| Author | Message | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 233 Registered: 4-2003 |

Do you want to cut the oil consumption on your pre-1983 Crewe V8 ? It is possible to fit the later valve stem seals, as fitted to SZ cars from chassis 6751 as standard, to all Crewe V8's from the S2 onwards without removing the cylinder heads. In fact I prefer this option as you don't disturb the liner seals. This is one of the most worthwhile mods in existence, and will eliminate oil consumption in most motors. The only drawback is that they cost more than aftermarket seals. Introcar sell them for £ 13 each, and there are 16 per car, that's around US$320 a set. The part number is UE75351. There may be an aftermarket equivalent, but you would need a sample to match. There is even a factory bulletin promoting this mod to all V8s before SZ chassis 6751 when they were standardised. It runs under the guise of eliminating the asbestos in the original rubbish "seals". I can send anyone the bulletin if you give me your e-mail address. E-mail me on richard.treacy@bluewin.ch If the heads are off for any reason, there is a much cheaper and even better solution from Crane Cams. If the heads are off, I would recommend that solution as a matter of course. | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 234 Registered: 4-2003 |

| |||||

Robert Chapman Prolific User Username: shadow Post Number: 53 Registered: 5-2003 |

Richard, I have a couple of concerns with that bulletin. Firstly,the valve stem seal used on later engines have a locating lip on their lower inner edge.This fits into a groove machined into the outside dia of the valve guide.The purpose of this groove is to positively lock the seal in position.Earlier engines dont have this groove and therefore the seal does not fit correctly and can slip off the end of the guide, turning into an effecite pump to force oil down the guides. It is practically impossible to machine this groove with the engine in the car. Secondly,if you delete the spring and cover from the earlier arrangement as will be necessary to fit the later type seal,there will be nothing to centrally locate the lower end of the valve spring around the valve guide.This could cause all sorts of problems including possible spring breakage.Later engines using this type of seal have a different type of lower spring seat for this very purpose. | |||||

John Dare Unregistered guest Posted From: 144.138.194.240 |

Still giggling from the money I "saved" on my speedo transducer/s (lacquered too!) I was about to race down to my dealer to get these later seals for my 1970 Shadow. Best I now wait until the situation with this modification is clarified, unless anyone can guarantee me that I wont suffer any unusual smoking/ engine damage etc., due to excess oil/broken valve springs as described above. | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 272 Registered: 4-2003 |

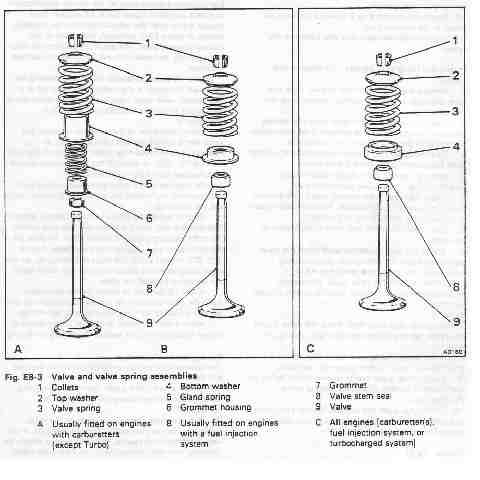

Robert, worry not, Concerning the conversion to later Spirit valve stem seals: this factory update has been around for 20 years and has been a routine factory recommendation for almost as long. I am not relying on anything just because it is written down. However, the official Crewe bulletin issued in the 1980s does recommend this course of action to support the matter. Refer to the TSD6000 bulletin from Crewe which I have posted for confirmation. This applies to all V8s from 1959 SCIIs. Each valve spring is located and correctly tensioned by its bottom washer. See TSD 4400 fig E8-3 Item 4 for all arrangements. There are three arrangements, the silly A type (as in Shadows and early Spirits, and the superior B and C types on later cars). The bottom washer is certainly not deleted. The new seals will not come loose from the valve guides. They are a press fit. Many cars have been updated in this manner by R-R/Crewe and others (including myself) with outstanding results. As specified in the factory bulletin, the guides do not require machining (totally impracticable in any case) for an in-situ change provided the R-R seal part number UE75351 (ie Type C and superseding type A and the similar type B) is used. The sharp bits may simply be smoothed and not machined, but this is a detail. If the heads are off, the better type of seal which I have recommended (ie machine the valve guide tops to suit the more widely utilised outer stem dimension of press-fit 3/8" stem seals) is in my opinion an even better solution. I have personal experience with both these courses. The results are overwhelming. | |||||

