| Author | Message | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 337 Registered: 5-2013 |

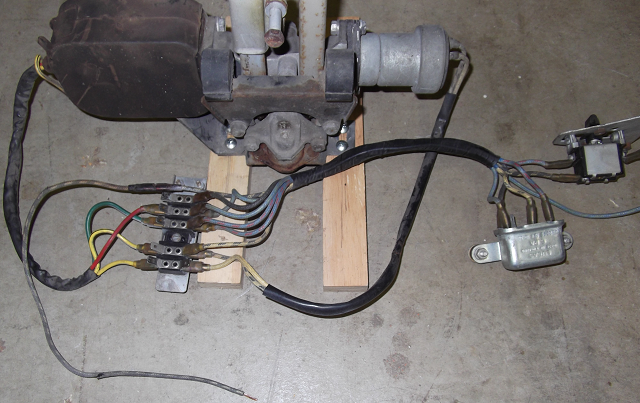

I've removed the driver rear window from the '66 cadaver car and I want to use it to test the window lift improvements. (http://http://rrtechnical.info/windowlifts/windowlifts) I have isolated the minimum requirements, meaning the open door light and the cigar lighter wires have been eliminated leaving only the lift motor, the switch and the 6RA relay.  The next thing I did was test the relay. I disconnected all the wires and measured resistance between the C1 tab and the C2 tab. Open Circuit. Then I put twelve volts across the W1 and W2 tap, heard a click and heard my ohm meter beep at me. Continuity. So, the relay works, but I don't think it is necessary to the core behavior of the window lift, so eliminate the relay by connecting the wire from C1 to the wire from C2. (I can't really tell the colors, but I think the C1 and C2 connections on the 6RA relay are "Yellow with Black tracer - Cotton (YB-C)" and "Black - Cotton (B-C)".)  I assume that relay is only there to permit driver window controls to override the local switch, so confirmation would be helpful. I verified that the switch works. Switch in neutral, all terminals open. Switch up, continuity between YB-C and UG-C; switch down. continuity between YB-C and UR-C.  So far, so good. I think the YB-C line that is not routed through the connection block is twelve volts, and I think the B-C on the connection block is ground. And I acknowledge that these are guesses, so verification or refutation would be helpful. Hook up the battery, activate the switch, and the motor should work. It doesn't. It is trying, meaning I hear slight activity like it wants to work, but something is not quite correct. Does anybody have any insight into this? Are my assumptions of twelve volts and ground correct? Is there some connection that has been lost by moving this mechanism from the door to my bench? It is valid to cut-out the relay? | ||

Robert Noel Reddington Prolific User Username: bob_uk Post Number: 279 Registered: 5-2015 |

This is a Lucas designed system. The 2 yellow wires to the motor and solenoid brake are when the system is not being operated, both 12 volts. Depending on which yellow wire is grounded governs which way the window goes. There are no relays in the standard Lucas system. The switches earth out one side of the motor. The wiring and switches are not robust enough. To test the motor and solenoid brake apply 12v to it. It should go fast. To cure the the dodgy wiring and switches. leave the wiring and switches as is. Fit two relays inside each door. The relays then use the exsisting circuit to signal the relays. The relays then have a separate power supply Brown wire. For full instructions go to Shadow tech stuff. The relays are 5 pin normally open and normally closed. The 4 fuses for the windows should be changed from 25 amp to 3 amp. The power supply should be protected by a 25amp fuse. Note the rear doors have a cigar lighter and the brown wire to the lighter can be used as a power supply. The front doors don't have a suitable power supply so new brown wires will have to be run. Use 30 amp brown wire. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1506 Registered: 6-2009 |

Chris, Without having the time to dig into this, I don't think the window lift improvement is applicable to a 1966 model. The text explicitly states that it's from model year 1972 and chassis number 13752 and onward. In fact, Richard Treacy notes that his Bentley T did not need the improvement because prior to that chassis number the window setup is quite different. Brian | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 338 Registered: 5-2013 |

Hi Brian, The '66 cadaver car is donating the equipment for my laboratory where I will test the circuitry. The modification will go in the '71 and '72. I think I have a minimal configuration, meaning absent any complicating influences, like multiple locus of control or ancillary functions. The immediate question is how to get the standard window lift to lift. Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1507 Registered: 6-2009 |

Chris, Are you certain that the motor is functioning from the donor piece of equipment? It's been a while, but I thought during the era you've "borrowed" from the window lifts always were live circuits and the window switch completed the circuit such that the motor would wind in one direction or the other (it is DC). That relay is clearly an SPST, which means an on/off switch. I've never looked at the wiring diagram for the windows, but it's on the technical library (or I think it is). Also be certain that the brake solenoid, which is opposite the window motor, is disengaging the brake when the switch is depressed (or just remove it during testing). Brian P.S. I started composing this over an hour ago and am just finishing due to interruptions. You may already have an answer I haven't seen yet. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 289 Registered: 8-2012 |

"Hook up the battery, activate the switch, and the motor should work. It doesn't. It is trying, meaning I hear slight activity like it wants to work, but something is not quite correct. " Is there 12 volts across it? If so, it's the motor or mechanism jammed. If not, it's an electrical fault. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 340 Registered: 5-2013 |

Hi Bob, I'd like it to be that simple... I think maybe the solenoid is preventing movement. And it looks to me like the solenoid is completely controlled by the motor. The motor says, "I want to turn." and the solenoid says, "Yes, Sir!". I removed the solenoid, and I get up and down as expected. so I have to conclude that the solenoid is not wired correctly, but I don't understand it, yet. All control of the solenoid comes from the motor, I believe, but I would like to be proven wrong. More to come... Chris. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 341 Registered: 5-2013 |

Hi Brian, I arrived at the same testing procedure you did -- remove the solenoid, further simplifying my test. That is useful, since it is now clear that the solenoid is the culprit. It looks to me like the solenoid is controlled by the motor. So, how do I test to determine if my understanding is defective or the motor is defective? Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1510 Registered: 6-2009 |

Chris, The solenoid is not "controlled by the motor" but it is energized at the same time the motor gets juice and deenergized when the switch is released. You should be able to figure it out just by the wiring, as that's how I figured it out at the time. If the motor operates sans the brake solenoid then it works (though it could be slow/weak or otherwise partially compromised). I don't think the brake solenoid alone should be able to stop the motor itself, though it would add extra strain to fight against. It's purpose is to prevent the glass from lowering under its own weight. Many have removed their brake solenoids and I have yet to hear of a single person report their windows then lowering under their own weight. Brian | ||

