| Author | Message | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 574 Registered: 07-2018 |

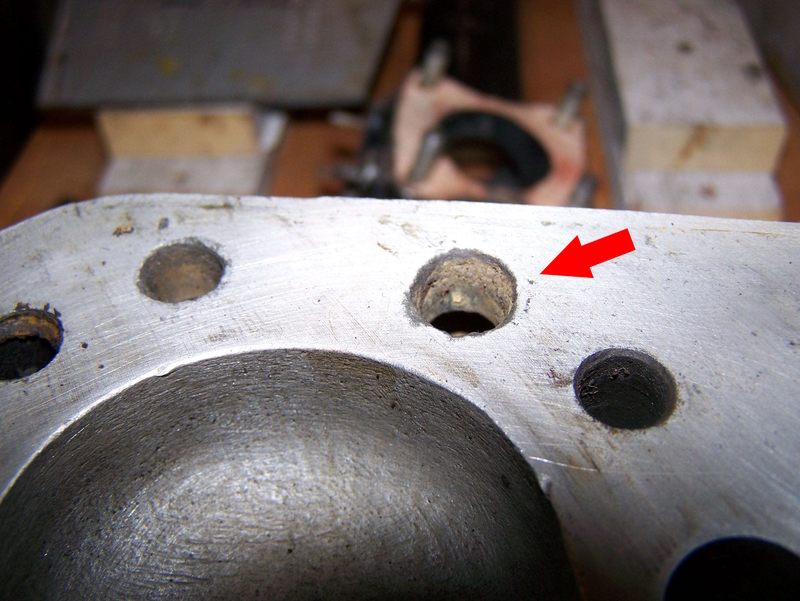

If you look at the photos, you can see that some of the water passages have corroded back past the "crimped" area of the head gasket. While the gasket is not leaking catastrophically into the combustion chamber or on the outside of the block, it appears that coolant is seeping under the gasket and making its way up the studs, thus making the removal of the head difficult once again. I don't think coolant is making its way past each stud from the water jacket as even some of the centre studs that don't come in contact with the water jacket, showed signs of corrosion. I was thinking of having the head welded in the area's where needed and machining things back to spec. OR mill out the coolant holes about 3/4 of the way down and press in an aluminum plug _ and machine back to spec. My machinist thought I should just use the copper spray gasket, but correcting the offending coolant passages would stop any further deterioration. Not sure what to do, but I'm leaning towards my pressed plug solution, but I still may use the copper gasket spray as the block looks OK, but not perfect. The welded studs that gave the most problems all were in the vicinity of the corroded coolant holes on the head.     |