| Author | Message | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1153 Registered: 6-2009 |

. . . and my first real one (I don't count a dead battery and dying fuel pump at home as FTPs). Any assistance in long-distance troubleshooting is appreciated. Just got home in a cab, and it was a Christmas miracle that they'd come out to a bit beyond Lone Fountain, VA, to pick us up (and were the only local cab service dispatching this evening). My partner, Jim, and I had been motoring along for about 30 minutes without a hitch. Cruising along at 55 MPH, I heard something that sounded like either a slight backfire or a stone hitting the underside of the car. The engine promptly stalled afterward. Immediately after the stall, she'd start up again perfectly normally and run for less than 10 seconds, then stop dead. Ah, fuel starvation I thought . . . my fuel gauge must not be working. Well, a kind stranger and 3 gallons of fuel later that theory was shot to @$&%. She wouldn't start at all in "normal start configuration" (pumps not ticking, no additional throttle given, turn key). After calling the cab at the kind stranger's house I waited a while and tried again. Again, no start in "normal start configuration." Decided to try holding the gas pedal down a bit. She fired right up and ran, perfectly, at the very high speed my foot position commanded. Kept running and I slowly eased off the gas. Still very smooth all the way down to idle. Once at idle, still seemed OK but, after somewhere in the area of 10 seconds, conked out again. You can hear ticking when the engine is running, but it strikes me as "the usual" brake pump ticking I've had since I acquired the car in 2006. I later tried another restart like the above and had pretty much precisely the same results. Clearly I do not have a fuel pump problem or a fuel line blockage or I should not be able to keep the engine running at well above normal idle speed without any irregularity that I can tell. I don't know even where to begin trying to tackle this issue or to direct a mechanic (which I may go that route, there is a local shop that's done good work for me before and he's a crack diagnostician [who also has worked on another Shadow that used to be here in Staunton]). If anyone has theories as to what might be happening here based on the behaviors above please do share. If there's anything you think is worth trying as a roadside repair before resorting to calling a tow truck tomorrow that would be helpful to know, too. Brian, who's still counting his Christmas blessings because in the grand scheme of things, this is a problem with a solution | ||

David Gore Moderator Username: david_gore Post Number: 1494 Registered: 4-2003 |

Brian, Sounds like a fuel problem to me - first check I would do would be to disconnect the discharge fuel line from the fuel pump and do a flow test. This should reveal any pick-up/filter blockage in the tank/inlet fuel line to the pump and any fuel pump problems. Using a fuel tap to throttle the discharge to put back-pressure on the pump may be useful. Second check would be to start and run the engine WOT as you describe and let the engine die back until it stops. Disconnect the HT lead from the coil, put a clean rag or similar over the exhaust outlet, crank the engine for a minute or two without using te accelerator and then smell the rag for fresh fuel [not exhaust gas]. If you can smell fuel then there may be a carburettor flooding problem or a float chamber needle valve that is sticking at idle speed due to low or no fuel pressure at idle; no fuel smell then a problem with a stuck float, stuck needle valve and/or an intermittently blocked filter/fuel line. Does your Shadow have the low oil pressure ignition cut-off safety switch? If so, this may be faulty or you have extremely low oil pressure at idle. The fact that you can start and run the engine under WOT but not at idle suggests the ignition system is not the problem unless you have a worn breaker plate bush that keeps the points closed at low revs but moves sufficiently from point spring tension transfer to open the points at high revs. Please keep us posted on the outcome. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1155 Registered: 6-2009 |

David, Thank you for your suggestions. I shall keep everyone posted as events progress. I have a question regarding the ending part of the second check. The way you've written this reads to me as though I have a problem if I can smell fuel *and* if I can't smell fuel. Either my reading comprehension is off due to today's adventures or something's off here. There appears to be no "normal" outcome in this step. I am not certain whether this car has the low oil pressure ignition cut-off safety switch or not. It is a UK spec car. I must admit that I hadn't even thought to look at what the oil pressure gauge was showing. When I first got the car the oil pressure sender was replaced with an alternate (not of my choosing, but the then mechanic's, who has extensive British car experience) which I believe is a Ford pressure sender. It has always read low on the dial, but the testing showed that normal pressure was present and that what I watch for as "normal" on the 4-way instrument oil pressure is simply shifted "down" the scale. If memory serves the pressure switch for ignition cut-off is a separate item from the sender for the oil pressure gauge. If anyone knows whether my memory is correct please let me know. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 577 Registered: 5-2012 |

Hi Brian If the ignition timing had somehow stuck in it's advanced state then this would cause the symptoms you describe. i.e. the engine will run at high revs but as soon as you let the engine return to tickover the engine stops. Although unlikely, it is possible the centrifugal weights have seized or failed in some way, causing the engine to be too advanced for tickover. It would also explain the backfire. I would certainly try retarding the ignition timing just in case, purely as a get you home measure. Geoff | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 578 Registered: 5-2012 |

The ticking you hear could be pinking, also caused by the ignition being too advanced. I believe the SY2 has a vacuum advance - also a potential point of failure. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1156 Registered: 6-2009 |

Geoff, It's not that I don't understand what you're saying, I just have no experience of doing it. It will take decades, if the time ever arrives, before I will be able to say I've "been there, done that," with all the systems in these cars. My partner is pushing for me to have it towed back to Staunton, and I'm leaning toward doing this so that I can experiment in my driveway at leisure. If, however, I could drive those 10 miles or so, even conservatively, it would beat having to involve a tow truck and making sure that they tie the car down correctly. Brian | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1547 Registered: 4-2003 |

Well these arm's length problems are more like a horse race with punters! My money would be on the oil pressure switch (not the sender) as David suggests. These can fail in a number of ways and should be replaced every few years - they are not expensive. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1157 Registered: 6-2009 |

Bill, I'm gathering you mean like a horse race with the group of "crazy" betters [that's the best I can do, with quick research.] If that's correct then I know precisely what you mean. I am eternally grateful for even semi-wild speculation from those who've experienced (directly or otherwise) something similar. It gives me, who's clueless beyond my initial speculations, some specific things I can look at. This is infinitely better than shots in the pitch black dark. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 579 Registered: 5-2012 |

Hi Brian I am definitely with Jim on this. Involving a local garage is to open up another channel of expenditure. So much better, as you say, to get the car home where you can work on it. The practical side of retarding the ignition is very simple. If the SY2 is the same as the SY1, it is just a case of reaching over the right hand fender and getting your left hand behind the distributor. This is the location of a pinch bolt which needs to loosened a half, maybe one turn with a 1/2 sae wrench. I use a short stub wrench and always use a length of string to tie it to my wrist - it is a bit fiddly and easy to drop the wrench. Once loosened, just rotate the distributor clockwise by 1/4 inch. Tighten the pinch bolt and see if the engine will run on tickover. If it does, you will be able to drive home, albeit on reduced power. This will not harm the engine. It's worth a try. Nothing to lose and this may be the problem. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1158 Registered: 6-2009 |

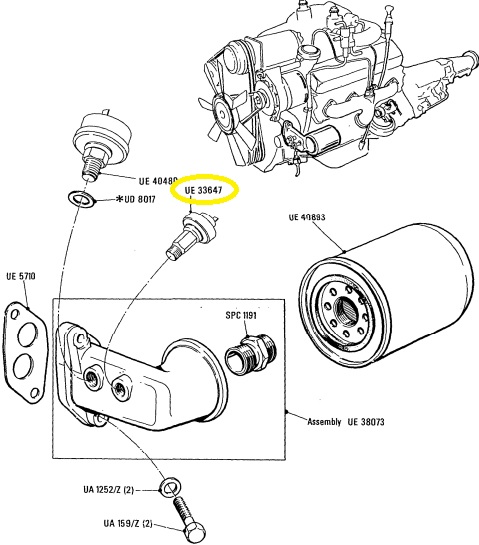

In searching the Spare Parts Catalog and the Workshop Manual I am not having much luck finding the oil pressure switch. Is the part who's number I've circled in the below image from the parts catalog the thing in question?:  Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 580 Registered: 5-2012 |