Robert Noel Reddington Prolific User Username: bob_uk Post Number: 286 Registered: 5-2015 |

The solenoid is not controlled by the motor it is wired in parallel with the motor. When the motor gets power so does the solenoid. To test solenoid connect to 12v. The armature will move inside the solenoid. The solenoid will work without the motor connected. The motor as shown is series wound and square. With solenoid removed connect motor to 12v. If the motor doesn't run then its either a faulty motor or seized gearbox. The gearbox likes oil if seized. Motors also seize on the bearings. The ones on your driving car are I think round and permanent magnet. If so the permanent magnet type have no relays in the window circuit. Motor brushes are available. If not use brushes from something esle and cut down to suit. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 208 Registered: 6-2005 |

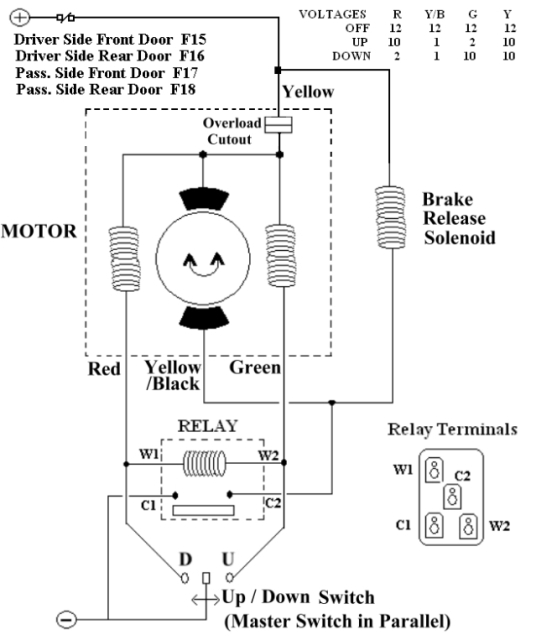

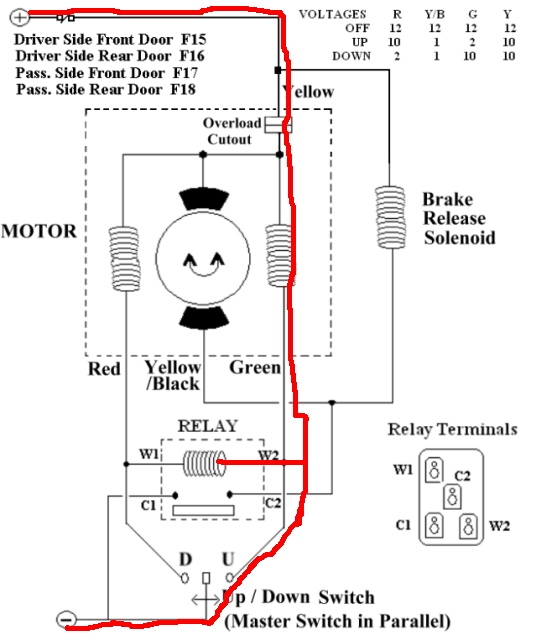

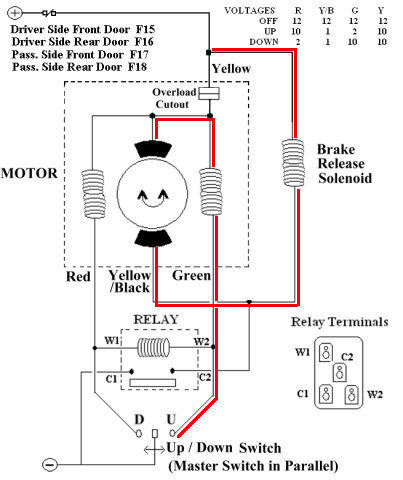

Here is a diagram showing the window circuit for the early Shadow. When the window motor is energised the solenoid releases the brake. For a window mechanism in good condition the window will most certainly drop under its own weight if the brake is removed. Incidentally early Shadow window mechanisms did not generally give problems as the wiring was of a heavier gauge and did not have the voltage drop evident in later models.  | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1511 Registered: 6-2009 |

John, Even though I don't own an early Shadow I can't thank you enough for posting that diagram. This is the sort of thing that's invaluable and very difficult to find. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 831 Registered: 5-2012 |

John - My thanks also. Re: For a window mechanism in good condition the window will most certainly drop under its own weight if the brake is removed. I have also read of a test whereby if the window is closed and the switch kept pressed, the thermal switch will cutout, de-energizing the motor but not the solenoid brake, whereupon the window should slide slowly down to fully open. This interests me as I believe this applies to the very early iterations of the winder mechanism, but not the later ones. Unfortunately I cannot find any documentation for the very early winders. Logically, for the windows to slowly slide down when the brake is released, there must be a clutch mechanism involved. When I removed my winders there was no trace of such a clutch and the gearing was such that it would be impossible for the window to fall under it's own weight. I have been running now for three years without the brake solenoids, without any problems. I prefer this as there is no chance of the solenoid brake only partly disengaging and dragging at the window mechanism. Chris - since your winder is off a 66 car, it would be very interesting if you could let us know how the winder works. Is there a clutch? In any case, I strongly urge you to strip the unit down and re-lubricate it. When I did mine, the 40 year old grease had turned into something akin to a very thick and sticky lump of earwax. No wonder the winders were slow. Geoff | ||

gordon le feuvre Frequent User Username: triumph Post Number: 81 Registered: 7-2012 |

13754 was termed the 1972 electrical package upgrades. There was a seep rate factory publication booklet explaining all. There MUST still be one out there! I can remember shimming brake motors on early cars as windows were slow going up, and when brake off too much drag. I cannot remember window sliding down when solenoid unbolted? As I remember the purpose of brake solenoid was to stop window dropping fractionally when power released due to slack in chain/gear. The training course was 1967 so forgive lack memory. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 209 Registered: 6-2005 |

Geoff, When the solenoid is energised it releases the brake so if the switch is kept pressed after the cut out operates the window will drop under its own weight. My car is 1966 and does this. Whether the window falls completely to the bottom depends on the condition of the mechanism. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 832 Registered: 5-2012 |

