| Author | Message | ||

Brian Vogel Grand Master Username: guyslp Post Number: 833 Registered: 6-2009 |

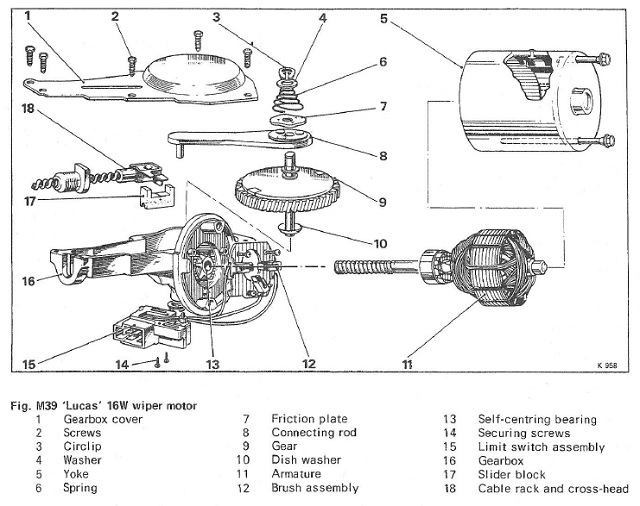

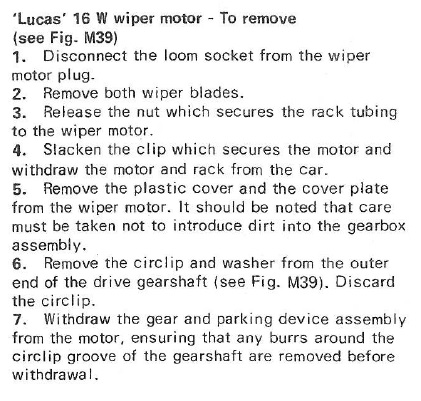

I've gone back and read the article that Jeff McCarthy so kindly supplied, but it does not answer the one question I have: How to get the entire wiper motor out of the car. I'm working on the left side heating duct and although one could withdraw it just by loosening the wiper motor mounting bracket, getting it back in appears as though it will require me to get that motor out of the way. I've already got the various mounting bits loose and all the wiring apart, but can't quite figure out how to get either the rack (cable) separated from the motor or, alternatively, the rack able to be withdrawn through it's tube. The Workshop Manual is not particularly helpful here. This is Figure M39:  and the instructions for removing the motor which immediately follow it:  There's either a lot not explained in step number 2, step number 4, or both. Any assistance would be most appreciated. I do not want to break anything, I just want to get my duct back in and the new replacement strap I made on to the left duct like it is on the right. Brian | ||

Jim Walters Experienced User Username: jim_walters Post Number: 18 Registered: 1-2014 |

Brian, undo the nut on the end of the tube holding it to the motor and the cable will come out with the motor. Just pull on the motor to separate it from the tube. Alternatively, turning the wiper posts will push the cable out of the rack tube and the motor with it. Take the wipers off otherwise they will spin around hitting the cowl. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 835 Registered: 6-2009 |

Jim, Thanks. Is this cable "toothed"? I'm trying to picture how it engages the bits that the wipers are moved by. I hope that sliding it back in is as easy as withdrawing it. I'll definitely replace the motor covers before I attempt to withdraw the motor and rack together. Brian | ||

Jim Walters Experienced User Username: jim_walters Post Number: 19 Registered: 1-2014 |

The wiper posts have gears on the inner end with teeth, the cable has a spiral construction that engages the teeth. Works like rack and pinion steering. | ||

Jim Walters Experienced User Username: jim_walters Post Number: 20 Registered: 1-2014 |

Or, remove cover (1), remove clip (3), lift and remove drive arm (8), then lift cable drive end (18) complete with tube and nut to clear housing and remove motor without disturbing the wiper arms. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 836 Registered: 6-2009 |

Jim, I followed your original advice and have just come inside after withdrawing the rack (cable) and motor, which comes out very easily. Once I saw the rack I realized that it is, essentially, a long flexible worm gear. One of the things that threw me in the workshop manual was step 2. This may be one of those "two people separated by a common language" things, but I would have said wiper arms, not wiper blades. Once the wiper arms are off the motor almost falls out if there's nothing holding it in place. I'd far rather remove two wiper arms and that cap nut than the alternatives. Thanks again for your assistance. If anyone wants photos of this let me know. I can take some before putting the rack and motor back in place. Brian | ||

