| Author | Message | ||

John Beech Prolific User Username: jbeech Post Number: 101 Registered: 10-2016 |

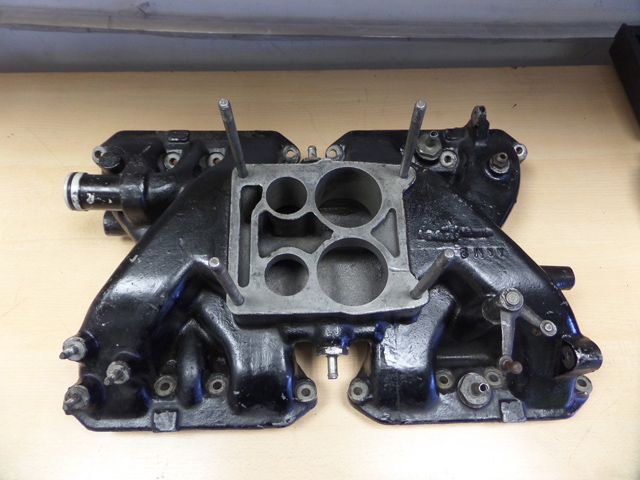

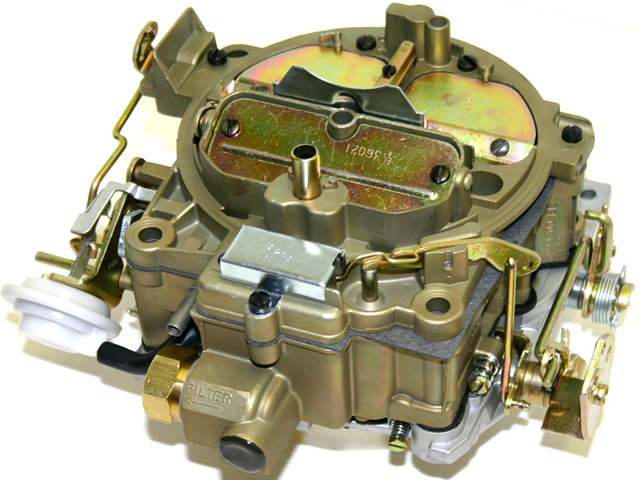

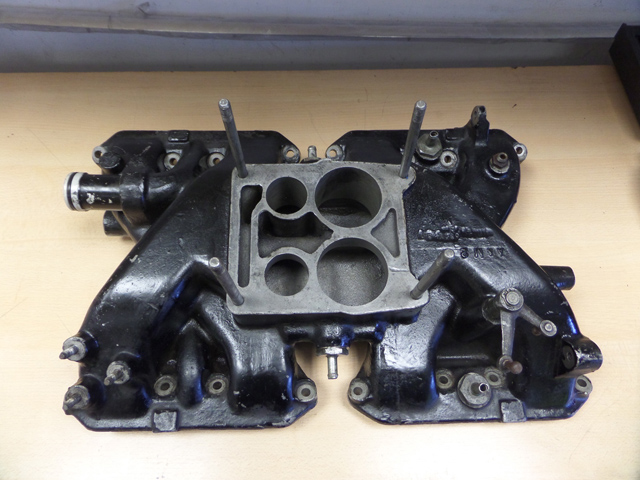

- Convoluted and involved post . . . the Backspace-key is your friend. Based on a thread in which Vladimir mentioned his US-sourced Camargue is equipped with a Holley 4-barrel carburetor, a private conversation ensued. I learned the manifold was stock and the Holley had been fitted by a previous owner. Moreover, he insisted the carburetor's base flange was merely slotted about 1/4" for two of the mounting bolts and otherwise, there was nothing especially involved in fitting it to the manifold. Thus informed of a possibly easy way to modify the car's performance characteristics, and fervently believing a picture is worth a thousand words, I asked for and kindly received a photo of said manifold.  - Vladimir's naked manifold was available for a photo because the engine is presently disassembled for rehabilitation. My interest was in part based on a coincidental conversation with Larry, our local RR chapter-president (and über-experienced retired-RR and all-things-automotive, mechanic). He expressed a keen personal interest in installing a 4-barrel carburetor on one of his Rollers (one that he drives a lot). This, because he believes he'd obtain significantly improved fuel economy (and I'm pretty sure he's right). Anyway, I sympathized with his interest because motivating 2-1/2 tons of steel isn't exactly cheap in terms of gasoline consumption when virtually nothing has been done by Rolls-Royce in terms of optimizing the engine's performance. In short, it's my opinion quite a bit of horsepower has been left at the table . . and where's the fun in that even if you're just the chauffeur? Thus piqued, I investigated further. As background, it should be noted that while the twin SU carbs on Tootsie function perfectly, Larry has his ducks in a perfect row because cruising on smaller (1-3/16") primaries should deliver significantly greater fuel economy versus operating the engine on the larger (2") bores that are always at part throttle. This is the benefit Larry's principally after. However, while that's all well and good, what holds rather more interest for me is the fun factor of a 4-barrel. This, because when the need/desire arises, opening a pair of secondaries offers that kick in the pants for which V-8 powered American cars are well regarded (and I bet this is the case in performance-oriented Australia as well). Thus, in concept, the switch to a 4-barrel carburetor holds promise. Especially because in my admittedly limited experience, accelerating Tootsie is akin to driving a heavy old Ford pickup truck equipped with a 1-barrel carburetor because in effect, that's exactly what the Roller uses, a pair of one-barrel carbs (each feeding 4-cylinders). Anyway, the term gutless wonder comes to mind because basically, there's just no punch! Yet with 380ci of displacement, she should be able to manage war emergency power with greater alacrity 'and' save money by burning less fuel when driven in a sedate fashion because the comparatively tiny primaries would serve the engine's needs perfectly (and with better throttle response to boot). That would just leave the exhaust part of the breathing to attend to but I recall mention by Robert Noel [Reddington aka Bob UK] of using, if I'm not mistaken, slightly larger exhaust diameter components, plus muffler and resonator chambers, which he's made himself! Anyway, as long as finding, making, or modifying a suitable manifold 'and' making it work isn't a huge pain in the hind end (enough so as to make it motivationally-impossible), I continue because while 'anything' is possible, I don't want to be stupid. However, since I'm both stubborn (and presently) sufficiently motivated, I'm proceeding further because I view this as an interesting expenditure of my time. Oh, and regarding the difference between motivationally-possible, improbable, and