I'm thinking in terms of simple get you home measures, that can be carried out at the side of the road. To this end, could Brian just run a wire from a 12v supply directly to the coil to circumvent the oil pressure switch. Geoff | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1550 Registered: 4-2003 |

That's it my friend. The diaphragm goes in these switches either completely or leaks. The simple solution if this is the problem is to disconnect the thing, When you get home unscrew it and take it to your local parts people and they should have one to fit otherwise get it from from Flying Spares | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1551 Registered: 4-2003 |

Does this car have a fuel weakener? | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1159 Registered: 6-2009 |

Bill, I gather from your proposed solution that this is an "On when there's no pressure/off when there is sufficient pressure" switch not unlike the switches for the brake/hydraulic system. Just curious if there's a place to disconnect this that's on *top* of the engine bay and easily accessible rather than crawling underneath at roadside? I have to believe this is another one of those parts that's common as dirt, it's just a matter of knowing what manufacturer(s)/part number(s) were renumbered UE 33647 by Crewe. Life is so much easier when I can go to my local NAPA, Federated Auto Parts, AutoZone, or Advance Auto Parts as opposed to ordering from anyone else, domestic or offshore. Also, I just saw your second question. The weakener system is still on this car and connected. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 581 Registered: 5-2012 |

Brian Don't forget to check your dipstick first. It may be the case the oil pressure switch is telling the truth and your engine oil is lying in a pool half a mile down the road from where you failed to proceed. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1160 Registered: 6-2009 |

Geoff, Not that I won't check, but I'm doubting it. Were that the case I should have insufficient pressure to keep the engine running at higher speeds. No oil means a perpetual "no pressure" situation. I didn't walk back down the road by half a mile, but did have to cover quite a distance until I found the home with the gentleman who assisted me. I didn't notice a trail on the way back, but I quite likely wouldn't have noticed a number of things given my predicament. It always makes sense to check the easy stuff first!! (Even terribly unlikely easy stuff is *still* easy stuff!) Brian | ||

David Gore Moderator Username: david_gore Post Number: 1495 Registered: 4-2003 |

Hi Brian, Re the smell or no smell of fuel; these characteristics relate to two alternative sets of problems relating to the carburetors: 1. The smell of fuel indicates fuel is getting to at least one carburetor and is passing through the engine. The problem is then determining whether there is too much or too little fuel entering the intake manifold at idle and why....... 2. The lack of a fuel smell indicates fuel is either not getting to the carburetor[s] due to an internal problem in the carburetor[s] or a blockage in the fuel line/carburetor fuel filter[s]. Again, the problem is where and why...... After more reflection, I suspect the oil pressure cut-out is the most likely caused followed by a distributor fault affecting the timing at idle. However, Murphy's [Sods'] Laws apply and the cause could be a never-experienced-before problem........................ | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1552 Registered: 4-2003 |

brian, You are correct. The switch is on the back of the oil filter pedestal usually accessible with a long arm going down between the alternator and the side body panel and below the radiator inlet pipe. Wrap you arm in an old towel. Otherwise take a sheet of flute board - you get these from your local grog shop and lie on the ground and feel between the radiator and the engine. Have a good led torch toes what you are looking for. The terminal is a push fit. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 582 Registered: 5-2012 |

Hi Brian I think the important thing is to make sure you have a clear set of procedures to work to that covers all possibilities when you return to the car tomorrow - oil pressure switch, fuel delivery and ignition timing. With a bit of luck you will be able to get the car home. Geoff. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 3139 Registered: 4-2003 |

It could even be as simple as a vacuum leak. Look for a split hose coming from the inlet manifold region. Maybe intermittently it opens up. It is not unheard of for a backfire into the inlet manifold to cause an old vacuum hose to rupture. In Australia we would call the NRMA to fix it free of charge whatever has gone wrong. R. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 204 Registered: 8-2012 |

That oil pressure switch is a menace, for this very reason. Fortunately my Shadow doesn't have one, but if it did I would have permanently bypassed it as soon as I learnt about it. Anything that cuts off the ignition or fuel without warning, and without explanation, is a complete no-no in my book. If it turns out to be faulty I certainly would not replace it. As regards the distributor advance I would not tamper with any adjustments at the roadside, as that would introduce another unnecessary fault; which is the last thing you want. If you take the distributor cap off you should be able to tell whether the advance mechism is stuck by trying to rotate the rotor arm by hand. It should rotate against spring pressure and then spring back when released. That is the advance mechanism working. If the advance mechanism is seized, the rotor arm will feel solid. You don't say how the engine 'stalls' when it decides to stop. Does it splutter and come to a gradual stop, or does it cut out and stop suddenly? It sounds like an ignition problem to me. It is difficult to imagine a fuel problem that would allow the engine to run normally at high revs, but cut out at idle. A leaky needle valve would cause problems at idle due to an over-rich mixture on 4 of the cylinders, but it probably wouldn't be enough to stop the engine. Just cause it to hunt and run roughly. It might gradually splutter to a halt if the idle speed is set very low, but it would not cut out suddenly. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1161 Registered: 6-2009 |

Bob, Just for the record the stall was an immediate engine shutdown. No spluttering or rough running, just cutting out entirely, like a "switch was thrown." Also, the normal idle speed on the car is clearly too high and that was on my list of "things to adjust later." This morning I'm heading out to the car to explore the state of the oil level and that oil pressure switch. If that isn't the problem I'll at least look for something like a split vacuum hose, etc., that would be obvious if present. If nothing like that shows up then I'll arrange for a tow back to my driveway. Although the car is off the road it's not so far off the road that I feel comfortable undertaking any major repairs at the site. Brian, who should have been clear about the instant-cut-off nature of the stall | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1162 Registered: 6-2009 |

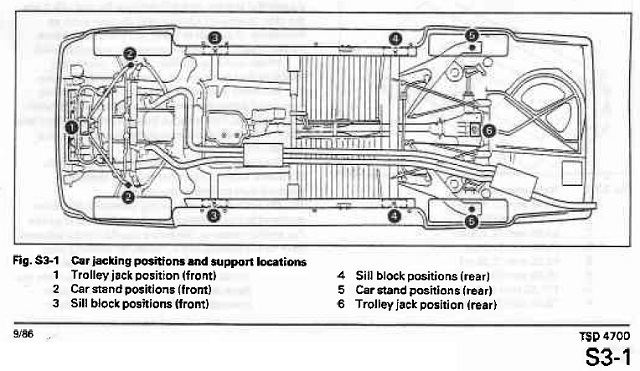

One additional bit: my partner says that we definitely had a backfire. That's what it sounded like to me, too. Now, another question: If one is having the car winched on to a flat bed tow truck, is the point where the hook should be attached the same spot one uses when putting the car up using a floor jack at the front (#1 in the diagram below)?:  Brian | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 205 Registered: 8-2012 |

Almost certainly an ignition problem then, and that pesky switch looks like the likely culprit. Backfires can occur in the induction system and in the exhaust system. The fact that you said it sounded like is was underneath the car probably means it was in the exhaust system. If the ignition system cuts off for any reason, this would allow unburnt fuel to enter the exhaust where it could be ignited by the heat of the exhaust system. I had to have my Shadow trailered recently, and they did indeed use point No.1 on your diagram. But make sure that the winch rope does not foul the bodywork at the front, particularly the spoiler on a Shadow 2, as it starts to go up the ramps. The bloke who came had been doing the job for 40 years and was well aquainted with dealing with broken-down Rolls-Royces - even when new! He said that if you contacted a RR dealer for assistace, the first thing they would do is to rush out with a car cover and cover it up so that nobody could see that a Rolls-Royce had broken down! They would then send a mechanic out some time later to fix it. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1164 Registered: 6-2009 |

