| Author | Message | ||

Marty Unregistered guest Posted From: c211-30-225-8.carlnfd3.nsw.optusnet.com.au |

Gidday all, Has anybody tried this stuff? I put it in Chloe last weekend, and it was hard to tell, as the day was very wet and quite cool, but the thermo fan wasn't needed at all in a slow traffic crawl right the way through Mosman, Neutral Bay, etc in Sydney. Normally, after sitting still in traffic for 15 minutes, The temp would come up to 80 - 85 degrees, and the thermo would come on. It must be doing something, what's in it???? Cheers Marty (Message approved by david_gore) | ||

Robert Wort Grand Master Username: robert_wort Post Number: 328 Registered: 12-2004 |

Hi Marty, Iím always suspicious of any aftermarket products when it comes to fuel, oil or coolant additives. Motor manufacturers spend many millions of dollars in research when testing various products for use in their cars. They do, after all, have a reputation to uphold, especially our cars. I would be very wary with these aftermarket products when using them in our engines especially the alloy V8ís. There is really no reason why our RR/Bís should have overheating problems. In well maintained condition, they usually run quite cool. And thatís the rub. Prevention is always better then cure. By flushing the system and changing the fluids every couple of years and checking and replacing the hoses and belts as necessary, one should never have any overheating problems. Itís recommended that our cars use an ethylene glycol based coolant and inhibitor concentrate mixed 50-50 with water to the cooling system. Iíve heard that some people use a glycol free coolant and I really canít understand why. Rolls-Royce invented Ethylene Glycol coolant for their aircraft engines before WW11 and to this day, they still recommend itís use. I have no reason to doubt their judgement. If this Redline additive is as good as they claim, then manufacturers would certainly use it as standard and the mainstream oil companies such as Castrol, Mobil etc. would have an equivalent also. In a nutshell, experiment with these things at your peril. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1075 Registered: 4-2003 |

Well put, Robert. Not one major oil company or motor manufacturer I know of recommends an additive for any fluids whatsoever. In the 1960s, the likes of Chrysler and GM would sell you a little bottle of rust inhibitor as they knew that many cheapskates ran tap water in their radiators. The recore shops loved those days. Business boomed on a frosty day, and again when the clogged radiators boiled over on a very hot day. The business of additives and additional inhibitors vanished once inhibited ethylene glycol became the affordable norm for all. Some manufacturers are converting to long-life propylene glycols, but only to last out the warranty period without changing it. Remember those household icons: Redex, Bars Leaks, STP ? They are now the preserve of the shonky used car lots. R-R always specified 40% pure inhibited ethylene Glycol for the pos-war 6 cylinder cars and 50% for our V8s, and never with an additive. Be clear: most coolants in supermarkets are premixed at 35% for Holdens and Fords (freezes at -20C) and is totally unsuitable for any dilution. Even concentrates are often just 60% glycol (-50C), so the dilution should then be 1 part water for 5 parts concentrate for the V8s or 1 for 1 (6-cylinder). The correct mix will freeze at -26C (6-cylinder) and -37C (V8). The only reliably easy way to test the coolant is with a refractometer, as a hydrometer is highly inaccurate with more than 30% glycol. Anything below 20% glycol accelerates corrosion compared to pure water, whilst 30% or higher stops corrosion dead. As to Water Wetter: that was developed for drag racers doing 5 second bursts with cast iron motors stretched to the limit, and the water coolant changed every time. I have no idea how it will react with ethylene glycol, especially long-term. It is certainly unsuitable for our V8s and 6-cylinder motors with so much alloy. Drag racers may be searching for every 1% using all sorts of short-term additives, but our cars have so much reserve cooling capacity that it makes no sense to experiment. With so many billion of vehicles in the world nowadays running with no additives other than those applied by the coolant manufacturers in co-operation with the entire motor trade, why on earth should we depart from the lead set by Crewe early last century and now the industry norm ? | ||

Bill Vatter Frequent User Username: bill_vatter Post Number: 26 Registered: 9-2004 |