John Dare Unregistered guest Posted From: 144.138.194.55 |

Sounds far too convoluted for me, what with encylcopeadic like instructions/sheets/bulletins et al, not to mention smoothing out "sharp bits"(??!!) and all. Glad am I that my professional mechanic of 35 years standing, simply slipped in a set of relatively common "off the shelf" valve stem seals as tried and proven in the real world. And (you get more!) CHEAP too; both parts and labour! Specific details to follow for the edification of all. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 54 Registered: 5-2003 |

Richard, Thanks for the info,I understand what you are saying about type (B)and (C)arrangements,its type (A)I am referring to,Clouds,Shadows and early Spirits. If you ref to the bulletin TSD6000 you posted, you will see the very first item listed under the heading "procedure" clearly says "1)Remove and DISCARD the gland springs(UE319),valve grommet HOUSINGS(UE4727) and the original valve stem seals ".(I take it that means delete it) It is this very grommet housing that centralises the lower spring seat(UE30268) around the lower end of the valve giude,and since the grommet housing is a snug fit over the valve guide it is impossible to fit the later type seal and leave the housing in place. Therefore following the instruction will result in refitting the valve spring with no means of location at its base.The lower spring seat(UE30268)"bottom washer" will not cetralise the spring. When you have performed this up date did you not encounter this problem?. I dont think I suggested deleting the lower spring seat ("bottom washer"),I made the point that later arrangements have different spring seats that overcome this problem.(They are a snug fit over the guide and centralise the spring). The bulletin TSD6000 makes no mention of different valve seats in the new parts required to perform this up-grade. Still worrying. | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 277 Registered: 4-2003 |

The bulletin is clear an correct as I recollect. 1.) Remove and discard the Glang springs, Valve grommet housings and the original valve stem seals (valve grommets). Those are items 5, 6 and 7 in the attached diagram. The lower washer remains to locate the valve spring. If it fouls the new stem seal, simply cut the tower off about 3mm from the base. On 6 cylinder cars (11/32" guides), it is best to save the grommet cover and replace it with a plain washer of the same thickness to maintain the inner valve spring pressure. I have fitted Crane Cams seals to several cars including my own R-Type and others' Shadows without any problem. RROC(A) member, Harry Heuchan in WA, is presently running the UE75351 seals in his Silver Shadow II with great success, and is considering to replace them with Crane Cams seals right now as his heads are off for stud repairs. I shall mail him to obtain his confirmation of which washer type is fitted, and whether he fitted later ones when he upgraded. If you are concerned, by all means fit later bottom washers too.  | |||||

Robert Chapman Prolific User Username: shadow Post Number: 55 Registered: 5-2003 |

Richard, Sorry I dont seem to be very good at explaining this sort of thing. I am not suggesting there is anything wrong with the lower spring seat"bottom washer" (Item No4).There is no problem with it fitting over the new type stem seal(the opening in the top of this part measures .775 and the OD of the fitted seal only measures .725) so there is ample clearence and definitely no need to cut bits off of it. My problem is with the deletion of the housing (Item 6),because this is the part that centralises and locates the valve spring NOT the bottom washer (Item 4). The OD of the flange on the housing (Item 6) measures .935 and locates inside the bottom washer(Item 4) which measures .940. It can be seen that deleting the housing (Item 6) make it impossible for the valve spring to be correctly centralised or positively located around the valve guide that measures only .625 .The lower end of the valve spring free to walk around is obviously a very undesirable situation and a definite resipe for trouble. My concern is that other owners may follow the instruction of TSD6000 blindly. And the ones that have been up-graded in this way will eventually suffer valve spring breakage with all the engine damage that would ensue. | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 285 Registered: 4-2003 |