Re: As I remember the purpose of brake solenoid was to stop window dropping fractionally when power released due to slack in chain/gear. I remember reading this also, a couple of years ago when I overhauled my window winders. Thing is, I notice no difference without the brake solenoids. There may be a fractional drop, but it doesn't cause any problems. With my windows up I do not get any wind noise. When you think about it, the brake solenoids were essential for the early, "slipping window" models. Maybe they were just carried over when the winding mechanism was changed to "non slip" Geoff | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 833 Registered: 5-2012 |

Hi John Yes, this ties in with what I have read. It definitely appears the mechanism was changed in the later models. I pause to say upgraded - from a safety point of view the early models were much better. Geoff | ||

Christian S. Hansen Experienced User Username: enquiring_mind Post Number: 26 Registered: 4-2015 |

Doors of CRX2508 have an access port at bottom to insert a hand winder crank to operate the windows in the event of motor failure. Unique to the MPW? or used universally? | ||

gordon le feuvre Frequent User Username: triumph Post Number: 82 Registered: 7-2012 |

The crank handle was unique to c/built cars, shadow/corniche, and certainly cloud 3 and James young sct100. If you open either door on corniche doc, below the striker plate is chrome hexagonal bolt with screwdriver slot in it, this is access for rear window(should there be a problem). The standard( and later) corniche changed to a motor known as permanent magnet type, but can't remember when. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 342 Registered: 5-2013 |

Hi John, Excellent diagram, and just what I needed. It answers all my questions. I had produced my own diagram based on the wiring that I actually saw, and except that mine is upside down, they are functionally identical. However, I have more confidence in yours... I still have a mystery that could use some discussion... The solenoid works quite well, if I jolt it with twelve volts, however in the circuit it only produces the barest minimum of a shudder. It is not retracting the brake pads by any measure, but there is a tactile response when I hold the solenoid in my hand and flick the switch. My battery is producing 13-ish volts at both the battery end and the window lift end of the wire feeding my experiment, so I'm losing nothing to three decimal places in the delivery of the current. (NB: This loss conclusion was later discovered to not be true. If I measure the delivery with a load, I see a three volt drop across that wire.) I've removed the solenoid and put a volt meter in its place, raised and lowered the window and I read 10 volts, which seems like it should be enough to activate the solenoid, but apparently not. I've removed the motor and put a volt meter in its place and again I read 10 volts. Both together, 10 volts. The only other thing in the circuit that is in series with the motor/solenoid is the relay, and the voltage drop across the C1-C2 is zero to two decimal places. I'm not getting any hot components or wires. Where do you suppose my current is going? That window lift motor is probably not using the full fifty or sixty amps from the battery. ======== I wrote the previous paragraph, and did a lot more measurement. I've discovered, as hinted above, that I'm losing the three volts in my supply wire, which was an orange extension cord in a previous life and probably 16 gauge. It's obvious, now that I've discovered it. I replaced it with an old washing machine cord, which is 12 gauge, and Voila! Everything works as expected. So, the lesson here is that these windows are sensitive to voltage, which drops in the absence of current and small gauge wires restrict the current, as do the coils that keep a workshop looking neat and orderly. With sufficient voltage, the windows are quite strong! I think I read earlier discussion implying that the solenoid might be slowing the window. I don't think that can happen. The solenoid does not behave like a proportional device, meaning I can't get it to retract halfway, if I use half the voltage. It is an all-or-nothing response. Without evidence to the contrary, I'd suspect that the design of the solenoid has remained unchanged, so my observations of the '66 probably articulate to subsequent years. Geoff: I assume your question is what happens at the limits of the window travel? I see nothing external, meaning there must be an internal component that "sees" the motor strain, maybe an over-voltage condition, which stops progress in that direction. Maybe it is just an assumption that a sensible operator will stop pushing the button when there is no longer a need to push the button. Obviously, the designer hadn't heard of kids... The diagram has a component labeled "Overload Cutout", and I suspect that is what stops the window from pushing through the top of the door frame, if the operator fails to recognize that the job is done. I know from experience that when that cut-out trips, the window won't move either way, and I've never tried to trip it with the window fully up to see if I can lower it and I doubt I've ever tripped it during normal operations. I haven't disassembled the motor, and I don't plan on it, so I can only guess. I can speak directly to cut-out behavior. I have a recalcitrant window on the passenger front side. This window creeps up and will sometimes successfully close, but more often than not, it will stop an inch or two from fully closed, as the result of a cut-out. It takes thirty or forty-five seconds to reset. However, the window never retreats, regardless of how long I hold the switch, and the '66 experiment holds the window firmly in place without the solenoid, simply by force of the resistance of the motor armature and the drive gearing. This window is one of the motivations for the experiment I've done today. I now know what measurements to expect and where to expect them. Chris. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 290 Registered: 8-2012 |

You will get a voltage drop along the supply wire, which is proportional to the current flowing through it (Ohms law). The brake solenoid does draw quite a lot of current, so by removing the brake solenoid you will actually increase the voltage across the motor. This may be enough to tip the balance and make it work. In my Shadow, the window mechanism is driven by a worm on the motor shaft driving a pinion (I think this might be true of all). The ratio is so high that the worm is not back-drivable. It doesn't matter how hard you try to turn the pinion, it will not rotate the worm! It will just try to push the worm (and motor shaft) sideways. There is too much friction to back-drive the worm, and pushing the pinion harder only serves to increase the friction. So there is no way that the windows can fall by back-driving this particular mechanism. They can only fall if a gear slips or the chain stretches, and the brake solenoid wouldn't prevent this anyway as it only brakes the motor shaft and not the window itself. The windows could conceivably fall slightly if vibration of the car, or the shutting of the door, caused the motor shafts to turn of their own accord. But how unlikely is that? In fact when the motor is idle, the circuit applies 12v to both terminals of the motor, effectively short-circuiting it. This short circuit provides an electrical brake to the motor. A weak one, but enough to prevent it from turning through vibration alone. I removed my brake solenoids years ago and the windows have never fallen a fraction. As soon as I saw that mechanism, I realised that the brake solenoids were redundant, as you cannot back-drive a worm drive (unless it is a very high pitched one like the governor on an old gramophone which is designed to be back-driven). I can only conclude that the brake solenoids were a carry-over from an earlier mechanism where the brakes were actually necessary. On a worm-driven mechanism the worm will provide the brake. Were earlier mechanisms not driven by a worm? | ||

richard george yeaman Grand Master Username: richyrich Post Number: 334 Registered: 4-2012 |

