| Author | Message | ||

Robert Howlett Prolific User Username: bobhowlett Post Number: 122 Registered: 9-2010 |

Hi guys Had to move from general discussion to the dark side .What's the best way to replace this. I was thinking off with the bonnet,top header tank which isn't a big deal but any advice as to install a new unit the best way will be greatly appreciated. Yeah its knackered no resistance at all and high temps. cheers cheers | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1340 Registered: 6-2006 |

Some years have enough room to remove the fan from coupling. Leave sitting there. Remove coupling from pump and wiggle out. Otherwise it's tank off. Not the worse joob, just outstretched most of the time  | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1134 Registered: 6-2009 |

Robert, I definitely used the technique Paul notes when I was replacing the viscous fan clutch on LRK37110. I did, however, end up fitting an alternative clutch and fan blade set. Details are on the three threads: Alternate fan and/or viscous fan clutch for the "Two Series" cars Fan Clutch Questions Fan Shroud Issue The job is tedious, but far from impossible. Having long arms makes it easier. Having the hood/bonnet off makes it much easier. If you've got a willing assistant or two it's well worth taking the hood/bonnet off if you can. As long as you've marked around the brackets so that you can reposition it exactly when you put it back on that's not such a terrible job; it just requires a couple of willing assistants (or at least one and quite a bit of skill with your free arm). Brian | ||

Duane Ridenour Experienced User Username: kg4ibj Post Number: 11 Registered: 12-2013 |

On my 1986 Silver Spur, I replaced the fan clutch without removing the bonnet. Yes, it was a slow process. When I do this again I will remove the bonnet AND the grill. What alternative part did you find? I used a 1992 Discovery fan clutch that was less than USD68.00. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1135 Registered: 6-2009 |

Duane, The alternate viscous fan clutch and fan blade set are documented in the first thread I posted the link to (at the very end of the thread, there was a lot of trial and error in getting something where both would fit together). Brian | ||

Bob UK Unregistered guest Posted From: 94.197.122.82 |

When the car is moving at over 15mph say, a guess. The fan is not doing much and at 30 mph the fan is going with the flow. If the car is overheating at speed then it's more than just a coupling. If the car gets hot in traffic only then the fan is the the whole problem. The fan can be removed without taking the bonnet off. Remove the top half of the scowling and header tank. Use 1/4 drive sockets. On assembly grease all the bolts. On the front is a bimetalic spiral spring this moves a thingy inside which changes the speed of the coupling. The spring can fall off. Worth a look. However these couplings don't last forever, the oil leaks out, and they are not that expensive. An electric fan conversion costs about the same. Plus the ac will work better with a new coupling.} (Message approved by david_gore) | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 305 Registered: 5-2013 |

Hi Bob, Tell me more about the electric fan conversion? Thanks for the help, Chris. | ||

Bob UK Unregistered guest Posted From: 94.197.122.72 |

These are made by kenlow. The kit comes with an adjustable thermostat switch, which fits inside the top hose. The advantages over a viscous coupling are small. However if changing the air con to 134 from 12 an additional electric fan that works when the compressor clutch is engaged, will help in hot climates. In the UK this is not necessary, it doesn't get that hot. This fan is fitted behind the grill in front of the condenser. The main reason for electric fans is that the engine is side ways. My jeep has a viscous fan and an electric one which cycles when the engine is started then turns off. Because engines have thermostats it is not possible to overcool the engine because the stat will simply close, or close a bit. As I said once a car is moving at 30 mph all the fans are doing nothing, because of a 30 mph wind coming through the rad. These fan kits aren't cheap unless one uses junk yard stuff. A general purpose new condenser cooling fan such as I suggest for hot hot places on 134a are £100. without relays and switches. Which is about the price of the coupling. And of course electric fans use power from the alternator which uses petrol. The viscous fan probably uses a wee bit more. But it hasn't switches that go wrong, couplings last years. 20 years and 200,000 miles are common. Mine is 40 years. When fitting an electric fan to increase the efficacy of the ac condenser. I wire them via the compressor clutch relay via another relay. This means that when ever the ac is one so is the fan. This sounds wasteful but the waste is small and the system is simple and reliable and in traffic the ac works better the compressor uses less engine power and less petrol so swings and roundabouts. Also when the car is moving then the fan uses less power, so that needs factoring in to the efficiency calculations. I suspect it's not worth calculating. The fans I use are very quiet. My car is original and has no electric fan. It never overheats. Note if fitting an aux electric fan to the condenser the viscous fan must still work. Note. Electric fans have controlled speed therefore the speeds that cause harmonic problems are avoided. Therefore the blades can be evenly spaced. Engine driven fans run at whatever speed the engine is. Which is why SY fans aren't evenly spaced. I am a bit disappointed with my fan because it's not a nice shape. Bristol cars with the BMW derived engine had an aeroplane propeller styled fan. Where as the shadow one looks like a paddle steamer. (Message approved by david_gore) | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1136 Registered: 6-2009 |