Robert, I understood exactly what you meant the first time, but cannot remember whether I fitted a centring washer or whether the bottom washer fits into a recess in the head. In any case I deleted the grommet housing last time.I have asked a gentleman to confirm this in the coming days. In either case, it is not a major issue. Of course, never blindly follow the bulletins, let alone the manuals. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 56 Registered: 5-2003 |

Richard, There are definitely no ridges or steps at the base of the valve guide intended to locate the valve spring and centring washers would have to be manufactured, all 16 of them. Do you really think that "it is not a major issue" I would have thought that possible major engine damage that could cost several thousand dollars,caused by following a procedure given by a FACTORY bulletin and then PUBLISHED and PROMOTED on this forum and others, would certainly be regarded by the unfortunate owner as a" major issue". And what of the legal implications,we have often heard on this forum about the possible "legal ramifications", who will be liable when one of these engines breaks a valve spring,droops a valve and destroyes the engine. For any engineer/gentlemen to try and suggest that this floating valve spring is an acceptable situation would surely invite ridicule.Even my second year apprentice when asked what will be the affects of deleting the gland housing asked "whats going to position the bottom of the valve spring". If owners should"never blindly follow the bulletins let alone the manuals " why are they quoted and promoted on this forum? | |||||

John Dare Unregistered guest Posted From: 144.138.194.192 |

STILL waiting and waiting and WAITING (ZZZzzzzzz...) for A CLEAR, UNequivocal (AUTHORITIVE would be nice too!) "explanation" as to WHY and HOW the abolition/deletion (whatever) of valve spring seating and locating mediums/components/devices can be JUSTIFIED, particularly in RR V8 engines. Informed readers will be aware that car mnfrs. are always looking for ways to save money without compromising the basic integrity/safety of their products. A saving of a mere $2.00 per car would translate to over a million dollars p.a to the likes of volume producers such as BMW etc. Once I receive the hitherto unknown, earth shattering "secret" information, I will be on the first flight towards Munich to collect my royalties. I doubt though that any BMW supremo will be able to steady his "Mont Blanc" long enough to write the cheque since he/she will most likely be convulsed by both derision and mirth. At least I will be able to tell them (gulp) that the great ground (and SPRING breaking!)"idea" was actually advocated by people not far away. Not far away from THEM, that is. | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 316 Registered: 4-2003 |

r e a d T S D 6 0 0 0 | |||||

John Dare Unregistered guest Posted From: 144.138.194.144 |

Even if I were able to comprehend and accept the ominous ramifications of deleting a specific part (which clearly results in the absence of any visible or apparent medium to seat and locate the valve spring) how do I "know" when to accept or decline information provided by factory bulletins/manuals etc,given recent advice to the effect that such publications should never be "blindly followed"?. | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 333 Registered: 4-2003 |

I can't be bothered anymore. A sensible dialogue on perhaps the most worthwhile and simple modification to the motors of these cars has been hijacked. Satisfied ? | |||||

