| Author | Message | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 30 Registered: 5-2012 |

My 1974 SY1 has developed a problem over the past week where the gear change upshift has become alarmingly jerky. The upshift from first to second gear is delayed, the engine revs quite high and then suddenly the gear change takes place with no slip at all; just a loud bump and a kick in the pants. I am about to start my own personal crash course on the GM400 but pending that has anyone experienced a similar fault. Would a transmission fluid change help? The downshift is perfect, just the upshift that is giving problems. | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 31 Registered: 5-2012 |

I should add that I have searched this forum and also looked at the tee-one topics. I note that David has given a presentation on transmissions and that he recommends a tutorial book however I believe the book is for the previous 4 speed hydramatic box. The workshop manual fault finding chapter lists vacuum as a potential cause which is encouraging as it may mean I do not have to remove the gearbox from the car. | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 32 Registered: 5-2012 |

I've just found a good thread in the Silver Spirit section. There should be enough similarities in the gearboxes to start my investigation re: O-ring seal at the top of the oil intake tube and vacuum modulator unit on the side of the gearbox | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 64 Registered: 3-2012 |

Geoff, you haven't by any chance adjusted the accelerator linkage,just prior to the commencement of this problem? Gear oil good colour and no burnt smell? | ||

David Gore Moderator Username: david_gore Post Number: 1162 Registered: 4-2003 |

Hi Geoff, the book I referred to by Ron Sessions is absolutely and unequivocally dedicated to the GM T400 as fitted to your car and not the earlier Hydramatic transmission. I hope it is still available although it might also be available from an automotive second-hand bookshop. This book tends to be tightly held due to its worth to DIY and racing enthusiasts. I suspect your problem may be a failed/missing O-ring at the top of the fluid pick-up tube allowing air to be sucked in with the fluid, a faulty modulator or early signs of an impending clutch pack failure associated with the fluid control valve or the clutch pack itself. For your interest, there is a modification involving the removal of some parts to give an instantaneous take-up of the clutch pack for racing use or to increase clutch plate life where stop/start city driving is the major part of the transmission's life. The standard Turbo 400 allows significant clutch slip to give the smoothest possible gear changes however this is at the expense of increased wear necessitating clutch plate replacement after relatively low mileages [less than 100,000 miles has been quoted]. This positive take-up is identical to the upshift you describe and happens at each upshift under moderate to hard acceleration. The upshifts under light acceleration are slightly more perceptible than those of the unmodified transmission. | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 33 Registered: 5-2012 |

Hubert - Yes - I have made changes to the accelerator linkage recently during work I carried out on the automatic choke. This is an OMG, what have I done moment. The gear oil is a good colour with no burnt smell. However I checked the fluid level in the prescribed way, after a 15 mile drive, in Park with the engine running and found the level to be just above minimum on the dipstick. I will be attending to this, but have ruled out low fluid level as a cause. | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 34 Registered: 5-2012 |

David, apologies for misquoting you regards the Ron Sessions book. I have been studying the manual and feel armed enough now to carry out your suggestions of checking the O-ring and modulator. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2725 Registered: 4-2003 |

This is a classic case of a split vacuum hose at the modulator. The repair takes minutes and a replacement hose (about 10cm long) costs 10 cents. BTW if you need access to Ron Sessions' publication send me a PM. RT. | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 35 Registered: 5-2012 |

Thanks for that Richard. Tomorrow I shall check out the vacuum hose and modulator as you and David suggest. I have already ruled out the possibility of the kickdown switch being permanently activated. My changes to the accelerator linkage check out ok and the ohm meter verifies that the microswitch is working as it should. I looked up Ron Sessions on Amazon.com. They list two of his books on transmissions, one at $16.85 and the other at $189.54. Guess which one I need if it comes to a transmission rebuild. | ||