Only slightly different view here: In the US, Detroit Diesel, a major manufacturer of diesel engines for over-the-road trucks, recommends an additive from the Penray company, Pencool 3000, for use in coolant systems. This is a supplemental corrosion inhibitor, and it compliments glycol-based antifreeze by enhancing or adding to the inhibitors of the antifreeze. The anti-freezing properties of Glycol don't wear out, but the corrosion inhibitors do get used up, and the Pencool 3000 makes sure there is enough. Richard, with respect, I question your statement that less than 20 percent antifreeze is worse than none at all from a corrosion standpoint. Could you explain that more completely? My understanding is that glycol really doesn't prevent any corrosion, it is the inhibitors packaged with the glycol that prevent corrosion. Without specific knowledge, I would guess these additives are (1) a pH buffer, (2) an oxygen scavenger, and (3) something that incourages formation of a passive layer on the aluminum parts. (I think (3) would be called a passivating agent.) With regard to additives like these, a little should be better than nothing at all. Perhaps I am missing something here, and if so, I want to be enlightened. For antifreezing protection only (differentiated from corrosion protection) only a small amount of glycol is really needed. I have read this is between 5% and 10%. If the temperature drops below the freezing point for the percentage of glycol that you have in the car, it freezes as slush, not as a solid mass accumulating at or around the coldest spot. Therefore, the extreme pressure that breaks blocks caused by the specific volume of ice being greater than liquid water doesn't occur. The slush simply pushes into the expansion space of the cooling system. This "slush-freezing" process is progressive. The freezing is really water coming out of the solution, which leaves behind a higher concentration of glycol, which freezes at a lower temperature. While ethylene glycol (and I think also propylene glycol) will slightly raise the boiling point of the coolant, that isn't significant. What's more important from a cooling persepctive is that the thermal conductivity of glycol is significantly less than water, and therefore any misture of water and glycol is going to run hotter than pure water. This being only when conditions cause the thermostat to fully open. Therefore if your cooling system is marginally adequate, water is going to work better than a glycol mixture. Based on the above understanding, in my cars I am running 25% ethylene glycol based antifreeze (easily found 100% strength in the US) and distilled water, with 1 pt. Pencool 3000 per 4 gallons coolant volume (recommended concentration). Now I am not hung up on being right over this; I just want to be sure of the facts. Therefore, please give me an opposing argument. Incidentally, I think Water Wetter does its thing by reducing the surface tension of the fluid. Therefore bubbles formed in sub-cooled nucleate boiling form more easily, increasing the sub-cooled nucleate boiling heat transfer which is surely occurring at the hot spots in virtually all engines when running under load, and if there is a surface condition that prevents the water from wetting the surface, possibly a fouled surface on the indside of the radiator tubes, the reduced surface tension will help that. Anyway, that's what I think. | ||

John Kilkenny Experienced User Username: john_kilkenny Post Number: 18 Registered: 6-2005 |

Further to this discussion, while it is necessary for Glycol based coolants to be used where the ambient temperature can fall below freezing, for areas where this does not occur (such as coastal Australia) there is no need for it. As well as having a low freezing point and high water miscibility Ethylene Glycol is a sweet tasting poison which can be oxidized by heat and air to produce corrosive organic substances. Additives are included in glycol automotive coolants to reduce the effect of this oxidation but it is still recommended to change these coolants every one or two years. A further disadvantage is that a coolant containing 50% Ethylene Glycol at 180 Degrees Fahrenheit has a Specific Heat Capacity (i.e. Heat Transfer Capability) only 0.86 that of clean water, and while Glycol will marginally raise the boiling point of the coolant this is immaterial for pressurised systems. Of course it is still necessary to use additives to prevent corrosion but these have a far longer life than the Glycol based product. For example Caltex manufactures XL Corrosion Inhibitor Concentrate which is used at a concentration of 7.5% in clean water, recommended for aluminium engines and is specified to last for 250,000 Km or 5 years. It costs around 10 AUD for 500 ml, so 1200 ml will be required for the Shadow cooling system. See http://www.caltex.com.au/products_oil_detail.asp?id=320 for product specification (for the diluted coolant). Interestingly the ownerís handbook for my car (SRH1405) specifies a 25% mixture of an antifreeze to BSS 3150:1959 to give protection down to 11 degrees C of frost, but also approves the use of SQ36 (?) inhibitor (3 fluid oz to each Imp. Gallon of water) in countries where the ambient temperature is above freezing point at all times, and anti-freeze is not available. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1076 Registered: 4-2003 |

