| Author | Message | ||

Randy Roberson Grand Master Username: wascator Post Number: 397 Registered: 5-2009 |

Gents, I took the Wraith II out this evening for about 20 miles to get things circulating; also I'm trying to use the fuel down so I can repair the gauge sender/float (I hope it's the float). On our return home I decided the idle seems high so out comes the dwell meter (ouch that's hot) and it is around 900. The idle screw will not slow it; I can get off it entirely and it still idles about 900, but it will speed it up as expected if I turn it in. The choke is well off and it is not on the fast idle cam. Ideas? Should the idle be about 600 RPM (USA Car)? | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 708 Registered: 5-2012 |

Hi Randy Given you have already checked the choke idler screw I would check the accelerator linkage clamps on the throttle butterfly valve spindles. If one of the butterfly valves is slightly open and the other fully closed, this would cause the symptoms you describe. It may be one of the clamps has loosened slightly causing it to slip out of adjustment on the spindle. Geoff | ||

Bob UK Unregistered guest Posted From: 94.197.121.197 |

600 to 700 rpm. Call it 650 rpm Oil the linkage. Close butterflies by assisting the return spring manually. Do a few times. (Message approved by david_gore) | ||

Randy Roberson Grand Master Username: wascator Post Number: 398 Registered: 5-2009 |

Geoff, I looked carefully at the linkage clamps, and I could not find anything I could move the least bit. I also visually verified the idle screw is not touching its landing. Bob I am lubing the linkage but it moves quite freely. I will work it some and report back, but it really seems pretty-much in good order. I recall reading about a hot idle compensator one has to disable before setting the idle; could this be acting up somehow? | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1321 Registered: 6-2009 |

Randy, When I was trying to set the idle speed on LRK37110 I found that there was a lot of additional detail in Chapter U of the workshop manual. See the thread I posted entitled, Searchable Chapter U - Shadow II/T2 Workshop Manual - TSD4200. Take a look in that chapter if you haven't already. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 710 Registered: 5-2012 |

Hi Randy Re: I recall reading about a hot idle compensator one has to disable before setting the idle; could this be acting up somehow? You could try disabling it and seeing if it makes a difference. It is a simple task to remove the rubber hose from the out connector and blank it off. My money is on misalignment of the throttle valves. If the idle screw is not touching it's landing, then the throttle valves are acting as the throttle stop. If both are fully closed you would have difficulty getting the engine to idle at all. This is why I think the one valve is acting as the throttle stop and the other is partially open. I guess my previous entry was a bit vague. The only way to make sure both valves are fully closed is to reset them. There are several possibilities so it is for you to decide how to work through this problem and in which sequence. Another possibility could be the distributor has come loose and the ignition has retarded slightly giving a higher idle under no-load conditions. Highly unlikely I would have thought, but a possibility. Geoff | ||

Bob UK Unregistered guest Posted From: 94.197.121.120 |

Remove dashpots and pistons dont mix up. slacken throttle stop and the buggerflies should be shut. The by pass by air screws screw out from closed 1 turn. Screw throttle stop in so that the butterflies open a wee bit. Check they are in unison. Reassemble. Start engine. Adjust throttle stop to get near to 650 rpm. Then adjust by passes to fine tune. Disconnect A1 note rev drop. Reconnect. Disconnect B1 note rev drop Reconnect. If the rev drops are the same then the bypasses are in balance. If not turn out the one with smaller rev drop. And turn in the bypass that has bigger rev drop. Do not turn by pass out more than 2 turns else it may whistle. Note electronic ig systems dont like being disconnected so use an earthed spark plug. Note the linkage is well made and providing no one has maladjusted it. It is very unlikely to be incorrect. (Message approved by david_gore) | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 200 Registered: 6-2005 |

I don't know the Wraith but if the idle speed on my Shadow 1 suddenly increased for no apparent reason I would check the aircon fast idle which is used to raise the idle revs to 900 in Park or Neutral. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 711 Registered: 5-2012 |