freaking-impossible, I once saw a very large mixed-breed canine attempting to mount my little Dachshund bitch (and with her active cooperation) and have no doubt absent my intervention they would have eventually succeeded. Or as we all know, where there's a will there's a way! But I digress . . . It's also worth noting; this fits in with my philosophy regarding Tootsie, e.g. of being willing to do pretty much anything as long as it's easily reversible. Basically, with her I draw the line at cutting into the wheel wells and re-contouring the lips to fit larger rims/tires because I cannot unbolt said modification. Of course, if Tootsie were not such a nice low mileage example I might feel differently. Put another way, some girls have perfect hooters and a bit of lipstick suffices to tart them up, while with others, there's a significant benefit derived by augmenting the front bumpers. This image, which I tripped across on the internet, serves to make my point regarding doing a little massaging of the basic Rolls-Royce recipe.  - The quest for performance, a supercharged Roller as art when money's no object - note the roll cage! Anyway, Vladimir thought obtaining a similar intake wouldn't be easy because only just over 500 Camargues were ever made. While that's very true, I was rather more sanguine because as a manufacturer myself (granted, on a tremendously smaller scale), I know how very loath I am at making a part with just one possible application. Or put another way, how diligently I seek to reuse existing parts whenever possible. Considering the investment required in casting an intake manifold is not exactly insignificant for any manufacturer, even Rolls-Royce, I suspected the manifold was perhaps more easily sourced than Omar imagined. After all, even the mighty are not immune to the exigencies of economics. Thus, armed with Omar's photo, I considered myself quite fortunate when Chris at Flying Spares soon confirmed he had one, which I promptly purchased. Thus ended a very brief quest to locate and purchase a 4-barrel manifold suitable for Tootsie's 6.3L engine. Whether I was lucky will only be determined by the next guy's effort (and success) in finding same.  - Viewed from above, the Mulsanne-turbo intake manifold reveals a spreadbore mounting pattern - hmmmm, something's missing! However, this isn't the end, but only the beginning of this story. First, the easy stuff. For example, the OEM carburetor is outfitted for pressure (basically contained in a sealed box) because it's for a turbocharged application. I neither have a turbo (nor any desires) but I was rather curious about the appearance of the Solex 4A1 carburetor because the mounting pattern on the manifold looked suspiciously like that of the ubiquitous Rochester Quadrajet. If you're not in the know, the Rochester Quadrajet carburetor is both loved and hated and was fitted to quite a lot of General Motors automobiles. Wikipedia has a decent enough entry: https://en.wikipedia.org/wiki/Quadrajet . . . and since GM and RR made deals for power steering, air conditioning, and the transmission, it wouldn't be any great surprise for other incestuous tendencies to reveal themselves if you look. Anyway, at it's most basic, the Quadrajet is quite capable of delivering both very good performance 'and' excellent fuel economy because of the disparity in size of the two sets of bores. What's this got to do with the the price of eggs in China? In parts it's my astonishment at learning how very dear the Solex is for prospective purchasers (thousands of pounds at Flying Spares, from whom I lifted this image).  - Solex 4A1 pressure carburetor as used in turbo applications like Mulsanne Meanwhile, with some judicious poking around on the internet, I satisfied my opinion the two are related because not only does the Quadrajet look like a kissing-cousin but a quick visit to my local NAPA revealed (via a manifold gasket) that a Quadrajet is a perfect fit needing but to slot the two aft mounting holes about the same 1/4" mentioned by Vladimir.  - The uniquitous Rochester Quatrajet, a very popular spreadbore carburetor New Quadrajets are relatively inexpensive, too at <USD$400 and with many units sized specifically for ~400ci engines. After all, the 6.3L is about 380cu and the 6.75 is 411ci so we're in the ballpark of the displacement of American iron (and vacuum secondaries cover a host of sizing sins). For specific example, this is new carburetor for a light pickup truck probably weighing (in real world use) about the same as a Roller, or 5000 pounds: http://tinyurl.com/j7ou8a5 . . . and in the alternative, Holley also plays in the spreadbore league with the popular 0-80555c carburetors, also priced under USD$400.  - Popular Holley spreadbore 650cfm carburetor is easy to tune However all is not bliss in Mudville. Note the area of the manifold where the thermostat resides. It's MIA because in the Mulsanne Turbo manifold, as compared to the SU-manifold pictured above, it's just not there. Of course there may be RR parts to complete the picture (we'll see) but it wouldn't surprise me in the least. and note, THIS IS THE PRINCIPAL QUERY IN THIS THREAD.  - SU-carb manifold - top view Thus, some homework remains . . . but things don't look any worse than maybe welding an inline thermostat housing to the manifold:  - Billet aluminum inline thermostat housings are readily available for <USD$100 Or use one of these 90° types, also under a hundred bucks!  - Billet aluminum 90° thermostat housing Or something like this can be ginned up, which has the added benefit of offering a higher fill point and is also easily within the capabilities of a skilled fabricator with a MIG welder (I have a large Miller water-cooled unit in the shop but the welder is a hired gun because my skills are abysmal).  - This type housing delivers a higher fill point to ease bleeding. . . . or if it comes to it, hacking off a piece of one manifold and MIG welding it onto the other (along with some light grinding to ensure form as well as function). But hopefully (and more likely), the Mulsanne manifold I have is just missing some of the parts that RR made to move the water around. But I'm perfectly willing to weld and grind if it comes to it, believe me! Hmmm, it may even prove better to weld a flat carburetor adapter-plate to the stock SU-manifold and then hog out the holes to match using a die grinder, yup, that might work, too - and with less expense (but only if there's enough metal available because filling huge gaps with the MIG isn't fun. Anyway, more as it develops. Finally, I am actively considering this as well.  - Holley Sniper EFI ~USD$1250 . . . yes, it's about 3X the price of the carburetor but welding a bung into the exhaust to install an oxygen sensor brings a veritable host of modern functions to an old car. I welcome all thoughts and in any case, I am having fun with this because my back of the envelop calculations lead me to suspect this pays for itself in fuel saving despite my principal interest being the convenience of fuel injection, which I covet. Added to which, I can mount the control unit discretely and it will display water temp and turn on auxiliary cooling fans (or sound an alarm), which sounds interesting to me. By the way, a Sniper will also control NOX injectors (and the injectors for the added fuel required) if an extra 100hp would come in handy occasionally. For example, easier merges at freeway speeds. And considering Rolls-Royce engineers saw fit to use forged steel connecting rods plus forged steel crankshaft (both staples of the hot rod world), the occasional use of chemical horsepower isn't contraindicated in my view . . . as long as reason is used. Of course, and quite frankly, I'm just idly speculating out loud with this last (regarding laughing gas). It's just force of habit - like how a long time (and happily married) man will covertly eyeball a gorgeous gal perambulating slowly in a short skirt and high heels). E.g. most can no more keep themselves from looking than will yourself to stop breathing! I'm that way about hot rods, not that Tootsie is a hot rod, of course. | ||