Update: Drove out to the car, popped the connection off the switch and she started and ran like nothing was wrong. She is a bit low on oil (as she leaks, and I hadn't checked recently) but has been at this level before without issues. The people who live in the white farmhouse you can see in this Google Maps Street View of 1684 Hanky Mountain Rd, were kind enough to allow me to park the car next to their barn. My main immediate worry was one of three things happening: 1. Vandalism (unlikely, but possible) 2. Someone hitting the car. 3. The State Police hitting her with a tow tag and then having her disappear before I could make arrangements myself to move her. Bob, thanks for your input re: backfires. The sound issued, without doubt, from beneath the car and more toward the back than the front. I had the same thought you did, that the engine cut off and raw fuel was pumped back through the exhaust system as I slowed down and maneuvered myself off of the roadway. Some previous custodian long ago removed the air dam on SRH33576. I don't think US spec cars ever had them. I must admit that I find the concept of worrying about aerodynamics, and that's generally what air dams are about, on a Shadow which is about as aerodynamic as a barn to be more than a bit amusing. In one "official" book or another I read of RR having rushed out and covered a car that failed to proceed in London, but that was definitely a pre-war car if memory serves. The whole "they rushed out and covered the car" as a routine thing has, I believe, spun its way into urban legend. It would be interesting to know if that was ever "standard practice" anywhere. Brian, who will fill the oil and try to drive her home if my partner will be my follow car (he may try to insist on towing - he's a tad less "adventurous" than I with regard to these things) | ||

Bob UK Unregistered guest Posted From: 94.197.122.90 |

For a petrol engine to run it must have air, fuel and a spark at the right time. If the car has points set car a tdc if points open then the timing is about right and therefore so is the valve timing. If the king lead has a ht spark then check a cylinder. No king lead spark, jump positive coil terminal to live feed. Go to ballast and check. If the ignition is dead and jumping it also turns on the fuel pump suspect the oil switches. Note some oil pressure interlocks with both ignition and fuel are bypassed when the starter is engaged. Some only interrupt fuel, but are still bypassed by the starter. To get round this earth the oil switch wire. Remove carb float cover and it should have petrol in it. If all of the above is correct then check that the exhaust is not blocked. Crank engine and pressure should be heard and felt at the tail pipe. If in doubt release the exhaust clamp just after the front box. This is rare but it does happen usually the blockage is partial and the car starts but won't rev. I saw one that wouldn't start because the exhaust was completely blocked. Remove gear box cut out. I wouldn't bother with a garage because when the fault is found it will be simple. Non runners always are. (Message approved by david_gore) | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1165 Registered: 6-2009 |

Update: Definitely a good news, bad news combo. The good news is that the car is now about 3.5 blocks from my home and I expect I'll be able to get it the rest of the way once she has a chance to cool down again. I guess the other good news is that I have more data that will help those helping me to get to the root of the problem. She started up like a charm and drove like one, too, until approximately 1 mile before home. While descending a grade with no accelerator applied but no braking at that moment, either, I got a definite, loud backfire. My windows were open so there was no doubt. My partner was trailing behind me in my daily driver and reported a *very* loud boom back there along with a puff cloud of brown-ish smoke, but the engine did not promptly die out this time and I pulled in to a parking lot to see if it would do so in short order. When it didn't I decided to try to make it the rest of the way home. She ran fine until I had gone up a short, steep hill and descended the other side. At the base of the hill, when rounding a corner on to another street, after having had to stop very briefly at a traffic light, I got a stall - an instant stall. No backfire, just the stall. She allowed me to start her right up again, and since I was now within about 4 blocks of home I thought I'd try to nurse her there. Drove up over a slight rise and was heading down the other side (and this was probably all of 35-40 seconds after restarting) *clonk*, stalled again. This time she's behaving precisely as she did last night and will not turn over at all under "normal starting conditions." I did try to start her again with my foot on the gas, and she would, but was definitely not as smooth as last night. Of course, last night I was trying the restarting after I'd spent the better part of an hour and a half going house to house, going with someone to get gas, going back to the house to call a cab, then returning to the car. My current plan is to let her cool down and to go back and restart her afterward. Unless something completely "new" has occurred I now know: 1. Problem only occurs once the engine is thoroughly warmed up (distance driven approximately 15 miles and over 20 minutes, most at 55 MPH until you get to town). 2. Not likely that it has anything to do with the oil pressure switch since that is disconnected and we have a repeat episode. 3. I suspect I must be running horribly rich or am now becoming that way, particularly when speeds decrease. There's got to be a "too much unburnt fuel" situation that's causing the backfiring to occur. Any additional theories based upon the above information will be gladly entertained. If you have a question about anything I will at least try to answer it. I can never be certain about what data points I may be missing or that someone may want. My very sincerest thanks for all the assistance that has been offered so far. I'm just really grateful that it appears I will get her to the driveway before I go to bed tonight. If not I will probably at least be able to get her the 1.5 blocks to the shopping plaza parking lot just down the street from my home. Brian | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 583 Registered: 5-2012 |

Hi Brian Great news that you have practically got the car back home. Three questions - Did you top it up with oil before you drove the car back, as intended. Did the oil pressure remain constant and did the engine temperature remain within correct range, on the journey home. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1167 Registered: 6-2009 |

Geoff, Yes, 2 qts brought it to almost dead center between the MIN and MAX marks on the dipstick. Yes, the oil pressure was fine. Yes, the temperature was WNL. Brian, who tried walking down and starting her again after a 1.5 hour rest - not enough - just like last night I can get it to start and run at high revs but she just dies instantly once the foot is taken off the gas pedal | ||

Chris Browne Prolific User Username: chrisb Post Number: 174 Registered: 2-2010 |

Brian, I had exactly the same symptoms on my Shadow 2 (SRH37131) about two years ago. The car ran great, from cold, for about 20 - 25 minutes then it would cut out suddenly. What I discovered was that it was the oil pressure switch on the oil filter housing which was starting to fail. Once the engine oil was thoroughly hot and became thinner, the pressure switch was fooled into thinking the oil pressure had dropped to a dangerously low level and it shut off the fuel pumps as a precaution. On my car, using 20W50 oil, when the engine is hot , at tick over, the oil pressure needle drops below the white band on the gauge. As soon as the engine is revved, the pressure picks up to normal. I renewed the oil pressure switch and I have not suffered with the problem since. Hope this helps with your diagnosis. Kind regards, Chris | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1168 Registered: 6-2009 |

Chris, I truly appreciate the help, but today's little adventure occurred with the oil pressure switch intentionally disconnected. Since it is not contributing any input to the system at this point it seems impossible that it's the culprit. I was really, really, really hoping this was the problem but the end of today's trip put the kibosh on that theory. I definitely think that something's radically weird with air-fuel mix but how that came to be, and without warning, is the mystery. Brian | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 206 Registered: 8-2012 |

Rotor arm. The modern chinese rotor arms are known to fail when they get hot (after about half an hour of running). These have been responsible for all sorts of mysterious faults - and I speak from experience! This has been discussed on here before. I would also suspect the condenser, which can also break down when hot; but I think the Shadow 2 has electronic ignition and probably doesn't have a condenser. Anyway, change the rotor arm. If it isn't the culprit at least you will eliminate it as a cause. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1169 Registered: 6-2009 |

Bob, Thanks for another thing to check. I know that the distributor cap on this car is not original. It's a blue one that was a Land Rover cap, if my memory of discussions of the various alternative rotor caps used is correct. Heaven only knows what rotor arm is under that cap. I think the Shadow II uses the Lucas Opus II electronic ignition. Brian, who needs to dig in to the distributor on LRK37110 already, so why not make it a pair of distributors! | ||

richard george yeaman Prolific User Username: richyrich Post Number: 242 Registered: 4-2012 |

Hi what about that blasted little ballast resistor sitting down there out of sight below the coil. This caused me loads of problems until I pulled it out and set it on the top shelf in my garage only take a minute to bypass it. Richard. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 172 Registered: 6-2005 |