"Not a nice shape" is an understatement!! The first time I saw a UE32635 fan I thought, "This thing *can't* really have come from the factory looking this way, could it?!!"  Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1137 Registered: 6-2009 |

Bob UK wrote: Note. Electric fans have controlled speed therefore the speeds that cause harmonic problems are avoided. Therefore the blades can be evenly spaced. Engine driven fans run at whatever speed the engine is. Which is why SY fans aren't evenly spaced. This has always struck me as another of Crewe's "solutions in search of a problem". There were (and still are) untold millions of cars out there with engine-driven fans with evenly spaced blades that have operated without issue. Brian | ||

Bob UK Unregistered guest Posted From: 94.197.122.89 |

I call the sound that a fan makes when the rpm is at a critical value beating. Evenly spaced engine fans that are not driven by a viscous coupling or electric motor will at certain speeds beat. It sounds like a slow throb. Because engines are noisy the sound melts into the general noise. Other car makers also use unequal spacing. Some are not so obvious. Having a fan shaped like a aero propeller is probably not efficient but it does look good. I was going to paint my fan red, but I decided that black doesn't show its horrible shape. Warning when couplings fail they can seize, which makes the fan overspeed. And maybe fan blades fly off. So never run with a dodgy coupling. Or don't rev the engine. I have seen holes in car hoods. (Message approved by david_gore) | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1341 Registered: 6-2006 |

Harmonics is what causes the beating. At a certain rev. And ... at lesser volumes, multiples or fractions of that speed . Stick to the correct fan and couplings. Most engines and cars are so noisy it does not make a difference. A droning RR is defiantly not the experience the vast majority of owners drive a RR for. Brian, many cars have many things that are different to a RR, But that does not make it acceptable on a RR. To perspective diy'ers, in my experience each bodge and bastardisation devalues and degrades the car a step more. I guess it comes down to whether you enjoy driving a RR in the best possible condition or saving money in the short term. Long term. turning your car into some junk heap challange may be fun on the day, but come sale time    | ||

Nigel Johnson Prolific User Username: nigel_johnson Post Number: 139 Registered: 12-2008 |

The poor mans Rolls, P6 V8 Rovers have unevenly spaced fan blades. Regards, Nigel. | ||

Bob UK Unregistered guest Posted From: 94.197.122.87 |

You mean the Rover P5 and with a V8 P5B. These cars were stockpiled by the UK government for future use. HM Queen Elisabeth 11 has one. Sage green with grey top and tan leather. That car was given to BMW and is now in Gaydon in the UK. This was fortunate because Rover is now owned by the Chinese. Rolls- Royces are a rich man's Rover. The P5 is a,good car apart from rust. The V8 version was not much faster. So I recommend the mk 3 with the straight six. The coupe looks good and has 4 doors. The 6 is 2/3 of price of a V8. Paul Yorke has got it in nut shell, everytime the car is modified the car becomes less of a Rolls-Royce, and probably worse for it. If you want a car like a Ford or GM then buy one. (Message approved by david_gore) | ||

gordon le feuvre Frequent User Username: triumph Post Number: 56 Registered: 7-2012 |

The original UK cars came with a fixed fan. It was quite quickly found that there were problems with noise. The technical name is heterodyne. It can best be described as a twin engine prop plane with the engines are "out of phase". Heterodyne was the word used in the R-R bulletin that described the "fix" by retro fitting a viscous fan kit. The best way to test viscous fan is to fire car from cold. The fan will roar for short time, then go quiet. Leave car on fast idle, as engine gets hot fan roar will come back in if working correctly. P.S. ALWAYS remove gearbox isolator when running as SO easy to knock in gear! | ||

