| Author | Message | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 579 Registered: 07-2018 |

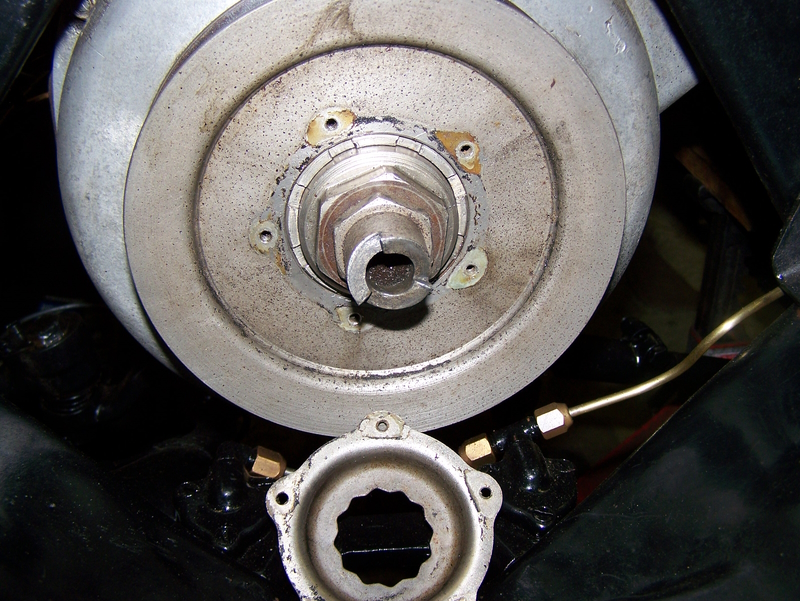

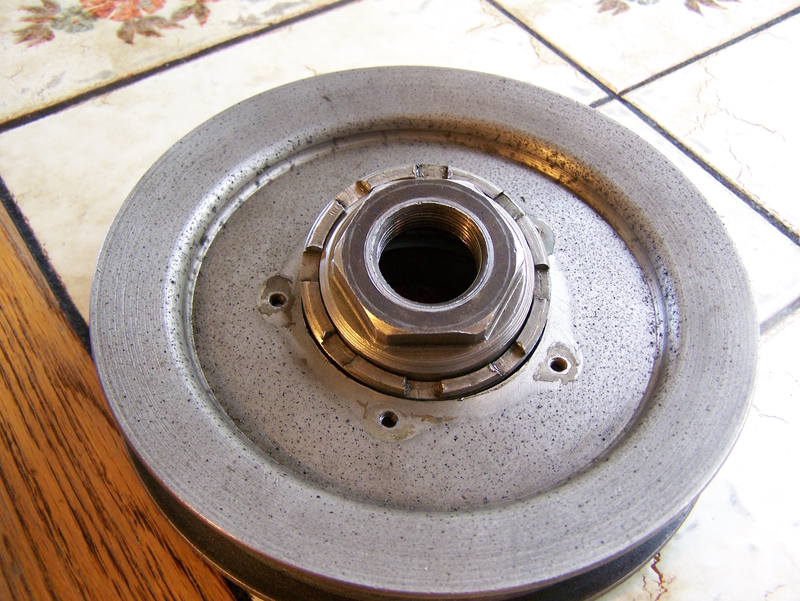

The big nut measures at 1.582, but no BSF or Whitworth size exists in that, closest I can find is 40mm, that may be too small. I would have to order a socket to find out for sure. The book calls for 1617/T1001 box spanner, but a box spanner, that seems inadequate since the "Bench Type" damper uses the slogger bar ? I think I removed it by getting a socket on the starting dog while the crank was locked up at the front.  The big castellated nut is 2.048 ID with 8 segments and I can't find any info what so ever what tool there is for that. When I did the engine some 25 years ago, I think I just used a blunt chisel to remove that, but it would be nice to have the correct tool. A slogger bar can't be made as the pulley is proud of the nut. Hopefully someone has these tools where I could borrow or purchase them. Thanks This is all I could find on it in the library. https://rrtechnical.info/mkvi/wshop/4.pdf The other problem is that there is always this drop of oil hanging off the front pully, so I have to find out why that is and where it's coming from. . | ||

Carl Heydon Experienced User Username: car Post Number: 181 Registered: 02-2004 |

I use a 3/4" drive socket 1 5/8" | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 581 Registered: 07-2018 |