Bob one of my windows did not work when I got my car I done away with the brake solenoid and it works perfectly and dosent slip | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 834 Registered: 5-2012 |

Re: I can only conclude that the brake solenoids were a carry-over from an earlier mechanism That is absolutely my conclusion also. Given I have read the windows on the early cars will slowly slide down if the solenoid brake is removed, and John's confirmation of this, I have to conclude the early mechanisms either contained a rudimentary clutch or were of a totally different design to the later models. The only reservation I had to removing the brake solenoids on my car was it meant the weight of the window was ultimately resting on a single cog of the nylon gearwheel. In practice, the strength of the gearwheel is easily up to this. I removed my solenoid brakes three years ago, with no problems and improved performance of the windows. Chris - Given your unit is off a 66 car and is on your workbench, could you check to see if light downward pressure on the chain causes it to slip backwards. i.e. Could you try to simulate the sliding down of the window when the solenoid brake is removed. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 343 Registered: 5-2013 |

Hi Geoff, > Chris - Given your unit is off a 66 car and is on > your workbench, could you check to see if light > downward pressure on the chain causes it to slip > backwards. i.e. Could you try to simulate the > sliding down of the window when the solenoid brake > is removed. Even substantial pressure will not cause it to slip. The issue remains what will happen when the unchecked mechanism is exposed to long periods of vibration; will closed windows crack open? I think there is enough experience here saying, "No problem." that I can risk it. This discussion has saved me a whole pile of work! It is so much easier to simply disable the solenoids then to compensate for marginal voltage with taps and diodes. I'm simply going to shim mine out to "disengaged" and remove one of the wires. Done. Who knows where I can get some of the edging material that looks like industrial velvet? Chris. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 292 Registered: 8-2012 |

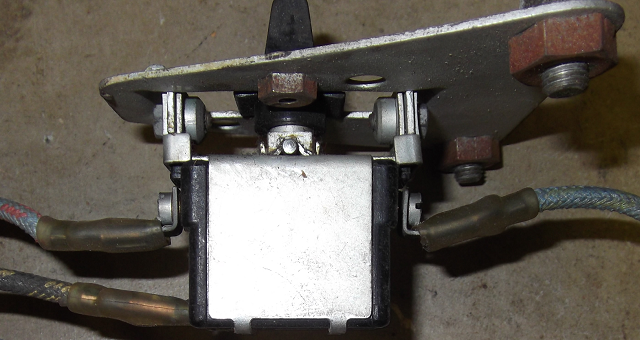

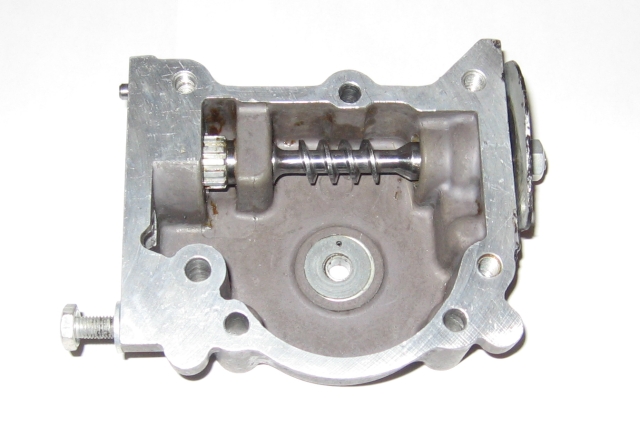

No shimming necessary. To disable the brake, you just need to remove this piece:  Yes, and remove one or both wires; and insulate each one independently. (I removed the wires completely.) | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 293 Registered: 8-2012 |

"The only reservation I had to removing the brake solenoids on my car was it meant the weight of the window was ultimately resting on a single cog of the nylon gearwheel." But this happens anyway, even with the brake solenoid on. The weight of the window always rests on that gear tooth, whether the motor shaft is braked or not! | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 835 Registered: 5-2012 |

Bob - That's what I figured. I was just trying to think of a reason why the Crewe Engineers would include a solenoid brake in their design. As you said, it must be a carry-over from an earlier mechanism. Geoff | ||

David Gore Moderator Username: david_gore Post Number: 1684 Registered: 4-2003 |

Geoff, It may have been something as simple as using up stocks of the original mechanism to avoid the cost of writing them off. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 210 Registered: 6-2005 |

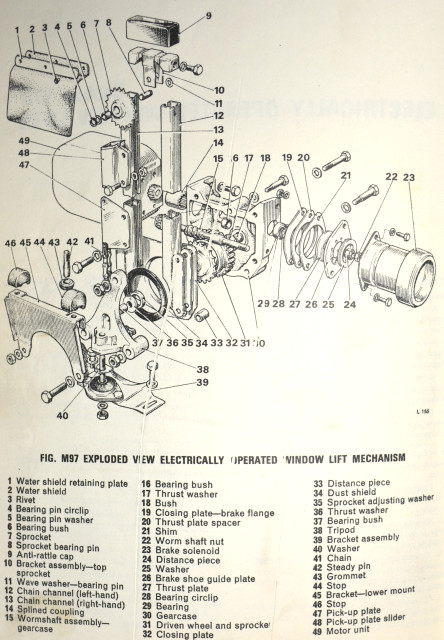

There is obviously a difference between Window Mechanisms for early and later Shadows. This morning I checked my car (SRH1405) by raising the windows and holding the switch on after the cutout operated. Each time the windows slowly dropped, two right to the bottom and two part way so there is no doubt the solenoid brake is a necessity in my case. There is no clutch, the chain sprocket is fixed to the driven gear which in turn is driven by the motor wormshaft. Perhaps the gears are cut differently in later versions, preventing the weight of the window turning the worm and dropping the window ? The diagram I posted on July 14 included a table showing the voltages one should expect when operating the windows. This is worth checking if slow or stopped operation is experienced. Operating the windows every couple of weeks will help them remain free.  | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 344 Registered: 5-2013 |

