| Author | Message | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2492 Registered: 6-2009 |

No, I don't need help understanding how to do this in the big picture, or even how it works, but am wondering if there is a good place "top side" of the engine where I could measure this? I am using a Neiko 20713A Digital Tachometer, which seems to be well-rated, but the detecting distance for it is 50-500 mm. The distance from where one can safely get an aim on the engine flywheel on the top side of the engine bay is definitely further than 500 mm (50 cm) away and getting down on the floor to try to measure from that angle is inconvenient (and may be impossible in the garage itself - space is tight). If anyone has suggestions regarding where one could attach the small square of reflective tape somewhere that allows relatively easy aim from a "standing next to the engine bay" position please offer them. There's got to be something that's rotating at the same speed as the flywheel and I want to make sure that's what I select as the target. It sure will make it easier to do my timing when I can check the engine speed and adjust same without having to contort myself and/or drop to the floor to try to get a reading from the flywheel. Brian Side Notes: The climate control system appears to be working just fine and I'm getting heat when and where I expect to get it from and the AC compressor is running as expected. The accumulators have surprised me, too, in that they've got a decent charge after sitting for four years (for the one I rebuilt) and much longer for the other. I'm getting 28 and 32 pumps before warning lights illuminate. Also, has anyone found a good way to "highlight" the timing marks on the flywheel? I marked the 15° mark with white paint a couple of years ago, and had tried a thin piece of masking tape for TDC which worked well for a while. It would be nice to have a system of marking that's durable and allows for very easy differentiation of the various marks when they're under the timing light. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1597 Registered: 9-2004 |

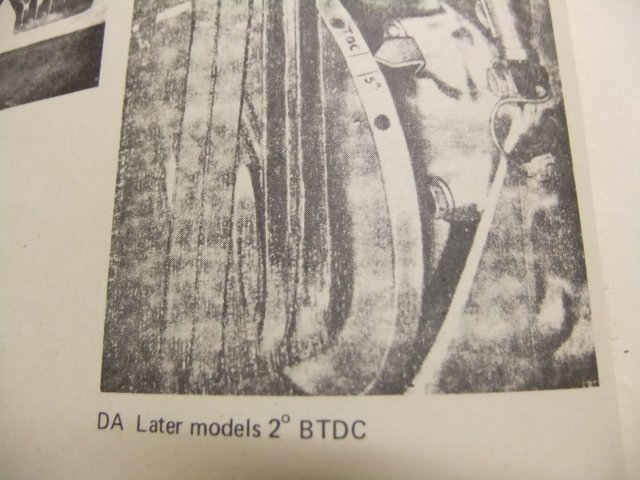

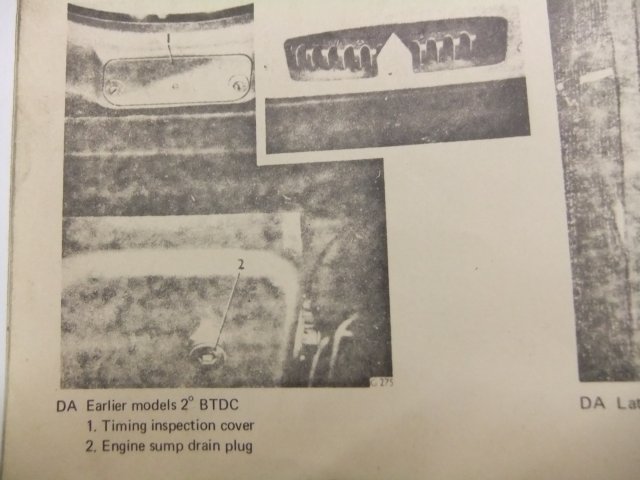

Thought the later cars used the damper for the timing!!!!!!!................small pix:  | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2493 Registered: 6-2009 |

That would be the thing with the marks, which an awful lot of people other than myself have referred to as "the flywheel" on these forums on many occasions. This has been the thing, regardless of what one elects to call it, with the timing marks on it on the SY series cars. It's awfully difficult to use a photo tachometer aimed at this or anywhere near to it from the top of the engine bay, hence my question. Getting a visual on it with the timing strobe is a cinch since careful aim is not required. Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1598 Registered: 9-2004 |

Brian if the damper is referred to as the flywheel what is the flywheel called? The early type timing shown in the flywheel pix.  BTW are you sure 15% mark. With the strobe you wind in 15% @ 1200RPM and use the TDC mark. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2494 Registered: 6-2009 |

