| Author | Message | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2301 Registered: 6-2009 |

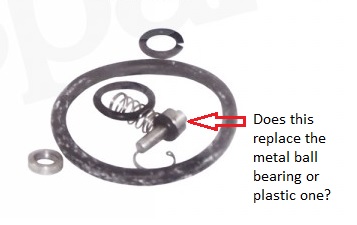

Hello All, If you take a look at the web page for the RH2619P Accumulator Rebuild Kit it shows what's below as the contents of the kit other than the diaphragm, and I've annotated the photo:  and their descriptive text reads, "This kit includes a modified valve which replaces the original nylon ball." Unless I've taken leave of my senses (and that could be) I could have sworn that it was the small metal ball bearing that is used on the inside of the accumulator and that acts as the primary valve beneath the spring and circlip that holds the spring in place. The secondary seal is the O-ring that's slipped inside the port cap and the tertiary seal is the plastic ball that gets rammed into the opening when the cap is screwed on and deforms slightly to form a seal (in theory, anyway). Am I completely off base about this or is there an error on the FS page? I've decided that ditching the tertiary seal for hydraulic thread sealant, e.g. Loctite 545, on the port cap threads is far more effective, anyway, but inquiring minds . . . The FS replacement for the primary valve of that "pin and O-ring" in place of whichever ball is a thing of engineering beauty and a stroke of brilliance because it actually works! Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1704 Registered: 5-2012 |

Hi Brian I think you have definitely found an error in the FS product description. It should be reported to them as the kit does not come with instructions (at least it did not in 2012 when I fitted the parts to my spheres.) I'm just wondering if that pin is long enough to dislodge the (erroneously fitted) ball bearing if it is used on the wrong side of the port. A potential safety issue for any future owner removing the port cap, as the full 1000 psi pressure would be acting directly on it. Just to clarify what I mean by "erroneously fitted", I am assuming that if someone fitted the pin on the outside of the port they would have already used the original ball bearing in place of the pin. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2302 Registered: 6-2009 |

Geoff, Thanks for following-up. Based on your feedback I sent an e-mail message to sales@flyingspares.co.uk detailing my concerns and closing with the following: "I think it would be wise to change the phrasing to say that this modified valve replaces the metal ball and renders the nylon ball unnecessary. It would also help if a set of step-by-step illustrated instructions were included for putting the new valve back in to the bottom half of the accumulator sphere itself." Personally, I'm rather surprised to hear that instructions are not included with the kit (or were not, anyway) since I know that there are a lot of DIY-ers who purchase these kits. I didn't myself, but now routinely advise anyone who's going to buy an accumulator rebuild kit to go with the one that Flying Spares makes. That improvement on the primary valve is worth any differential in price. I'd love to hear from those who've installed this kit regarding whether they're seeing significantly increased longevity in their sphere charge afterward. I have never believed that the primary escape route for the nitrogen is through the rubber diaphragm, as this does not make sense from several different angles. It's well known that the original valving design on these things was leaky as a sieve and that's how the whole "three seals" thing came to be. It strikes me that this is just as insane as the lead-plug thermostat workaround of a bad design rather than just going to a more conventional one that doesn't involve galling like the original one so frequently does. By the way, I passed along your concern regarding the projectile potential since I have no idea whether that pin is long enough to displace the metal ball if it's inserted into the port facing the center of the sphere and then the port cap is screwed on. That could have some very unfortunate results if it were to displace that ball. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1705 Registered: 5-2012 |

Hi Brian It will be really interesting if you could publish the FS response to your email, assuming they do take action on this. I have just checked and can confirm that the date on which I fitted the kit to my accumulators was Nov 2012. I always think in terms of "a couple of years ago" however time flies - it has been 4 1/2 years since I reconditioned my spheres. The last time I did the brake test, a couple of months ago, I got up to 60 pumps of the brake pedal with no warning lights illuminating so stopped at that point. The lights do come on after a few days of the car standing so I saw no point in testing further. I also think the pin is a significant improvement and would be interested in hearing any other views of owners who have fitted this kit. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2311 Registered: 6-2009 |

Sweet vindication!! This is the response I received from a representative of Flying Spares, first thing this morning: Brian, Many thanks for your email. You are absolutely correct! I am quite embarrassed because I think I added the note to the website many years ago and you are the first person to helpfully point out my error. As you have recommended we will look to also create a set of instructions to go out with the kits and also to be included on the web page. Thanks for the feedback, much appreciated. Regards, Ben Handford P.S.: He should be thanking Geoff for the suggestion on making a set of instructions. | ||

Chris Browne Prolific User Username: chrisb Post Number: 269 Registered: 2-2010 |

Hello Brian, Ben Handford is the Managing Director of Flying Spares so your reply has come from the man at the top. They actively encourage customer feedback and act on it when constructive critisim such as yours is received. It has been my experience that FS put customer service first and having dealt with them for many years, I have always been impressed by the quality of their service. I have no connection with FS other than as a very satisfied customer. Kind regards, Chris | ||

Brian Vogel Grand Master Username: guyslp Post Number: 2314 Registered: 6-2009 |

Chris, This is wonderful to hear. I also see that as far as the description on the website goes that they took action on it with equally great speed. I have always said that instances such as this, where a mistake has been made and identified and where corrective actions are needed and taken promptly, are very clear indicators of good customer service. No one is perfect, and handling errors swiftly and appropriately, and showing appreciation when they've been pointed out, speaks highly of an organization. Brian |