Hi John, When Geoff asked about my experimental window lifts from the '66 cadaver car (SRX1182), my reply was that the window lift will withstand substantial force with no solenoid, but I didn't do the experiment that you did. I did not run it to a limit and force the cut-out. However, I just tried that and remarkably, it does not cut-out! I waited thirty seconds or so, continuing to request that the window be closed after it had reached its topmost position. No cut-out. At least none that I could see, meaning nothing got hot, nothing stopped working, and nothing slipped. It simply quietly waited for me to ask the next thing, and then did it. Is thirty seconds enough time to initiate cut-out? Reviewing the diagram you posted, it occurs to me that if I am raising the window, and continue to raise the window beyond the endurance of the cut-out, then the motor stops driving the window, but as long as I hold the switch, the solenoid remains disengaged, so even with the solenoid, the window will slide down if the cut-out engages and the switch remains closed. The switch holds the solenoid retracted, irrespective of the cut-out. When your window cuts-out and slips back, how long must you wait until the cut-out resets? When the cut-out is the result of raising the window, can you immediately lower the window under power, or has the cutout disabled all motion? This is interesting because, you'll notice that the '66 cadaver car is just a tad older than yours, so maybe we are observing an export vs. homeland difference? Seems wildly unlikely to me... I have three other window lifts that I will be removing in the very near future, and I plan to test each, to see if maybe the one I have is a replacement somewhere along the line? Maybe the lubrication is old and less effective and there is more friction for a descending window to overcome in my system than yours? Permanent magnets in my motor and not yours? The diagram you posted looks like my unit. I think we have a mystery... Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 836 Registered: 5-2012 |

What a mystery. Here's a picture of the driven wheel and sprocket off my car.  My theory is the nylon gearwheel on the early cars was an interference fit, which allowed the gearwheel to slip on the spindle. This allowed the sprocket and chain to slowly rotate whilst the gearwheel was solidly held by the worm drive. On my car (74 SY1), the driven wheel/sprocket assembly (31) are fixed. Just a thought Geoff | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 211 Registered: 6-2005 |

Hello Chris, If I close a window, wait a couple of minutes to let the motor cool then push and hold the up switch it takes 20 to 30 seconds for the cutout to operate. It clicks and the window slowly falls. If I keep the up switch operated after another 10 to 12 seconds there is a faint click as the cutout restores and the window goes up again. With my finger still on the up switch there is now a shorter time for the cutout to operate (the motor is hotter now) and the window will cycle up and down while I hold the up switch pressed. Geoff, It's been a while since I've pulled apart a window mechanism but I can't see how it could work if the sprocket wheel was loose on the shaft. My memory tells me that both sprocket and driven gear are fixed to the shaft. John | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 837 Registered: 5-2012 |

Hi John I have to agree. I was just speculating. The thing is, I've studied the diagram you have put up and the mechanism is very similar to my window lift, which has no slip. I think this is going to have to remain one of the great mysteries of science. Geoff | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 212 Registered: 6-2005 |

Hello Geoff, I agree, it is quite strange ! As Bob points out it is difficult to see how the driven gear could drive the worm but it certainly seems to happen with my windows. It is also difficult to see how the Brake Release Solenoid remains energised after the cutout operates. This only occurs if the up switch continues to be pressed and if the switch is released the window stops falling immediately. You would think the relay would drop out as soon as the cutout operates but perhaps the actual circuit is not the same as the diagram. Anyway the next time I need to fix a window lift I'll investigate. The window lift circuits were certainly much simpler when the permanent magnet motors were introduced . John | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 296 Registered: 8-2012 |

"It is also difficult to see how the Brake Release Solenoid remains energised after the cutout operates. This only occurs if the up switch continues to be pressed and if the switch is released the window stops falling immediately. " The brake solenoid works in reverse. The brake is normally on, and energising it switches it off. This is why the window stops falling immediately when the switch is released, or the cut-out operates. It is actually an 'anti-brake solenoid'! | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 213 Registered: 6-2005 |

I do realise that Bob. What I am saying is that I would expect the relay to drop once the cutout opened, and this would prevent current through the Break Release Solenoid and so stop the window falling even though the UP switch was still being pressed. But the window kept falling until I released the UP switch. This is what puzzles me. All four windows are the same. Nor do I see why the Brake Release Solenoid is independent of the Cutout. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 345 Registered: 5-2013 |

Hi John, The motor and the solenoid are parallel to each other, as I learned earlier in this thread. So the cut-out, as part of the motor only, breaks the circuit for the motor only; the current still flows to the solenoid, keeping it energized and retracted. Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 841 Registered: 5-2012 |

Hi Chris That's true, but according to the circuit posted above, the relay that energizes the brake solenoid is in series with the overload cutoff, so power to the solenoid should be cut when the overload cutoff is activated. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 346 Registered: 5-2013 |

Hi Geoff, I don't see that. I see the relay in series with the combination of the motor and the solenoid, meaning the relay is powered by both and it would require a unanimous vote to disable the relay. I agree that the motor cut-out should have been designed to also disable the solenoid thereby applying the brake, but I'm also pretty sure that it wasn't, and John's reported experience agrees. This was why I originally thought the motor controlled the solenoid. Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 843 Registered: 5-2012 |

Hi Chris Actually, I don't get the circuit. I've done a trace of the electrical path when the switch is turned to up. I can see how the motor is energized, but not the relay. From the diagram, the relay would never be energized, unless there is a hidden ground. I have left out the parallel path for the solenoid.  Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1516 Registered: 6-2009 |

Geoff, The W1 & W2 terminals are for the relay coil and all the lines are live at rest, all the switch does is determine which direction the motor will turn. When the switch is pressed in the UP direction it completes ground/earth for the relay coil via the W2 terminal which causes the normally open C2 -> C1 switch to close and complete the circuit for the brake solenoid (causing it to release) and the correct combination of electromagnet and armature bits to get the motor turning in the UP direction. When the switch is pressed in the DOWN direction it completes ground/earth for the relay coil via the W1 terminal which causes the normally open C2 -> C1 switch to close and complete the circuit for the brake solenoid (causing it to release) and the correct combination of electromagnet and armature bits to get the motor turning in the DOWN direction. All the directional switch does is to make a connection to ground for the correct combination of components to get the brake solenoid released and the motor winding in the direction you want it to go. Also, since the branch to the brake solenoid occurs "upstream" of the cut-out the brake solenoid remains energized when the switch is pushed in either direction entirely independently of whether the motor cut-out has kicked in or not (which I do think is rather strange, you'd think the solenoid would be wired in just after the cut-out so that it would be energized/deenergized like the motor is in all circumstances). Brian, who's made a valiant effort to try to ensure I'm reading the above diagram correctly (but may not be) | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 844 Registered: 5-2012 |

