| Author | Message | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 738 Registered: 07-2018 |

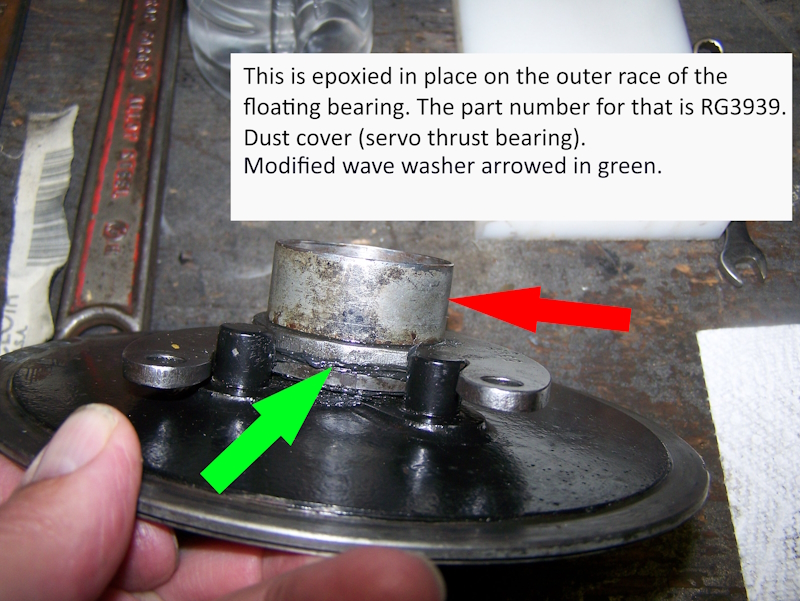

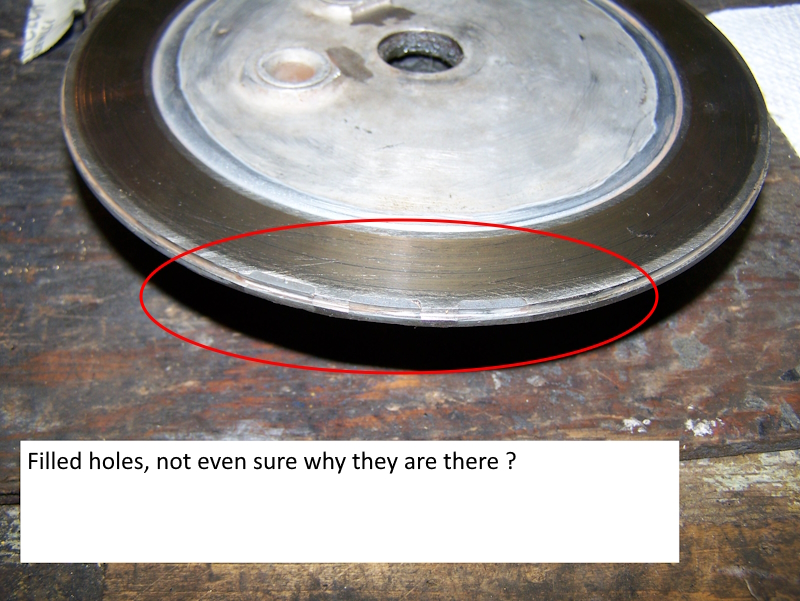

There hasn't been a thread that covers this: There has been an updated "wave washer" to deal with this issue, but I found unless the press fit of the "Dust Cover Bearing" onto the outer race of the pressure plate bearing is just that, that the wave washer has little effect. Mine is not a press fit, it can be easily removed with my bare hands. I epoxied the dust cover bearing in place, and if that lets go I'll use machine screws next. Dust seems to also be a factor making the servo "grabby", so that was taken care of, and hopefully that will help, as none of these modifications have been tested. There was a fair amount of dust from the new friction disc installed. Here's a link to the service bulletin that should be read concerning the servo and other RR modifications. https://www.rrtechnical.info/mkvi/bull.html The next odd thing is this part from Flying Spares (Intro-Car has it too) Part #RH377 (P). It is not shown in the original RR parts catalogue, nor does it show it in any of the drawings that I can find. I even contacted Flying Spares and they evaded my question. It is described as "Servo Cover Plate Internal Seal" here's the link to it, and as you can see, how is it supposed to fit anywhere inside and what is it sealing ? https://www.flyingspares.com/servo-cover-plate-internal-seal-rh377p.html I used a JB-Weld epoxy and in this case it's much thinner to provide the strongest bond as possible and I guess the equivalent in the UK and Australia would be Araldite   I filled these holes in, I have no idea what purpose they serve other than to let dirt and other contaminates in. I can't imagine them being of any use to let the friction disc dust escape.   | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 739 Registered: 07-2018 |

Got an explanation of RH377 over at the US forum, here the link to that thread. https://www.rollsroyceforums.com/threads/part-rh377-where-does-it-go.35978/?post_id=236984#post-236984 I also found this in the service bulletin to take up any slack between the plunger and the master cylinder at .050 thou. This cured the problem of servo lag at very low speeds. Before adjusting, if I was just starting to move in a parking lot and someone stepped out in front of the car, and I "panicked" braked. There would be no brakes for a split second, then the car would suddenly stop with a nose dive, that has now gone. https://www.rrtechnical.info/mkvi/r/bull.html Under "Brakes", second page from the top. |