Patrick, I refer you to Chapter U of TSD4200, PDF page 524 since we're dealing with a car that was destined for the USA. I don't know how one would interpret the instruction, "If the timing pointer does not coincide with the 15° B.T.D.C. mark on the crankshaft damper then adjust the timing as follows," other than that the pointer should show as pointing to the 15° mark. I am not going to get into another of your pissing matches over terminology. This piece is very commonly referred to as "the flywheel" when people refer to timing. Feel free to make the translation rather than being a pedant about something that really could not matter less. Also please refer to the documentation for the model and year under discussion before bothering to post images from documentation that does not apply. You know very well where you can go to consult this documentation: rrtechnical.info. Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1599 Registered: 9-2004 |

SUN, Snap-on data could not be more USA, that is what I used. when I have time will look at the RR info. I cannot believe that RR say make up your own 15% mark and use a strobe with no settings! Cripes you would be doing the centrifugal and vacuum advance setting checks taking days if it was at all possible! | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1942 Registered: 6-2006 |

Tipex or white out. Don't use the timing mark for the rev counter. Paint a big one at 180. If the counter can't catch it then bin it and get a strobe with a H.T. Rev counter combined. . The easiest place on top of the engine will be the rotor arm. ;) Front damper or pulley Brian. Flywheels also have timing marks and if things are very confusing it's good to double check the pulley and the flywheel match. Early cars only had flywheel markings  They had fluid dampers so timing marks on them were pointless. They had fluid dampers so timing marks on them were pointless. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1600 Registered: 9-2004 |

Brian yes your "BAD" timing marks stated quote "direct the flashing light of the stroboscope onto the CRANKSHAFT DAMPER marks and timing pointer. Nothing about flywheel however go to Chapter E of TSD4200 and talk about removal of "FLYWHEEL" RR can not have two flywheels can they. Back to your prob, have used a mirror in some cars that are difficult to get to the marks close up. To carry out the RPM above the engine use a meter like this multi purpose one https://www.harborfreight.com/lcd-automotive-multimeter-with-tachometer-kit-95670.html. Use an advance type of timing gun to set the timing using the TDC mark on the damper. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 617 Registered: 11-2015 |

Patrick, Not a harbor freight fan, but that's a new digital dwell tach for 35USD. Might run down to HFS and get one myself. The one I use is analog , non self ranging and has capacitors assembled by dinosaurs. Probably time. Brian, I'll report back how it works I'll compare it to my scope and not the dwell tach as the unit is of questionable accuracy. As for the part on the front of the engine, it's either a crank pulley ( solid metal) or a harmonic balancer ( two metal parts separated by a rubber damper ) It's likely the latter, but it is not a flywheel. Another easy way to do rev counting is with a cheap digital hour meter. They pick up on the #1 HT lead and indicate the rpm. Their sample rate is slow with like .5 second refresh rates, but they are accurate. Good explosion counting. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2495 Registered: 6-2009 |

Paul, I believe I used typing correction fluid to highlight the 15° on the crankshaft damper [I hope Patrick L is happy now], but it's getting hard to find. I'll have to look around to see if I can get either a correction fluid pen or, perhaps, a white paint pen. It would have been nice if these things had been paint impregnated to begin with then you could just wipe off the crud and be ready to go. When the lines get rusty, though, they just disappear. I'm not quite sure what you mean by "paint a big one at 180" but I'm interpreting that as creating one on the opposing side of the crankshaft damper, which is what I did (but using the reflective tape included with the tachometer), but you can't get close enough to that, at least not conveniently, to take a reading with the Neiko. I was hoping that something like the fan or the AC compressor (back side, which turns constantly) might somehow spin in 1-to-1 correspondence with the engine speed. There are lots of things that are spinning but I'm not sure which, if any, are spinning at the same rate as the crankshaft damper and thought someone might know off the top of their head. For me it's a lot easier to tell exactly which mark is which when I color code them as well. I had TDC in bright pink which reflected beautifully under the timing light as does pure white. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1839 Registered: 5-2012 |

My personal view is to spend the extra and buy a quality timing light. e.g. https://www.amazon.com/INNOVA-5568-Pro-Timing-Light-Tool/dp/B000EVU8J8 Harbor Freight sell some great tools but often their electronic devices are very poor. One of the big problems with a cheap timing light is they do not pick up the HT pulses through the sensor properly. Check out the customer reviews on the timing light pointed to in Patrick's entry. They are not good and mirror the problems I have had with cheap timing lights. Brian could use the compressor pulley to read rpm on his digital tachometer, and then do the math. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2496 Registered: 6-2009 |