Interesting, as the handbooks and workshop manuals for the R-Type specify 40% pure glycol, and the T-Series and Turbo R 50%. They specifically warn against lower doses. The concentration has most to do with engine performance at normal temperatures and far less to do with the added benefit of withstanding -37C without freezing. The user list for that Caltex inhibitor includes Detroit Diesel, Mercedes Benz trucks, MB 312.0, Scania, MAN 248, Liebherr MD 1-36-130 (DCA), MTU (MTL 5049) Series 2000/4000 engines, Deutz (TR0199-99-2091) medium & large engines, Wšrtsilš diesel/gas/dual fuel engines, MAN B&W, 2 and 4-cycle engines, MaK, New Sulzer Diesel, 2-cycle engines, Ruston (MAN B&W), Ulstein Bergen 2.13.01, diesel and gas engines, Yanmar. These are trucks and ships mainly, with not a Rolls-Royce in sight let alone a Holden. True, at DaimlerChrysler we used water and inhibitor in MTU locomotive and marine diesels. They are a little different from automotive engines, and the main reasons to use basically water were to limit the heat expansion and to reduce costs. Also, those huge motors usually run around the clock, even when parked, to save on temperature cycling wear, so warm-up times were not relevant. By comparison, motor cars are designed for glycol, and benefit from its faster warm-up: thatís why expansion tanks were fitted early by Crewe and later by the industry at large when glycols became the norm in the 1970s. On electric machines such as mining electric shovels and in the electrics of diesel-electric locomotives, we used either oil (horrible stuff and a poor coolant) or concentrated glycol to cool thyristor/GTO/IGBT components and the like. Water is out of the question there. To answer Bill Vís question, once the inhibited ethylene glycol concentration is below about 20%, then there is insufficient inhibitor to protect the motor. The glycol effect then increases corrosion, the glycol being more effective as a corrosive agent than the protection from the inhibitor when too dilute. Pure water is safer, but why not do as Crewe instructed in the first place and use a sufficient concentration of glycol ? Practically every passenger vehicle manufacturer recommends the same. As to the need for antifreeze as such, donít forget that much of Sydney has frosts 10km inland. Sure, water has a better heat transfer co-efficient than glycol, but who cares ? Our cooling systems have plenty of spare capacity for the Australian deserts, poking around the streets of Dubai and blasting down the German Autobahns in summer on the rev limiter. Itís also nice to know that the motor will not split when you visit Canberra or Penrith in winter or take a holiday at Thredbo or Zermatt. | ||

John Kilkenny Experienced User Username: john_kilkenny Post Number: 19 Registered: 6-2005 |

Richard, Don't you think that the reason Caltex lists large expensive engines and not a myriad of car engines is to emphasise the safety and effectiveness of the product. Also it takes a lot more than a heavy frost to freeze a car cooling system. The fact remains that a 50% glycol coolant is generally an overkill and is a one size fits all arrangement to ensure a sufficient quantity of inhibitor is included. As the world becomes more environmentally conscious hopefully this will change. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1077 Registered: 4-2003 |

