| Author | Message | ||

Mark Glanville New User Username: mark_glanville Post Number: 33 Registered: 05-2008 |

Trying to resolve carburetter issues on a 49 Silver Wraith. After fiddling and getting this car to run, I'm trying to adjust the carby to run smoothly at idle. The carby has been rebuilt with new gaskets jets etc. Next step are the three adjustments screws on the carby. There are two idle needle valves and the throttle stop screw. Easy enough most would say. My issue is the throttle stop screw as it rests on the fast idle cam. There are teeth on the cam for the screw to rest against and possibly hold the screw against at various points.This appears loose and due the the action of the accelerator pump arm, the cam drops and the screw no longer sits against the cam and it becomes ineffective. The idle then drops to the point where car stops. I will try an add a utube link, if thats a thing, for you problem solvers to follow.https://youtu.be./uZWWiarJBI8 Cheers | ||

Mark Glanville New User Username: mark_glanville Post Number: 34 Registered: 05-2008 |

Try https://youtu.be/uZWWiarJBI8 | ||

James Senior New User Username: jamess Post Number: 12 Registered: 09-2016 |

Hello Mark, Funnily enough I have been reading about the AAV-26 just last week as we have a 49 Silver Wraith. Other than the Service guide, the closest instructions I could find online are for a 55 Buick. These are very informative and worth a look. https://www.hometownbuick.com/1955-buick-stromberg-2-barrel-carburetor/ The key difference between the Buick and the Rolls is the thermostat which adjusts the position of the fast-idle cam as engine heats up. On the Buick there are heat pipes from the exhaust, whilst on the Rolls the thermostat is mounted in a water jacket on the inlet manifold. Have you checked this is adjusted correctly? It may be too strong, rotating the cam before the engine has warmed up enough? I don't have access to the car now, but might be able to take some photos/comment on springs in a week or two if that helps. That said, the reason I was researching it is because the automatic-choke has never worked in the 30 years my father has owned the car! He uses the throttle on the steering column to set the idle manually, something which the handbook suggests isn't necessary. Keep us updated please. This is of interest to me! Regards, James | ||

James Senior New User Username: jamess Post Number: 13 Registered: 09-2016 |

Hi again, I just discovered a pretty great animation showing the construction of a Stromberg Carburetor, except that the only thing it doesn't include is a fast-idle cam! I thought I'd share it anyway as it's useful to compile multiple sources of info in these threads for future reference. https://www.youtube.com/watch?v=2q5JshGd4nA James | ||

Mark Glanville New User Username: mark_glanville Post Number: 35 Registered: 05-2008 |

Thanks James there is plenty of information to digest. In the first link there was a lot more information than I was able to find. | ||

Trevor Pickering Experienced User Username: commander1 Post Number: 141 Registered: 06-2012 |

One problem is that the "hot spot" can become blocked by debris in the cooling system thus allowing no hot water through. Take manifold off and check that all is clear from the waterway in the head and the water passage in the manifold.Also check the pipe from the water pump to the underside of the hot spot | ||

Mark Glanville New User Username: mark_glanville Post Number: 36 Registered: 05-2008 |

Thanks Trevor, that sounds like another rabbit hole and a big job, which no doubt should be considered. Taking the words of another wise blogger on this site, first fix the problem your dealing with, which is, a dicky fast idle cam not staying in position. | ||

Jeff Martin Experienced User Username: jeff_r_1 Post Number: 84 Registered: 07-2018 |