Patrick L:

Uh, I'll follow the instructions in TSD4200, and to the letter, as I have been trying to do. Believe it or not I actually consult the workshop manual and pore over it, carefully and thoroughly, before I undertake these sorts of tasks. Your method and Crewe's method are not congruent. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1840 Registered: 5-2012 |

Brian - I used white enamel from Michael's hobby store. 85 cents for a small bottle. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2497 Registered: 6-2009 |

Geoff wrote, in part:

Indeed. Which is another option that would be perfectly fine if anyone knows what "the math" happens to be. If the compressor pulley were to rotate at 3 times the speed or half the speed (or whatever) of the crankshaft damper it's a simple matter to do the math and it's simple to target with a photo tachometer "up close and personal." Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1841 Registered: 5-2012 |

Hi Brian It would be a simple ratio between the circumference of the damper pulley and the compressor pulley. Taking the measurements would be a bit fiddly but not impossible. Geoff | ||

Omar M. Shams Grand Master Username: omar Post Number: 1356 Registered: 4-2009 |

Dear Brian, My experience tells me that trying to set the timing on the damper pulley is in itself not 100% perfect. I have always found that the mark bounces around a little bit. It is never rock steady. For this reason I would not go to another location as you can end up losing accuracy. I think a one-off purchase of a good timing gun will be a wise investment and that will allow you to set the timing from the conventional opening that everyone else uses. That is not to say that your options will not work - of course they will - but the hassle factor and the end result ought to steer you towards a replacement timing light. Good luck buddy. Omar | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1601 Registered: 9-2004 |

Brian, but how much interference belt movement rotation slip will result. Not in TSD4200!!!!!!!!!!!!!!!!!!!!!!!!!! But,"I'll follow the instructions in TSD4200, and to the letter, as I have been trying to do" "simple to target with a photo tachometer "up close and personal." Not with the flywheel in place of a damper pully, a big error even for the DIY .......... Who said: "Your method and Crewe's method are not congruent" But mine work yours it seems do NOT. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2498 Registered: 6-2009 |

Patrick, Sod the *$#&# off! I am sick to death of your putting words in my mouth and techniques I am not using out there as if I were. It is clear, from almost the outset, that I misused the term "flywwheel". It was also quite clear, after your first image post of the crankshaft damper, that I cleared up that this is exactly the thing that I was aiming the timing light at regardless of my error in terminology. For most people that would have ended it, but not for you. You are a freakin' pain in my arse and I really, really don't need or want the kind of help you wish to offer. This will be my final response to anything you wish to post, either to me or to anyone else. I don't have time for your antics, nor the patience to put up with them. Brian | ||

Mark Aldridge Grand Master Username: mark_aldridge Post Number: 468 Registered: 10-2008 |

I have the earlier version of this; absolutely brilliant. http://www.ebay.co.uk/itm/AccuSpark-Ignition-Chrome-Finish-Adjustable-Strobe-Timing-Lamp-Light/391346184301?_trkparms=aid%3D222007%26algo%3DSIM.MBE%26ao%3D1%26asc%3D20160908110712%26meid%3D3fd19ed 0715c41b3b9e9d18a292703a2%26pid%3D100677% 26rk%3D14%26rkt%3D30%26mehot%3Dpp%26sd%3D180699064006&_trksid=p2385738.c100677.m4598 Mark | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2499 Registered: 6-2009 |

Mark, Looks incredibly similar to the Innova 3568/5568 (which are the same thing, essentially, the 5568 has a beefed up case and one or two additional functions). The metal case is incredibly similar to my classic Sears model:  which feels very solid in the hand compared to the more typical plastic cases (which the Innovas have). Brian | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1943 Registered: 6-2006 |

But the rev counter is the important part that is missing on yours Brian. Also - yes the damper was beautifully marked with white paint in the lines AND the letters. Of course!! Unfortunately your car's custodians have neglected the monthly wash and wax to protect it. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2500 Registered: 6-2009 |

