| Author |

Message |

Christian S. Hansen

Grand Master

Username: enquiring_mind

Post Number: 921

Registered: 4-2015

| | Posted on Thursday, 27 September, 2018 - 18:14: |    |

1959 Silver Cloud LSMH109

Help me think thru a "cheapskate workaround" repair on the Cloud air conditioning.

In another thread Omar has noted that "hoses are hoses."

The question here revolves around what is the operating pressure within the hose between the compressor and the condenser in front of the radiator matrix?

My rudimentary understanding of the basic system is that the refrigerant is compressed by the compressor into a liquid state where it passes under "higher pressure" to the condenser and then travels also at a "higher pressure" to the evaporator where it evaporates into a gaseous state and in the process draws heat from the air that passes over the evaporator matrix and into the cabin. The refrigerant gasses then travel presumably under "lower pressure" back to the compressor where the cycle repeats.

Bottom line is that there is a "lower pressure" input to the compressor and a "higher pressure" output from the compressor. In my case it is this "higher pressure" hose that needs to be repaired or replaced.

The question is, "What sort of high and what sort of low pressures are within the system and especially that "higher pressure" output line going to the condenser?"

The application: My system checked out as being fine and functional except for a small leak in the compressor to condenser hose right at the crimped fitting as it exits the compressor. That fitting appears to be a standard fitting. Given that removing that line for replacement involves the removal and replacement of the radiator shell in order to access the condenser end of the line and for which labor of about $600 to $750 is quoted, my proposal is to repair the hose by simply trimming about 2" off and replacing the existing crimped fitting with a compression fitting. There appears to be sufficient slack in the hose to reattach it to the compressor in its shorter length. I have used compression fittings to repair hydraulic hoses on my skid steer and that system runs under pressures of around 2100psi so presumably would also work in this application.

It seems to me that this is a "field expedient" repair that is worth trying. If the repair does not hold pressure, then the only things lost are some refrigerant and the fitting.

What is the consensus?

Shall I proceed along this line or is it a fool's errand?

Of course, setting aside for the sake of this discussion that a LOT of things I try in life turn out to be fool's errands!! That SOME work keeps me eternally optimistic.

. |

Christian S. Hansen

Grand Master

Username: enquiring_mind

Post Number: 922

Registered: 4-2015

| | Posted on Thursday, 27 September, 2018 - 19:58: |    |

Later...

Been doing some research and to some extent answered my question. The reusable compression fittings are rated for over 5000psi so that is not the issue. Whether the hose in the Cloud is the proper size for the available fittings (the fitting and hose MUST properly match) remains to be seen. Seems worth further investigation.

. |

Christian S. Hansen

Grand Master

Username: enquiring_mind

Post Number: 924

Registered: 4-2015

| | Posted on Sunday, 30 September, 2018 - 06:24: |    |

While hoses are hoses, the contents vary. In the past I have noticed that hydraulic lines develop leaks from rubbing against other objects which weakens the hose to the point that a leak develops and the pressurized hydraulic fluid squirts out or in a case of an old and worn hose it bursts.

In addition to rubbing wear as a cause, leaks in refrigerant hose seem to develop as tiny holes that cannot be seen except with the dye added. What is it about the nature of A/C refrigerants that causes these tiny leaks to develop in the sidewall of the hose?

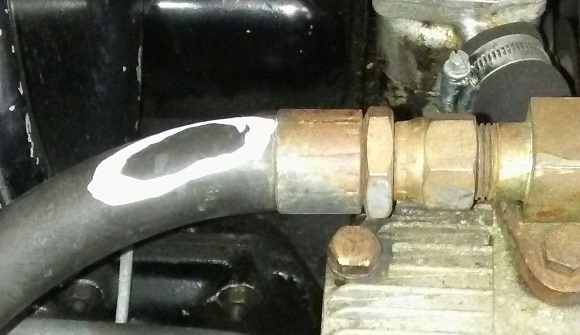

Hole circled in white indiscernible to naked eye:

. |

Christian S. Hansen

Grand Master

Username: enquiring_mind

Post Number: 925

Registered: 4-2015

| | Posted on Monday, 01 October, 2018 - 12:39: |    |

1959 Silver Cloud LSMH109

Continuing with the thread mistakenly posted in the EPW Category (about the Compressor to Condenser A/C hose)...

I have cut off the end fitting and 2" of the hose containing the pin hole leak and replaced with a reusable compression fitting end. System is now ready to recharge, but what about the receiver/dryer? Should it be replaced as a standard procedure any time the system has been empty? What is the downside to not replacing it or is it one of those things you never do not do?

