioned to save a lot of bother, go electronic. I do have a Powerspark unit sitting in my desk, however I am loathe to fit is as the first one failed. My guess is this was due to the heat in the distributor. Ambient temperatures here are often over 100F in summer and under a hot hood the engine compartment will be higher than that. It's quite possible the temperature within the distributor went higher than the design spec for the Powerspark unit, causing it to fail. This is why I am uneasy about going electronic again.....>>>> Yes Geoff....my own experience over the years has been that electronic systems that have their electronics mounted to the distributor or the engine will fail because of heat issues. I have found the best ones are those with either a simple reluctor unit or optical trigger mounted in the dist. with the electronics mounted remotely. Set up properly as the manufacturer intended and they will last indefinitely  | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 533 Registered: 10-2008 |

We have had to replace accuspark units( similar to powerspark), but have found Pertronix more robust. I keep a spare accuspark unit in the car, for the ones still on accuspark.I also have a complete points base plate built up for the S1 in the car in case pertronix fails. Worryingly, we have had 4 coils fail when hot recently on different cars. Mark | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1942 Registered: 5-2012 |

The thing is, England has a much more moderate climate which probably helps keep under bonnet temperatures slightly lower. If your local clime regularly produces summer temperatures of over 100F then that is where I believe the problem lies. There's no doubt that electronic ignition is the best and I might look into systems where the electronics are mounted remotely as Maxwell has suggested, perhaps even in the passenger compartment. I've just completed my "annual" tuning and the one thing I'm pleased about is I paid slightly extra and bought a really good timing light. The carburetor adapters I bought from britishtoolworks.com have also been an absolute boon. My view is it's really worth making the investment even though these tools are only occasionally used. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 535 Registered: 10-2008 |

Geoff, just purchased a carb set from Kelly, will try these out shortly. In the UK we consider it excessive heat at 80F ! Summer is nearer 70F. Mark | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1943 Registered: 5-2012 |

Hi Mark Fabulous tool. Couldn't resist putting the pic up from yesterday's tuning session. The gauges appear blank because of the flash reflection. One of the things I really like about Kelly's adapters is they are so easy to use. I used to use a flow meter which meant I had to remove the U shaped air ducts from the carbs, which was a real hassle. I would guess the adapters method is also more accurate.  | ||

richard george yeaman Grand Master Username: richyrich Post Number: 967 Registered: 4-2012 |

I agree the gauges are the best investment I have made lately. Richard | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 537 Registered: 10-2008 |

Can someone jog my memory as to how to adjust the carb sync at running speed, not just at tickover ? Mark | ||

ross kowalski Grand Master Username: cdfpw Post Number: 788 Registered: 11-2015 |

Mark, Carbs synced at idle really should be synced at rpm. If not, something is amiss. I usually rev the engine between adjustments but I,'m not sure why I do this. I guess I am thinking it assures the butterfly valves and or slides are in their actual non sticking positions. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 539 Registered: 10-2008 |

Ross, sadly my son has discovered if there is any wear in the carbs they will be out of sync above idle and need adjusting to get the best of compromise. The worst culprit is the piston and dashpot assembly and the misbalance caused by wear can be significant on a rolling road test. This also affects fuel mixture balance over the rev range.New carbs are the real answer if seeking perfection, and the owner has a deep pocket ! Mark | ||

ross kowalski Grand Master Username: cdfpw Post Number: 789 Registered: 11-2015 |

Mark, Just out of curiosity, how far out were the readings at speed? | ||

Maxwell Heazlewood Prolific User Username: tasbent Post Number: 192 Registered: 9-2017 |

Regards the trusty SU's, it's rare for the dash pistons to have excessive wear unless they have been neglected or badly maintained which is frankly quite often the case on both counts. Cleaning the pistons and bores give the piston lands and the bores a light polish with silicon spray. Check the condition of the needles and their respective jets, making sure that the pistons land squarely with an audible 'click'. Quite often the jet's are misaligned causing sticking and excessive needle wear which leads to heavy fuel consumption. A dirty gas reticulation system will help to foul up SU pistons very quickly! Before worrying yourself to death over piston synchronization....remember, this is controlled by throttle butterfly syncing! Get those correct first, then work up from there. Don't use heavy grade oil in the dashpots....you get best results from normal auto trans fluid. | ||

Alan Dibley Prolific User Username: alsdibley Post Number: 144 Registered: 10-2009 |