Paul, Oh, I am aware that the rev counter is the crux of the matter here. What I'd like to know is how one did keep track of the RPMs in the car when doing timing "back in the day" before all of the handy gizmos we all take for granted and now integrated into the one unit existed. They had to be getting the RPMs in some way not integrated with the timing light since the "official instructions" tell you to look at the timing at 1200 RPM (approached from above) where the 15° mark should be aligned with the pointer and at 650 RPM, where it should be somewhere in the range of 7° to 13° [which is a pretty wide range]. I thought there might be some obvious way to do this that I was overlooking, hence my question. It only made sense to believe that some "pre-laser" equivalent of a hand held tachometer was used. Ignorance is curable while stupidity (or willful stupidity, anyway) is not. As far as the "monthly wash and wax" it appears that the bulk of the world's custodians are remiss on that count, at least if posts regarding not being able to read the marks so conveniently etched into the crankshaft damper by Crewe are any indication. If by far the easiest way to accomplish the goal at hand is by buying a new high-tech (for some value of high-tech) timing light then that's what I will end up doing. Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1603 Registered: 9-2004 |

"I'll follow the instructions in TSD4200, and to the letter, as I have been trying to do." You will have to get a move on at this rate. Back in the distant past the tune up including carb set up was about an 1 hours work. This pix is an early SUN setup in the late 30's in the US.  | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1944 Registered: 6-2006 |

Originally an analogue Dwell and tacho gauge was used. Then digital. Both just plug onto the Coil / battery / HT lead / inductive clamp over the A1 plug lead A very quick look on Ebay shows lots of cheap tachos. Yes by far the easiest way is a strobe timing light with dwell, revs, and adjustable timing . 1. You set the gun to the required setting (15 degrees BTDC I think you said - but read the manual and advance from the figure stated in the 70s /80s as necessary to allow for unleaded fuel which burns slower). 2.Point the strobe at the timing mark. 3.rev to speed. 4.Rotate the distributor until the light and mark are flashing on TDC. Simple and fast. Is it worth the extra expense? Only you can say. I feel like this project has been ongoing for a couple of years. I don't think some trial an error would take much longer at this stage. Get the car hot. Take to 1200 rpm (guestimate). Twist the dizzy to advance and retard it until you find the highest revs, move it back a bit. That will be as close as it will get for that tank of fuel, air temperature, humidity, density. Road test and tweak once the rest of the car is done. | ||

Jim Walters Prolific User Username: jim_walters Post Number: 128 Registered: 1-2014 |

Brian, an analogue tach-dwell meter that clips onto the coil low tension leads is the most basic and easiest means of registering RPM's. Probably not as accurate as a digital one but should work fine for diy. I thought you had one you were using for dwell readings. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1842 Registered: 5-2012 |

Paul The method you have just described does not require a timing light or even monitoring of the timing marks. I can see the advantages over just setting the timing according to the spec, as it automatically takes into account fuel, air temp, humidity and density, as you mentioned. Is this your prefered method? Geoff | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1945 Registered: 6-2006 |

The was and wax was tongue in cheek. But yes the marks were there. I've had a customer with a terribly starting Shadow I who has had loads of starting / running issues. Was 100% sure he had it timed right - but it always ran better adjusted by hand. 2 years later he has just found an extra timing mark (and correct one) - Runs MUCH better tuned to that one.  Also a quiet word of warning for anybody else wondering about changing cars from standard. Sometimes it is much better to spend a bit extra, get original spec parts, and only spend an hour doing a job - than chasing dragons trying to improve on what is now a reliable system - and being stuck with a non-runner for years. Something to watch. Good luck  | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1946 Registered: 6-2006 |

Geoff, If an car comes in for the first time or it's running badly, I like to check that it is set right first , then adjust from there. You must remember a couple of things though. . . I've been Tuning RR&Bs cars for 40 odd years. The cars I work on (post war mainly) have been going out of spec for up to 70 years, (Distributor wear, carb wear, cylinder wear, valve ware, etc) so tuning to the book may not be the best setting. But start at the book settings and go from there. If you do fine tune by ear, keep a book of what you adjust and the effect it had. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 618 Registered: 11-2015 |

Patrick I bought that dwell tach this morning. Works a treat. It even comes with a K thermocouple along with a set of probes and a inductive pickup.  I checked it against my analog dwell tach and it was right on. I also tested the RPM and VDC against the silly scope and it was RIGHT on. Geoff mentioned that people gave it bad reviews, but people kind of aren't qualified to work on cars, so it might be that. Here's a video on youtube of someone reviewing that exact meter. https://www.youtube.com/watch?v=9HWCyNvmUv8 It's almost entirely incorrect information. If you don't own a dwell tach meter or don't own a small one, this is a good buy at 29 USD. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1947 Registered: 6-2006 |