Randy Roberson Grand Master Username: wascator Post Number: 336 Registered: 5-2009 |

I changed the viscous coupling in SRH9391 as the one fitted was seeping oil and I had a good used one. I will look for a substitute when I can but I spent some time a year or so ago and was not able to identify a substitute for the one on pre II Series Cars. It is logical that the coupling was not made solely for the Shadow and was used by other machines. | ||

Bob UK Unregistered guest Posted From: 94.197.122.88 |

So easy to knock it in gear and easy for a daft mechanic to think it's an indicator stalk. I shall remember heterodyne, I was going to mention aeroplane props out of sync, but my shadow doesn't have twin engines. My fan moves quite a bit of air, enough to dry my hair on idle. The blades flex forward as load comes on. Incidentally. If you are in a hot hot climate and R12 is unavailable and you have 134a. Then the air con may struggle as I said. If fitting a condenser fan make sure it's not obstructive to the original air flow though the grill. Do not go treasure hunting in junk yards for a used fan, because they are loud. Buy a slim high efficiency jobbie. 4 12v brushless dc computer fans may Work. These are super quiet and thin. Note electric car fans are designed as either a pusher or puller reversing the direction mucks up airflow big time. Heterodyne I shall study this on Wikipedia. (Message approved by david_gore) | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 307 Registered: 5-2013 |

Hi Folks, > P.S. ALWAYS remove gearbox isolator I see this warning frequently, but I confess, I have no idea how to accomplish this. Can anybody advise me? Thanks for the help, Chris. | ||

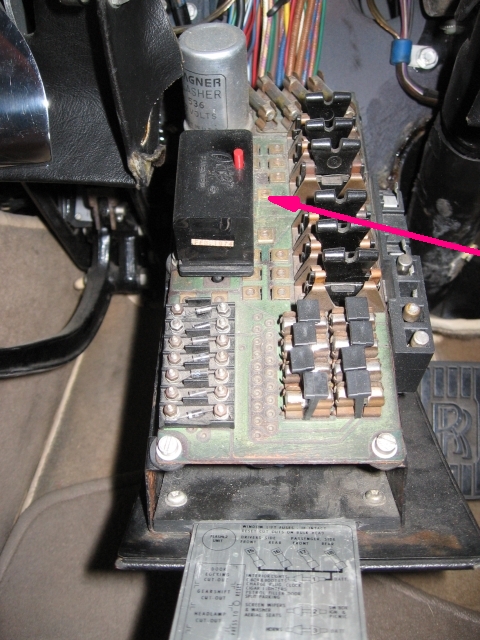

Geoff Wootton Grand Master Username: dounraey Post Number: 566 Registered: 5-2012 |

Hi Chris It's the black box located on the fuse panel, arrowed in this picture.  Fuse panel is located under the steering wheel - just undo the knurled knob and the panel drops down. I've never removed mine. I'd rather not disturb 40 year old connections that are functioning ok. I always disconnect the battery. Geoff. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 202 Registered: 8-2012 |

When I disconnect the battery and reconnect it again, I get a very loud machine gun sound, which I think is coming from the gearbox actuator. It lasts for a few seconds and then stops. This has only recently started to happen, and I almost jumped out of my skin the first time it happened, as there is also a big spark when I reconnect the battery terminal. This seems to happen whatever position the gear lever is in. I wonder if anybody else has experienced this. | ||

gordon le feuvre Frequent User Username: triumph Post Number: 57 Registered: 7-2012 |

I need to shout from the highest building!!!! When ever the engine is run in the shop OR at home remove the isolator, Please DO NOT worry about removing a 40 year old relay and subsequent issues because the result of the car running off in gear and on choke without anyone in the driving seat will far out way any connections problems that you MIGHT encounter by removing isolator. I have done this, Was in passenger seat working on car and my elbow knocked selector!!!! | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 309 Registered: 5-2013 |