John Dare Unregistered guest Posted From: 144.138.194.220 |

I have shown the relevant TSD to a gentleman (he REALLY is!) who was a lead designer of one of the worlds greatest GRAND PRIX competition engines, and also, to a semi retired friend (previously a well recognized "Porsche" mechanic)who, whilst apprenticed at Repco in the mid 60s, was involved with the development of the famous "Repco" V8 race engine at Mitchell St.,Maidstone. Not SURE,but I think his immeadiate "boss" was the legendary Phil Irving. He still has some of those engine components (Pistons etc) on his mantlepiece at his little farm near Heathcote. I also showed both of them,actual sample components nos. 4 and 6, as illus. in diagram/column 'a' of the TSD referred to, and as ADVANCED and PROMOTED on this forum. I asked them what,in their PROFESSIONAL opinion, would be the LIKELY practical consequence of the deletion of item no. 6, ie the grommet housing. Each pondered the relationship of the two components (as laid out on the "Laminex") WITH a (by now!) somewhat grease thumbed TSD. Both ASKED me (almost at the same time!) what means/medium would remain to locate and maintain item no. 4 (spring "seat/guide") AND the actual valve SPRING;item 3 (which locates/seats UPON it) CENTRAL to the valve/valve guide, to avoid the possibility of the spring fretting and/or (at worst) tending to "walk" off centre, thereby LEADING to; 1/ MISalignment. 2/ INvoluntary "release" of valve collets(item 1). 3/"DROPPED" Valve with UNtold consequential engine damage. Regretably, I didnt know the "answer" then, and (sadly) I STILL DONT!!. | |||||

Richard Treacy Grand Master Username: richard_treacy Post Number: 335 Registered: 4-2003 |

Rubbish. | |||||

David Gore Moderator Username: david_gore Post Number: 289 Registered: 4-2003 |

My initial response to the content so far is that if the TSD quoted by Richard was fundamentally faulty then we can all be certain it would have been withdrawn and replaced "post-haste" as the warranty cost of one engine rebuild would have seen to that!!! We must be missing something along the line that will only be apparent to an experienced engine reconditioner or someone who has read this thread and then replaced the valve seals. (Message edited by david_gore on August 31, 2004) | |||||

john Dare Unregistered guest Posted From: 144.138.194.247 |

Yes indeed, for I seem to recall a UK master mechanic effectively conceding the existence of the problem (said problem being the apparent absence of any medium/device to positively seat and maintain the alignment of the valve spring (relative to the valve guide/valve) when he suggested that "it (the problem) shouldnt be a problem" on engines that run under a certain rev.ceiling, making passing reference to "flat fours" etc. Since a VW(?)engine is cheaper(much!) to replace than a R-R V8, two questions appear relevant; WHAT is the rev."ceiling" AND "Do you feel LUCKY?". THEN, in what seems to be another (veiled) concession; words to the effect, THAT, "if one is still concerned then fit the later bottom washer too". Hhhmmm.. would that be a device which in itself (or with other peripherals, DOES indeed seat (or assist to seat) and POSITIVELY MAINTAIN, position "seating" of the valve spring?. IF so, do I need AND "want" it/them?. YES please..(and 16 pieces too!) if it will allay my concerns about the POSSIBILITY of a "dropped" valve, which probably wont fare too well against a piston. Any of them. | |||||

Pat Lockyer. Unregistered guest Posted From: 81.131.97.17 |

From my many years of experience with many MANY types of engines that i have delt with i can categoricaly state that valve springs will not walk provided that the machined collet retaining ring locates them securely. The lower locating washer is of no importance in valve spring alignment and location other than aiding assembly. The valve springs must be able to centre themselves at the non critical base to allow the correct alignment at the vital moving collet end. If they were rigidly located at the base the valve springs would never find their true settling points and may possibly cause fast valve stem and guide wear. The main role of the lower washer is to provide a good a good suface for the spring which does not cause wear to the cylinder head casting. It spreads the loading,and stops pressure indentations from forming in the head suface caused by the spring. The washer material is always far far harder than any cylinder head material for that reason,and it is important for it to be able to move slightly when required to compensate for assembly or fatigue with age. This prolongs valve and spring life. It is essential to have hard washers which can move slightly when needed especially with an alloy head,[soft material] Replacement springs would most likely be misaligned by any form of grooving and be unable to recentre themselves. That could be castastophic. Valve bounce may of course cause all sorts of problems this can only occur with very weak or broken valve springs,and a firmly located valve spring base will not make matters better but worse. For these reasons I see that the TSD6000 is totaly and quite correct in its recommended procedure. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 69 Registered: 5-2003 |