A Bargain Ross :D Bad Reviews . . . . What I find is that the internet is full of bad reviews - most often for silly reasons - because that's all people can be bothered to post. Same with car problems, people think that head gaskets / or ignition modules / or brake systems / or whatever fail all the time. Because people only write about the failures. I was talking to somebody recently who had been going to a restaurant for 10 + years. Always brilliant. Last visit he had a bad meal and a bad waitress. Did he chat to the manager? Did he email the manager? Nope - he put it on Trip Advisor!! I asked if he had diligently put every GREAT meal that he had there on Trip Advisor? He looked at me like I was mad. I hope he thought about it afterwards though! I'll shut up now! LOL :D | ||

ross kowalski Grand Master Username: cdfpw Post Number: 619 Registered: 11-2015 |

Paul, How true. case in point For the love all that is good and holy, 7% of people gave the 10" vise grip a bad review. What?@?! Those people are not just ignorant I can assure you. I have an almost infinite faith in people becoming more learned, but bad reviews for vise grips? I almost, but not quite, want to read those bad reviews to probe the depths of that hole. Next I'll check the bad reviews on Mackinosh rain coats, Glenlivet, puppies, and pencils. What in the planet is wrong with people. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2501 Registered: 6-2009 |

Paul Yorke wrote, in part:

I have repeatedly said, in regard to both automotive forums and computer support forums, if one were to use these as an accurate metric regarding the functionality of either subject item you'd believe that cars and computers both never run at all or constantly malfunction when they do. When I point people to these forums, or similar, it's always with the proviso that they exist primarily to assist people who are encountering difficulty. No one writes to forums (as a general rule, anyway) to document their many happy hours of motoring or surfing the net (or whatever one might prefer to do with computers). I remember reading reviews for an aftermarket key fob and door and/or boot locking/unlocking system that excoriated the instructions because they were not written with a specific make and model in mind nor for the average DIY-er. I wrote a counter review where I took that idiotic one down, point by point, and mentioned that it helps if one has a basic understanding of basic principles and notation for wiring and also of how the system in one's own car actually works from the switches. The idea that any set of instructions can be "all things to all people" is ludicrous to begin with, and in this situation even more so. Ross, if ever we are in the same place at the same time and copious quantities of gin (or other spirit of choice) is available perhaps we can enumerate a list of what "is wrong with people." Brian, who loved your line about bad reviews on puppies, in particular | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1843 Registered: 5-2012 |

As the person who prompted the "reviews" sub thread I have to say I agree with everything said here. I was being lazy and should have related the whole story of how I bought a timing light from Harbor Freight and it would not pick up the HT signal properly and was giving spurious results. I returned it and paid the extra $70 for a good quality timing light with tacho, dwell angle and offset capability. That old RR adage about the quality being remembered long after the cost is forgotten applies here. I took the short cut and pointed to the bad reviews which echoed my findings. I agree that bad reviews have to be balanced against all the factors given above. However, here's one company for which bad reviews are definitely to be taken seriously. When I lived in Las Vegas I had a couple of dealings with a company called "The Touring Shoppe" which specialized in Rolls'. This was an awful company. Luckily I recognized this before I entered into any financial deals. I smile at the google reviews for this Company and believe every word written, except for the 5 star reviews which I suspect are plants. ,https://www.google.com/search?ei=7dj_WfnOFZjIjwP_yYvICg&q=the+touring+shoppe+reviews&oq=rolls+royce+shoppe&gs_l=psy-ab.1.1.0i71k1l4.0.0.0.9375.0.0.0.0.0.0.0.0..0.0....0...1..64.psy-ab..0.0.0....0.DRvjcT8GUuY#lrd=0x80c8c404f4e3b3f3:0x9080589bb9fe0703,1,, Geoff | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1604 Registered: 9-2004 |

Going a stage further for the timing etc it is best carried out with all the checks, this is for the timing curve this will show up many problems if present. The first is the setting of the centrifugal advance starting at 0% at say 700RPM if showing a any variation then check the bob weight springs tension ETC. The next check is 11-15% at 1000RPM if ok go to the next check 41-46% at 4000RPM ending total centrifugal degrees. All the the above is with the vac advance disconnected. The next check is total centrifugal degrees with the vac advance connected at 49-60% 4000RPM If not ok then check the vac unit diaphragm or vac hoses etc. Other centrifugal degree failings can be sticking bob weights and wear. Different speck for different models. There is more but the main check before all the above is carried out is to have the DWELL set correctly. Ross, pleased all is well with your meter, did look good value. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 622 Registered: 11-2015 |