Hi Brian Thanks - you've got it. It also explains why the brake solenoid remains energized. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 347 Registered: 5-2013 |

Hi Geoff, I'm not clear on the question... Maybe this will help. The solenoid is parallel to the motor, so you can completely eliminate the motor from the circuit, and either position of the switch will still energize the solenoid. When the cut-out trips, that is exactly what happens -- the motor is eliminated from the circuit. Because the solenoid is still energized, and there is no motor lifting the window, some windows slip back down. Am I on the right track? Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1517 Registered: 6-2009 |

Chris, That was the question and we've both answered it in varying levels of detail. The solenoid is definitely energized whenever the switch is pushed in either direction, releasing the brake, but since the cut-out can remove the motor from the equation while the brake is still released you can get roll-down on windows in some of the early cars when this occurs. Of course, you'd have to keep holding the switch after the cut-out kicks in for some time to achieve full roll-down. Anyone I've known whose removed the brake solenoids entirely has not had this problem, but none of them had very early Shadows, either. Brian | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 348 Registered: 5-2013 |

Umm... Well, now that I review the diagram, in light of my explanation, I think I also don't understand it... If the motor were eliminated, there would be no current to drive the relay. The cut out should also drop the relay, which would drop the solenoid. I think Geoff's careful reading of the diagram is more accurate than mine. I think this diagram is not accurate, for slipping window models, which apparently keep the solenoid energized after the cut out has cut out. My first thought is, I want to measure some voltages, but my '66 cadaver car experiment will not cut-out, surprisingly, so I can't create the conditions I need to measure. I now agree with you, Geoff, that if the motor is cut-out, then there is no current available to keep the relay closed, and the solenoid should also drop. Maybe this is the difference between "slipping window" models and "non-slipping window" models. It might be a wiring discrepancy. Chris. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1518 Registered: 6-2009 |

Chris, Where would the overload cut-out come into play in your wiring if the bits were all still in the car? I realize that you've eliminated that entirely from the equation since I think that's located on the fuseboard for all the cars, but I can't picture where it would have been removed in your setup. You may be able to answer your own question if your cadaver car's cut-out is wired elsewhere in the circuit than on this diagram. I agree that once the cut-out kicked in that should interrupt a power source to either W1 or W2, which instantly causes the C2 -> C1 switch to open. Brian, whose previously valiant effort fell short | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 845 Registered: 5-2012 |

Chris I take your point - if the cutoff throws, then the supply side is lost to both the motor and the relay, so according to the diagram, the brake should be applied. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 349 Registered: 5-2013 |

Hi Brian, I think the cut-out must be integral to the motor... The original picture shows the red and green plastic insulated wires coming from the motor to the connection block, and there to the switch and relay, so there is no opportunity to loop another component in to the circuit. I'm not sure why my cut-out won't cut out, but I gave it sixty seconds yesterday, and no reaction. The insight that Geoff gave me, is that the cut-out interrupts power to both W1 and W2. I was misreading that. Chris. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 214 Registered: 6-2005 |

1. The circuit works because of the difference between the resistance of the field windings (low) and the relay coil (high). For example when the UP switch is ON the RH field winding gets maximum current while the LH one gets little. 2. I didn't read the diagram properly. The cutout is inside the motor. Because it restores itself it must detect the heat of the stalled motor. 3. I re-checked the diagram with TSD 2218. It is the same. I suspect a discrepancy but will need to pull a door apart to resolve. 4. A likely discrepancy is that the cutout only breaks the armature current of the motor. This would be sufficient as far as motor safety was concerned but would allow the switch to control the brake release solenoid. 5. An interesting puzzle. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 350 Registered: 5-2013 |

Hi Folks, New and very interesting development... My experimental setup is the driver rear window lift. As a result, I now know how to wire the lift in-situ so that it operates. So, I was in my shop, straightening up, drinking a beer wondering if the passenger rear behaved the same deviant, but correct way as the driver rear, meaning no slip. Since I knew this was easy, I wired it up and tried it. It slips! So, I now have two lifts which behave differently, and I can see at first blush are wired identically, so it is clearly a minimum case and there are no inadvertent wiring bugs to complicate the comparison. Now I can make some measurements to see if I can determine any difference between the two, and experiment to see if there is a simple wiring modification that will do what Geoff has pointed out is the correct behavior, meaning when the cut-out trips, the relay drops and opens thereby disabling the the solenoid and braking the window. My questions are: 1) Why does driver not trip the cut-out? This is apparently idiosyncratic, since my lift is the only reported instance of this behavior. Still, I want to know. 2) Why does driver rear hold with no solenoid and passenger rear slip, meaning what is the mechanical difference between the two? 3) Why does cut-out on passenger not drop the relay and subsequently drop the solenoid braking the window, meaning what are the electrical differences among the two lift implementations, and the diagram? Of course, the answer to 2) may make 3) moot, since it is irrelevant that the solenoid fails to drop when the cut-out trips if there is no slippage as a consequence, however I think it is still interesting, since the behavior is at variance with the diagram, and I'd like to know the difference. Chris. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 351 Registered: 5-2013 |

Hi John, > 4. A likely discrepancy is that the cutout > only breaks the armature current of the motor. > This would be sufficient as far as motor safety > was concerned but would allow the switch to > control the brake release solenoid. That's a really good analysis, and completely explains what we see, and means the diagram is wrong. This gives me a working theory and something to expect. Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 847 Registered: 5-2012 |

Chris Very interesting. I'm hoping you may find time to dismantle the passenger rear winder mechanism. There has to be a design difference. It is possible the nylon gearwheel is just slipping on it's spindle. Very unlikely I would have thought, as the slip occurs on all four windows of John's car. It must be designed in. Would be great if you could enlighten us all. BTW - Nice to see you back on the forums. Geoff | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 216 Registered: 6-2005 |

