| Author | Message | ||

Brian Vogel Grand Master Username: guyslp Post Number: 389 Registered: 6-2009 |

Hello All, Does anyone happen to have one of these on hand that they could do measurements on for me? I definitely took measurements when I last did this job in 2008 on a Crewe Original kit and found that every seal was an AS568A standard sized EPDM O-ring, with the exception of the two quad-rings that seal the shaft. What I think I didn't do was record the thickness, in particular, correctly since I have 1/16" as the thickness for every one of these O-rings, while the quad-rings are 3/32" thick. It strikes me that all the O-rings were somewhat "fatter" than the quad-rings so I think I screwed up either in my measurements or recording of same. Thanks for any assistance you can offer. Brian | ||

David Gore Moderator Username: david_gore Post Number: 1284 Registered: 4-2003 |

Hi Brian, Some advice based on expensive hard-won experience, I hope you have securely tagged all the lines connected to the height control valve body with their correct location as it is very easy to transpose lines when reconnecting. If you do transpose them, when you pressurise the system and test the valve manually with the linkage push rod; the piston will knock the end of the valve body off turning it into scrap metal without a moment of consideration let alone warning. It will make a grown man use language that he would never ordinarily use.............. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 390 Registered: 6-2009 |

David, The last time I did this job I followed the instructions given by Jon Waples in The Shadow Owners' Companion. He's very explicit about telling you to be certain that you know exactly which port each screw-in is supposed to screw back into and about the spacing washers used on each. As a result, I created a work table explicitly for this job and kept everything "oriented correctly" such that it looked like an exploded view in the parts manual. If you look at my photos over time you'll see I'm quite anal retentive about the use of labels and/or color coding when I take *anything* apart. The height control valve was far less complex to deal with than I'd initially thought it would be. The thing I remember most was how difficult it was to get the quad ring seals in place. The warning you offer, though, is most welcome and should be carefully heeded by anyone doing this job. Brian, who's not so certain about that "never ordinarily use" part, at least as far as car maintenance "malfunctions" go | ||

Randy Roberson Prolific User Username: wascator Post Number: 127 Registered: 5-2009 |

Ha, good advice! Reminds One of One's Dad, removing the house batteries from his motorhome, to replace them. Could he wait until I drove 1.5 miles to assist? No, of course not. In world-record time he removed and piled the cables and connectors from 6, 6-volt heavy-duty batteries, removed the batteries and placed 6 new ones in place (sort of). Then he expected me to install the cables correctly, having never seen them nor having any sort of technical literature. Advice: do not ever attempt to connect 6 heavy-duty batteries unless you are sure the connections are exactly correct. Randy, who agrees with Brian... | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2827 Registered: 4-2003 |

Watch out. Crewe did a large run of these kits (RH2435 seal kit and RH10067 repair kit) with the wrong seals - size and material - and valve bits which do not fit properly. They are out there causing endemic problems. Even one of the independent UK outlets sold the Crewe kits, and they are failing quickly. Crewe may have corrected them by now I hope. However, Albers has the correct kits at the right price, as do Introcar and SpurParts. They are not expensive and have the correct valve bits. With the price and availability as it is, a partial kit of generic parts is not really worth the risk I suggest. That applies especially if you copy the wrong kits !! RT. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 392 Registered: 6-2009 |

Richard, My guess is that the incorrect seal kit is what I received from another owner for measuring and documentation. It's clear that the largest seal is entirely too large and has entirely too narrow a cross-section/thickness. This is also true of the next two sizes down. I'm sorry, but I'm simply going to have to disagree with you re: pricing. The last time I priced a seal kit it was more than $50 U.S. That's ludicrous for a collection of 8 EPDM O-rings, all of which are standard sizes. As your own warning pretty much implies, all Crewe is doing is collecting EPDM O-rings, bagging them, and selling them as a kit (and sometimes making mistakes). The call is still out there: If you've got the seal kit or repair kit I'd love to have the seal measurements. I can state, with complete certainty, that the two quad rings used to seal the operating shaft are AS568A-113 size (Crewe UR10832). I've already used these, sourced from Marco Rubber in the U.S., for my last rebuild. Brian | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2828 Registered: 4-2003 |

Point taken Brian. One may hunt around arguably to save the price of a pizza up-front. Consider, though, the time taken to assemble, distribute and sell a kit for just $50 with a bunch of BS214 etc EPDM o-rings and add-ons. If a shop or individual saves just 20 minutes by buying a kit for a $50 premium hassle-free, it is ahead based on a moderate hourly rate. Add to that that these components are safety-critical and high-leverage low-cost items, a kit with a warranty for parts, labour and consequentials is pretty cheap at even four times the asking price of $15-$100. R. | ||

Brian Vogel Grand Master Username: guyslp Post Number: 393 Registered: 6-2009 |

Richard, Were I or any of the myriad DIY-ers out there a professional shop the dollars and cents equations can and do change, but we're not. For the one-time, less than half-hour effort it takes to document these seal kits I've saved a *lot* more than "the price of a pizza up-front" over the last 6 years. I thank each and every person who's lent me a given kit to document, and many have thanked me for the availability of that information when they needed it. My route is very cost effective for me, and in the end that's all that matters to me. It also serves as a good record for others who are in my situation. Brian | ||

Brian Vogel Grand Master Username: guyslp Post Number: 432 Registered: 6-2009 |

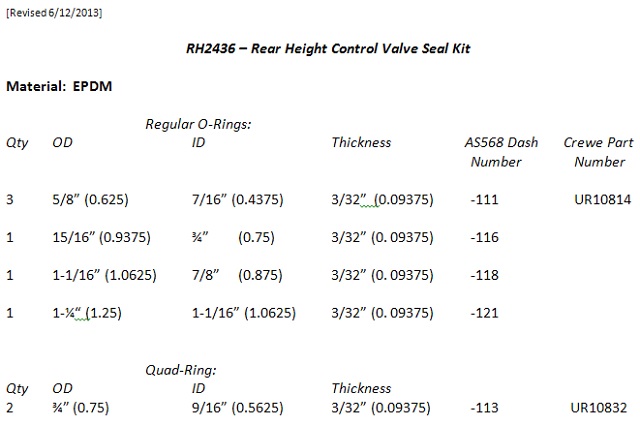

Hello All, Based upon information sent to me from a fellow Shadow owner in Ireland, I think I've solved the mystery of what was wrong with my original list of seals for the height control valve. I know for certain that the quad ring that's used as the shaft seal (size AS568-113) was correct because I used these rather than the ones from the kit I had to verify that they functioned. These have a thickness of 3/32". On all the other seals, for some reason I'll never know (maybe the kit I was loaned as a template was one of the "bad" ones), I had recorded the thickness as 1/16", which is definitely way too thin. They all appear to have a cross-section thickness of 3/32". The below is a revised list, which I would ask anyone who happens to be doing this job with a Crewe Original kit or a seal set they know to work to verify and confirm. It's not definitive until I or someone else gets this data from another set of seals that function. Brian  |