Randy A couple of tips to expand on Bob's entry. Before removing the dashpots, mark them so they go back in exactly the same position as they came off. I used a centrepunch on one of the lugs where the dashpot screws go in to mark mine. When you remove the piston, never rest it on it's side - the needle will be taking the weight. Drill a hole in a shelf so the needle pokes through and the weight is taken by the base of the piston. Absolute cleanliness of course - I use paper towels to cover any work area I store the parts on. Keep the parts for each carb well away from each other - it is easy mix them up. Keep the piston vertical unless you want oil down your clothes. This is a great time to check and refill the piston oil level as well. When you have loosened the clamps, use your finger to push the valves fully closed before re-tightening the clamps. As Bob said, you will need to fine tune the carbs when they have been reassembled. This is done when you have restarted and warmed up the engine, by adjusting the volume screw. I use a unisyn carbalancer for this. Geoff | ||

Randy Roberson Grand Master Username: wascator Post Number: 399 Registered: 5-2009 |

Bob and Geoff: great information, very clear and I understand what to do. One question: If I find one of the throttle plates not closed, I loosen the linkage clamp, slip it on the shaft to close the throttle plate completely, then retighten, correct? This with the idle screw backed out. Seems to me this situation could be what's behind the symptom I reported earlier: a shudder on pulling, yet not a tire balance issue. I wonder if we would notice something like this if the carbs are out of balance enough? All this has been happening with the air conditioning OFF (I am repairing it anyway, so basically there is no AC right now). I will look for the device which speeds the idle up slightly when the AC is on, though. I noticed I do not have the throttle dampener that I saw in one diagram. I will also check out the hot idle compensator. Anyway, I am planning plugs, wires, cap, rotor, etc. although these look decent: this car is not one of the neglected ones, but the PO passed on around 7 years ago so I doubt it has had much attention or driving in the intervening years. I think the choke is a little rich and the insulation is missing from the heater tube, so I have that to do. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 712 Registered: 5-2012 |

Hi Randy Yes, you've got it. However, I think it best if you just go through the balancing procedure in full. My method is to loosen both clamps and fully back off the choke and throttle screws. I then adjust the throttle screw so it protrudes about 1/8". I then put my finger into the carb and push the top of the butterfly valve to ensure it is fully closed and at the same time tighten the clamp. I then repeat the procedure on the other carb. When you've undone the clamps, it is a good idea to flick the butterfly valve back and forth with your finger just to check it is not tight or binding. It should move freely. Once you have done this you can restart the engine and check/adjust the tickover. Remember you will need to reset the choke screw also. Finally you can fine tune the balance by adjusting the volume screw. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1323 Registered: 6-2009 |

Randy, Black silicone covered fire sleeve works just perfectly for replacing the insulation on the stove pipe to the choke. I bought quite a bit of it when I was doing that job on LRK37110. If you'd like for me to send you a segment long enough for the purpose just e-mail me. I'm certain I have more than enough left and I actually think I know where I've got it in storage. If the pipe has rusted through it's easy to make a replacement out of either copper or cunifer tubing. That's been covered in Tee-One Topics. Brian | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 201 Registered: 6-2005 |

Randy, Before you do a major re-adjustment of the carburetters do this simple test. With the engine idling in P or N switch on the aircon. Does the rpm increase ? John | ||

Bob UK Unregistered guest Posted From: 94.197.121.120 |

And to expand on what Geoff. Often one finds that the dash pots are marked already. Fill dampers with engine oil or ATF. If over filled the level will sort its self out. If the inlet horns are removed. The piston without damping oil should hit the bridge with a click when dropped from max height carb assembled of course. Rover V8 inlet horns simply pull out they have O rings. Much better than the Rolls Royce V8. I have taken my carbs off via the centre bolt and refitted with no adjustments required. That bit I like. The governing factor of idle speed is gear box bump when selecting a gear. I like a slight bump that doesn't cause the car to start moving. I set the idle rpm accordingly. There is no advantage in low idle rpm. The engine is liable to stall when the steering is worked. (Message approved by david_gore) | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 255 Registered: 8-2012 |