Hi Gordon, > remove the isolator I really did not intend to hijack this thread! But is appears to be an important issue, so I'm not embarrassed. > I always disconnect the battery. Is this not sufficient? Thanks for the help, Chris. | ||

gordon le feuvre Frequent User Username: triumph Post Number: 58 Registered: 7-2012 |

Chris, if you do NOT intend running engine, just disconnect battery.But when ever you run up engine to do ANY workshop jobs remove isolator. Because it was DESIGNED to have a light feel the selector is so easy to knock in gear it is important not to do this by accident. I have seen cars that have run out of control because owners have read owners manual on running up engine for 4 minutes in order to check the level in the hydraulic reservoir(which is correct) and then done something through drivers window and accidently caught lever and knocked car in gear. Have you ever tried stopping a Shadow moving in gear. Unfortuately, the hand/park brake was never that good, even worst on early chassis numbered cars. | ||

Chris Miller Grand Master Username: cjm51213 Post Number: 310 Registered: 5-2013 |

Hi Gordon, Good point... With the battery disconnected, you can't start the car, so the issue is moot. If the car is running, the alternator can compensate for the battery being disconnect, so disconnection will not have the desired effect. So, the warning is only in the cases where the engine is running. There is no need to worry about this otherwise. Ce n'est pas? Thanks for the help, Chris. | ||

gordon le feuvre Frequent User Username: triumph Post Number: 59 Registered: 7-2012 |

Chris, it is so easy to forget that not every one has the experience of 50 years working with the product and the priceless benefit of having attended one of the first 2 WEEK training courses on the Shadow at R-R School of Instruction at Hythe Rd in London in early 1967. | ||

Mark Aldridge Prolific User Username: mark_aldridge Post Number: 182 Registered: 10-2008 |

I can only emphasise Gordons advice, having been hit by my own car 16 years ago when my shirt cufflink caught the gearstick as I was getting out of the car, with the engine running. £4k worth of damage to the car and some bruises and hurt pride to me! Also always check the selector is in park before putting the ignition key in ; I have knocked the selector out of park when cleaning the car and if it has stood for a longish period so the brakes have depressurised the result when switching on is interesting, especially if the car is on a slope !! This also applies to SZ series as well. Mark | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 567 Registered: 5-2012 |

Bob The only time I had a machine gun sound was on a car with a low charged battery. What was happening was the starter solenoid was engaging the pinion and closing the starter motor contacts but because the battery was low it hadn't the power to crank the engine. Since, the load on the starter was diverting the current away from the solenoid, the solenoid was disengaging, cutting the load through the starter motor, whereupon the current was available again to re-energise the solenoid. This cycle of events was causing the starter solenoid to sound like a machine gun as it kept rapidly switching in and out. Unlikely in your case as I'm assuming your battery is in good shape. The large spark you get when you reconnect the battery implies something is on that shouldn't be. Do you get a large spark on disconnection? Is the battery being drained on normal use of the car? Curious fault. Geoff. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 568 Registered: 5-2012 |

Gordon, Your shouting from the highest building has not been in vain. In light of your and Mark's experiences I will take your advice. As a point of interest, when you knocked the selector lever from the passenger seat, did you "get away with it". i.e. did you knock it into neutral, or did you engage reverse/drive. Geoff. | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 203 Registered: 8-2012 |

No I don't get a large spark on disconnection. Everything works as it should. If I disconnect the battery and immediately reconnect it again I get the machine gun sound. After a few seconds it stops and everything works as normal. Whatever it is is obviously drawing quite a large current. The problem is that I can't be in 2 places at once so it's difficult to determine exactly what it is whilst I am in the boot connecting the battery! It sounds like it's coming from underneath the car, so the gearbox actuator is the obvious culprit. I could remove the gearbox cut-out and see if it still does it I'm not too worried about it because I don't disconnect the battery very often. Just wondered if anybody else had experienced this. | ||

Bob UK Unregistered guest Posted From: 94.197.122.85 |

If the battery is disconnected then the engine can't be started. If the device is pulled from the fuse board then the car cannot select a gear while the engine is running. If the work you are doing requires the engine to be running, then either remove the rear wheels or the device. If the car takes off driverless it will stop when it hits something. The device is fitted to a glass fibre circuit board which is strong. Removing the device will clean the contacts as the brass bits slide over each other. Runaway automatics is more common than you would think. I know of a XJ6 that went though a show room window and across the road into a pub. Seriously, you have been warned (Message approved by david_gore) | ||