John, I really can't agree with an implied recommendation to depart so widely from the manufacturers' recommendations and to the passenger vehicle industry norms. This is one area where Crewe is very specific and seemingly correct. On MkVI and R-Types, the original 25%-40% glycol recommendation was quickly superseded by a bulletin to fill all cars with 40% pure glycol. Ask any Phantom III owner about the perils of fiddling around with coolants Just look at the huge number of postwar Crewe car owners assuming that our cars have inadequate cooling systems on our site alone ! That is bunkum propogated by poor cooling system care. I put down the life of our radiators and perfectly functioning cooling systems to proper maintenance and the correct coolant. B174UM had its first new core two years ago due to stone damage at 700,000 km, SBH13247 has never had its radiator so much as removed from the chassis in 350,000 km, and Turbo R BSH20037 will receive its first new radiator today at 270,000 km due to a possible slight stress leak. These cars all have spotlessly clean cooling systems and have never hinted at overheating. Remove the thermostat and you can see that the water passages look like new. When all else fails, read the instructions. 40%-50% coolant concentration is not specified for fun. As to other brands, BMW specify 40% minimum for its iron engines, 50% for the alloy ones. Holden specify 35% glycol for its iron Ecotech V6 to the point that Castrol sells a special 35% mix called Castrol 350 for Commodores. Holden do not go to the expense of a proper coolant unless it is necessary: http://www.castrol.com/castrol/multipleproductsection.do?categoryId=8000018&contentId=7000401 I beg you to stand in the wind on a windy frosty and clear morning. You chill very quickly. The cars radiator can freeze very quickly in these conditions and split, even if the motor may take a lot longer. Really, are all the world's manufacturers wrong ? I don't see a single GM, DaimlerChrysler, VW or Ford approval on the Caltex stuff for passenger vehicle, only for some of their heavy motors like DC's MTU. I do on most coolants.  (Message edited by Richard Treacy on September 19, 2006) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1079 Registered: 4-2003 |

And this is the workshop instruction for a humble 1994 iron-block, alloy-head BMW 325i. The next paragraph warns of corrosion danger with less than 35% and that under no circumstances should any additives be filled in.  | ||

Bill Vatter Frequent User Username: bill_vatter Post Number: 27 Registered: 9-2004 |

Interesting discussion; thanks to all who are participating. Richard, I question your apparent claim that the cooling systems are more than adequate for whatever conditions might be encountered anywhere in the world. At least I question that for the early postwar, pre-Cloud cars. The Bentley radiator grille was modified with the vertical slats opened wider, and then the radeiator itself was changed to one with greater frontal area. (Chassis numbers B320CF and B270DA respectively.) If the original configuration was more capacity than needed, why would those modifications have been introduced? The larger radiator (designated Mk VII by the factory) was also incorporated in the Silver Wraith, but later at chassis BLW43 in 1953. I believe the Silver Dawn had the larger Mk VII matrix from its initial introduction. Since the Silver Wraith shutters open much wider than the fixed Bentley vertical slats, I assume cooling was not as critical a problem for those cars. My Silver Wraith (WGC66, 1949 with early radiator matrix) never overheated before I added an air conditioning system. (You could argue the wisdom of that modification, but all should recognize that a happy passenger makes for enjoyable travelling.) The condensing coil is in front of the radiator, behind the movable shutters, which continue to function as before. There is just enough room for some space between the condensing coil and both the radiator and the full-open shutters, and the only drawback to this condenser location is that I need to wait until the engine is warmed up and the shutters open before I turn on the A/C. However, even if I forget, the high pressure cut-out for the compressor should protect the system if the condenser doesn't get sufficient cooling. With the A/C installation, on a very hot day, there are occasions (stop and go with lots of red lights) when I must turn off the A/C to prevent the engine from overheating. With the A/C turned off the engine seems to run a bit warmer on hot days than before the modification, which I attribute to reduced air flow caused by the restriction of the condensing coil ahead of the radiator. This is most noticable in stop and go traffic, where there is marginally sufficient airflow even without the A/C. Now the purpose of that long-winded discussion is not to promote or speak against addition of an A/C system, but to point out the radiator is not over-capacity. In my car, a 25% antifreeze mixture will run noticably cooler than a 50% mixture. On my trip to the RROC (US) national meet this year, in very warm weather, I let out some 50% coolant and refilled a couple of gallons distilled water to improve cooling, and that made a noticable difference. So I conclude for the early postwar (pre-Cloud) cars, if the corrosion problem can be addressed with supplemental inhibitors, less antifreeze is better. Of course, if my radiator was new it probably would cool better, and maybe I could use 50% glycol without a problem. However, I don't think it is in very bad condition, at least as good as the average situation in an early postwar car. Most of us would like to make our current equipment work as well as it can before biting the bullet for a new radiator core, not an insignificant expense or labor. (Message edited by Bill Vatter on September 19, 2006) | ||

Marty Unregistered guest Posted From: c211-30-199-88.carlnfd3.nsw.optusnet.com.au |

