| Author | Message | ||

John Rowney Experienced User Username: johnrowney Post Number: 136 Registered: 02-2015 |

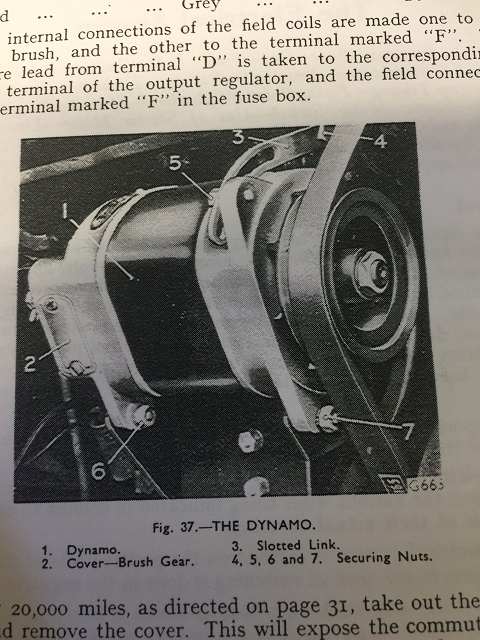

My 1951 Bentley Mk VI special B25KL, had a horrible squeaking noise. Advice from learned people said to replace the fanbelt. Replacing the fanbelt was a mission. At some stage, a sheet metal pan was attached underneath the lower pulley on the end of the crankshaft, and did not allow the ready removal of the old fanbelt. I had my hoist occupied with another car, so I had to squeeze under the car to remove the pan. Much cursing later, this was done and I removed the fanbelt. I replaced the fanbelt with an identical belt, but it was such a tight fit that I had to take off the dynamo to get the job done. See the photo to see how tight the fanbelt is now. Best of all was the squeaking completely disappeared.  The lack of adjustment of the dynamo. I looked at the Mk VI handbook and the photo below suggests that the belt needs to be much longer.  Mk VI handbook photo of dynamo and fanbelt The original fanbelt is identical to my new fanbelt and matches a Flying Spares fanbelt I purchased as a check. It looks like my upper pulley with a diameter of 7 1/2 inches is larger than the original 7 inches. This might explain the tightness of the fit. I can purchase larger fanbelts with 20,30 and 50 mm additional lengths, which would give 10, 15 and 25mm additional displacement on the adjustment link. Any advice regarding the optimal displacement of the dynamo on the adjusting slide would be most welcome. | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 455 Registered: 07-2018 |

The longer the belt the better as it provides more contact on the dynamo pulley and thus prevents slipping, although with such a wide belt, it's not going to slip anyway. You don't want such a long belt that one runs out of adjustment, but one long enough so you don't have to remove the dynamo to get the belt off. If you have the later style pump where the pulley is mounted on the front of the flange, then you didn't have to remove the dynamo to get the belt off. It's possible to remove the four pulley and fan bolts on the water pump, this enables removing those assemblies so the belt can easily be removed. However once you get a longer belt, then none of this should be necessary. On my car I have the early type of water pump flange where the pulley is mounted behind the flange, that makes it impossible to remove with out having the water pump on the bench where I have to use a puller to remove the flange in order to get the pulley off. I have no choice to remove the dynamo to get the belt off. If I use a longer belt for easy removal, I think I would run out of adjustment of the dynamo. Note that my pulley is similar to the later high speed pulleys that were used, it's only 5-3/4 inches and uses the 16-1/4 inch fan. When the later high speed pulley was used, a special 17-1/4 inch fan was used to cut down on wind noise and vibration. In your case, because you have a larger pulley on the pump, you can fit a longer belt, it's not that critical, put the longest belt you can get on there, but not so long that you run out of adjustment on the dynamo. The belt you have on there now, was probably meant for my smaller pulley. Read this article, and go to page 28, "History and Cooling System Modifications". The article would suggest you would have the 17-3/4 inch fan, or maybe even the 18 inch version. https://kda132.com/wp-content/uploads/2018/04/Cylinder-Blocks.pdf | ||