Robert Howlett Prolific User Username: bobhowlett Post Number: 125 Registered: 9-2010 |

Hi guys the part has arrived ..took the bonnet off ,header tank and ready to go. If it all goes bad I'll have my granddaughters magic on my side cheers Marry Christmas from Aussie Land Rob   | ||

Bob UK Unregistered guest Posted From: 94.197.122.83 |

It won't take long to fit. Meant to say earlier. fan blades when dirty are noisier and not as efficient, the air flow gets mucked up. They don't need to be immaculate just not dirty. A wire brush and a coat of gloss black from a rattle can won't take long. Plus the header tank while it's off. I shall stop there because this is how jobs escalate when I fix cars. I can't resist it, the parts look so nice when painted. Even if the fans looks broken. (Message approved by david_gore) | ||

Robert Howlett Prolific User Username: bobhowlett Post Number: 126 Registered: 9-2010 |

Thanks Bob I'll give it a good clean and fresh coat of paint .I wasn't even thinking of that. Got my two sons coming round ones a fitter and boilermaker and the other, well he's not in jail, that's a blessing I guess.I'll put them to work while I have a few coldies on Xmas day .. cheers | ||

Bob UK Unregistered guest Posted From: 94.197.122.91 |

Fitter boiler maker is a worthy trade. He can paint the tank while you do the fan and the other one can make the tea. Satin black or gloss black. I am torn between the two. Either way I spray Matt black first as a primer. Use hair dryer to dry it quicker and too prevent bloom if humidity is high. These bits are small enough to piant in a warm kitchen. Allow at least an hour for paint to harden, overnight in warm kitchen even better. (Message approved by david_gore) | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 762 Registered: 5-2012 |

Hi Folks Removed my fan clutch this evening as the replacement has arrived. Everything went really well - I even remembered to disconnect the battery. Not that I don't always do so, just that this time I didn't have to be reminded by being covered in a shower of sparks. Lots of good info in this thread. Being a 74 SY1 this is quite a simple job. I decided to remove the header tank, disconnect the fan clutch and pull it out vertically upwards. I of course used my celebrated "bench" (well, celebrated by me anyway) to gain easy access to the fan coupling nuts. I'm thinking of upgrading the "bench" to include a cushioned top and coffee cup holder. This will be the deluxe version. Anyway, I digress. So far so good. Well, not entirely: When I carried the header tank over to the workbench I noticed something was rattling inside. I will investigate it this weekend when I remove the cover plate. If anyone has had a similar occurrence I'd be interested to know what they found. Also, what is the consensus on using thread locker on the nuts that fasten the fan clutch to the water pump. The replacement comes with four new spring washers, but given the fact I don't much fancy the fan assembly flying off when I restart the engine, is the "belts and bracers" approach the best i.e new spring washers and thread locker. I'd be grateful for any views on this. Geoff | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 271 Registered: 8-2012 |

It will be the baffles come loose. The same thing happened to me. I took the header tank to Flying Spares to swap it, and the first thing he said was "Does it rattle?"! | ||

Brian Vogel Grand Master Username: guyslp Post Number: 1386 Registered: 6-2009 |

Geoff, Your question regarding spring washers, by which I am presuming you mean split-ring helical lock washers, has inspired me to dig out research I did regarding same back in 2012 and post it in the General Discussion forum in a thread entitled, Lock Washers Really Don't The title pretty much sums it up. The references to hard data backing that opinion are contained therein. Brian, who presumes thread locker would work better, but only if a connection is insufficiently torqued | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1376 Registered: 6-2006 |

Baffled . . . Don't worry about them I would say. You may get the warning light coming on a bit earlier when cornering, but should not affect the car. Quite a few are like that. I'm guessing you got on of the reproduction pumps if it has come with nuts and locking washers. All I would say is that the studs are not as strong as the original ones so you can not tighten them as much as you might think. You can usually turn the engine with the original type . . . nowhere near that now. And it's a pain to take them apart to helicoil if you do strip a thread. I would use threadlock and the spring washers. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 764 Registered: 5-2012 |

