| Author | Message | ||

Kelly Opfar Frequent User Username: kelly_opfar Post Number: 59 Registered: 7-2004 |

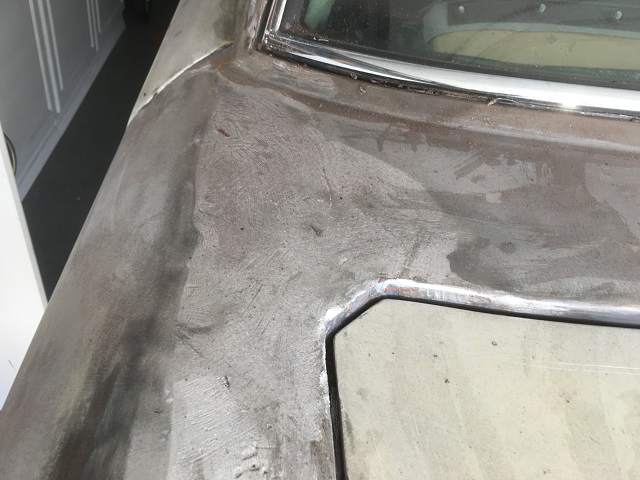

In response to Patrick Ryan's request for original factory lead seam pics, I thought I ought to start a new thread so as not to hijack Nick Adlam's original post of beautiful car pics. First, the pic that prompted the question:  Here are the seam pics:          | ||

Patrick Ryan Frequent User Username: patrick_r Post Number: 83 Registered: 4-2016 |

Thanks Kelly, These are amazing. Not many of us get to see a completely undressed Shadow body. What are your honest thoughts as to the quality of its construction and how it was put together? | ||

Patrick Ryan Frequent User Username: patrick_r Post Number: 84 Registered: 4-2016 |

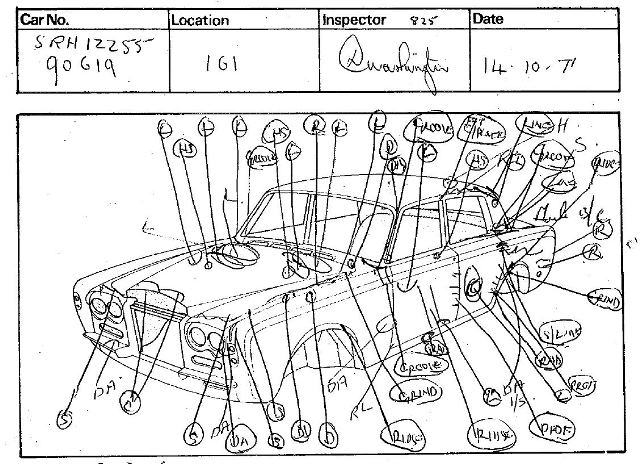

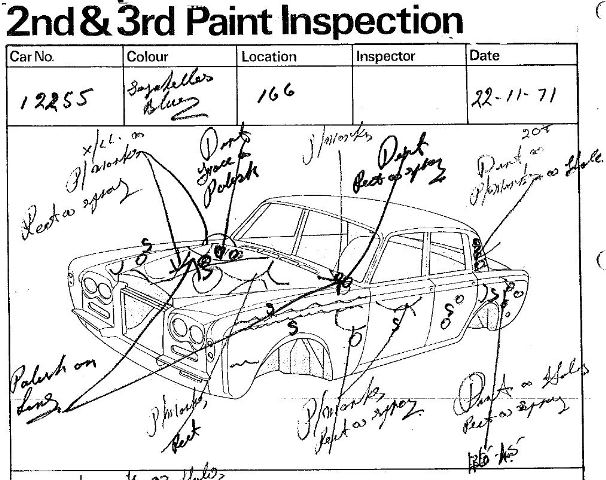

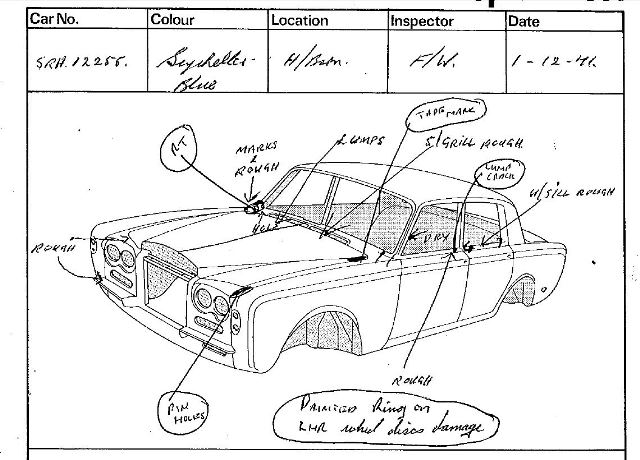

The reason I asked Kelly was this.  These marks appeared over about a 2 year duration, and have been the same, and not got any worse sine 2001 according to the cars long time mechanic. What is interesting are these pages from the build sheets. In order of date      In 4 of the 5 pages, this front area is noted. So it seems are a lot of the other lead wiped areas. Quite interesting I thought. I was interested to see where the actual join was in your car images. It was these bubbles in the car that the judges looked at and asked why I had chosen not to repair them, and my reply was they match the build sheet  They were happy with this. | ||