Gidday Bill, I agree with yourself. I have run inhibitor only in all my vehicles as there is no need for anti freeze in Sydney. The anti boil part of it, well, you are going to turn the motor off before the thing gets that hot. I know to fix my thing properly I need to strip the engine and clean out the block, but as the car runs perfectly, and the thermo fan keeps it cool, I don't think I will put myself through that just at the moment. Maybe when I'm retired, my kids have grown up, and I'm looking for something to do.......in about 20 years time :-) (Message approved by david_gore) | ||

Bill Vatter Frequent User Username: bill_vatter Post Number: 28 Registered: 9-2004 |

Marty, You may well have a lot of deposit in your block, but what you describe sounds like a radiator problem. You can get a rough estimate at the amount of deposit in your block by draining everything and then noting the volume required to refill, which should be about 4 imperial gallons. Whatever you are short of the four is space being taken up by something else. | ||

Laurie Fox Experienced User Username: laurie_fox Post Number: 20 Registered: 6-2004 |

I am all in favour of keeping corrosion down but I must say that I still have no clear idea of exactly what I should do on my MK VI. This situation arises because of the many different recommendations which are made which sometimes appear to be contradictory. I can understand why Rolls have made different recommendations at different times because each recommendation was made based on information available at the time and in relation to their expected use of the car concerned. I have accepted that corrosion of some sort or another will occur over time and that the performance of the cooling arrangements will suffer accordingly. This has happened on my B420EY (a standard steel saloon MK VI) and when it last reached the stage where some attention was needed I explored the situation as described in an earlier topic in this forum (Achives 2005, MK VI Overheating Question). My findings were that the primary cause was restriction in the radiator core resulting in reduced coolant flow, coupled (probably) with poor transfer of heat from the coolant in the radiator to the air. But the experiments provided one unexpected bit of information which now suits me very well. I found that with a new radiator the coolant flow through the cylinder block was significantly improved by omitting the thermostat and leaving the by-pass open without any detriment to normal indicated running temperatures. I know that the car has the advantage of being in the UK where, even this summer, air temperatures have been nowhere near what other people experience, is virtually never driven above 70 MPH because I am too old, and there are no long climbs to contend with. Slow warming up is not a problem since the coolant, nine times out of ten, is prewarmed with a block heater (250 watts in the pipe from the bottom of the radiator to the pump) so the mixture control only lowers the jet until the engine fires, which it almost always does within the first turn of the engine. So I have continued to run, for the last year or so, in this very unusual way and am very happy to do so in the interest of keeping temperatures down in the region of cylinders 5 and 6. The radiator thermometer reading varies between 65 deg.C and 78 deg.C on the driving I usually do. I don't really see the point of keeping the temperature up to 78 deg.C all the time and at 65 deg.C the heater works fine. Whether this situation will continue as corrosion proceeds I do not know. I can keep my eye on the pressure gauge which is still fitted and which indicates water pressure in the cylinder block. It is very comforting to see increasing pressure with increase in engine revs but I would like to now more about temperatures and pressures at the bottom of the radiator. I have the equipment to do this but whether it will ever get actually done is another matter. Just to complete this story of heresy for the moment I will confess that I do not use any antifreeze at all and the coolant is ordinary tap water from our hot water system. I am happy to do this since our electric kettle is normally filled from the hot water system and the kettle element is always free from scale. The rationale behind all this is that the increased coolant flow and the lower temperatures are kinder to the block. After all, the next owner can easily fit a fresh radiator if he needs to whereas attention to the cylinder block is going to be bigger job. Sorry that this post is a bit off topic. Regards Laurie | ||

John Kilkenny Experienced User Username: john_kilkenny Post Number: 20 Registered: 6-2005 |

Richard, With regard to your comments about how efficient your cooling systems are, can I ask you how often your cars have to run in stop and go traffic with an outside temperature of 40 plus degrees C and the aircon at full blast ? In particular SBH13247. I realise that most manufacturers specify a glycol content of 40 to 50 percent in cooling fluid but for older cars with a tendency to overheat in hot weather, exacerbated by air conditioning if fitted it makes good sense to fill the cooling system with clean water and an approved corrosion inhibitor (See my September 18 post), which will substantially increase the cooling efficiency. A glycol based coolant can then be substituted in winter if required. | ||