David Gore Moderator Username: david_gore Post Number: 1163 Registered: 4-2003 |

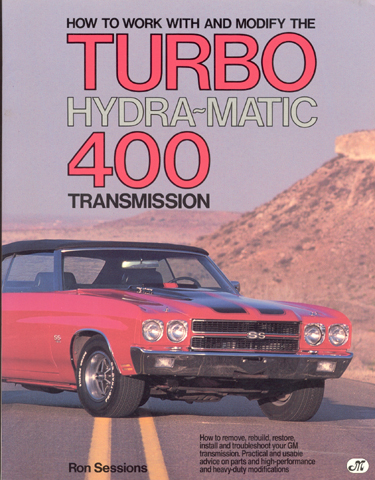

$189.54 - in their dreams. Geoff - keep an eye on auto swap meets in your area as this book should turn up for sale from time to time. Here is the front cover you need to lookout for:  | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 65 Registered: 3-2012 |

Hi Geoff, the reason I inquired re accelerator linkage adjustment is, I have read the chapter on gearbox, for the pre '68 non American market(silver shadow), similar box to that of old Cloud I believe . In that case(pre'68 shadow) accelerator Linkage plays a roll in correct gear change at correct speed etc fingers crossed its just the vacuum hose/O ring as suggested | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 36 Registered: 5-2012 |

Problem solved. You were right, it was the vacuum hose at the modulator. It was not split but the modulator end of the hose had become swollen due to small amounts of transmission fluid in the general area. Obviously I shall be investigating this leak further. The upshift is now silky smooth; certainly beats being thrown out the back window every time it changes gear. Hubert, my car is a 1974 series 1 and as far as I can tell there is no mechanical link to the gearbox from the accelerator linkage, however it was a good suggestion as it minded me to check out the kickdown microswitch. I have had this car for about 8 months now. Bodywork, chromework and interior are immaculate however the mechanical side has been neglected somewhat. I am gradually returning it to it's factory condition; in fact it is now starting to drive like a Rolls Royce. I'd like to say how much I appreciate all the help I'm given from members of this forum. | ||

Hubert Kelly Frequent User Username: h_kelly Post Number: 66 Registered: 3-2012 |

Geoff, happy days, safe motoring. | ||

Brian Vogel Prolific User Username: guyslp Post Number: 156 Registered: 6-2009 |

I have no idea what's "so special" about How to Work With and Modify the Turbo Hydra-Matic 400 Transmission by Ron Sessions, but the cheapest copy of it on half.com is sitting at $111.26 right now. My guess is it's now out of print, but it's a paperback, for heaven's sake, and not a really rare one at that!! I'll have to keep an eye out for this one if I could "flip" copies for that much!! Brian | ||

David Gore Moderator Username: david_gore Post Number: 1164 Registered: 4-2003 |

Hi Brian, Due to the popularity of the T400 for racing and drag cars, this book contains all the information needed to service, modify and troubleshoot the T400 as well as being an invaluable guide for DIY home mechanics. The book is far easier to read and understand than Section T in TSD2476 and I doubt I would have completed a complete overhaul of the transmission in DRH14434 in the same time as I achieved using this book and the guide provided with the B&M transmission kit I purchased in the USA. The procedures detailed for rebuilding the transmission are far more comprehensive and easier to follow than those in TSD2476. The only omission that could have proved to be a problem was the use of a wave plate in some versions [including the R-R version] of the transmission. This wave plate was not included in the kit I purchased. I am grateful for Ralph Appleby from York Motors for pointing this out to me after he perused my copy of this book and I believe he also purchased a copy for his Service Department. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2726 Registered: 4-2003 |

May I add that Ron Sessionís book is, in my opinion, one of the most remarkable technical publications that I have come across. It covers almost everything about the 3L80 (previously known as the TH400) that I can imagine. I first bought it in the late 1980s at Motorbooks in Neutral Bay, Sydney, to help me when doing up the transmission on our T-Series. It was spot-on. I have two cars (T and Turbo R) with this transmission, and one with the 4L80E: a 3L80 with an overdrive bolted to it and electric solenoids to control the shifts. The 4L80E shares almost all components with the 3L80 other than the overdrive unit. I have bought several publications covering the 4L80E but none match Sessionsí book. I am pulling the 4L80E out of my Conti R shortly to overhaul thr torque converter clutch as it is weak, and shall overhaul the whole transmission while I am at it even though it has covered just 120,000km. I only wish that I had the same standard of documentation for this transmission, but fortunately Sessionsí book covers most aspects by default. RT. | ||