Bob, Brian,Paul Many thanks for your reply's. I realized it was going to be impossible for me to have the baffles repaired in my header tank and given it has caused no problems in the past, had decided to refit it. I'm really pleased Paul has vindicated my decision. There's nothing like getting the nod from an RR professional. I'm not changing the pump, just the coupling. I will take care with torquing the nuts, just in case a reproduction pump was fitted by a previous owner. Geoff | ||

Bob Reynolds Prolific User Username: bobreynolds Post Number: 272 Registered: 8-2012 |

The baffle plate is only fixed in position with a few spot welds. Once these all corrode away, the whole thing is loose to move about freely. If you're lucky the pate might wedge itself against the internal fittings and cause no further problems. In my case, the baffle plate had come completely loose and was moving from side to side and hitting the coolant probes, causing damage and false readings. I had to swap the header tank for another one where the baffle plate was only partially loose! The only way to fix these tanks is to cut them open, weld the baffle back in position, and then weld the tank together again. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 766 Registered: 5-2012 |

I've just stripped the old patchwork of paint off my fan and sanded it down with 600 grade paper. I am satisfied the sanding process (in water) has removed all the residual paint stripper, however just prior to painting, should I use a solvent for a final clean. If so, which one? The paint I am using is duplicolor gloss black engine enamel from a spray can. I am also wondering if it would be better to go over the aluminium blades with 320 grade paper to allow a better key for the paint. I'm not looking for a showroom finish here, but I'm thinking 320 might be too coarse. Geoff | ||

Robert Noel Reddington Prolific User Username: bob_uk Post Number: 122 Registered: 5-2015 |

Enamel. White spirit. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 800 Registered: 5-2012 |

I'd just like to make some comments on the new viscous fan coupling I fitted a week ago. I have been using the car regularly since then so have had time to evaluate it. One of the tests for a worn viscous coupling, widely documented, is to turn a hot engine off and see how quickly the fan blades stop rotating. If the fan rotates for more than one to two revolutions then it needs replacing. I think this is misleading to hobbyists like myself. What I have found with my new coupling is the fan stops with the engine. The deceleration of the fan is very marked. There may be some "slippage", but it cannot be picked up by mere visual observation. The other giveaway, regards a worn coupling, is the wind rush from the fan is very noticeable when standing at the side of the engine. A paper towel held over a front suspension turret should behave like a flag in a strong wind. It may be that as the coupling starts to wear, more and more slippage occurs and, within limits, this is acceptable. The problem is deciding at what point the coupling should be renewed. The ambient afternoon temperature where I live is over 90F (32C), most days, and round town I spend a lot of time stationary at traffic lights, so an efficient coupling is essential. My advice, particularly if you live in a hotter clime, is to replace the unit if you are in any doubt about it at all. The great news for us SY1 owners is the Hayden coupling is a direct replacement and costs just under 60 bucks, including tax and P&P. Geoff | ||

Christian S. Hansen Experienced User Username: enquiring_mind Post Number: 34 Registered: 4-2015 |

Geoff... Pulling over from Brian's temperature thread, in my case, I just installed a new radiator core and so discount the accumulated debris issue, however in this thread you said... "One of the tests for a worn viscous coupling, widely documented, is to turn a hot engine off and see how quickly the fan blades stop rotating. If the fan rotates for more than one to two revolutions then it needs replacing. I think this is misleading to hobbyists like myself. What I have found with my new coupling is the fan stops with the engine." ...which piqued my interest as I have seriously suspected the coupling in my Early MPW Shadow CRX2508 as being a potential issue. Along that line, please clarify what you were saying. What conditions did you observe with the older coupling? Stopped promptly? Do I infer that you meant that the standard "test" of "the fan keeps rotating" after engine shut down is not an accurate indication of the condition of the coupling since, and this is where I begin "assuming", you were trying to say that in your case, that "test" did not indicate a defective couping due to the fan NOT continuing to rotate, however irrespective of that, replacement of the coupling solved the heating problem. The "lesson" being that a coupling can be defective even if it stops promptly. In other words, even though the observed rotation with the defective coupling was the same as the replacement coupling, the performance results were markedly different, thus leading to the conclusion that the standard "test" is not a reliable indicator for the condition of the coupling. To make a long story short, I hope that this is what you meant, and if so, when I have time, will be upgrading my coupling with that recommended by Brian in his reference sheet to see if that is the problem. Hope springs eternally! Thanks if you can clarify. | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 862 Registered: 5-2012 |