Peter Colwell Experienced User Username: peter_colwell Post Number: 21 Registered: 3-2005 |

increased coolant flow... As an aside, some european engines use the full flow system. Ie. the block receives full flow under all conditions at all times. The block is a closed circuit when the engine is cold. As the block temp rises the thermostat allows an increasing flow through the radiator. This system would seem superior to the conventional system, as it allows full power flow through the block all the time. Apart from the scavenging benefits, it also avoids hot spots during warm up, and promotes even warm up with less hot spot distortion, which is a major cause of cold start wear. I know some Italian engines are designed like this, and some trucks too. (Message edited by peter colwell on September 20, 2006) | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1080 Registered: 4-2003 |

I was going to drop this topic as I have said my bit, but to answer your question here goes. B174UM and SBH13247 have spent their extensive lives, a combined excess of one million kilometres already, in possibly the most demanding set of hot and cold conditions based in our bushfire capital Canberra, with its heavy frosts and heatwaves, and also Sydney, with regular trips to Dubbo, Bourke and the like. That is, city driving in all temperatures, slow and fast trips in any heat that the outback can throw at you and so on. Weekend Summer trips to the South Coast would often be ended by a bumper-to-bumper crawl in blistering heat up the Clyde Mountain fully-laden on mid Sunday afternoons. If you know that road, it is the most taxing I know of for any cooling system, and the trip has often been marred by rows of overheating vehicles boiling by the roadside. It is a long climb, and a first-gear slug for very early Holdens. The NRMA patrols once carried a well-stocked set of cooling hoses to help the hapless, and were very busy at holiday times. B174UM has worried me a few times reaching almost 90C on the gauge as we crawled slowly up the mountain in heavy traffic, leaving a boiling margin of only 20C as the MkVII radiators only operate at atmospheric pressure. SBH13247 is always equally happy to plod it out in Clyde traffic or to ascend the mountain at the speed limit, always with the airconditioner blasting us cool of course, without the slightest change in coolant temperature. Going down the mountain is a very good test of your brake servo for any Silver Cloud or earlier by the way, and fortunately there are safety ramps if yours is not up to scratch. In short, if you want a very good test of every component of your car, just drive briskly from Canberra to Batemanís Bay and back one Summerís afternoon. That is a fortnightly trip for many Canberrans who love the beach. Since the 1960s, everyone has expected every motor car, new or old, to rise to the occasion in all weather. Long gone are the days when Dad rushed off to buy antifreeze for the Morris the day before a trip to the Snowy Mountains. Sure enough, the car would overheat the next week as the glycol loosened the crud and the radiator blocked. With a good thermostat and proper coolant all the time, it's never a problem. A final point: every recommendation I see warns not to mix grades and brands of coolant. We can only imagine how a concentrated water inhibitor additive may react with a coolant's formulated inhibitor. And for Peter: our blocks and cooling systems ARE full flow, MkVI, Silver Shadow, Turbo R and the rest included, unless you decide to block the bypass in order to fit a cheap replacement thermostat or to remove it. They are very superior systems. (Message edited by Richard Treacy on September 20, 2006) | ||

Marty Unregistered guest Posted From: c220-239-251-169.carlnfd3.nsw.optusnet.com.au |

Gidday Bill, I was talking to a bloke the other day, and he suggested that I should run a hose from the tap at the rear of the block and slice it into the heater hose coming off the water pump, to aid in circulation through the block. Do you think that is a good idea? I like your measuring idea. I will give it a go. I still have the top radiator hose filter in place, which I empty out every time I drive the car, it always catches something, so still a lot of gumk in the system. I wish I had fitted the filter much earlier! I am driving Chloe to Wollongong on saturday, about a 2 hour run south of Sydney, which I am really looking forward to. The forecast is for 28 - 30 degrees C, so a good test of the cooling system. The car will cruise all day on 50-55 mph, it is sitting in traffic that sends the temp up. So, I agree it is possibly more a blocked radiator than a large buildup of deposits. The tap at the back of the block runs freely when you open it. Might be time to whip the rad out and back flush it with high pressure. Glad I bought this topic up! Cheers Marty (Message approved by david_gore) | ||