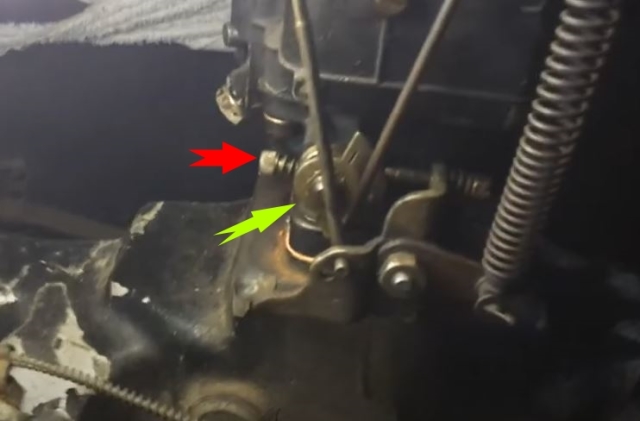

A fast idle cam is used for choking purposes only and should be fully disengaged once the engine is fully warmed up. The fast idle cam can be engaged manually when the chock is pulled on, or through the automatic choke, and in the case of RR, through a wound bimetallic spring, but not in this case. It's a manual choke. After the choke is disengaged and the engine stalls when fully warmed, then the butterfly valves are closing all the way, or at least not staying open far enough to let air in, and it stalls. What seems to be going on here is it is assembled wrong, and or parts are missing. After the choke is off, there has to be a throttle stop that can be adjusted to set the idle once the once the high idle cam is disengaged. On some carbs, the butterfly valves are fully closed at normal idle. In this case there will be a separate idle circuit controlled by adjustable needle screws. Is the mixture screw out by 1.5 turns after from being fully seated. Check to see if there is a broken or missing coil spring inside where the green arrow is.  | ||