Pat L, In regard to your opinion that"the lower locating washer is of no importance in valve spring alignment and location other than to aid assembly"this is completely and obviously incorrect. Location and centralisation of the spring at its base is imperative,and failure to do so will considerably reduce the fatigue life of the spring. Industry standard for spring out of square is only .04 mm per 1.0 mm ,this would easily be exceeded by an uncontrolled spring. The addition bending stresses caused by the dead coils moving combined with the normal torsional stresses will cause increased fatigue. The movement of the lower end of the spring will also cause side to side pitch variation of the active coils also adding to fatigue. The remainder of you comments regarding the spring seat hardness etc are to coin a phrase"stating the bleeding obvious".There is no issue about the spring seat. I would simply ask, 1)If location was not"of any importance"why has every R-R engine made before (petrol and Diesel)this bulletin been equipped with a location device. 2)Why has every R-R engine made since this bulletin been made with a location device. 3)And why were the R-R engines covered by this bulletin originaly fitted with location devices. Are you seriously suggesting that R-R made and fitted these parts unnecessarily? I dont think so. The point is that the solution is so obvious and inexpensive,when all is needed is a $2.oo spacer fitted around the base of the guide to locate and cetralise the spring seat. Bill Coburn is replacing V.S.Seals on an engine covered by this bulletin as we speak,I am sure he will give us a full detailed report. | |||||

Patrick Lockyer. Frequent User Username: pat_lockyer Post Number: 14 Registered: 9-2004 |

R Chapman. Read the high speed internal combustion engine by Ricardo revised by H.S.Glyde third edition 1941 may help you on your walking springs. also understanding The basics with regard to compression ratio's calculated and fixed also many other topics some now well out of date though. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 80 Registered: 5-2003 |

Hi Pat, Thanks for your reference,of course I own the very edition of this book.Please advise chapter and page in the book where this is refered to. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 90 Registered: 5-2003 |

Hi Patrick, No I am sorry there is nothing on page 226 that remotely relates to the positioning of valve springs,is this another one of your " incorrect facts" as you describe them. | |||||

Patrick Lockyer. Frequent User Username: pat_lockyer Post Number: 27 Registered: 9-2004 |

Hi Robert,Start page 226 keep reading to 259 complete chapter with grafts. | |||||

David Gore Moderator Username: david_gore Post Number: 318 Registered: 4-2003 |

Gentlemen, To avoid possible future confusion, could you both post the edition/reprint date/date of publication of your personal copy of this book so we know you are both referring to the same material. It is possible different editions/reprints may have different page numbers for the relevant material. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 91 Registered: 5-2003 |

David, Yes of course you are quite right. Pat has already posted that the book he refers to is "The High Speed Internal Combustion Engine" revised by H.S.Glyde Third edition 1941. This is without doubt the very same edition I am refering to. Perhaps Patrick could aviod further confusion by quoting on exactly which page it says location of the lower end of the valve spring is not necessery or graph's that support this view .Surely this would be the quickest solution. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 93 Registered: 5-2003 |

Pat Lockyer, where are you. You have quoted a reference book by Sir Harry Ricardo, that you said validated your contradictory position. This has been checked and found to be incorrect, there is no such validation in the book, yet another "Incorrect Fact" (oxymoron) as you like to describe your own mistakes. People more cynical than myself might suggest that your failure to "put up" says it all.And once again your eagerness to contradict has exceeded your technical knowledge. Will this be another case of "as for Chapman I will get back to him when I can",to answer how the ignition timing on all cylinders can be individually checked by as you said "moving the timing light pick-up to each spark plug lead in turn". When it was suggested to you that this would only work on 2 cylinders I believe your answer was "easy! simply fit a degree wheel to the front of the crankshaft ".I am still waiting to hear from you how that is "easily" done in position. | |||||