Richard, If you are able to permanently bypass the ballast resistor without destroying the ignition coil there are two possibilities. Either you make very short trips or you have a 12 volt coil instead of the 7 or 9 volt version used with the ballast resistor. The purpose of the ballast resistor is to maintain an adequate voltage to the coil when starting, to offset the voltage drop caused by the starter motor. | ||

richard george yeaman Prolific User Username: richyrich Post Number: 243 Registered: 4-2012 |

Hi John when I bought my car it had points and condenser and a ballast resistor it went well for about five mile or so and then if I slowed to go round a roundabout or stop at a junction or turn a corner where I had to slow down it would stop dead I replaced everything coil, ignition leads, condenser, rotor arm all to no avail then one day I found this thing down in the bowels out of sight the ballast resistor, I then fitted a 12 volt coil and an electronic system, no more problem, what I am saying to Brian that if this little blighter is faulty it could be his problem and that by passing it temporarily will confirm or not if this is the problem. Richard. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1170 Registered: 6-2009 |

Richard, Thank you also for another thing to consider. This will be my final report for December 26th. I just walked down the street at 10 PM, approximately 6 hours after the FTP this afternoon. The behavior now is precisely the same as this morning (except I didn't set the choke): fired up perfectly and as per usual on the first turn of the key. Drove her the very short distance home and she's now in her spot in the driveway. Something is definitely going on that only occurs once the car is hot, and pretty thoroughly hot. It still seems to me that there has to be a fuel factor involved due to the backfiring but also that the fuel factor that's causing the backfiring is perhaps non-overlapping with whatever is causing the "sudden death" once warm and refusal to start again until thoroughly cold. I do wonder, though, if a rotor arm is going faulty once hot, and a cylinder might imperceptibly miss or a sequence of misses occur in very rapid succession as part of the stall, if that could explain a bit of both. I'll definitely pull the distributor cap tomorrow and start poking around to see what I can see. I took her out for a long drive only a few short days ago, and for a longer time and more miles, and there was not even the slightest hint that anything was amiss (because, at that point, it wasn't). This was an untelegraphed development. If the additional repeat of the this morning's cycle gives anyone an additional "lightbulb moment" I beg you to share. Brian, who remains very grateful for all the assistance and kindness shown during this unexpected situation | ||

Bob UK Unregistered guest Posted From: 94.197.122.83 |

Ignition. A sudden back fire or stoppage is a typical ignition fault. Fuel faults because of the float bowl and the reservoir of fuel tend to be slower. It is unlikely that the fuel mixture would be suddenly wrong and then cool down and be right. But electrical stuff is famous for exactly this. Carbs can play up but once going unusually one can limp home. Check condenser and rotor arm. The rotor arm must be the correct fit. Any condenser will get you home. Typical condenser fault is open circuit. This causes the sparks to disappear at any thing faster than idle. Short circuit and no sparks at all. The rotors can short internally from the brass bit to the dizzy shaft. Impossible to see and test with meter. Proceed as follows. Remove dizzy cap leave rotor arm in place. Flick the points to try and make a ht spark from the king lead to the brass bit on the rotor. If it sparks it means the rotor is shorted. Also inspect the ballast resistor because they get hot and can develop high resistance where the coil is joined to the terminals. Seen a few do this on various makes. Recommend you get a red rotor if faulty and join a recovery service. My jeep went tits up and the AA came out diagnosed an ignition coil fault and recovered the jeep to home. Then I simply replaced the coil and back in business. £130 per year for any car even if it's not my car and some one else is driving as long as I or my wife is in the car. Also to prove that the coil was faulty he wired a spare coil in the the engine ran. But because it wasn't the right coil he took it off in case prolonged running buggered the dizzy module. £130 sounds a lot but I got a free diagnoses and safely home. As you know costs can escalate and without membership £130 is cheap. Plus 9 months later I left the lights on. Plus I have legal insurance thrown in. Which I had occasion to use and I was very impressed with their legal team. They slaughtered the other side. (Message approved by david_gore) | ||

David Gore Moderator Username: david_gore Post Number: 1496 Registered: 4-2003 |

Years ago when driving an old "paddock-basher" at a friend's farm, we used to deliberately create backfiring by revving the engine, turning the ignition off before the engine reached maximum revs and then turning it back on when the revs started to decrease. End result, a magnificent backfire accompanied by clouds of soot from the exhaust pipe. Scared the s**t out of the cattle unfortunately. Another trick was to swap the #1 and #4 cylinder spark plug leads on the 4 cylinder petrol/kerosine tractor, this resulted in the engine starting normally but it would die as soon as you let out the clutch. You could then start it again and the same thing would happen. We learnt this trick from an old army mechanic who said it was used in WW2 to stop Jeeps being stolen or used for joyrides. The swap-over causes the engine to fire on the intake rather than compression stroke. Good fun while it lasted... My misdeed suggests your backfiring could be associated with an intermittent ignition fault such as a rotor short, points malfunction or condenser failure as suggested by the contributors above. I would add breaker plate misalignment due to an excessively worn pivot pin bush as I experienced this many years ago with a high-mileage Ford 351 Cleveland V8 fitted with a Lucas single point dual advance distributor and the behaviour described by Brian is similar to what I experienced when the plate began to misalign when the vacuum advance was functioning. | ||

Vladimir Ivanovich Kirillov Frequent User Username: soviet Post Number: 55 Registered: 2-2013 |

Brian what rotten luck at this time of the year ! And indeed I lrnt about the oil pressure switch fiasco from other contributors. First, a lecture - two quarts of oil to bring the level up between the marks on the dip stick. Very naughty Brian almost sadistic. Keep the oil up to the top mark or sooner or later you are going to croak the bearings amongst other things. Perhaps the sump holds enough for you have not to have damaged permanently the internal parts that use oil for survival but don't ever take that risk again. I was trained to check the oil on any vehicle before I started it. Mostly that's a waste of time but its never a waste of time after an engine has been destroyed from lack of oil. The backfiring may be the key to the puzzle or it may be an aside. I would like to put up the concept of fuel contamination. At this stage we don't know what you have in the fuel tank or how much is in there. It is not out of the question that the fuel guage is faulty and that the car has sucked up a gutful of crap from the remains of an empty tank. The fact that it will rev but stalls and won't idle or will only idle intermittently to me announces a contamination in the idle circuit. Furthermore, and this is rare but I have seen it happen a few times - the contaminated fuel croaks the spark plugs. Some wags might ask if you put diesel in it. I won't be so cruel. However, when we refuel our cars we expect that what we are putting in the fuel tank is what we have paid for ie premium unleaded fuel. Three things to consider here 1. Greed can get the better of a fuel station owner where they decide to blend the fuel with something cheaper. 2. Water has somehow got into the fuel. 3. The tanker has put diesel in the petrol storage tank. Happened in Weipa Queensland Australia only a few months ago, yes , 17,000 litres of diesel in the fuel tank before the tanker driver realised what he had done and that was after a whole stack of people filled their cars up,. HO HO what fun! Now I am not ruling out an ignition problem but because of the backfiring I would isolate totally the fuel problem. 1. Drain the tank. I don't know if its got a nice brass plug on the bottom like a 420G Jaguar but have a look and if it has drain the fuel tank and capture the first half litre of fuel in a clear glass container. Have a good look at that fuel to see whether it is full of muck especially water. Also, see whether it is the right colour for premium unleaded or leaded if you are a scrooge and run the thing on just leaded. Next pull the fuel filter off. If its a sealed unit, cut the mongrel open and look for contamination. Next, open the fuel bowls at the carbs and inspect for contamination. Ok so no contamination then look at the ignition system. And heres a unicorn for you. I think there is a remote possibility very remote like a polititians heart that the distributor gear has stripped a tooth or teeth. Highly unlikely but possible. The only reason I would go the attack on the fuel system is the backfiring. Well that's my two cents and I can tell you whilst mechanics might pretend that they get it right first time every time like a magician there is an awful lot of ar** covering that goes on in the game internationally for the purpose of convincing the customer of their astounding precision in finding the fault first time round. In reality that just does not happen. Enjoy and keep us posted. Remember you car did not break down it simply failed to proceed. I am the walrus ooh kook a chew and sorry about the mistakes in my blab but this laptop has switched on the overwrite button instead of the insert mode. Time to load the shottie but I send this info to you as I realize your present state of frustration. | ||