John Rowney Experienced User Username: johnrowney Post Number: 137 Registered: 02-2015 |

Thanks for the info, Jeff. I ended up buying an additional belt which was 20 mm longer that the original one, which gives good adjustment. I couldn't have a larger belt than this one since there is a strut supporting the radiator nearby and the dynamo pulley would hit that. With the new belt, I can fit the belt without taking the dynamo off the engine - a big saving in time and effort. My guess is that there was a lot of modification done to the dynamo anchoring as the setup is quite different to that shown in the handbook. The curved adjusting strut is on the other side of the dynamo bracket as shown in my earlier post, and the top pulley is larger than expected. The fan that was on the car when I bought it 8 years ago looks like it was a homemade version which is 15 inches diameter. I had the radiator re-cored about 7 years ago and fitted a modern 5 bladed fan which is also 15 inches diameter. Since my Mk VI is a special, I know that the radiator is cut down in height, so the smaller fan blade and the larger top pulley might have been fitted then. With all this non-standard equipment, the cooling of the engine has never been a problem. . | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 465 Registered: 07-2018 |

John, could you post a photo of that homemade 15 inch fan, I would like to see how it compares to the RR ones that were used ? It's odd why such a large pulley on the water pump was used with such a small 15 inch fan. The large pulley would slow the fan down when compared to the small pulley. This in turn would move less air and one would think that it would overheat on a hot day in slow traffic. When RR went with the large pulley, they increased the fan to 17.75 and later 18 inches. So you have a set up now with a large low speed pulley with an even smaller fan of 15 inches when compared to Rolls Royce's smallest fan of 16.25 inches, according to the article in the link. Your rad must be 3 or even 4 tubes deep. Also is your water pump the type where the pulley is mounted behind the flange or on the front ? If it was on the front, you could have simply removed the four bolts holding the fan on and the pulley would have come off with the fan. This assumes that there would have been room to remove the fan from the engine bay, and this is possible on the standard bodied cars, but since yours is a special, maybe not. . | ||

John Rowney Experienced User Username: johnrowney Post Number: 138 Registered: 02-2015 |

Jeff  The old Bentley Mk VI fan. I can't tell how many tubes deep my radiator actually is. The water pump looks like the pulley is mounted in the front of the flange.  The fan, pulley and water pump for the Mk VI. After I installed the "new" fan I subsequently installed a spacer to bring the fan closer to the radiator. (This info was from my notes at the time, as I had completely forgotten about it. I think that there were a couple of spacers supplied with the new fan.) I think there is plenty of room to remove and replace things. One thing I forgot to mention was that I have an electric fan which is operated by a manual switch. My old notes said that I no longer needed to operate the electric fan after re-coring the radiator and installing the new fan. I am as mystified as you are that someone has put in the slow speed pulley. | ||

Jeff Martin Frequent User Username: jeff_r_1 Post Number: 466 Registered: 07-2018 |

After seeing that fan, I know why the low speed pulley was installed. The low speed pulley runs the fan and about .85 to 1 of engine speed, and the high speed pulley runs at about 1.11 to one (early) and 1.10 to 1, (late). With those huge fins, I would not want the small pulley in there. And what you're calling the old Bentley MK VI fan, isn't a RR fan, as far as I know, that's some sort of after market fan, while your present one is what looks like a flex fan. Here is what a RR fan looks like, which I'm sure you know, but I thought I would post it for reference purposes. I think RR was more concerned with silence rather then cooling efficiency. In the end, you can't have your cake and eat it too, but I really think that RR tried.  I think that RR even used this fan in the first generation Shadows/T Types, but it wasn't efficient enough for the big V8 engine(s). I remember club members with Shadows complaining that they could not be driven in a parade at "creep" speed because they would over-heat. Later RR installed a shield around the fan, but I don't know how successful this was. All of this is just what I picked up with casual conversation, but there must be some truth to it. At any rate, clutch fans were installed and later electric fans as technology improved things. |