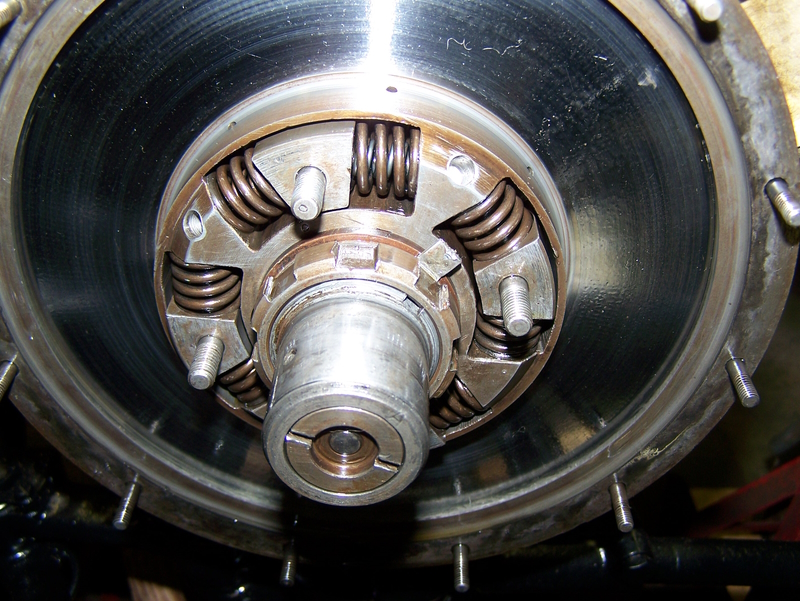

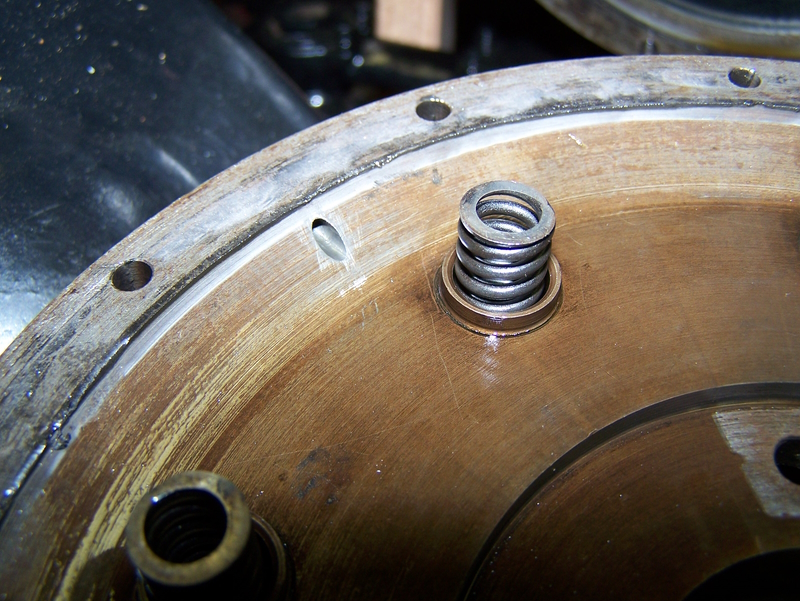

It's been over 20 years since I've had the damper apart, and I now realize that the big nut on the front pully for the Wraith Type damper does nothing more then to hold the pully in place. I removed the oil pan and locked the crank up at the front of the engine with a block of hard-wood. I used my big crescent wrench (4 foot handle) to see if the nut would move, and it did. Carl, the 1-5/8 socket is quite sloppy, so I didn't feel comfortable using that, I'll acquire a 40mm socket and see if that works. The locking castellated locking ring you see in the photo is just a device to extract the pully from the crank when the pully is removed. I did take mine off with a small punch (left hand threads) to clean things up. It was sort of chewed up from another mechanic no doubt trying to remove it clock-wise; perhaps too it was thought it had to be removed to get the pully off. There is very little "how to" info about the Wraith type spring drive.  Take note that there was always oil dripping off the pully, this in turn was always flung everywhere from the belt. There was always this film of of oil in the engine bay from this. A Bloody mess ! From what I can gather the oil from the damper bearing right at the front of the crank shaft was getting past the threads of the castellated nut and leaking oil all over the pully. When I removed the castellated nut, the threads were soaked in oil, and there should be none. I'll put some sealant on the threads of the pully nut as well as the woodruff key, and even on the taper fit where the pully meets the crank. That should take care of the oil problem. It's tempting to install a bench type damper, but I don't know if it will fit on the crank that may only fit the Wraith Type. | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 584 Registered: 07-2018 |