Vladimir Ivanovich Kirillov Frequent User Username: soviet Post Number: 56 Registered: 2-2013 |

Just an nothing nibble at it Brian check to see the wires to the fuel pump or pumps is secure and if its got a fuse for the circuit check to see that the fuse is not corroded at the contacts. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 173 Registered: 6-2005 |

Brian, After reading the thread I feel you should follow up Richard's suggestion. The fact that the fault occurs after engine components heat up points to an electrical failure. The ballast resistor gets quite hot when the engine is running and its position encourages corrosion of the wiring connections. A sudden open connection of the resistor would immediately cut power to the coil which would explain the backfire you heard. Because the resistor is bypassed when the starter is operated this would explain why it would start for a few seconds. The fault is likely to go away as the resistor cools, which is what you are experiencing. Unfortunately the position of the ballast resistor makes it difficult to check, but I suspect this is the cause of your problem. Good luck. John | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 207 Registered: 8-2012 |

Everybody seems to be forgetting that this is a Shadow 2 with electronic ignition. It doesn't have points to flick and test, and probably doesn't have a condenser or ballast resistor either. But it does have a rotor arm. I still think this is the most likely culprit. Don't waste your time trying to test it, just change it. Keep the old one as a spare if you must. I always carry a spare rotor arm, points, condenser, distributor cap, ballast resistor and spark plug in the boot. They take up no space. You've got nothing to lose. You don't even need to buy new, just keep your old ones as spares. This is even more important today, with all the cheap poor quality parts coming from China which can break down at a moments notice - and they do. The Classic Car forums are full of horror stories. Buy your distributor parts from Distributor Doctor. He is not making Red Rotor Arms for the Shadow yet, as he still has a stock of the Lucas originals. You can see the difference straight away. | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 174 Registered: 6-2005 |

Bob, The Shadow 2 has a ballast resistor. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 208 Registered: 8-2012 |

OK thanks for that. I wonder why. Most electronic ignition systems don't have them, as they shouldn't be necessary, in theory. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 908 Registered: 9-2004 |

"Bob, The Shadow 2 has a ballast resistor." Well mine does NOT have one! Years ago I had the same problem with mine, adjusted the air gap and had no more problems for years until about a year ago when it failed big time. Fitted a new RR unit none of this after market stuff and has been fine. IMO all this messing about with after market stuff is a no go. Later folk buying a car won't have a clue what is correct when setting up the cars specifications. | ||

Chris Browne Prolific User Username: chrisb Post Number: 175 Registered: 2-2010 |

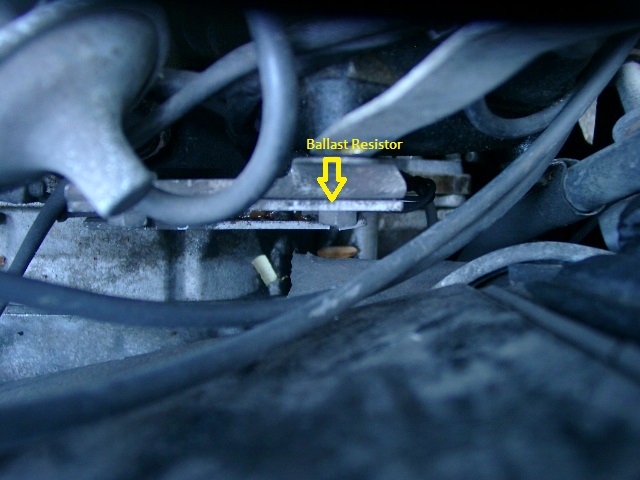

The ballast resistor on a Shadow 2 is bolted to the back of the A bank cylinder head and is well hidden. It is not one of the early ceramic jobs and so is easy to overlook. (Photo attached)  Kind regards, Chris | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1172 Registered: 6-2009 |

Can someone possibly post a photo, or point me to the item in the spare parts catalog, that is the ballast resistor? I really hate that by the time the two-series cars were introduced the identification table for all the parts numbers is omitted from the catalog. They seem to have recognized the lunacy of this move since the tables came back in the IETIS system later on. I definitely intend to have a careful look at the ignition system, including ballast resistor if the car has one, as the first order of business. For a wide variety of reasons other avenues seem, at this juncture, to be far less likely to me than something in the ignition system failing once sufficient temperature has been achieved for sufficient time. The almost "perfect" consistency in the time and distance of travel, travel speed, etc., and in failure and recovery behaviors makes me think failing electronic component first. All the more given its "instantaneous onset" without any hints of trouble in the previous weeks and trips. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1173 Registered: 6-2009 |

Chris, Thanks for fulfilling my latest request before I'd even had time to post it. I will let everyone know what I find on this car later today. I'll also take a look at LRK37110 to see what the setup is there. SRH33576 does not have the raft of additional stuff in the engine bay that an EGR system places in the area, so it's far easier to get around in there. Any pointer on the Crewe Original part number and/or commonly available alternatives that have the necessary spec would also be appreciated. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1174 Registered: 6-2009 |

Photos from so far today:   Distributor Cap - clean as can be inside  Rotor arm - glossy dot where coil lead contact touches near at the center of the distributor and outer edge where it glides against the contacts in the distributor cap   The ballast resistor is definitely there, attached at the back of the A-Bank cylinder head as Chris described. You'd definitely think it's part of a bracket if you weren't looking for it. It's also described on page M3-4 of the Shadow II/T2 workshop manual. However, the component location diagram makes it seem as though you should be able to see it quite easily. Their viewpoint is as though you have a hole in the firewall and are looking directly out that hole with the ballast resistor directly at eye level. QUESTION: Does the rotor arm simply pull off or is there a set screw or similar hiding somewhere? I can't seem to locate a specific answer in the formal documentation on this. Brian | ||

richard george yeaman Prolific User Username: richyrich Post Number: 244 Registered: 4-2012 |

Brian it just lifts of rock it slightly as you lift it looks as if it is an after market one O E dosnt have a rivet in it. Richard. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 909 Registered: 9-2004 |

Rotor pulls strait off. Can be very tight over time. Have you checked the ht coil as they can fail when hot under load. My ss2 has a 12v coil fitted and no ballast starts in all weathers. If you had these symtoms with the ss1 I would suggest the contacts or condensor being the fault. Cripes just seen another failing in the pics for ss2, it has the carbon ht leads fitted, do check the coil ht lead as this can pack up suddenly when hot. Blue distributor cap! what in the heck is that? | ||

Jim Walters Experienced User Username: jim_walters Post Number: 27 Registered: 1-2014 |

You might also have the wrong cap on it. I have found the aftermarket caps are sometimes too big in diameter. When it is clipped down see if you can move it side to side. You should have no movement at all. If you do the air gap between the rotor arm and terminals inside may be too large on one side or the other if the cap is not centered. This puts more load on the rotor, the spark tries to find an easier route rather than jumping the air gap. It will short out through the plastic rotor to the distributor spindle. The bluish rainbow marks on your rotor look like it's been arcing to it instead of out to the terminals. I have read that aftermarket cheap rotors are made with a plastic that has more carbon in it than the originals which exacerbates the shorting problem. I have found this a fairly common problem on the cars I service. SRE22493 NAC-05370 www.bristolmotors.com | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1175 Registered: 6-2009 |