Patrick Lockyer. Frequent User Username: pat_lockyer Post Number: 29 Registered: 9-2004 |

Update on distributor testing on Shadows a clue for you Robert just one,fibre optics. Still not worked out the walking springs,yes no need to locate the bottom, think and read it will come to you soon i am sure. | |||||

Robert Chapman Prolific User Username: shadow Post Number: 96 Registered: 5-2003 |

Pat Lockyer, A clue for you, Colonic Irrigation,because your full of it. | |||||

Patrick Lockyer. Prolific User Username: pat_lockyer Post Number: 32 Registered: 9-2004 |

Robert Chapman your true colours shown. | |||||

John Dare Unregistered guest Posted From: 144.138.194.182 |

To validate the ENTIRE concept of the R-R TSD which started this thread, we were told that certain pages of Harry Ricardos famous book were relevant. It was suggested that one could read text suggesting that valve springs do NOT require a medium (typically a simple spacer AS ROUTINELY USED BY OTHER ASSORTED AUTO ENGINE MNFRS.!) which seats and locates the base of the valve spring, maintaining its concentricity to the attendant valve guide/valve. The pages as quoted (eventually!) reveal NO such information, explicit or implied, however this should come as no suprise, as the esteemed H.Ricardo was obviously aware of the clear need to deploy and retain such a seating/locating medium, AS WAS THE DESIGNER OF A MOTOR CYCLE ENGINE (CIRCA 1911) AS RECENTLY SIGHTED BY ME. Such a medium WAS clearly present then and has remained so (over DECADES!) in a wide range of auto engine valve gear. Accordingly, it would appear that even 100 years ago (almost) engine designers were aware of the need for this simple and basic medium, as have been contemporary auto. eng. mnfrs., and most other people, including even, my friendly postman who,to his credit,freely admits to being no more than an amatuer tinkerer of sorts. (Message approved by david_gore) | |||||

John Dare Unregistered guest Posted From: 144.138.194.15 |

In order to proceed, hopefully to finality, I continue to await advice regarding the pertinent pages in H. Ricardos acclaimed book (copy readily available to me) which allegedly validate, in ANY way, the concept of the ABSENCE of a medium to locate a valve spring at its base in order that said spring be located (and maintained) concentric to the attendant valve guide/valve. Such mediums are in the form of "spacer" type washers/locating "seats" or "distance" pieces etc. The pages previously quoted, do NOT support, in ANY para./sentence therein, the proposition that such devices are unecessary and/or, IF present, may be deleted. I ask that the CORRECT (relevant) pages OR pages from ANY other AUTHORITIVE source/publication, be quoted in reply. A reasonable and SIMPLE request is it not? (Message approved by david_gore) | |||||

Patrick Lockyer. Prolific User Username: pat_lockyer Post Number: 89 Registered: 9-2004 |

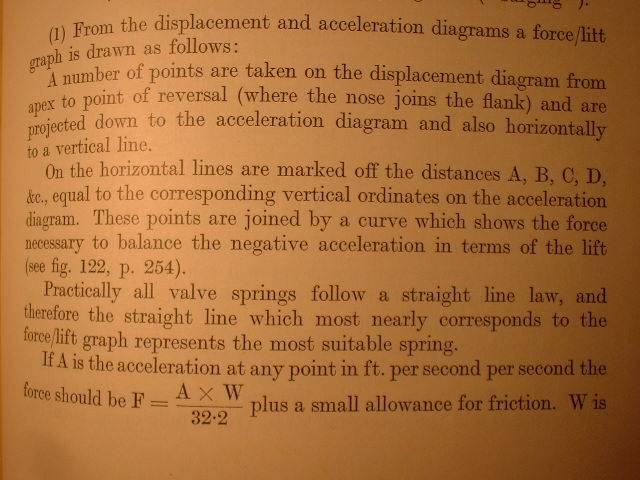

Strait line law. Out of date now things move on. Valve located at the valve collet retaining plate modern correct springs follow strait line. Fooled by the turned up plate it is for oil retention to let them move about,no worn guides for miles.  | |||||