Bill Vatter Frequent User Username: bill_vatter Post Number: 29 Registered: 9-2004 |

Richard, I see the detailed account of your cooling system experience, and perceive mild frustration that we have doubted your claim of excellent performance when new. Like so many others, I probably have fallen into the trap that since I haven't noticed cars performing excellently in this regard, I assumed none perform well. Of course RR must have had excellent performance. First rule in evaluating our cars is to remember they really were excellent when new. Wealthy people are usually not stupid, and RR could not have sold cars at the price asked if they did not perform in an excellent manner. Those who claim "They're all like that" when discussing a problem are usually wrong. It is sometimes difficult to notice the cars that are performing well. Frequently their owners are simply silent during the discussions of problems. So the conclusion probably should be that virtually all of us are suffering some performance degradation; some more than others. This is because of various amounts of neglect over the past 50-60 years. Also a factor is the water that was put into the car over the years. Those esperiencing hard water have more hard scale in the block than those that have had soft water. I suppose that is a dimension of neglect. Marty, I still think your radiator is fouled inside and you could have some passages plugged. Do you have a separate ground on your dynamo? If not, and the dynamo is grounded to the engine block through its mounting bracket, you could have electrically deposited material inside your radiator. Reverse flushing might help, and also chemical cleaning, but the bottom line for most radiators that don't cool well is a new core. I have chemically cleaned on some engines, and that can help, but there is a danger that harsh chemicals may dissolve more than just the crud, with potentially dissasterous results. While not common, internal perforation of your cylinder head is one possible outcome of chemically cleaning the entire system. Another approach might be to block off the radiator inlet and outlet and fill it up with some rust/lime/scale removing chemicals, which will probably be sulfamic acid, hydrochloric acid, or citric acid is some combinations. You let it soak for awhile and then vigorously flush followed by soaking in a mild base to neutralize any acid that may have migrated into a crevace, and more vigorous flushing. I think that what you can get at the parts stores for this purpose will not strong enough to do very much. You might inquire at the service depots that work on diesel trucks to see if they have something strong. There would also be value in testing on a sample of the material you are going to clean to gage how much attack to the metal you might experience. Taking the radiator out is not a very easy task, and I would address the radiator in the car first. If you take the radiator out, I would seriously consider a new core. That water circulation method is interesting, but I am skeptical. What will happen is you will create a new bypass path, and a portion of the water flow will take this path in preference to passing through the radiator. That will hinder, not help cooling. Refer back to the principle I stated in the second paragreph above. The cars performed well when new. If they don't perform well now, they probably need repair, not modification. The strange water connection method would prevent some of the percipitate from accumulating in the bottom of the block, by increasing flow in that area. That is not a hot place, so why do it? I think you could possibly rob some flow through the cylinder head, which would not be the thing to do. I think that a better method to prevent accumulation of crud at the bottom of the block would be to use soft water, corrosion inhibitor, and change frequently, my opinion every 2 years should be often enough. | ||

Marty Unregistered guest Posted From: c211-30-197-18.carlnfd3.nsw.optusnet.com.au |

Thanks Bill. Pulling the rad out of a standard steel is bad enough, out of the freestone & webb is a nightmare. I have used both the backflush method assisted with compressed air and the chemical method. Both achieved results, but there is still improvement to be made. 55 years of crud is still there! A new core may be a solution, however I am still happy with its performance, so the gradual improvement method will do me for now. Cheers Marty (Message approved by david_gore) | ||

Philip Sproston New User Username: phil2025 Post Number: 2 Registered: 7-2006 |

Marty, or any one owning a post war six, before you do anything look up kda132.com. Go to technical, cooling section D, read "Temperature control problems in post war sixes to 55". Then go to section B, "engine cylinder blocks, a few deviations". It all boils down to removing the motor from the car to fix the problems, otherwise you can cause a lot of damage. | ||

Richard Treacy Grand Master Username: richard_treacy Post Number: 1088 Registered: 4-2003 |