Neville Davies Experienced User Username: nev_davies Post Number: 43 Registered: 9-2006 |

Geoff. The leak that you have may well be the modulator valve itself.If after a week or so you pull the vacuum pipe of the valve a small amount of of oil in the pipe will indicate that the the diaphragm within the unit has split and a new modulator is needed.Watch you don't drop the little valve when you change it. | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 37 Registered: 5-2012 |

Neville, Thanks for that, I'll check it out when I investigate the leak. The other possibility on my car is there is a thick bead of red jointing compound all the way round the edge of the sump, where it is bolted to the gearbox. I personally feel uncomfortable about that, prefering to use a new gasket. Maybe the previous owner used both. | ||

Brian Vogel Prolific User Username: guyslp Post Number: 157 Registered: 6-2009 |

Geoff, It seems that using gasket sealants in their myriad forms has become de rigueur over the last few years, even with new gaskets. I personally hate the stuff. I've very seldom had a new gasket, properly installed, leak. In addition, that stuff makes cleaning up to install the next new gasket a living hell, in my experience. I'd rather have to redo the occasional gasket than deal with the stuff. Brian, who will probably eventually "join the borg" on this, but not yet | ||

Jeff Young Frequent User Username: jeyjey Post Number: 100 Registered: 10-2010 |

I joined the borg many years ago while racing Formula Ford. Laguna Seca and Sears Point were different enough that we had to swap out the 3rd gear ratios every time we went from one to the other. Under these conditions, one quickly learns to love hylomar. ;) (Still hate the stuff that sets, though, as it is a bear to get off later.) | ||

Omar M. Shams Grand Master Username: omar Post Number: 306 Registered: 4-2009 |

I once convinced one of my apprentices that I owned the company Hylomar. I explained to him that everytime I walk into the factory the staff all greet me by the product name. He believed me for years!!! How cruel was that???? Omar (without the Hyl) | ||

Geoff Wootton Experienced User Username: dounraey Post Number: 38 Registered: 5-2012 |

On the subject of gaskets, am I the only person horrified by all those "make your own gasket" videos on youtube. Here's an example: http://www.youtube.com/watch?v=6rx5hGKt1PY There's no way I'd ever take a hammer anywhere near a machined surface. | ||

Brian Vogel Prolific User Username: guyslp Post Number: 158 Registered: 6-2009 |

I've never heard of Hylomar before today, and will have to look it up. When I think gasket sealant I always think of the stuff that smears on, usually in relatively electric colors if it's not black, and that sets to almost rock like hardness. When I replaced the thermostat in LRK37110 I cursed the tech who used the red glop that I had to scrape off, being exceedingly careful not to accidentally gouge the soft metal surface in the process. The paper (or it sure looks like some sort of paper) automotive gasket material that I cut and used this time around hasn't leaked a single drop and it's without a bit of additional sealant. Brian - pressure and elasticity R' Us | ||

Neville Davies Experienced User Username: nev_davies Post Number: 44 Registered: 9-2006 |

Like Jeff I was involved with Formula Ford and as he says Hylomar was the standard sealant in the late 70/early 80's so it's been around for a long time.However whilst I'm sure it could be used with gaskets the gear boxes in question didn't use them and the beauty of hylomar was it worked well metal to metal cleaning off easily between uses. | ||

Mark Aldridge Frequent User Username: mark_aldridge Post Number: 86 Registered: 10-2008 |

I believe Hylomar was designed as a metal to metal joint sealer by Rolls Royce Aero , not as a gasket sealant, but I may be wrong ! I still use Wellseal, old fashioned but works. Mark | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 2744 Registered: 4-2003 |

I have posted a follow-up under Miscellaneous. RT. p.s. Hylomar has been around since the 1950s and is a bit too primitive for my liking. I saw it on the shelf at Canberra Spares in Fyshwick last week. I have not used it since the 1970s, and find that Loctite products have many virtues. | ||