Thanks to all. I have taken the rotor arm off and done a bit of polishing on the brass. I don't think it's a Lucas rotor arm but the thing is *not* flimsy in any sense. The brass plate on top is quite thick as is the plastic molding that forms the body. It definitely says "Made in Italy" on the top but I have to go out and note numbers. I can find no manufacturer name so far, but need to look closer. I am not quite certain what "rainbow marks" are being referred to. Before popping the cap off it certainly did not feel like there was even the slightest bit of movement. Not that things can't fail, as I already realize that something has, but the equipment that's on the car has been on the car since before I bought it and this particular area has not been touched during that time. I'm looking at a coil replacement as the first order of business and am leaning toward a 12V coil, which would eliminate the ballast resistor from the equation and ignition system entirely. I am taking a "change one component at a time whenever possible" approach here, but there are times, like a different coil, where two variables get tweaked at once. I hate ever having a "throw parts at it" situation, but depending on what cures this, and when, it will be a succession of either adding the next part/variable or removing the last fix and trying the next possible culprit. Some things, like the coil, it just seems sensible to replace due to age and known issues with aging. Brian, heading back outside right now | ||

Mark Aldridge Prolific User Username: mark_aldridge Post Number: 184 Registered: 10-2008 |

Brian, try applying a vacuum to the vacuum advance with the engine running. I have had two failures of wires where they enter into the Opus module , which cause ignition failure intermittently when the vacuum advance operates ie on/off load . Replaced coil, rotor etc and only found the fault by accident after removing the module for close examination and noting that one lead into the module seemed rather too flexible. The break is where the wires enter the silicon type sealant on the module pcb. I think the SS2 is the same as the 1982 Spirit and late SS1. Mark | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 584 Registered: 5-2012 |

Hi Brian Lucas was bought out by an Italian Company called Magneti Marelli in the 1980's, which may be why you have a Made in Italy stamp on it. Patrick makes a good point. The carbon trace burns back into the insulation as the leads get old and can leave small gap. Arcing causes the carbon to heat up, which could cause a break in continuity. Certainly worth trying a different lead between the coil and distributor. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1176 Registered: 6-2009 |

Very quick update before I go out to get things a bit more in order before sundown. I was asked to perform a test with the coil lead and the rotor arm then to the engine. When the coil lead is placed within 1/8" of the center of the rotor arm absolutely no spark is seen jumping from the lead to the rotor arm as the engine is being cranked. At the same time, though, there is a clear spark being thrown from the end of the rotor arm as it rotates even without any contact between the coil lead and the rotor arm. When the coil lead is placed within about 1/4" of the engine metal itself, and the car is cranked, the spark seen is neither blue nor constant. It is mostly yellow with traces of blue, and intermittently jumps like lightning to the engine metal. It is also a very slight spark and silent when it occurs rather than something constant, strong, or "noisy." Now, on to another question. There appears to be a felt pad in the center of the spindle on to which the rotor arm is pushed. I am presuming that this is the bit that's supposed to get a few drops of oil placed on it, but have not touched that yet. Can someone confirm this presumption (or refute it) and if it should have oil what type is best to use. Brian Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1177 Registered: 6-2009 |

A few final pictures for the day:     Brian | ||

Mark Aldridge Prolific User Username: mark_aldridge Post Number: 185 Registered: 10-2008 |

Brian, just checked part no.s, module on your car is the same as the one on my Spirit which about drove us mad finding the intermittent fault. Cured it by fitting Pertronix unit. Mark | ||

richard george yeaman Prolific User Username: richyrich Post Number: 245 Registered: 4-2012 |

Brian yes there should be oil on that pad below the rotor arm any light oil is ok and this should be applied on a regular basis, There is absolutely no problem with the colour of the distributor cap some of the worst ones out there are Black. Richard. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1178 Registered: 6-2009 |

Mark, Thanks. If a few preliminary attempts (e.g., replacing the coil) doesn't promptly cure the problem a new electronic ignition will quickly become a part of the picture. I just want to see if something simpler cures this, since the problem does not appear to be intermittent, in any conventional sense, but was reproducible under virtually identical circumstances with precisely the same signs. That, in and of itself, is a huge blessing! Brian | ||

John Kilkenny Prolific User Username: john_kilkenny Post Number: 175 Registered: 6-2005 |

Brian, Try this quick check. Start the engine and let it warm up for a few minutes. Tap the ballast resistor with a screwdriver blade several times and listen for uneven running. | ||

Randy Roberson Grand Master Username: wascator Post Number: 340 Registered: 5-2009 |

Similar to my experience with the '86 Jaguar: runs fine, then dies suddenly; sometimes restarts; often does not. Problem: ballast resistor. Tossed into the rubbish bin as advised by someone on a Jaguar forum; no problems since. Hope this helps you. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1179 Registered: 6-2009 |

I am getting some very mixed input (here and via private communication) about the likelihood of ballast resistor failure, coil failure, and precisely what type of coil I should use as a replacement with the existing Lucas distributor. I am not saying that anyone is right or wrong, but so far there have been a lot more votes for "ballast resistors seldom fail" than "frequently fail". There are also a lot more votes for "coils frequently fail and should be tried first." However, that brings up a complication: What coils are suitable: 1) If you keep the existing ballast resistor or buy a replacement (and then, the question of what's appropriate for that) what coil spec should be used? 2) If you want to chuck the ballast resistor entirely, what coil spec should be used? It's been interesting trying to research this and I am probably as confused now as when I started. Personally, if I could and it's a simple matter to do so, I'd prefer to get rid of the ballast resistor. It's simply another thing removed from the list of things that can fail. That being said, it surely means that a change to the coil specifications would be in order. Brian, who will try that resistor tap test just to see if there is a clear difference, but probably not tomorrow [it's going to be raining almost all day] | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1349 Registered: 6-2006 |

When the coil lead is placed within 1/8" of the centre of the rotor arm absolutely no spark is seen jumping from the lead to the rotor arm as the engine is being cranked. At the same time, though, there is a clear spark being thrown from the end of the rotor arm as it rotates even without any contact between the coil lead and the rotor arm. Can you run through that again? Where is the spark coming out of and jumping to?? If a spark is coming out , it must be going in. The rotor arm is fitted onto the distributor? | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1180 Registered: 6-2009 |

Paul, The lead from the coil is being held approximately 1/8" directly above where the little contact, that appears to be carbon, from the distributor cap normally touches the rotor arm at where it centers when it rotates. You cannot see a spark jumping from the coil lead to the center of the rotor arm. (I didn't say that something wasn't going on, just that you really can't see it.) The outer end of the rotor arm that normally throws the spark to the various contacts inside the distributor cap was clearly throwing a spark from the tip of the arm as the arm rotated. The arm is fitted to the distributor. The cap, obviously, is off. The coil lead was being held with a pair of insulated pliers. There is no other way to describe it. Brian | ||

Bob UK Unregistered guest Posted From: 94.197.122.89 |

Any engine oil for the dizzy also because there is a drain hole in the bottom and there are no points, oil can be squirted under the base plate at the centrifugal advance. (Message approved by david_gore) | ||

Bob UK Unregistered guest Posted From: 94.197.122.89 |

Gentlemen. Brian is up shi#t creek without a paddle now is not the time to argue over ballast resistors. From the photos shown the connections to the coil are rusty. If a ballast is fitted and the terminals are the same then it won't help. The rotor arm looks bad, the grey appearance I don't like. Brian I am afraid I going to have to tell you off. If you have to ask how the rotor arm comes off then you have not serviced the dizzy. A common mistake with contactless ignition is thinking that because it has no points that it needs no maintenance. There are other bits in there that require servicing, just an oil up. However the lack of oil will not stop the engine running, it will just not run right. Incidently although the traditional ceramic open coil ballast may not be there makers also can use resistance wire which looks similar to normal wires. Ford do this and use a loop clipped to a chassis leg. I thought the car had points. If the dizzy is a Lucas factory fitted one. Then this fault is also typical of ignition module failure, the car starts gets warm starts misfiring then dies. The mechanic spends 1 hour checking and head scratching car cools car runs, then does it again., This module was from 1976 to about 1982 when it was changed. Another level of complexity I am afraid. (Message approved by david_gore) | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 910 Registered: 9-2004 |