I assume that it is common knowledge that the "cylinders" (the aluminium bell-shaped covers) in which the pistons slide have a right way and a wrong way to be installed. They are matched to the base during manufacture. If installed the wrong way round there may be piston-to-bore contact. Maybe someone doesn't know that? Alan D. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 540 Registered: 10-2008 |

My son restores and prepares pre war cars that are competed and every HP counts.The effect of carb wear is surprisingly significant. I will have a play with my MG when I have time ,and ascertain how much carb in balance develops as revs rise having used Kellys tool to balance at idle, balance again at say 2000 rpm held on the throttle pedal, and then at 3000 and 4000 rpm.The carbs have about 75k miles use. Mark | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1882 Registered: 9-2004 |

The mixture set up on the carbs is most important after the synchronization of carbs. As we all know one carb feeds two cylinders only on each bank of four. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 544 Registered: 10-2008 |

an update, we balanced the Shadow (1) carbs, and achieved exact readings at idle. At 3000 rpm, there was a 30 thou discrepancy. More important, at just above idle, one carb was opening faster than the other. The cause was wear in the linkage pin ue37334 .Duly adjusted, balance is perfect at 3000rpm and piston lift is balanced.Also set up carbs on S1 and Sprite. This tool is invaluable. Mark | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1898 Registered: 9-2004 |

Mark, what was the overall MPG before adjustment. Are you getting a better MPG now. Best I have ever had was 18mpg driven gently on a 250 mile run. CO was 3.7% HC was not checked at the time. LPG is another ball game! | ||

Trevor Pickering Experienced User Username: commander1 Post Number: 43 Registered: 6-2012 |

I have just ordered 2 Gunson Colourtune sets and will use them after balancing carbs using Kelly's gauges. For those of you who may not have seen Colourtune before, a brief explanation: The Colour tune unit is bascily a spark plug with clear glass where the white ceramic usually is so you can see what is going on when the spark ignites the air/fuel mixture. The ideal mixture is obtained when the flame is Blue. Check at two or three points across the rev. range. An orange flame is a rich mixture and a white flame a lean mixture. I have used one of these in the past to good effect. It shoul help geting the mixture spot on. Trevor Pickering 1964 SC111 | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 552 Registered: 10-2008 |

Patrick, it averaged 13.5 mpg over 11 years when in daily use, and I generally drive quite "spirited", hence the Bilsteins and uprated rollbar. I have a nice 600 mile round trip next week, we will see what the mpg is. Mark | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 553 Registered: 10-2008 |

630 miles completed, A34, A303,M5, A30 to Falmouth Return. 15.9mpg driving on the speed limits, Shell 99 octane fuel.. Engine perfectly smooth and responsive with smooth idle, despite the unusual UK heat. Mark | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1970 Registered: 4-2016 |

If we ignore the US / imperial Gallon thing.. That’s roughly 16 litres / 100km (for us Metric folk) Which I must say is very good | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1919 Registered: 9-2004 |

Mark interesting figures not bad and now for a worked out figure for the CO% 4.25 not bad, IMO could be a little better say co% 3.8 4.0 max. I note that the Phantom V1 runs 4.25 max at 600rpm. The Camargue runs 4.5 max. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 554 Registered: 10-2008 |

Incidentally Patrick, I fitted the discounted Viscous coupling you advised me of. It worked perfectly- excellent. Mark | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1975 Registered: 4-2016 |

Mark, I also fitted one of these viscous couplings. A huge difference and all vibrations gone when fan comes to life. Mine must have been a bit ordinary for a long time. Gave everything a nice new coat of paint while off as well. My fan was basically back to bare aluminium. The best economy I have achieved from SRH12255 is 19 litres per 100kms. Again if we ignore the US / Imperial gallon that is roughly 13mpg That was with a heavily loaded car and 4 people on a trip to Canberra and back. I,m happy with that. | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 555 Registered: 10-2008 |

Patrick, I make it near 15 mpg UK. Very acceptable Mark | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1920 Registered: 9-2004 |

Mark, btw going on mpg with an older type car with a long run, to calculate the CO% emissions the magic number for petrol engines 6760. Divide 6760 by the cars mpg this will give the CO% this will not work on the more modern cars with CATs etc. Old diesels have a magic number of 7440. Likewise will not work with moderns with DPF etc. | ||

Patrick Ryan Grand Master Username: patrick_r Post Number: 1976 Registered: 4-2016 |

I’ll take that MPG Mark  |