Brian Vogel Prolific User Username: guyslp Post Number: 215 Registered: 6-2009 |

Jumping into the way back machine, Geoff, I absolutely agree with you regarding that guy and his hammer. When I have to do this sort of thing it's much simpler to flip the object on to the gasket material and run an X-acto knife or similar around the outer edge to get the whole gasket form. It's then easy to hold the material in place and create holes where needed in a similar fashion. It's also faster than this tedious method, too. Brian, who still generally avoids sealants on gasket surfaces whenever possible | ||

Nigel Johnson Prolific User Username: nigel_johnson Post Number: 109 Registered: 12-2008 |

BSA motorcycle owners in the USA use Yamabond on machined surfaces. Regards, Nigel. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 940 Registered: 6-2006 |

So many sealants these days! - and when you find one you love , they put something 'better' in the same tube that just doesn't do the same thing or work in the same way. Hylomar old fashioned? Possibly - but in it's defence, I feel it may be a case of the original chemist / engineers getting it right and not letting the marketing people push the 'new product developers' to reinvent it. It can be used face to face or on a gasket. It doesn't harden so you can pull it apart again if you need to. It cleans off relatively easily. You can put it on, get a phone call, go to lunch, get back and carry on where you left off. If somebody is a little heavy handed it will stay in place and if it doesn't it will stay soft and not turn into a rubber ball or stopper and block up oil ways etc. Transmission sumps should not need any sealant, just a new gasket. If somebody has been too heavy handed before you get there, you may need a very little sealant. I have heard of boxes being ruined by excess sealant in the sump.  | ||

Jan Forrest Grand Master Username: got_one Post Number: 437 Registered: 1-2008 |

Despite owning a 36 year old Shadow 1 I'm far from being a Luddite! I still feel that some things that come down the invention line arrive complete and fully formed to such an extent that no appreciable improvement is necessary for decades or even centuries. In the natural world the cockroach is a shining example. They have remained identical since they first came into being before the first dinosaur roared a challenge to the universe and now successfully defy all of puny mankind's attempts to wipe them out. Everything has to be marketed as 'new and improved' even though the phrase is an oxymoron. (if it's new then it can't be an improved version of something that already exists and vice versa!). Why can't the different versions of Hylomar (blue and red) be considered to be the finished article? | ||

Vladimir Ivanovich Kirillov New User Username: soviet Post Number: 9 Registered: 2-2013 |

During my apprenticeship in motor mechanics in the seventies almost everybody used lashings of gasket cement called "Gasket Goo" on everything. In the eighties there was some rumor in the trade that silicon was the go. Then came a wave of paranoia over the use of any gasket additive. Horror stories abound in the trade about the use of it on Carbys and Transmissions and legends have been established of the stuff blowing up engines by blocking the oil galleries in cranks etc but for myself I have seen not one instance of any problem. I have often used it merely as holding device with large tricky gaskets that have been folded and can be infuriating to get into place. If the two mating surfaces are dead flat then I think the use of it is unneccessary. Generally I use only a thin film of grease on a gasket and have not had any trouble. I think the subject is a bit like all the additives you can put into oil whose manufacturers claim marvellous extentions of use. I have always felt there is a bit of snake oil salesmanship going on coupled with a need for these companies to make a buck. But on the question of Turbo 400 transmissions can anybody tell me whether an overhaul kit sold by GM for Chev Cadillac etc is the same as the kit sold by Rolls Royce. To date the information I have is that they are all the same transmissions and the only difference is the bell housing stud pattern and the fact that RR uses a super smooth electric shifter which I must say I thought was totally cool bordering on pure decadence when I first operated one. | ||

Paul Yorke Grand Master Username: paul_yorke Post Number: 971 Registered: 6-2006 |

Not everybody puts the same filters and gaskets in their kits. Make sure the filter is the paper / fabric type and not just a wire mesh strainer. I prefer the black (usually) gaskets to the cork ones which tend to keep on needing to be nipped up to prevent weepage. | ||