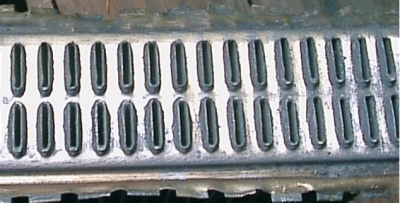

I know that this is the wrong vehicle category, but the subject is correct. I replaced the radiator on my Turbo R just over a week ago. It showed signs of a possible leak. It was losing 1/2 litre in six months, so I took no chances and fitted a new one. I do feel this is a far better choice than rodding, which should never be necessary, or repairs: throwing good money after bad in each case. I removed the crimped plastic tanks to return to Crewe, and inspected the core. As you may see, there is no corrosion or sediment in the tanks or matrix, and I put that down to using the prescribed 50% glycol coolant. That's after almost 20 years and 260,000km. The old core on my R-Type looked the same after over 50 years and 700,000km. Both cores were replaced due to stone damage, and neither car has ever had cooling difficulties.   | ||

Bill Coburn Moderator Username: bill_coburn Post Number: 736 Registered: 4-2003 |

I must have my fourpence worth. It seems to me that there are two problems writers are dabbling in, prevention of corrosion and overheating. Being a simple soul and not very bright I tend to regard large organisations such as Rolls-Royce (as it was) with some respect. If they say use 'X' amount of 'Y', in the absence of equally qualified advice I do what they say. The only time I get suspicious is in other fields where they are apparently playing pretty boxes i.e. whip a unit out of a crate slap it into a pretty bag then in a prettier box slap on an impressive part number and charge 20 times the cost of the item! So if the Factory's reputation is not enough for you we have the benefit of Richard Treacy's considerable experience, knowledge and scientific qualifications so I am impressed by those that would second guess him. As to overheating, chemical properties of the coolant notwithstanding, the design of the blocks on immediate post-war cars required clear unimpeded flow particularly the 4 1/4 litre engine. The flow through the radiator however is much easier to check and of course the unit is much easier to replace. This unfortunately is reflected in the original service bulletins which gave detailed instructions on flow testing radiator cores. Of course to 'flow test' the block would require mind boggling equipment to get any results. So for the salient observation in all these opinions, my money goes to Phil Sproston. The block has to be clean, that is, no scale. Not only does scale impede or even block coolant flow it allows hot spots within critical areas of the engine causing distortion and even fracture of the casting. Sorry but the scale has to come out which today can be done chemically very much more safely and effectively than in my day when we tossed half a gallon of bricky's acid in the thing and waited for the bubbles to cease! You can change radiators, re-route piping throw away the thermostsat (that is bordering on vandalism may I opine) fiddle with all sorts of coolant and additives and use fresh water but the system has to be clean - that includes the block. Popping a new radiator core onto a system with a scaled up block simply invites bits of scale when they break off to clog up the new pipes so you are back to square one. As you have probably detected I am an irritable old fart and probably not very helpful but we should try and qualify our advice. If we can't afford the time or the money to correct these problems properly please don't present solutions as being the cure. We all of us at some time take short cuts or do Band-Aid repairs but let's qualify our advice with that clearly stated, lest some poor sod takes such advice as gospel and then woders what the Hell we were talking about when he does serious damage! | ||

David Gore Moderator Username: david_gore Post Number: 649 Registered: 4-2003 |

Well put Bill, There have been legions of opportunists trying to sell "instant cures" for automotive [and other human afflictions] problems for many years. The essential common characteristic of these "cures" is a quick and easy solution to a problem that really requires a time-consuming and/or complex repair procedure. The reality is the result is basically a "cheap band-aid" that doesn't cure the actual cause of the problem. This why so many additives have come and gone over the years? Saving money by skimping on specified preventative maintenance only to subsequently spend the "savings" on "quick-fix" products is difficult to justify especially when numerous attempts to cure the problem followed by an expensive overhaul are the final outcome. As Richard's photographs graphically illustrate; using the recommended products and following the specified replacement schedules protects the components and avoids the need for "quick fix miracle additives". Unfortunately, there is a well-known and recognised behaviour in people where the more they pay for an item; the greater is their belief that it works. |