Chris, To try to answer your questions- 1. The cutout is a heat sensitive switch and it is possible for it to fail. 2. On my car all the windows behave differently. The lifting speed varies, the slipping speed varies as does the amount of slip. This is due to the mechanical resistance to window movement including the friction of the window channels. 3. A simple check could answer this - For a window that slips, with no switch ON put a voltmeter lead on W2 and check for +12V Press the UP switch and check for 0 to +2V while the window rises. Hold the UP switch ON until the cutout operates then immediately release the switch and check the voltage before the cutout restores. If the voltage is +12v it means that the cutout only controls armature current. John | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 305 Registered: 5-2015 |

The sprocket is driven by worm and worm gear. Worm gears and worms if a finer helix is used they become non reversible. Making it impossible for the window to drop. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 352 Registered: 5-2013 |

I have not disassembled anything yet, but I do have a report. With the addition of my second lift from passenger rear, which manifestly slipped while fitted to the car, I tested the force necessary to reverse the motor, meaning I pushed on the bolt that normally holds the window. I had already disabled the brake solenoid by removing the plastic crown. It took a surprising amount of force to reverse the motor, but I knew this one did, so I persisted with ever greater force until I was able to drive the fixture down and reverse the motor. Then I tested the first lift from the driver rear. It took what I guess is a little bit more force, but it also "slips". My first report that it didn't slip was an erroneous conclusion based on the supposition of the amount of force the window would exert and I was apparently wrong about that. I was going to measure the relative forces, but I don't think it is useful. The point is that both do slip, so I don't have a "slip/nonslip" comparison. The only mystery now is why the driver rear lift does not cut out, but the answer is not generally useful and probably simply indicates a malfunctioning cut out. Chris. | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 317 Registered: 5-2015 |

Chris before you delve too deep into this system check your 1972 car. I think your 1972 car has round permanent magnetic motors and a different wiring circuit. Also the mechanical bits like to be well oiled and greased. Use engine oil on the chain etc. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 217 Registered: 6-2005 |

Later cars with the permanent magnet motor have a much simpler circuit as the motor only has a single (rotor) winding and its direction is changed by reversing the current via the door switch. As the brake release solenoid is connected in parallel the brake will always come on when the cutout operates. So no slip. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 857 Registered: 5-2012 |

Hi Chris I am still curious as to how the windows on your 66 car slip. My guess is the angle of the worm on the early cars must be much less than on the later cars. Here is a picture of the worm from my window winder mechanism. The angle is such that the gearwheel would never be able to reverse it. I think the term used in the trade is "self locking".  Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 356 Registered: 5-2013 |

Hi Geoff, I detached the brake solenoid so I could see its behavior and not have it effect the operation of the lift. All my observations of behaviors were made without an attached brake solenoid. This circuit is much more complicated then it initially appears. All the coils give it a huge inductance and there is some natural capacitance, so there is LC resonance, and that is causing behavior that I can't explain because I don't understand it. There are the brake coil, two field magnets, and armature all parallel with each other, exhibiting obvious inductance and unknown but non-zero capacitance. I don't have sufficient understanding to analyze the effects of this, beyond the observation that LC circuits resonate, and resonance in the presence of coils produces current. First: Permanent magnets. The motors with non-permanent magnets, I think they are called field magnets, will let you spin their armature with nearly zero resistance compared to motors with permanent magnets because there is no magnetic attraction to the armature without current. I suspect this is a part of the explanation, but not the biggest part. Second: This circuit behaves in a completely explainable way. It is not a simple restive circuit. The good news is that the diagram is exactly correct. I peeled back the rubber cover and I found the cut-out. It is very simple. I verified continuity from Y-P (Yellow-Plastic) to G-P, Y-P to R-P, and Y-P to YB-P. Then I tripped the cut-out and I verified open connections on all three. So, according to both the diagram and my example, the cut-out controls current to both field magnets and the armature. Now some random observations:

The key to stopping window slip is understanding how the relay remains closed, retracting the brake solenoid, when the cut-out has tripped and eliminated the twelve volt source. It may be something as simple as putting a resistor in series with the W1/W2 coil to reduce the sensitivity of relay closure. I'm going to have to learn more about electronics before I'll be much help understanding what is happening. So, Geoff, I know you have been seeking a mechanical difference, but I now suspect it is electrical, however, I will see if I can get at my worm gear for a comparison. I suspect my worm gear from the '66 cadaver car will be exactly like yours, but we won't know for sure until I look. I count four ridges on your worm, so you suspect that I will find fewer than four ridges on the '66 cadaver car. I'll look and let you know. The reason I suspect no mechanical difference is that the window slips with nearly zero provocation while under power with the cut-out tripped, very much less than it does without any power at all, so I suspect that the window slip is actually powered and an unintended consequence of the design of the motor, which changed to permanent magnets and probably eliminated the unintended consequence. Chris. | ||

Robert Noel Reddington Grand Master Username: bob_uk Post Number: 322 Registered: 5-2015 |

Chris you are over thinking how it works. The motor has two field coils. Depending on which field coil is connected gives the motor direction. Up or down. The inductance resistance and capacitance of the circuit have no real value when working out how the circuit works. These motors are nothing special and are used widely un engineering stuff. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 218 Registered: 6-2005 |

Chris, A very thorough investigation. However when you see 6 volts across the brake release solenoid this means the relay is NOT energised, otherwise you would see 12 volts. But there is another circuit operating here ; current can flow through the Brake Release Solenoid, the Armature Winding , the Up Field Winding and the Up Switch to Earth. Maybe this is enough to keep the brake off. An interesting point here is that the current through the armature is now reversed which would tend to help the window drop. John  | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 357 Registered: 5-2013 |

Hi John, Brilliant! And so simple! And it explains everything I've seen, including six volts across the solenoid (series with the armature and field magnet) and why substitution of permanent magnets for field magnets rectified the problem (disrupts the path to ground). And it can be fixed with a diode on YB-P! I'm embarrassed that I didn't see the simple answer; it was right there in front of my face, but I'm gratified that you did. Good job! Now, if anybody can spec a diode for me, I'll happily try it out. Geoff: I opened the worm drive and the '66 cadaver car is identical to the picture you posted. I have a picture, but it is not immediately available, and apart from the degree of "stuff" in mine and not in yours, I'm happy to use your picture as a proxy for mine. (-: . Given this new development, I think it is quite conclusive that there are no mechanical differences anyway. Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 859 Registered: 5-2012 |