Christian - have transferred this post to the proper topic for you. Regards David

|

Christian S. Hansen

Grand Master

Username: enquiring_mind

Post Number: 926

Registered: 4-2015

| | Posted on Tuesday, 02 October, 2018 - 17:40: |    |

(Thank you, David)

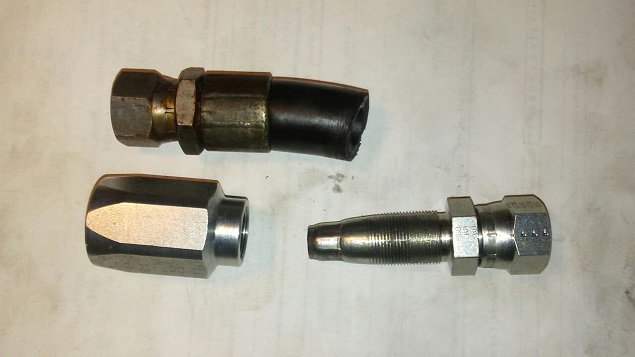

Repaired hose in place. System ready for refrigerant:

Old fitting cut off and two pieces of compression fitting ready for installation:

. |

Jim Walters

Prolific User

Username: jim_walters

Post Number: 198

Registered: 1-2014

| | Posted on Wednesday, 03 October, 2018 - 04:32: |    |

Christian, not to be pedantic but for the sake of clarity for others that may read your post in the future those are not compression fittings. Compression fittings are used on tubing. The fittings shown in your post above are known as "reusable hydraulic fittings".

SRH8505 SRC18015 SRE22493 NAC-05370

www.bristolmotors.com |

Paul Yorke

Grand Master

Username: paul_yorke

Post Number: 2061

Registered: 6-2006

| | Posted on Wednesday, 03 October, 2018 - 06:18: |    |

Hi, If the system has been empty or had air in it then a dryer should be changed. If fact after all these years it should be changed anyway.

It contains a desiccant which wears out. Also old R12 desiccant does not work with R134a

And free moisture in the system can freeze but more importantly turns corrosive when mixed with the gas.

Put a modern one somewhere else if you like, well . . if you have the big can one under the front. |

Christian S. Hansen

Grand Master

Username: enquiring_mind

Post Number: 928

Registered: 4-2015

| | Posted on Wednesday, 03 October, 2018 - 06:23: |    |

Jim...

Thanks for that correction. I knew what I wanted to do but not the proper terminology.

Paul...

I have an old Borg Warner add-on system from the period with the evaporator and dryer in the boot. Called the "Texas Boot Model" I believe. Am taking it to the shop today to identify and order a dryer. Thanks.

. |

Christian S. Hansen

Grand Master

Username: enquiring_mind

Post Number: 934

Registered: 4-2015

| | Posted on Thursday, 04 October, 2018 - 15:24: |    |

The Devil is in the details.

I have learned quite a bit from this effort.

It is relevant to note that many A/C systems use fittings that are different from standard hydraulic fittings. The fittings in my system all had male and female flange end fittings and there are two different angles to the taper of the flange.

Standard hydraulic flange tapers are 37 degrees and are designated as "JIC" whereas A/C fittings, while using the same threads, have a 45 degree taper on the flange and are designated "SAE". What this means is that while the two different fittings will thread together, the tapers will not mate properly. Whether or not this makes a difference is subject to opinion and argument. Ideally the tapers should match.

What I found was that the young guys at the hydraulic shop did not know this and although the older guy apparently did know, he did not mention it even though I told him that I was doing A/C repairs.

Bottom line is that you have to do your homework and not rely exclusively on what others tell you. Especially the young guys who just want to stand in front of the computer and repeat "What's the application? Year, make, model, serial number?" Those guys are frequently useless when it comes figuring out old cars.

I have had similar experiences simply finding an appropriate receiver/drier for the 1960s era aftermarket A/C system. Again, a case of a little knowledge can be a dangerous thing. Not understanding the difference between expansion valve systems that use receiver/driers and orifice tube systems (that were not invented until decades later) that use accumulator/driers.

Getting currently available parts for old systems where the manufacturer has been out of business for years if not decades can be like reinventing the wheel, but I'm getting there!

. |

Robert J. Sprauer

Frequent User

Username: wraithman

Post Number: 70

Registered: 11-2017

| | Posted on Thursday, 04 October, 2018 - 21:30: |    |

Aircraft and stainless steel flares are usually 37 deg |