Patrick L, The dwell on my dizzy is the externally adjustable kind, I'll try and film or take photos of setting the dwell on the RR this weekend when and if I get a chance. | ||

Mark Luft Prolific User Username: bentleyman1993 Post Number: 131 Registered: 10-2016 |

Brian said: Also, has anyone found a good way to "highlight" the timing marks on the flywheel? I marked the 15° mark with white paint a couple of years ago, and had tried a thin piece of masking tape for TDC which worked well for a while. It would be nice to have a system of marking that's durable and allows for very easy differentiation of the various marks when they're under the timing light. Brian, I have used in the past a "timing tape" which is available from Jegs or any other speed shop.This tape goes around your balancer and with a strobe timing light will give accurate readings for TDC and other degrees needed. You could even test the centrifugal advance using this. Good luck! | ||

Jim Walters Prolific User Username: jim_walters Post Number: 129 Registered: 1-2014 |

This is what we use, 'Lacquer Stik' fill in paint. https://www.ebay.com/itm/Lacquer-Stik-Paintstick-White/401281483772?hash=item5d6e3d83fc:g:i9kAAOSw4A5YsEMz It is a hard stick of almost dried paint that when rubbed over the marks fills them in with white paint. Scrub marks with a small fine wire brush first then degrease and rub the stick over the marks to fill them in. Let dry a while then rub off the extra paint with a soft cloth until just the marks are highlighted. It lasts a long time if the area is cleaned well first. This paint stick is also used to highlight the ignition switch lettering when refinishing the face of it. SRH8505 SRC18015 SRE22493 NAC-05370 www.bristolmotors.com | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2502 Registered: 6-2009 |

Mark & Jim, Thanks to you both for the recommendations. I actually like the idea of the Lacquer Stik since it should fill in those fine lines really well such that you can not only see the line markers but the degrees BTDC that each mark is for. I know that the white mark that I have for the 15 degree line shows up quite well, but is a bit fatter than the actual etched line is. Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1606 Registered: 9-2004 |

"I know that the white mark that I have for the 15 degree line shows up quite well, but is a bit fatter than the actual etched line is." Well for sure the above is not in the TSD4200 manual, sloppy error of + or - degrees may do for some with a fatter line. Those who use an adjustable strobe light can dial in the necessary degrees and just use TDC mark. With the RPM set to the necessary figures with the strobe degrees dialled in using the TDC Mark on the Damper and the fixed pointer, doing a timing curve check is a real cinch and a bonus for showing up other faults. 3 days! and counting. | ||

Patrick Francis Prolific User Username: jackpot Post Number: 199 Registered: 11-2016 |

Hi guys On SRH 17968 according to any info I look up, I only have th option to set timing at idling, not at various rpm which is the norm on other cars. Works fine though, using the rule of 1degree retard for every Octane below 100 which is what mine was designed to run on. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1608 Registered: 9-2004 |

Hi Patrick F your car being a 1974 the following data is given: The centrifugal advance starts at 0% at 500 RPM 1st intermediate is 5/900RPM 2nd intermediate is 20-24/2000RPM Total centrf ends 34-38/3000RPM. The distributor has not been fitted with vac advance on this model going by the book. A defective centrifugal advance [timing curve] can result in the engine timing being out of time at certain engine speeds causing loss of power, overheating or even engine pinking [spark knock]. My SS1 was built a few hundred before yours. Hope this helps. | ||

Patrick Francis Prolific User Username: jackpot Post Number: 200 Registered: 11-2016 |

Excellent, thank you Patrick. | ||

ross kowalski Grand Master Username: cdfpw Post Number: 623 Registered: 11-2015 |

Patrick L, The dwell on srh8844 is 26.8 degrees, right on target. The meter works pretty well. https://www.youtube.com/watch?v=YlBU0Dlku-w | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 1611 Registered: 9-2004 |

Ross good to hear all is ok. The dwell variation can be 26-28 with different revs, this is for shaft and breaker plate movement and cam lobe variation. The RPM inductive pickup with my meter sometimes is intermittent and so I have to turn the pickup 180% For nine years of use it has been good.  | ||

ross kowalski Grand Master Username: cdfpw Post Number: 625 Registered: 11-2015 |

Patrick, Same ea100 pickup with a Vauxhall Corsa on it, good to know I have nine years of service to look forward from it. |