"I am getting some very mixed input (here and via private communication) about the likelihood of ballast resistor failure, coil failure, and precisely what type of coil I should use as a replacement with the existing Lucas distributor. I am not saying that anyone is right or wrong, but so far there have been a lot more votes for "ballast resistors seldom fail" than "frequently fail". There are also a lot more votes for "coils frequently fail and should be tried first." " Why not pay your local garage to come to house and do tests to confirm your prob, tests will take little time and get to the fault without the trial and error of fitting alot of unessesary parts. Besides the problems of useing of spurious parts it seems can be corrected! | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 209 Registered: 8-2012 |

"Brian I am afraid I going to have to tell you off. If you have to ask how the rotor arm comes off then you have not serviced the dizzy." Nor changed the rotor arm. I don't know how often RR specifies a change of rotor arm, but the rotor arm is a service item and should be changed periodically. You only have to look at the end of the RA to see that it gets eroded by the spark. You can clean the black off by rubbing against a tyre wall, but that doesn't put metal back. I have always changed the rotor arm at the same time as the spark plugs - around 12,000 miles, and cleaned it up every 3000. Carry the old one as a spare. Brian - I don't know why you are even considering changing the coil, removing the ballast, and getting a new ignition unit, etc. before simply putting on a new rotor arm. This is a 5 second job that doesn't even need any tools, and IMO should have been done when you got the car! It is a service item that wears out, unlike the other items, and has been known to cause exactly the symptoms you describe. Even if it turns out that it is not the cause of the fault (and it may well not be) I say it should still be changed, because of its unknown age and history. Incidentally, there's no point in trying to visually inspect the RA for faults or tracking. The insulation breaks down internally between the rivet and the spring clip, usually when they get hot (which takes about 30 minutes on a Shadow!). http://distributordoctor.com/rotor_arms.html "Why not pay your local garage to come to house and do tests to confirm your prob, tests will take little time and get to the fault without the trial and error of fitting alot of unessesary parts." I suspect it would be cheaper to just replace the entire ignition system than to pay a garage to come out and try and diagnose it. In my book that would be a last resort. And it only happens when it's hot, so the fault may not even be there when the garage man turns up! | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 911 Registered: 9-2004 |

"Then this fault is also typical of ignition module failure, the car starts gets warm starts misfiring then dies." When mine failed it did not misfire it was a sudden complete instant failure when hot. Confirmed by a simple test! | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1350 Registered: 6-2006 |

There may be no other way to describe it, however more fully would be nice. Where is the spark jumping to? To test the ballast and ignition circuits just run a good 12v to the coil +ve | ||

Hubert Kelly Prolific User Username: h_kelly Post Number: 153 Registered: 3-2012 |

Hi Brian, years ago while driving an old vw golf she stalled a mile from home. I thought fuel..fuel pump etc.In the end it was the coil. I would query the coil as its possible when the cars is cold the coil is cold thus operating correctly, correct me if I'm wrong but a hot coil don't operate correctly and may may cause the the symptoms you describe. I'm no expert on coils but if you have access to a multimeter a simple check of same when cold and again when engine warn might reveal an insight to what's up?. Type in 12v coil test to Google to find test for same. HK. | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 912 Registered: 9-2004 |

"Where is the spark jumping to? " Or is there a spark at all when failed hot? Procedure testing in this case by your local garage man will pay dividends and save great expence and the fitting of many parts by trial and error. | ||

Chris Browne Prolific User Username: chrisb Post Number: 176 Registered: 2-2010 |

Brian, The OE part number for the ballast resistor is UE40912 which fits all Shadows from chassis number 30001 onwards. Kind regards, Chris | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 585 Registered: 5-2012 |

Patrick Procedure testing in this case by your local garage man will pay dividends and save great expence and the fitting of many parts by trial and error. I have to disagree. The whole lot would cost just 58.45 ukp. http://www.simonbbc.com/electronic-ignition-kits/rolls-royce-silver-shadow-corniche-electronic-ignition-conversion-kit http://www.simonbbc.com/ignition-coils/lucas-gold-sports-ignition-coil To check the leads, Brian could just (initially) replace the coil to distributor lead. End of problem for around $120 bucks inc P&P. I cannot imagine it would be cost effective for the local garage to send a mechanic out for less than that. Geoff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1181 Registered: 6-2009 |

Gentlemen, I really, really, appreciate the assistance I've received and am receiving. I am not perfect. I do what I can and describe the best I can. I am getting assistance "off forum" as well. The "test result" I posted with regard to the coil lead and spark jump (or lack thereof) was in direct response to an exact procedure I was requested to carry out by someone who maintains RR/Bentley cars for a living. The only spark one can see jumps off of the end of the rotor arm "into the air" because, obviously, the distributor cap is off. It looks like a movie special effect spark flying off the end of a fingernail. Based on the source of the test itself I believed that it's probably been done, many times, by many here and that the bit about the spark flying off the end of the rotor arm was extraneous. I am always happy to fill in detail when it is requested. One thing that seems to be unappreciated in these environs is that there is generally no "local garage" that knows anything about these cars (though distributor technology certainly isn't specific to these cars) and it is virtually impossible to get anyone to come to your home to do work - period. It's not customary and you generally are asked to have the car towed in. I said at the outset that this is "virgin territory" for me. No, I have not worked on this area before, but that's been true of every undertaking on this car. It's been my primary introduction to automobile mechanics though I do work on my Buick, Cadillac, and now sold Jag. There are similarities and distinct differences. One has to start somewhere and I generally start if/when events dictate or the next thing on my everlasting "to do list" pops to the top. My priorities may be very different from yours (for any "you"). I prefer to try to solve this on my own because the same sort of thing could, potentially, happen again or happen on my other car. One has to start learning somewhere. This is not my daily driver so I can do this at a very leisurely pace with very measured steps. It should be abundantly clear by now that different people have different theories based upon their own experience(s) over time. Any one of these could be correct. Some of them involve replacing parts that should probably be replaced anyway and that are not "bank busters," so working through these methodically makes sense to me and, given my circumstances and desires, that's what I intend to do. I have been told by several that the coil lead to engine metal test should produce a strong, blue spark up to approximately 1/4" away. Even when the lead was about 1/8" away from the engine metal I was getting a distinct spark, but definitely not blue, but yellow with an occasional trace of blue. The spark that flew off the end of the rotor arm was strictly yellow, in case that matters. I have received invaluable guidance that is allowing me to at least make an educated attempt to step-by-step my way through the list of likely causes. Given my own personal history and how I learn I have little doubt that this particular issue can be solved by my following the guidance I am given, but in doing so I have to pick and choose among that advice based upon what I actually have learned and what "my gut" is telling me is more likely versus less likely. Even if/when I understand exactly how something is supposed to work, nothing can make up for direct observation and experience. This whole thread has been a vivid demonstration of one of my favorite adages: In theory there is no difference between theory and practice, in practice there is. I'm calling upon the combined practice of the cohort to help me to filter through what I know in theory and to guide my own practice. Brian | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 913 Registered: 9-2004 |

"I cannot imagine it would be cost effective for the local garage to send a mechanic out for less than that." I can and have seen it to often, where the cars have been got at by owners who have replaced this and that. In this case there are to many items that could cause the type of fault here. I see you just assume the the Ht coil and electronic ignition are the fault. Fit them and you still have the fault and more from the fitting of spurious parts. Total waste of money. One point that seems to be overlooked by many is the car would start with the throttle wide open. Geoff maybe you would fit a mixture weakening unit now as well for good measure! And after this and it still has the fault, ah fit the ballast and it still has the problem. Total cost so far $sssss and a car that still won't go as intended. Best to get it checked with the simple procedure from your local garage. It could be just a!!!!!!!!!!!!!!!!!!!fault | ||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 914 Registered: 9-2004 |

The spark that flew off the end of the rotor arm was strictly yellow, in case that matters. Well you may have hit the nail on the head with one fault rotor arm however if not you may have caused another if the high voltage has found its way to the ignition pickup module below the rotor! Best get the local garage to do more testing procedures now. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1182 Registered: 6-2009 |