Jeffrey McCarthy Grand Master Username: jefmac2003 Post Number: 430 Registered: 5-2007 |

Brian, If you could take a few photos it might help fill in some of the gaps. Also because all my photos are of a right-hand drive car some positioning will be different. Thanks, Jeff | ||

Brian Vogel Grand Master Username: guyslp Post Number: 837 Registered: 6-2009 |

Jeff, Since the car in question was an RHD-to-LHD conversion I believe the wiper stuff is still in its original spot. I'll definitely take some photos. I'm trying to decide what, if anything, I should do as far as cleaning off and lubricating the rack before I put it back in. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 840 Registered: 6-2009 |

Photos from today's work. The motor and rack are back in. The one thing that always floors me when dealing with the electrical aspects of these cars is how slapdash things were when it comes to ground/earth. You'll notice in the several photos of the underside of the motor mounting bracket that there are two large capacitors, two grounding/earthing wires, and a washer stacked up. I took all of this apart to clean things up and what do I find on the bracket itself?: Paint under everything on both sides and, by all appearances, in the hole for the bolt itself. It must have been by hope of divine intervention that at least one thread might cut through the paint and establish a connection. I think that the photos are pretty self-explanatory. If there are any questions please feel free to ask away.         Brian | ||

Bob uk Unregistered guest Posted From: 94.197.122.79 |

Fit the rack upside down Align the wiper gears 180 degrees from original position This allows the UN worn side of the rack to mate with the unborn sectors of the wiper gears Use chassis grease nothing special This system is known as the Smith wiper system The rack does not turn It goes to and fro Where as worms turn (Message approved by david_gore) | ||

Brian Vogel Grand Master Username: guyslp Post Number: 841 Registered: 6-2009 |

Bob, I didn't touch the orientation of the rack and, to be honest, visual inspection didn't indicate any wear of any significance. Given that the wiper posts whirl like dervishes when you're withdrawing the rack, unless you made careful markings and observations, it would be very, very difficult to tell what portion of the wiper post gears is meshing with the rack upon reinsertion. I didn't, so I don't know. All I know is that the wipers are working correctly. You are correct, of course, about the rack and I should have already recognized this having had the covers off the motor before and seeing that the sweep of the rack is strictly up/down at its end inside the motor. The rack part is actually quite the ingenious little system. Brian | ||

Bob Reynolds Frequent User Username: bobreynolds Post Number: 91 Registered: 8-2012 |

Can you fit the rack upside down? I seem to remember there's a tag soldered to it on one side which operates the parking switch. While you've got the rack out it's a good idea to lubricate the wheelboxes and spin the spindles round to make sure they are rotating freely. If there are any tight spots, mark the position of the spindle and position the tight spot so that it is outside the normal range of movement when the rack is back in position. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 842 Registered: 6-2009 |

I'm beginning to hate you people!! ;-) Every time I think I've done "the final video" for Thing X someone always asks a question regarding something that had not been visible in the last one. Bob R's question made me go out and pop the plastic and metal covers off the wiper motor to show it running with all parts in view. I don't know whether the design may have changed on the rack, but in SRH33576 the rack tab is definitely set up such that the rack could not be turned over. The tab is also not purely horizontal, but is bent slightly to angle down into the slider block (#17 in Fig M39). You can see the park switch (or I think that's it) at the top of the sliding range of the block. The action he describes when the wipers are turned off and park. Wiper Motor Slow-Off-Int-Off Wiper Motor Fast Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 843 Registered: 6-2009 |

OK, Google Drive is being cranky after I replaced the AVI files (which are, relatively speaking, huge) with MP4 files for the above videos. Ignore those and try these instead: Wiper Motor Slow-Off-Int_OFF MP4 Wiper Motor Fast MP4 | ||

Geoff Wootton Grand Master Username: dounraey Post Number: 413 Registered: 5-2012 |

It's the same on my 74 SY1.  | ||

Bob uk Unregistered guest Posted From: 94.197.122.82 |

I have only turned the rack upside down etc on other makes of cars such as Minis We used to buy over long racks cut them down to fit The design of system made it adaptable and was fitted to many brit cars and commercials If the wipers now work well then that job should last many years I recommend greasing every 10 year's (Message approved by david_gore) |