Actually, I found that there was no need to mark the dashpots, as they will only fit one way. The 3 screws are not 120 deg apart. As long as you don't mix them up. | ||

Randy Roberson Grand Master Username: wascator Post Number: 400 Registered: 5-2009 |

Brian thanks for the offer; I have black silicone sleeve left over from repairing the 1970 SRH 9391 a couple years ago. The pipe itself is in beautiful condition: it must be stainless. The pipes on the '70 were steel and rusty so I fabricated replacements from stainless. Worked like a charm! | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 713 Registered: 5-2012 |

Hi Bob The dashpots on the earlier SY1s' carbs have 4 securing screws in a square configuration. In a sense SU have confirmed the desirability of always replacing the dashpots in the same position, by using the non-equilateral triangular configuration on their later designs. Geoff | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 256 Registered: 8-2012 |

Thanks for that, I didn't know they changed the dashpot design. But Randy's car is a 77, so presumably that should have the later 3-hole fixings? | ||

Bob of Dorset Unregistered guest Posted From: 188.29.164.117 |

Before doing anything else check for vacuum leaks. Cruise control and gearbox vacuum module. Assuming that the car was ok then the idle revs went up. The linkage is well made and normally shouldn't need adjusting -- ever. So something like a spilt vacuum pipe can just happen. My jeep did this. My first thought was the idle servo motor. But then I noticed a split vacuum pipe to the charcoal cannister. Us engineers can get complicated and miss the obvious. I had almost decided to remove the servo motor imagining it to be gunged up with black stuff. If I had done that then I am disturbing a 20 year old not very well made injection system. No worries with SU though. (Message approved by david_gore) | ||

Randy Roberson Grand Master Username: wascator Post Number: 402 Registered: 5-2009 |

Good point. Thanks. | ||

Robert Noel Reddington Yet to post message Username: bob_uk Post Number: 1 Registered: 5-2015 |

Test to check my registration | ||

richard george yeaman Prolific User Username: richyrich Post Number: 286 Registered: 4-2012 |

Hi Robert welcome to the Australian Rolls Royce forum where I am sure you will find a wealth of information to help you. Richard. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1326 Registered: 6-2009 |

RGY: It's a bit late to be welcoming Bob UK to the forum!! ;-) The number of monikers he's appearing under today is making my head spin. There's the old Bob UK, Bob of Dorset, and Robert Noel Reddington (with username: bob_uk). Brian | ||

Randy Roberson Grand Master Username: wascator Post Number: 403 Registered: 5-2009 |

Took a few minutes under The Bonnet this evening. I do not see any sort of device which would move the throttles when, say, the air conditioning is turned on. Please elaborate. Because it is not fuel injected, wouldn't a vacuum leak just lean out the idle mixture and make it idle poorly? Also, if there is an air adjustment screw, I can't find it on either carb. The only adjustments I can find are the fast idle screw on the choke cam and the normal idle screw on the B-bank carb. The carbs do each have three screws holding the damper covers. I am going in when I have the time to concentrate: I have a long weekend this week. While looking I noticed the probable source of a small coolant leak on the floor: the thermostat housing seems to require attention for at least the two sensor mountings; also it appears the coolant outlet on the front of the intake manifold is seeping at the O-ring seal. | ||

Randy Roberson Grand Master Username: wascator Post Number: 405 Registered: 5-2009 |

I read in 'Chapter U' that there is a valve on the throttle plate: the overrun valve. It is spring loaded and leaks some mixture through the throttle plate when it is closed suddenly under load. I will look to see if one of these is stuck open. Hummmnnn.... | ||

Robert Noel Reddington New User Username: bob_uk Post Number: 3 Registered: 5-2015 |

If the butterflies have these valves. Press the valve shut with finger pressure and turn at the same time. This seats the valve. Bob Uk Robert Noel Reddington. Bob of dorset. Dave Gore. How do I change my user name back to Bob UK. | ||