Patrick, Not happening. And if your contribution is going to be to lecture me about something I have already chosen not to do please desist. It's not helpful nor wanted. This is a situation where your methods and opinions and mine differ. Let them. Brian | ||

Hubert Kelly Prolific User Username: h_kelly Post Number: 154 Registered: 3-2012 |

Brian 1.fuel you said you topped up with fuel so are you 100 percent fuel ain't issue? 2. If your certain it is ignition.. test coil I have put two new coils on the car in last 4 years, not because they were gone but the new electronic ignition recommended the coil must have so many ohms output.. so 12 stg.GBp later new coil fitter . 3. Have you brought a piece of wire direct from boot battery to the CORRECT coil terminal ie + battery to Positive coil this will bypass any situation where full current is not at coil Ask for advice here on this. I have done this myself when trouble shooting in past.Do remember if the wires are crossed to coil it might be terminal\death to ignition terminal. 4.have you checked all fuses?. 5.on one of the photos of old rotor arm is it pitted at end?.just looks like it in photo Finally over the last 2 years I have replaced all ignition parts...leads plug's, coil, electronic ignition, ballastard resistor(which now is isolated as same caused loss of power with new electronic ignition.) New distributor cap and rotor arm, expensive at time but well worth it for comfort peace of mind. Check out fitting electronic ignition on you tube it might talk about how to test for a dodgy electronic modem with multimeter Correct me if I'm wrong but might your car start if the ballistard resistor is bypassed ..which is another way to see if it is the problem?. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 210 Registered: 8-2012 |

People are suggesting to wire the coil directly up to 12v for testing. That is Ok for a conventional system, or if the Opus system works like this. On many electronic ignition systems the coil is connected across the output of the ignition module and doesn't have 12v standing on it. So check first before applying voltages that might destroy the unit. It's situations like this that make me glad that I haven't 'upgraded' to electronic ignition - even though I have often been tempted! You can't beat the simplicity of points ignition for easy roadside diagnosis and repair. The regular 'chore' of checking the dwell angle pales into insignificance when compared to the major hassle of just one single breakdown. | ||

Hubert Kelly Prolific User Username: h_kelly Post Number: 156 Registered: 3-2012 |

People are giving real experiences of how they\one solved a problem. On my particular point I have suggested getting advice from others..given the fact this test may destroy the system as happened to me this year ..so I'm talking for experience and an expensive one. Signing out | ||

Bob UK Unregistered guest Posted From: 94.197.122.72 |

Take the ballast resistor off the car. Connect the ballast in series with 50w load ( a head lamp bulb) direct to the battery. The bulb should light a bit on the dim side. The ballast should get warm. The bulb should stay lit. Wobble the ballast around. Look carefully where the coil is connected to the terminals. I have seen a few resistors where at first they seem ok but as they warm the resistance at the coil to terminal connection starts to rise under the 4 amp load. The bulb then goes dimmer and fads leaving only millivolts. Leave connected for 1 hour. Checking spark colour direct from a plug lead especially carbon ones can be misleading. Get a piece of dry wood, two nails hammered in 1/4 apart. Earth one connect other to spark lead. Don't spark across this too many times because the amps consumed by the coil can go up and the output transistor in the switching circuit could pop. This ignition system weather electronic or points is entirely conventional and the same as Jag Rover etc. It is also similar to GM Chrysler and Ford. So if you have worked on any of these vehicles ignition you will not find anything different. I would also clean and grease all the ignition terminals in that area. If there is a spark at the king lead but not the plugs then it can only be the rotor arm and or cap. If the car ran before then the parts even if wrong worked before. Total lack of sparks at the plugs despite a spark from the king lead is always the rotor arm. Some plugs sparking but others not is the cap. Coils should be 3 to 4 ohms. About 3 to 4 amps. Ballast about 1 to 2 ohms. If the spark is weak then the electronics is switching as it should, and therefore working correctly. Incidently weather a system is points or electronic there will still be a voltage drop when the starter is engaged. So some sort of ballast circuit is still needed. Service needs of dizzys is a squirt of oil and a wipe out of the cap ever 6000 miles. Don't file edge of rotor although a tickle with a nail board is ok. Don't scratch the plastic on the cap or the rotor because it can start tracking. (Message approved by david_gore) | ||

Bob UK Unregistered guest Posted From: 94.197.122.72 |

Bob Reynolds how right you are about electronic ignition. Every now and then I think maybe I should up date, then I get a grip and carry on with the points. When my jeep played up I couldn't tell weather it was the dizzy or the coil, without test equipment. Where as with the tool kit in the boot I can get to the bottom of the problem in minutes with points. Electronic stuff is easy to damage at the road side. (Message approved by david_gore) | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1183 Registered: 6-2009 |

Hubert Kelly wrote: 1.fuel you said you topped up with fuel so are you 100 percent fuel ain't issue? I don't see how it could be given what we all know so far. I don't know of a single car with either a "bad gas" or fuel starvation problem that will start normally when cold, drive about 15 miles perfectly normally, then exhibit the behavior mine has, two times in rapid succession, and with almost perfect consistency in failure characteristics and aftermath. It's not impossible, but given the list of likely culprits it's improbable. The SU fuel pump was rebuilt in 2009 and continues to tick like a champ when you expect it should, so I don't think fuel pump issues are likely, either. Both sides dying at once on the dual pump is very close to impossible and I don't know of any circumstance where these run well cold but stop when hot (which doesn't mean there aren't any). What it comes down to is that I don't think this is at all likely, so that sort of checking will come at the end "if all else that's more likely to be wrong isn't." 2. If your certain it is ignition.. test coil I have put two new coils on the car in last 4 years, not because they were gone but the new electronic ignition recommended the coil must have so many ohms output.. so 12 stg.GBp later new coil fitter . This is actually looking like it's going to be the first "part thrown at it" based on the data I have so far. A new rotor arm is also likely to go into the mix, but only after seeing what happens with the new coil and all else being the same. When this is all done I'd like to know, as certainly as I can, what exactly did fail even if other things were/are suboptimal. As Bob UK said, this equipment has been working on the car for years. It is well-nigh impossible that everything that could possibly fail failed at the same time. 3. Have you brought a piece of wire direct from boot battery to the CORRECT coil terminal ie + battery to Positive coil this will bypass any situation where full current is not at coil Ask for advice here on this. I have done this myself when trouble shooting in past.Do remember if the wires are crossed to coil it might be terminal\death to ignition terminal. That's on the list of upcoming diagnostics. Based upon where I got the recommendation to try this (someone who knows these cars *very* well) I have to believe it's safe to do so. I tend to be very cautious with all things electrical, so being certain that the +12V from the battery direct to the coil is input to the + terminal on the coil is, well, certain. 4.have you checked all fuses?. No. This is easy to do and I now will, but there's nothing that suggests to me that the behaviors seen are likely to be fuse related. I'd expect "once dead stays dead" were a fuse blown and something far less consistent in manner of FTP if a fuse were the culprit. I'll definitely take a look at what the ignition fuse(s) look like. 5.on one of the photos of old rotor arm is it pitted at end?.just looks like it in photo I believe there is some very slight erosion at one side of the outer tip of the rotor arm. That's why I intend to replace it as part of this task. However, based on the sparks I saw flying from the end of it during testing (and that they were yellow) I suspect the coil far more than the rotor arm. Brian, who will also try the individual diagnostics suggested here that I have the time and equipment to undertake to eliminate (or identify) individual components that could be "the root problem" P.S. to Bob UK: The terminals and connectors at the coil are anything but rusty. The tops of each of the nuts on the terminals may have some, but I cleaned the actual terminals, inside threads and contact side of nuts, brass connections, and female slides that go on there last summer. They were also coated with a very thin protective layer of NoOxId to prevent future corrosion. | ||

Bob UK Unregistered guest Posted From: 94.197.122.80 |