Patrick Ryan Frequent User Username: patrick_r Post Number: 85 Registered: 4-2016 |

Now looking at your images. It appears the headlight support and the guard/wing are one piece? Thus no lead wiping where my bubbles are? | ||

Kelly Opfar Frequent User Username: kelly_opfar Post Number: 61 Registered: 7-2004 |

Patrick, my car had already been painted once in the past so I am unable to comment on the original finish. The lead work on it looks typical to the era for small batch cars. I had a '67 Camaro that I stripped and the lead work was much smaller and neater on it. The headlight support and wing are one piece. Your car could very easily have lead in the spot you mention. There is lead all along the tops of the door openings on mine (where a normal car would have a diprail). I'll bet I could find localized spots of lead if I were home to look right now. | ||

Patrick Ryan Frequent User Username: patrick_r Post Number: 86 Registered: 4-2016 |

Thanks Kelly. Very hand made I guess. I was sure the front panel was separate, so your great pics confirmed they are indeed one piece. And I think the quality of the body pressings and all the work seems pretty good. They certainly seem to hang together quite well. Hows the scribbles on the build sheets!!! Quite amazing really | ||

Nick Adlam Experienced User Username: crewes_control Post Number: 25 Registered: 12-2015 |

Hi Pat RR paid amazing attention to detail. If that were your typical BMC banger of the era, ALL of those blemishes would've happily sailed through with flying colours!. My Shadow was also riddled with pinholes, dints and rough surfaces. Good on you Pressed Steel!. | ||

Patrick Ryan Frequent User Username: patrick_r Post Number: 98 Registered: 4-2016 |

Nick, It's amazing the cars exited looking as good as they did. There seemed to be hundreds of hours work here. Surely pressed steel had to lift their game. I wonder how much Rolls Royce paid for the body shells from pressed steel? I have searched the net and I can find a few images of the production line at Crew working on the Shadows, but really can't find anything regarding pressed steel and or the body shells. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 1195 Registered: 5-2012 |

Hi Patrick If you try "Pressed Steel Fisher" you might get more. Geoff | ||

Patrick Ryan Frequent User Username: patrick_r Post Number: 99 Registered: 4-2016 |

Thanks Geoff, I'll give that a try. | ||

Kelly Opfar Frequent User Username: kelly_opfar Post Number: 67 Registered: 7-2004 |

I think this is the pic that Randy Roberson referred to in the Car Photos post. It seems appropriate here.  | ||

Patrick Ryan Prolific User Username: patrick_r Post Number: 102 Registered: 4-2016 |

That is an amazing image Kelly. I bet they would have no trouble selling those body shells today. Just wish there were better images and video from the day. There are a couple of videos available on YouTube showing mainly the final inspections, but this appears to be staged for sure. The lady acting like she is polishing the stainless steel gives it away. Some road tests and brake tests are there as well but not a lot. | ||

Omar M. Shams Grand Master Username: omar Post Number: 580 Registered: 4-2009 |

When I was younger, my father sent me to the UK to study. When I was studying at Banbury (Oxfordshire)in the 70s I would often see car transporters with several unfinished bodies just like the ones in the photo above being driven through town on their way north. I always used to stop and oggle at the shiny unpainted bodies. | ||

Patrick Ryan Prolific User Username: patrick_r Post Number: 105 Registered: 4-2016 |

What great memories Omar. | ||

gordon le feuvre Prolific User Username: triumph Post Number: 107 Registered: 7-2012 |

Don't forget that R-R was only small part of pressed steel work. I remember the really poor quality of early Spiirit doors /shapes/fit. They were focused on launch of Leyland Metro at same time.We were dealers for both! Standard cars took about 3months to build. Some cars got damaged and just went round &around in paint shop to be reworked. | ||

Randy Roberson Grand Master Username: wascator Post Number: 673 Registered: 5-2009 |

Seems that a lot of hand work was required, that today is eliminated due to high tech and high quality tools and fixtures on even the lowest-price car. This is why I have wondered if it is wise to completely strip a Car to refinish it, if it means stripping off all the panel corrections and other hand work, then having to redo it. Also I wonder if the well-known labour troubles of the 1960s-1970s had any effects at the Factory. It almost ruined Jaguar financially from what I have read. | ||

Patrick Ryan Prolific User Username: patrick_r Post Number: 113 Registered: 4-2016 |

Even though the Crew factory was building hand built cars, 3 months or longer does seem a very long time. All that labour doing slow work. It must have been a huge bourdon on the books, but I guess they had a reputation to maintain, not matter how much it cost. However, it does seem strange that the "best car in the world" had simple things go wrong that other manufactures could get right, like paint longevity, and a list that others could add to I'm sure. It seems that the late 70's and 80's was the low point in all makes regarding up keeping quality. |