James Senior New User Username: jamess Post Number: 14 Registered: 09-2016 |

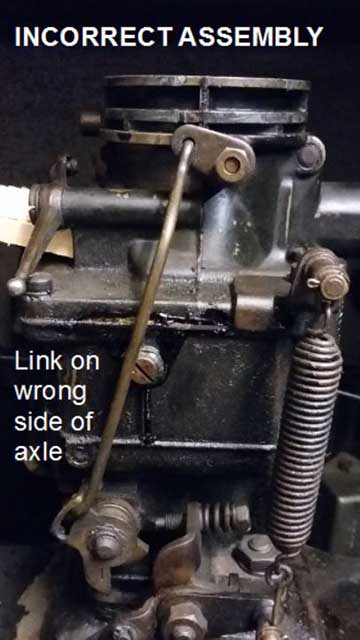

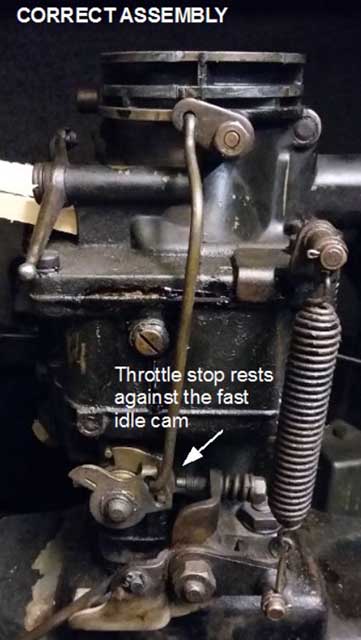

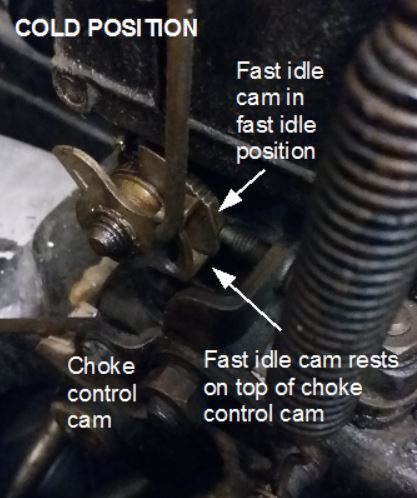

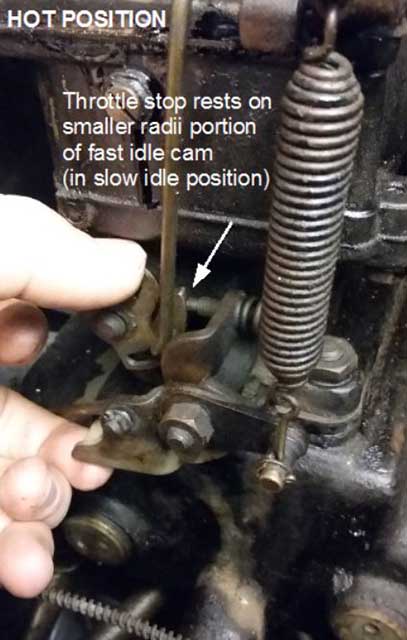

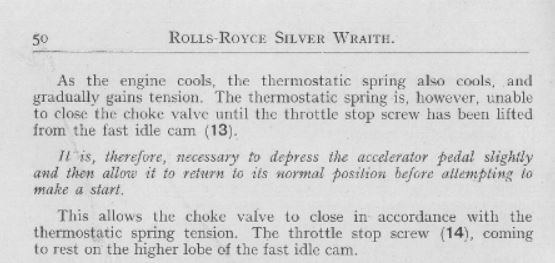

Dear Mark, Great news – I have fixed the carburetter on our 1949 Silver Wraith! I can confirm that it does have a functioning automatic choke/idle (albeit with a quirk which I will describe later). I shall start with what I discovered as the fault could be easily reproduced on other cars. Sometime prior to 1982 when my father bought the car, the carburetter appears to have been serviced and reassembled incorrectly. He was told that it didn't work so should use the throttle on the steering column! The link from the choke must have been disconnected allowing the choke control cam and fast idle cam to drop under their own weight. When the link was reconnected, these cams were pulled up on the wrong side of the axle. The result is that the throttle stop screw is clear of the fast idle cam, which now rotates anti-clockwise instead of clockwise as the bimetallic spring in the inlet manifold warms up and the link drops.   The picture above and the picture below both show the fast idle cam in the raised 'fast idle' position when the engine is cold. The cam does not have any springs; it spins freely on the axle and rests under its own weight on top of the horizontal tab on the choke control cam.  The next image shows the fast idle cam dropped into the hot position ('slow idle'). I have manually rotated the choke control cam as far clockwise as it can go. You can see that the throttle stop screw now rests on the smaller radii portion of the fast idle cam. If your cams are over rotating and the stop falls off the end, I wonder if there's something wrong with the bimetallic spring or linkages which is permitting too much travel of the link?  So what's the quirk I mentioned? Well the fast idle cam cannot rotate unless the throttle pedal is depressed as otherwise the throttle stop pins it into position. This is why the choke control cam and fast idle cam are two independent pieces and the former has a slot in for the link to travel – if this wasn't the case the choke would also be prevented from moving when the pedal is not depressed. This is also why you have to press the pedal before starting a cold engine – to reset the mechanism after it was last run (when hot):  Another consequence is that once started, the fast idle cam cannot rotate from the cold to hot position unless the pedal is pressed. This isn't an issue if you drive the car straight away, but if you leave the car ticking over without driving, what happens is that the engine starts fast and then runs faster and faster as the vapourisation of fuel improves with increasing temperature. When this happens, you similarly need to press the pedal momentarily to release the mechanism so that it's free to rotate from cold to hot (fast to slow idle). I have some video footage including close ups of the mechanism, the reset operation, and fast and slow idling. I need to put these together and upload them. This might take a few days to get around to. Hope this helps! All the best, James | ||

Trevor Pickering Experienced User Username: commander1 Post Number: 142 Registered: 06-2012 |

Very good James and a great help to many people! | ||

James Senior New User Username: jamess Post Number: 15 Registered: 09-2016 |

Thanks for that Trevor, I appreciate it. Even compiling a few images and text seems to take a couple hours! As promised I have uploaded a video explaining my understanding of the fast-idle mechanism: https://www.youtube.com/watch?v=owJRcj-RTgQ I have a question for you all. At 2:45 you can hear the engine running with the carburetter on slow idle. The service book says to set the speed to 350rpm. As you know these cars don't have a tachometer, but 350rpm is just under 6 beats per second which is what I have achieved (or have I...). Why is it then that if I connect my automotive multimeter to one of the spark plug leads, set to 4-stroke, it says 720rpm? These cars don't have a wasted spark as far as I understand, so what could be the cause? Do my ears deceive me and it's actually doing 720rpm, or could it be something to do with having three spark plug HT leads routed into the tube fixed to the engine block - resulting in interference? The reading is stable. Please let me know your thoughts on that! James | ||