David Gore Moderator Username: david_gore Post Number: 1223 Registered: 4-2003 |

Hi Vladimir, I used the B&M T400 overhaul kit I sourced from Summit Racing in the USA when I did the transmission in DRH14434 after a complete loss of fluid and clutch pack failure due to a burst cooler hose. This kit had everything needed with one exception, the front disc in the clutch pack fitted to R-R/B transmissions is a wave plate instead of the flat plate usually fitted in transmissions for GM assembled vehicles - no problem though as my local auto transmission parts wholesaler had them on the shelf and sold them individually. BTW the B&M instructions that came with the kit were excellent and made the overhaul a straight forward job within the capabilities of most DIY owners with some basic experience. http://www.summitracing.com/parts/bmm-21041/overview/ I note the kit contents have changed since I bought mine as the transmission filter and instructions are no longer included. I still have these instructions and can email you a copy if needed. The other enhancement that I highly recommend is to install a drain plug in the pan to facilitate future fluid changes. http://www.summitracing.com/search/part-type/drain-plug-kits | ||

Vladimir Ivanovich Kirillov Experienced User Username: soviet Post Number: 12 Registered: 2-2013 |

David if you could email those instructions to me that would be much appreciated. I intend to go one better and install an aluminum finned pan to the transmission which has a drain plug. Without a drain plug its easier get oil everywhere and quite a few people have gotten quite scalded when attempting to change the oil. I used to love taking the mickey out of the RR salesmen in Perth by pointing out that an $80,000 new Shadow (1977) should at least have an alloy finned tranmission pan without GMC stamped onto the bottom but I guess Crewe never intended the owners to get under the cars. Still I thought it was a cheap move by RR but maybe it was all tied up in the licencing agreement between GM and RR that the GMC stamp be clearly visible on the pan. I have only limited experience in autotrans so can you tell me if you require any special pullers to disassemble the transmission. Did the Summit Racing kit have cork gaskets or rubber and was the filter paper fabric type? Ta zzzzzcobetzzzzz@yahoo.com (PS there are five Zs on each side of cobet.) | ||

David Gore Moderator Username: david_gore Post Number: 1225 Registered: 4-2003 |

Hi Vladimir, the instructions are in Sydney and I am in Taree till Friday so you will not see them until next weekend. The only special tools needed are some home-made pullers to dismantle the internals and these are easy to make to suit the task if you have nothing suitable in your tool box; the most important tool is some sheets of 3 to 5 thou shim stock to wrap around the piston lip seals before pushing them home when reassembling the transmission. Unfortunately, I cannot remember what the gaskets were as 15 years have elapsed since I rebuilt the transmission - the filter was definitely a paper element. Another trap for the unwary is to forget to replace the upper O-ring on the fluid pick-up pipe from the pan to the valve body. | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 1489 Registered: 4-2003 |

Vlad before your tumescence gets painful, be aware that the GM400 transmission was one of the most popular units in the business and fitted all sorts of vehicles_ not just cars. The total production I think was in excess of three million units! Rolls-Royces' piddling order would not put them in a bargaining position to have a different oil pan which as you say would seldom be seen by an owner. As to scalding oneself, to start changing transmission oil that is hot would require first a psychiatric exam of the operator I suggest. One feature most people don't realise is that having drained the pan as far as you can, screw in a sump plug or diff plug which fits the 1"BSP thread of the side filler fitting exactly. You can then tilt the pan back and avoid the shower of smelly used tranny oil! Above all do not as David points out forget the 'O' ring. I did once and showered the entire engine with trans fluid which produced so much smoke I could barely see to drive! If you really want to change something for the better go to a speed shop or up market transmission shop and get them to find a deep sump with a revised filler. This was an option for these transmissions and extra oil in a sump that cops more cool oil flow can only be good practice. There is a plug to knock out in the main casting to fit a revised filler pipe! | ||

David Gore Moderator Username: david_gore Post Number: 1231 Registered: 4-2003 |

Vladimir, have emailed the B&M kit instructions to you tonight. Let me know if it doesn't come through; the PDF file size is 13Mb. If anyone else would like a copy, please PM me. Bill, this includes the Technical Library if you would like one. |