Michael Carr New User Username: carsie Post Number: 6 Registered: 7-2016 |

Wow John, Thank you for taking the time both to explore and to write up your musings and findings; I really like your thinking. I too am a great fan of "part sleuthing" or rather "what else was it fitted on?" it really can make a significant difference to operating costs. The point that you make regarding fuel consumption is a factor that prevented me from buying a rather beautiful BRG XJ12- how ironic that I ended up buy the Shadow. The way that I look at it is that my Rolls is my "best suit" and realistically will only cover some 5k mls p.a. the rest of the time I'll just take my Jag. Using this tool: http://www.fuel-economy.co.uk/calc.html and fuel costs at 104p ltr and 15mpg for the Rolls my fuel cost is £1575 p.a So a normal car at 30mpg would cost me half of this -say £750 To my extra £750, I then add back in zero depreciation and insurance savings of circa £300 p.a against a normal car and my man maths says I kinda break even. If I apply some costings against a capex on LPG install or different carburation then I can't get a sufficiently strong payback so long as depreciation or rather lack of is in the numbers and bear in mind I'm talking about a lack of, not appreciating, which these old girls have a habit of doing. Back to why explore other fueling options?- well I totally agree that the engine feels very asthmatic, indeed worse than I am and that's saying something  I think the electronic fueling/mapping route is the way to go, along with, I suspect, but don't know, some head flow work. Really interested to see how this one maps out (pun intended) | ||

John Beech Prolific User Username: jbeech Post Number: 104 Registered: 10-2016 |

No flow work on the heads - unless - I have them off, and that would require a disaster of some sort. Knock on wood against that version of reality! Anyway, I like how you think (in terms of costing against capex). I can massage figures with the best of them to justify what I want to do. Also reminds me the accounting joke. You know, the one where you ask your accountant how much 2 + 2 sums to and the response is, "How much would you like it to be?" Like everybody else, I occasionally engage in those kinds of mental gymnastics when I want something. Lynn just rolls her eyes and knows I am going to bull ahead, regardless. Meanwhile, I hope Robert Noel chimes in on my recollection regarding the exhaust system because I've read so much over the last month that some of it blends together. Even a slight increase in exhaust diameter would be significant improvement in her breathing, which at present reminds me of nothing more than a British bull dog with a cold. Anyway, right now I can;t find what i thought he wrote regarding exhaust pipe diameter but have found what he said about fabricating replacement mufflers on a DIY basis. Regarding diameter, I really don;'t know if he said that (I'm 90% sure but his confirmation would be nice), or it was merely a fevered dream version of the truth. Add to it, there are many other contributors of great forum with a world of experience, whom I am crossing my fingers in hope they will drop in with their thoughts. Meanwhile, and quite frankly, improved fuel economy is a non-issue for me because Tootsie (a 1969 model, Kelly) is not a daily driver (nor will she ever be). Instead, her purpose is for the occasional night to the theater with Lynn, or to visit for lunch on Fridays with the guys from the local car club, etc. Moreover, I do not foresee her ever accumulating more than 2-3000 miles per year and probably considerably less after the first year (once the bloom falls off the rose). Anyway, on another subject, I picked up a Pertronix ignition conversion the other day but she's starting and running so nicely I am loathe to mess with her. Maybe later. Right now I am trying to complete the bay in my building where I installed a 2-post lift so I can get her in the air and take good stock of the situation. I've had her on some cheapo ramps just to eyeball beneath her (I'm a portly fellow so space was at a premium even then) but once she's in the air I can look her over with a fine tooth comb. John, who has been a busy bee recently | ||

Michael Carr New User Username: carsie Post Number: 7 Registered: 7-2016 |

Hi again, I think its where you want to optimise your suck bang blow (that's what I tell Carol ;) ) If you've sorted out and optimised the ignition with a close loop system then breathing is de-rigeur. The increase in exhaust diameter assumes that the exhaust valves can push out sufficient gasses to optimise the increase diameter (allowing for positive pulses) and that means head work. Theres a great article here on the breathing of an XJ AJ6 engine. The guy comes across as a bit....well...how to put it...lol! I've seen him pop up on the Aston and Hillclimb forums - and he backs up his comments with fact. One interesting point that is made in reply to some of his comments is that the Jag engine was engineered for low end torque delivery rather than outright power- somewhat like the Rolls. http://www.jagexp.com/phorum/read.php?8,3855 http://www.jaguarforums.com/forum/xj-xj6-xjr6-x300-26/aj16-virtues-vices-148947/ Bedtime reading on exhausts.. https://www.xj40.com/viewtopic.php?t=614 Please,please,please include some of these with your two post wont't you? https://www.machinemart.co.uk/p/cts4000-2-tonne-tripod-stand/ https://www.youtube.com/watch?v=XLUjq6ijvVc Keep the posts and thoughts coming  |