Jeff Martin Experienced User Username: jeff_r_1 Post Number: 111 Registered: 07-2018 |

Just from the fan belt, 750 is pretty much correct. The service bulletins say 550. (tried to find where it says that and I can't now) There is a note there that says "owners agree that 550 is to fast and it should be at 450 to 350" Personally I think 550 is about right, it would be quite difficult to get it to idle at 450 let alone at 350. People have claimed they have done it, but I have yet to witness such a slow and smooth idle. | ||

James Senior New User Username: jamess Post Number: 16 Registered: 09-2016 |

Hi Jeff, I'm beginning to think you're right there... It occurred to me that you can watch YouTube videos at different speeds (click on the settings 'cog' in the bottom right of the window if you haven't seen it before). Viewing at 1/4 speed, I counted 45 'beats' in 28.5 seconds, giving (45/28.5)x4x60 = 379rpm. Of course the next question is does one beat equal one rpm? As you said the fan belt is wizzing by, even viewed at 1/4 speed. I then remembered watching a video uploaded by A&B Classics of a MkVI Bentley engine with the rocker cover removed: https://www.youtube.com/watch?v=9Wqfd6wrajI Viewed at 1/4 speed again, you can see each inlet valve depressing once per 'beat', suggesting that each 'beat' as I hear them is equivalent to 2 revolutions. Which then makes me really suspicious of the 350rpm in the original handbook and service book! My engine certainly couldn't rev that slow! I would imagine Rolls Royce had decent lab equipment, but almost wonder if in those days the average car mechanic did everything by ear, hearing 'beats' as I did? That may sound silly, but the fact that you are instructed to adjust the timing statically suggests that the average owner or mechanic wasn't expected to have any advanced analysis tools. Are you able to point me to a source of these magical service bulletins? There are one or two additional sheets inserted into my Service Manual, but not many. Cheers, James | ||

Martin Webster New User Username: martin_webster Post Number: 8 Registered: 09-2018 |

The engine in the video is idling much faster than my own Mk VI , B88 HR which is probably half that speed . I would imagine that 400 rpm is not unrepresentative of the correct speed . | ||

Jeff Martin Experienced User Username: jeff_r_1 Post Number: 114 Registered: 07-2018 |

This engine is idling a bit slower, mine is slower still. When I have it up and running I will post a video. Rhys Kent is the guy in the video and he rebuilds and tunes SU carbs. I know his work and he is good and fussy. His web site. https://www.sucarburetors.com/ https://www.facebook.com/sucarburetors/videos/476112566548757 The links to RR and Bentley Info. Pretty sure it's in there somewhere. http://rrtechnical.info/ | ||

Mark Taxis Experienced User Username: mark_taxis Post Number: 190 Registered: 04-2007 |

I have fitted a tacho to my Mk6 Special, and have found that the lowest smooth idle that I can get is around 450 RPM, any lower and it gets lumpy. James could the high reading on the multimeter be due to the dual points? I have converted mine to single point and the multimeter correlates with the rev counter. | ||

James Senior New User Username: jamess Post Number: 17 Registered: 09-2016 |

Hi Mark, the tachometer is only connected to one spark lead so I don't think it's that. Having seen the A&B classics video and witnessing the inlet valves opening once per audible beat, I now trust the tachometer reading. My engine is only revving that fast as that's how I set it! - around 6 beats per second (which I now know is 12 revs). Sadly I'm back at work in Warwickshire and the car is in Somerset... Next time I visit I shall reduce the idle speed and trust the tachometer. I suspect I can get 550rpm, but 350rpm seems pushing it - we'll see! I'm actually quite pleased. while I didn't think the slow idle was excessive, the resulting fast idle when cold starting really did seem rather fast. If I manage to get good results, maybe I'll replace the video I uploaded with a new one. Many thanks to everyone for their contributions! James |