John Dare Unregistered guest Posted From: 144.138.194.29 |

Hello Patrick. And so the long overdue "explanation" finally arrives!. Never in the history of automotive debate have so many, waited so long, for so little. The reference quoted, discusses the SELECTION of a spring (for a given application) hence the words, "represents the most SUITABLE spring". From this referenced page, I THINK (your posts,as usual, being decidedly vague and convoluted) that you have drawn certain conclusions, thereafter implying THAT.. A/ valve springs need NO locating medium at their base, since "modern/ correct"(?) springs presumably self centre (and do not MOVE!) thereby, at all times maintaining (at base) their concentricity, relative to the valve guide/valve. B/ That the "turned up (machined) plate"; eg spacer/locator/distance piece (at the spring base) is for OIL retention AND..to "let THEM (the springs?) move about". If THAT is what is being advanced, then clearly, B contradicts A, which suggests that NO movement occurs,see your "follow straight line" theory etc. Further, IF the base device/s, as described, do NOT serve to locate the valve, but RATHER simply exist to supply lubrication to the valve stem (see your "no worn guides for miles") HOW does the oil from this hitherto secret/magic "depository", rise UP and OVER the guide, to greet the valve stem?. I need a little time before cautiously concluding THAT all of this IS in fact WHAT you are saying and/or ATTEMPTING to say, after which time I will respond, hopefully to what I BELIEVE it is that you have proposed. (Message approved by david_gore) | |||||

Patrick Lockyer. Prolific User Username: pat_lockyer Post Number: 95 Registered: 9-2004 |

J.G.Dare. As i have said before and repeat you are not an engineer Just a professional with words. As your many postings confirm. As to the retaining plate to lubricate the valve guides you must be on another planet. You must take some satisfaction from your distructive postings as i am now of the sad opinion that folk reading your rubbish feel reluctent to follow the original topic after your postings at what could be a constructive discussion. (Message edited by david_gore on November 25, 2004) | |||||

John Dare Unregistered guest Posted From: 144.138.194.186 |

Thank you again, Patrick. On 23/11 at 6-20am, you wrote, Quote; "fooled by the turned up PLATE it is for oil retention to let THEM move about no worn valve guides for miles".Unquote. To avoid speculation as to exactly WHAT you perhaps INTENDED to say, could you please confirm IF your reference to the PLATE, means the "spacer/locator/distance piece"(as commonly deployed at valve spring base)AND further, that your reference to "THEM", alludes to the valve springs themselves, ie they which, quote; "move about" etc. If THAT is what your own words are intended to mean, are you not effectively proposing (in your post of 23/11) that the valve guides are additionally lubricated by virtue of the oil retained (as you suggest) at the base of the spring. IF so, then the question REMAINS as to HOW the oil "rises" upwards to provide such additional lubrication, resulting in, as you say, "no worn guides for miles". If THIS is NOT what you have implied, could you please clearly explain precisely what it is that you ARE proposing. (Message approved by david_gore) | |||||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 102 Registered: 9-2004 |

J.G.Dare If you were in a court of law you would look so daft instead of you takeing everyone to the cleaners it would be yourself taken,regarding your lack of understanding. As you now confirm you are no engineer,i will not waste any more time on your posts and hope you find another intrest to which you can occupy your sad sad brain. (Message edited by david_gore on November 25, 2004) | |||||