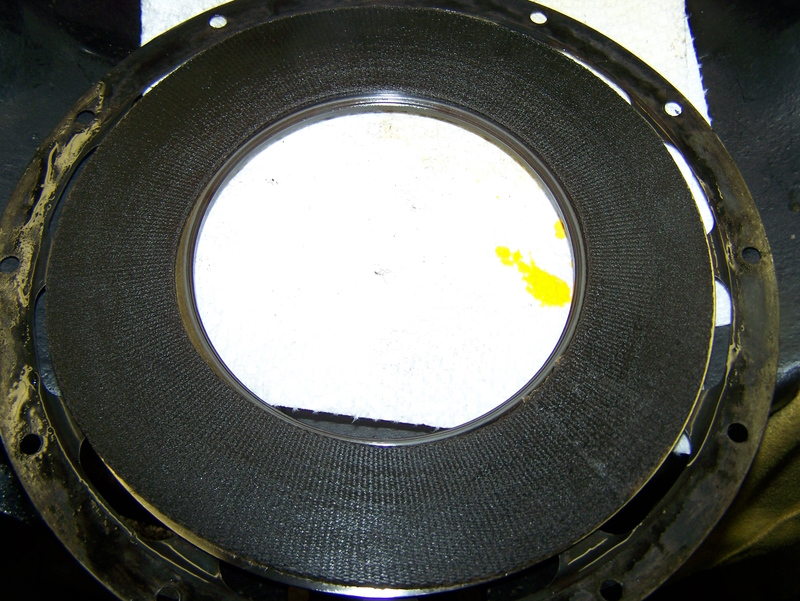

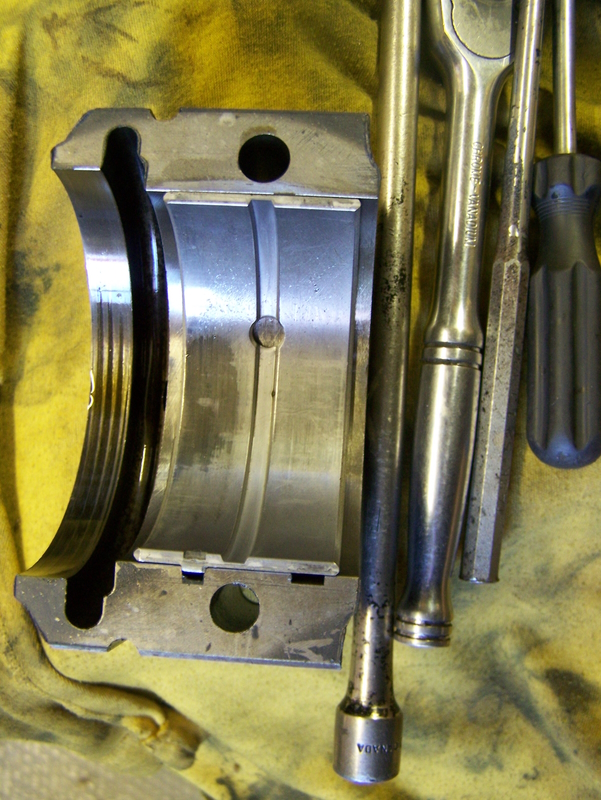

I can't get the locking tabs for the 12 2BA nuts anymore, so I'm going to use RED Loc-tight here _ on the studs as well if they'll come out. I made the tabs at the time, but I can't be bothered this time around.  On the Wraith damper, the front bushing is right behind the nut that holds the pully on; there's a lot of oil here. I'm assuming that it's filling up this area and making it's way past the woodruff key and overwhelming the reverse spiral, leaking onto the pully. AND/OR getting into the threads and making its way out that way, regardless, I'm going to seal up things and hopefully that will take care of the oil leak. It's not a bad leak, but it gets all over the pully and belt and spreads this mess all over the engine bay _ that in turn collects road dust.   Cotton washers are in nice shape, so I will re-use them, they're the same ones when I did the engine some 25 years ago. I cleaned them then with Tide and Oxy Clean, and got them almost white _ ironed and flattened them and set the tension. I wasn't sure what I was going to find after 21,000 miles since the rebuild, but I would say that things are quite pristine in there; all things considered and what was found on other engines.   I also dilled 3 holes in the front half as well so oil would not collect here, allowing fresh oil to always flow. This area was cocked right up solid with hard sludge when I got the car, so that's why I drilled the holes on the front half. I also drilled 3 holes on the back half as well. In all honesty though, I've looked after the car quite well, so even if there were no holes drilled, the damper would be just as clean.  Here's the rear main bearing shell showing a little acceptable wear. I posted this just incase someone asked if there would be a drop in crank oil pressure by drilling the 3 holes in the front cover. The rear big-end bearing is in good shape too, nice and shinny with no scoring, it looks just like it came from the machine shop yesterday. The damper was and still is working properly, I can drive the car from 45 to 80 mph and it's smooth with no vibrations from the crank. I'm also goin to add that using full synthetic oil here is a huge advantage to keep the damper from sticking while parked out-side in the cold. Synthetic oil is designed to keep it's proper viscosity in cold temperatures, unlike non-synthetic oils. |