Hi Christian My apologies for putting up such a misleading paragraph. What I was trying to say (badly) was, it is very difficult to gauge how many rotations the fan moves when a hot engine is stopped. This is a very subjective observation. I am in no doubt experienced mechanics will be able to tell straightaway if a viscous coupling needs changing, by observing it's behavior on turning off the engine, but for someone like myself it is more difficult. Even if one of the fan blades was marked with some white paint, I think it would be difficult to count those rotations. If the fan freewheels after engine switch off, then no problems, it's a worn unit. But how do you gauge between one or two rotations on a rapidly decelerating fan. Having seen how the fan slows with a new viscous coupling I would now be able to tell if a coupling needs changing. So, with the new coupling, the fan stops with the engine. The deceleration is very marked. With the old coupling there was run on, although even then, the old coupling appeared to pull up within two rotations. Note the word "appeared" - it is difficult to tell. Speaking for myself, that is. In answer to your questions: Do I infer that you meant that the standard "test" of "the fan keeps rotating" after engine shut down is not an accurate indication of the condition of the coupling Yes it is. If the fan keeps rotating it is an accurate indication that the coupling is worn. If the fan freewheels, then it's a nobrainer. The difficulty arises when the coupling has degraded and is working nowhere near full efficiency, but still has sufficient grab to appear to pull up quite quickly. The "lesson" being that a coupling can be defective even if it stops promptly No, if the coupling stops promptly it indicates the coupling is ok. even though the observed rotation with the defective coupling was the same as the replacement coupling, The observed rotation of the old and new couplings were very different. This became obvious to me once I had seen the new coupling in action. the standard "test" is not a reliable indicator for the condition of the coupling. Yes it is, so long as you know how to apply it. i.e. you know how a worn coupling behaves in terms of the fan's deceleration when the engine is switched off. I guess what I was trying to say is this is all very marginal. This is an excellent example of how experience is worth any number of articles on the subject. If you are in any doubt about your coupling, I would highly recommend you changing it. The Hayden unit is less than $50 and the job is very easy. It's just a case of removing the header tank, undoing the four nuts that secure the coupling/fan assembly to the water pump and pulling it out vertically. Paul Yorke (an experienced professional who works on Royces all the time) says on some cars the unit can be removed without taking off the header tank. This is done by separating the fan from the coupling in-situ (4 bolts) and carefully "wiggling" out the assembly, through the gap. Also note, the coupling is in full effect for a minute or so after a cold engine is started. You don't have to wait until the engine is hot to observe the fan. Geoff | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 1386 Registered: 6-2006 |

"I think this is misleading to hobbyists like myself. What I have found with my new coupling is the fan stops with the engine. The deceleration of the fan is very marked. There may be some "slippage", but it cannot be picked up by mere visual observation. " To test it more thoroughly, rev the engine up quite highly (3000 rpm) and turn the engine off. This will give the fan enough momentum to test the slippage. You will probably find on a new coupling that as time goes by and the 'clutch' beds in, the slippage will become noticeable. Eventually it will just keep spinning and spinning. (Another confusing observation is that the coupling will be locked up from a totally cold start. This is normal but does not mean that it will be locked up when hot.) You MUST try it hot as well. If your car is staying cool enough when cruising, but overheats as soon as you hit stop / start traffic or is stationary, then the viscous is the most likely culprit. ps ( this was written before Geoff's reply . . but I didn't press the post message. So most is the same I'm afraid. The reving the engine when testing is a good pointer though. | ||

Christian S. Hansen Experienced User Username: enquiring_mind Post Number: 35 Registered: 4-2015 |

Thanks for the clarifications. I guess I was optimistically reading what I "hoped" to hear. Since there is only modest expense and the potential of a resolution, I will in due time follow thru on that replacement. |