John Dare Unregistered guest Posted From: 144.138.194.168 |

Thank you Patrick. Your learned contributions, insightful and revealing as they are, fail yet AGAIN, to address elementary questions which simply invite your CLARIFICATION of WHAT it was that you were attempting to assert (or propose) in previous posts. I can but speculate as to the reasons for your inability or unwillingness to do so. I agree that I am not an engineer, having never implied that I am. Conversely, you have conspicuously avoided previous invitations (via this forum) to declare YOUR formal qualifications (evidence may be requested) AND nature (make/model etc) of practical automotive repair/engineering experience together WITH the associated duration (time period etc) thereof. Perhaps you can apprise us accordingly,in order that we may be convinced, to some extent, in respect to the accuracy,integrity and validity of your continued offerings. Such are typically presented as PROCLAMATIONS, duly delivered with conviction and "authority", as IF being conveyed by a eminent person imbued with extensive(and recognized) FORMAL AUTOMOTIVE QUALIFICATIONS. Such edicts and summations are usually "reactionary" (in RESPONSE) and appear to serve merely as OBJECTIONS to well intentioned posts from QUALIFIED automotive ENGINEERS and repairers with MANY years experience;"Daimler Benz"/"R-R" etc. Even the exhaustive findings of investigative METALLURGISTS and the courteous opinions from U.S based, "ASE" Master Mechanics, do not escape your vigorous challenge nor blatant contradiction. What, DARE I ask (once more!)ARE the particular qualifications held by YOU, which enable you to seriously dispute such INFORMED opinion, seemingly, at any and every opportunity?. (Message approved by david_gore) | |||||

Robert Chapman Grand Master Username: shadow Post Number: 125 Registered: 5-2003 |

Patrick Lockyer, " YOU CANNOT BE SERIOUS" Are you really trying to tell us that what the author refers to as the" straight line law "relates to the course the spring travels through compression and decompression? If so, it is obvious that you either have not understood a single word the man was talking about or you have looked for anything in the book that could remotely relate to your proposition,I suspect both. The reference to the straight line law ,as stated in the last paragraph on the page,refers to the force/lift graph. The straight line refers to a LINEAR rate/load/ at verious lift increase of the spring as opposed to sinusoidal. This has ABSOLUTELY NOTHING to do with valve spring location and ANYONE reading it would realise it. And as for the explanation of the "turned up plate" please, give me a break, that was pathetic. Funny that the lip on the outside of the plate matches the outside dia of the spring and the inner lip, the valve guide . Giving certralising location to the spring around the valve guide! You have preached for so long" its all in the book" and now under pressure to put up you try to represent this as your evidance! but let me predict your considered response now Pat,the same ones you always use when you are exposed. (Message edited by david_gore on December 03, 2004) | |||||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 132 Registered: 9-2004 |

Realy!

Patrick, your attachments are not uploading for some reason; could you please read the "FORMATTING" section under DOCUMENTATION on the LHS of your screen - go to "OTHER FORMATTING" then "IMAGES, ATTACHMENTS AND CLIPART". I suspect your problem is you either have not used the \ or { } symbols properly. If you have further problems; please contact me. (Message edited by david_gore on December 03, 2004) | |||||

John Dare Unregistered guest Posted From: 144.138.194.80 |

... and Truly have I tried to download these files. If and when I do, I expect,not unreasonably, to see a reference (express or implied..even vaguely) within any statement or para.therein, which clearly states that it is NOT necessary to deploy any device at the base of a valve spring,the presence of which ensures that the spring base remains concentric to the valve boss/guide and as a consequence, the valve itself. In the absence of any such reference I will be obliged to conclude that the PRIME question which arose (at the beginning of this thread) has remained UNANSWERED. (Message approved by david_gore) | |||||

Patrick Lockyer. Grand Master Username: pat_lockyer Post Number: 139 Registered: 9-2004 |

Robert. For the time being i will concede on this as i cannot seem to grasp the sending of text with this modern contraption. Pictures seem ok. |