David Gore Moderator Username: david_gore Post Number: 1621 Registered: 4-2003 |

Hi Bob, For some reason, all members names and not their user name identify their posts whereas guests can be identified by a user name. I suspect this is to make the forum more personal for members. If you have a specific reason for changing the name used to identify you on the Forum, I suggest you send an email to the Administrator [admin@rrforums.net] to discuss this further. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 259 Registered: 8-2012 |

I must be going senile in my old age. My dashpots ARE 4-hole fixing, not 3, and it is still impossible to put them on the wrong way round. The screws will only line up in one position. I've just tried it! | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 717 Registered: 5-2012 |

Bob I have just checked my carbs, as I've currently got them on the bench for rebuilding. You are absolutely right. Although, from a cursory glance, the configuration of the holes appear to be at least oblong, the fixing holes are slightly offset so the dashpots can only ever be replaced in the correct position. I must be going senile in my old age. Best Regards Geoff | ||

Randy Roberson Grand Master Username: wascator Post Number: 407 Registered: 5-2009 |

My 1970 has the air adjustment screws and obvious float chambers but the '77 does not. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 202 Registered: 6-2005 |

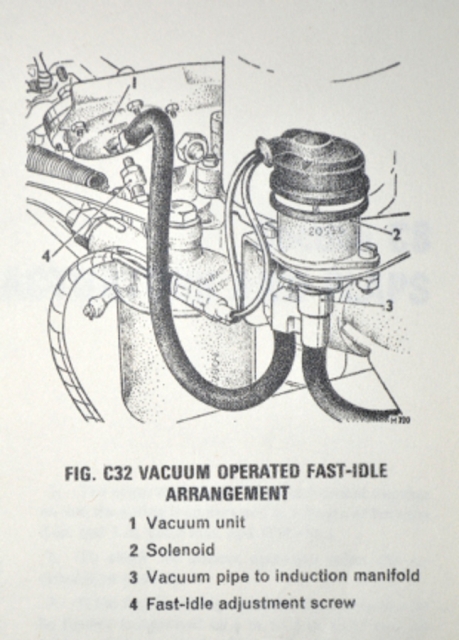

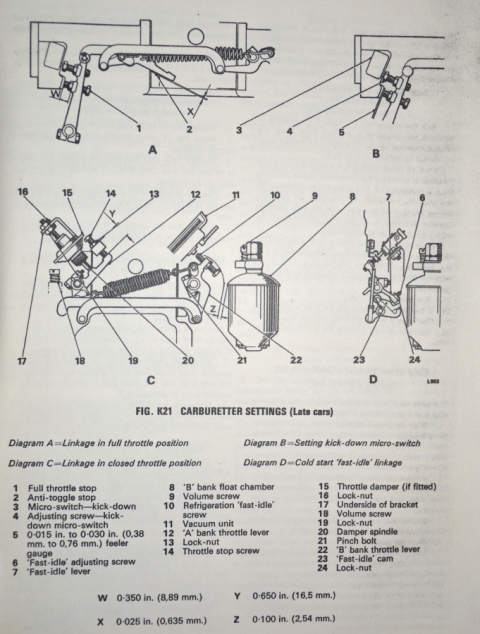

My car (SRH 1405) may not have the same arrangement as one eleven years on but here are drawings showing my idle controls. The refrigeration fast idle uses a small solenoid to connect the induction manifold to a vacuum diaphragm which pushes on the refrigeration fast idle adjustment screw. The other diagram shows the operation of the cold start fast idle. Both of these are worth checking for an unexpected increase in idle RPM.   | ||

Randy Roberson Grand Master Username: wascator Post Number: 409 Registered: 5-2009 |

My Car LRF 30305 does not have any of these parts. I removed the carb chambers last evening, examined the compensator valves which seemed perfect: everything in there was clean and the throttle plates were closed. I am going to concentrate on vacuum leak detection as an obvious possible source of the problem, before I start turning things. Again: no air adjustment screws on these carbs, far as I can tell. |