John/Chris Brilliant piece of detective work. A mystery solved. Mechanically, the window slip is impossible. Electrically - everything now makes sense. Brilliant. Geoff. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1536 Registered: 6-2009 |

Chris, Since these diodes - 1N4001, 1N4004, 1N4007, EM513 or equivalent - are used with the relay in the window lift modification I'd certainly give one of these a try as a first shot. I think I used a 1N4001, but it might have been a 1N4004. I can check my "electrical bits" box if you'd like. I know that multi-packs of any of these are available dirt cheap at Radio Shack (among myriad other electronic components outlets - Mouser, etc.) Also, to be pedantic, there is no actual window slip, the mechanism is still being driven. It appears that the whole brake solenoid was a solution in search of a problem that could have been solved with a better design on the circuit itself (and the "solution" doesn't really work, either). At least I will never feel any compunction about removing the brake solenoids on any SY car that uses permanent magnets. One less thing to worry about or go wrong. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 860 Registered: 5-2012 |

I was wondering if the original system was a very clever design to act as a safety system. The idea being that if (say) a child trapped his/her arm in the window and the up switch was either jammed or being pushed by the panicking child the windows would cutout and unwind themselves. This of course would have been abandoned once the move to permanent magnets had taken place. I guess we will never know. Chris/John - do the early cars have a disabling switch on the drivers door as do the later models? Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 358 Registered: 5-2013 |

Hi Geoff, I think mine does. I can't be entirely sure, since it currently doesn't do anything, but it is in the right place and I can't think of another use for it. Chris. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 359 Registered: 5-2013 |

Hi Brian, Thanks. I'm going to see if I can get one to test. Meanwhile, I suspect John Kilkenny will beat me to the punch, since his car would benefit, while I am just pursuing an experiment, although I don't have to tear down a door to do it. Chris. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 219 Registered: 6-2005 |

Geoff, My car (SRH1405) does not have a disabling switch. It would be nice to think that the circuit was purposely designed that way to protect little fingers ! John | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 360 Registered: 5-2013 |

Hi Folks, I am happy to report that I had a Diode of the correct spec and I have tested it and it works. I used a 1N5400 diode, because that is what I had and will support three amps of current. I soldered tabs to it. Female Tab on the banded side of the diode; male otherwise. Now, when I trip the cut-out, the brake solenoid is dropped, meaning it asserts the brake. This also means that the "hidden" path to ground is disrupted and the motor is no longer powered inadvertently causing window slip.  Chris. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 864 Registered: 5-2012 |

Hi Chris I am unsure as to why you would want to modify this circuit. It can do no harm to leave it untouched. The circuit was quite possibly designed as a safety feature. Geoff | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 361 Registered: 5-2013 |

Hi Geoff, It is probably not a safety feature, or it would have been preserved in later years. However, it may be construed as one, and some owners may want to preserve that behavior; others may not. I was interested to confirm our theory of the inadvertent ground path and understand why later years did not exhibit window slip. On my '71 and '72 I have less than optimal window performance, and this thread started as the preliminary work to improve them. Over the course of my discussions with you lot, I learned that I can simply remove the brake solenoid, but the question of window slip was not clear to me, and I didn't want to substitute one problem for another. It was initially not clear why the windows slipped, but through ruthless experimentation, I think we now understand what is happening and why. With that new understanding, I can improve my windows by deleting the brake solenoid and be confident that I am removing a superfluous part. Simplification is always a good strategy. Chris. | ||

Bob Reynolds Grand Master Username: bobreynolds Post Number: 302 Registered: 8-2012 |

"Simplification is always a good strategy." Very true, especially when it comes to Shadow design! If this was a safety device it was a very poor one. If fingers were trapped you would have to wait for the cut-out to operate, by which time you would have released the window switch anyway! Who's going to trap their fingers in the window and continue to keep the switch pressed up? In the case of a driver (who would have to be stone deaf not to hear the screams) he would have to keep the switch pressed for around a minute for the cut-out to operate and then continue to keep it pressed while the window was powered down very slowly. This behaviour would be unusual in the extreme. If they were going to deliberately incorporate a safety feature in the design, I am sure they would have done much better than this. Any safety feature needs to act as quickly and decisively as possible. Rather than being a deliberate design, I think this was probably an unintended consequence of the circuit design. And they may never have realised exactly what was happening after the cut-out operated. Some mysteries remain: These brake solenoids persisted throughout the life of the Shadow. Any junior engineer knows that worm drives are non-reversible, so why did they even put brakes on the window mechanism in the first place, when the motor itself acts as an effective brake. And why did they continue to put them on after the motor was replaced by a permanent magnet motor and there was no possibility of 'motorized slippage'. Even the Crewe tea-lady must have realised these weren't necessary, and were just sapping power from the motor. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 867 Registered: 5-2012 |

Bob I totally agree. I was just trying to find a rationale for such a poor design. As you said, now we know the "slippage" is not slippage at all, in a mechanical sense, even on the very early designs the solenoid brake is entirely superfluous and just acts as a sink for much needed electrical current through the already inadequate wires. It is a very strange story. One assumes when the designers tested the cutoff switch they would have wondered why the window motor had gone into reverse. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1546 Registered: 6-2009 |

Geoff, This presumes that there was any "intensive testing" of this system. I have come to accept that in earlier times, and in cars produced in what were spectacularly small numbers, that the kinds of intensive testing we know to be the norm today just didn't exist. It would not shock me at all were we to learn that the only concern was for whether the cutoff switch worked and when it was determined that it did that was the end of testing. As we all know, the windows continue to go up and down on these cars pretty well given their age. I wonder how the brake solenoid ever came to be put on, actually, as the way it's wired really does strike me as an afterthought associated with a work-around. Given all that's come out in this thread I know that I will remove the brake solenoids on LRK37110 when I get back in the groove with working on her. The two rear door panels have never been reinstalled so those two will be a cinch. I think this may also eliminate the use of a slide-connector "Y" connection in the window lift improvement modification wiring that is used to feed the brake solenoid. It has, however, been so long since I installed this that I need to go back and review what's connected and how. Brian | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 363 Registered: 5-2013 |

Hi Folks, Crew just never "unearthed" the problem... Geeze! I just crack myself up!!! Chris. |